6

HYDROPHORE

CONTROL PANEL

INSTALLATION, MAINTENANCE and OPERATION GUIDE

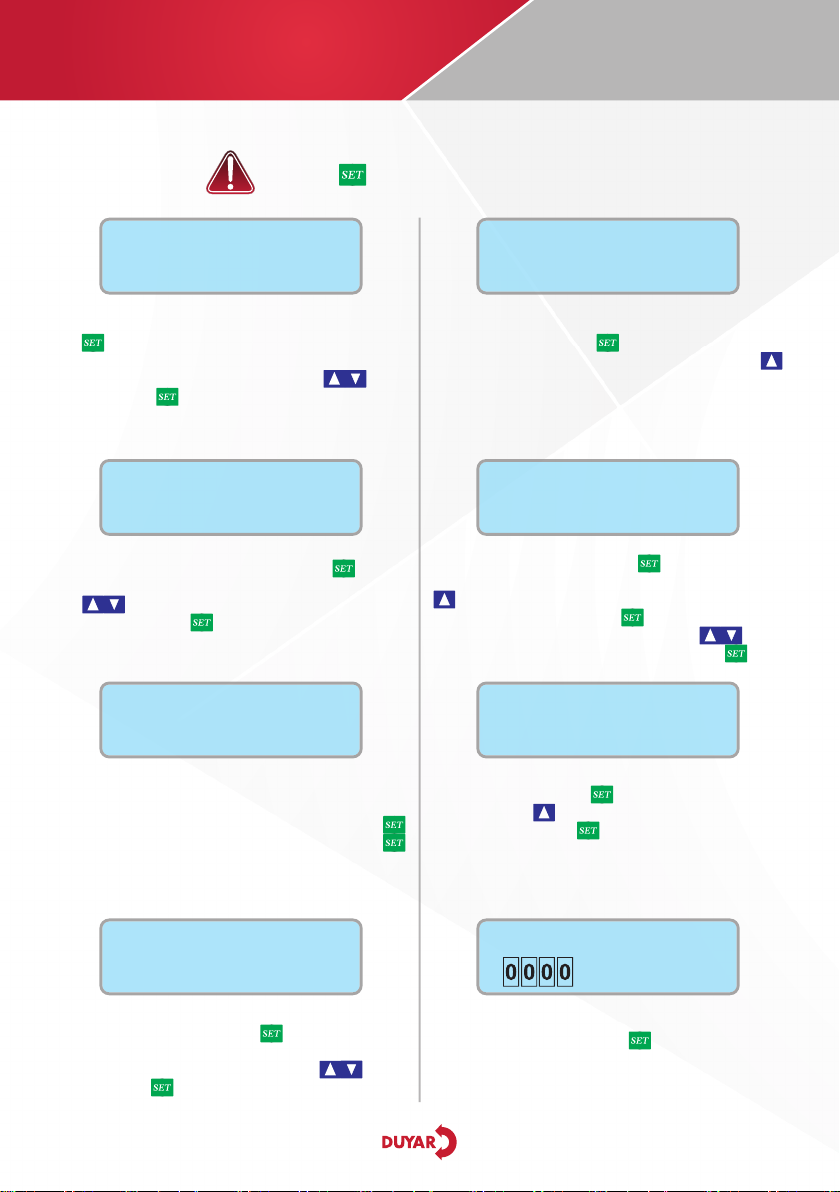

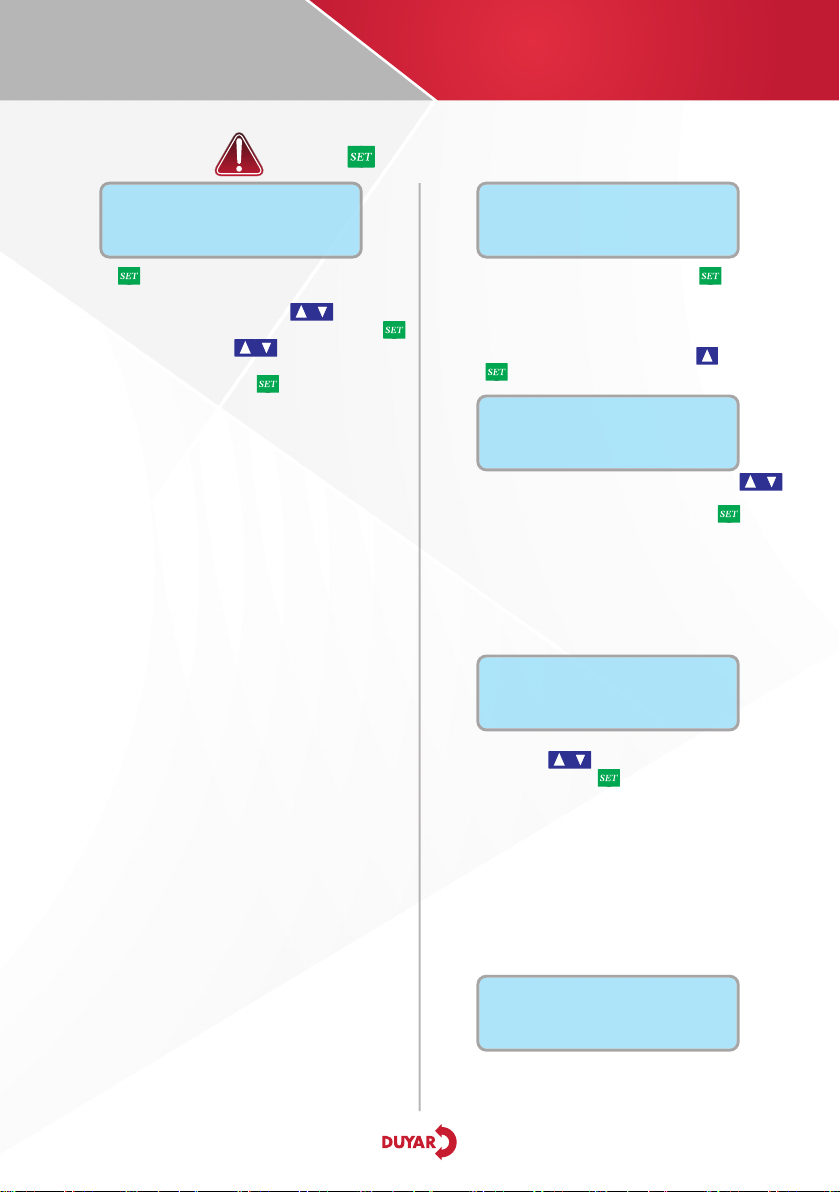

Press the button in the General Settings menu, the

text Voltage On starts to flash and the value next to it

can be changed with the help of the arrow keys,

after the change is completed, by pressing the

button value is memorized. arrow keys are used

to find the parameter we want to change and when

the parameter is hovered, the key is pressed and

the text starts to flash, in this case the value is changed.

Voltage On: It is the voltage-on time setting. Waiting

time for automatic reset when the voltage values

measured when the system is in fault state due to

voltage error again within the desired limits.

Voltage Off: It is the voltage error tripping time setting.

When the measured voltage values go out of the set

values, it is the waiting time to turn off. It is necessary

in order not to take the pump off frequently in case of

instantaneous fluctuations.

SSR On: It is the liquid level (SSR) reset time setting. It is

the waiting time setting for automatic reset when the

water comes back when the system is in a malfunction

state due to dehydration.

SSR Off: It is the liquid level error tripping time setting.

When the water in the tank or well runs out, it is the

time to wait for the circuit to go out.

Demerage: Inrush current time setting. During the

period set here, the currents drawn from the moment

the pump starts up for the first time cannot be

compared with the set values.

Current Delay: Current fault trip time setting. When

the lower or upper current goes out of the set value, the

time setting for stopping the motor is set in seconds.

Start Delay: When the signal comes from the pressure

switch, the pumps are activated as late as the set time

for the time set here.

Stop Delay: When the signal from the pressure switch

is lost, it turns off the pumps within the set time.

Reset Time: Reset time setting allows us to set how

long it waits for the system to be activated again when

it fails due to current error. The setting is in seconds.

Reset-2: It is the reset number setting.

Salt: Ability to limit the number of pumps on and off

in 1 hour.

Pump Change: It is the changeover time setting for

pumps operating in circulation mode.

The automatic test setting is pressed, the button is

pressed, the test factory setting is passive, when we press

the set button, the Test text starts to flash. appears as

a clock. The run time setting allows us to set how long

(seconds) the pump will run. Pump operation active or

passive option is selected by pressing the arrow key

and the key is pressed, it automatically saves.

Transmitter Setting is adjusted with the help of

arrow keys while the text "Sensor available or No sensor"

is flashing, and it is stored by pressing the key. If

the sensor is selected, the system now works with the

transmitter and does not read the pressure switch input.

Maximum: Pressure transmitter maximum (label)

value, enter 16 bar for 16 bar transmitter.

Set Valuei: Pump stop set pressure value.

Hys Value: Pressure hysteresis adjustment. For

example, if our set pressure is 8.0 bar hysteresis 1.0,

then 1 pump works at 7.0 bar, 2 pumps work at 6.0

bar, and 3 pumps at 5.0 bar.

Operation Mode Selection, operation selection is made

with the help of arrow keys according to the

pump used. Press the button and it will save

automatically.

Hydrophore: Standart hidrofor motorlarında bu mod

seçilmelidir.

Hydrophore + Ptc: If there is PTC protection in booster

pumps, this mode should be selected. Otherwise, PTC

protection will not do..

P + Joker: It is the choice of 1 main and 1 wildcard in fire systems.

Waste Water: This mode should be selected for

wastewater pumps. When this mode is selected, water

leakage and Ptc inputs are active.

Waste Water Stop Fit: In the selection of waste water

with stop floater, water leakage and Ptc inputs become

active and the system stops according to the stop floater.

Floater / SSR selection is the float or SSR electrode

protection selection setting of the device. Selection

is made with the help of the arrow key and saved by

pressing the set key.

General Settings

Voltage On = 05

Auto Test Settings

Test = Active

Floater / SSR Secim

Floater

Transmitter Set

There is Sensor

Operation Mode Select

Hydrophore

6. SETTINGS MENU

Press the button to enter the menu.