3 FT742-DM (RS485) Sensors –User Manual

5.4.3 Message Format..............................................................................................................31

5.4.4 Listener and Talker Identifiers.........................................................................................32

5.4.5 Calculating the Message Checksum...............................................................................32

5.4.6 Disabling the Checksum..................................................................................................32

6PARAMETER SETTINGS ................................................................................34

6.1 Command Types................................................................................................................34

6.1.1 Set Commands................................................................................................................34

6.1.2 Query Commands ...........................................................................................................35

6.2 User Calibration Table.......................................................................................................36

6.3 Timing Constraints............................................................................................................37

6.4 Command Parameters.......................................................................................................38

6.4.1 BR: Set or Query the Serial Interface Baud Rate............................................................38

6.4.2 CF: Set or Query the Wind Datum Offset Angle .............................................................39

6.4.3 CU: Set or Query the Continuous Update Setting...........................................................40

6.4.4 DF: Set or Query the Wind Velocity Data Format ...........................................................41

6.4.5 DG: Query the Run-time Counter....................................................................................42

6.4.6 DL: Set or Query the Command Delay Interval...............................................................43

6.4.7 ER: Query or Reset the Error Report..............................................................................44

6.4.8 FL.1: General Filter Settings ...........................................................................................45

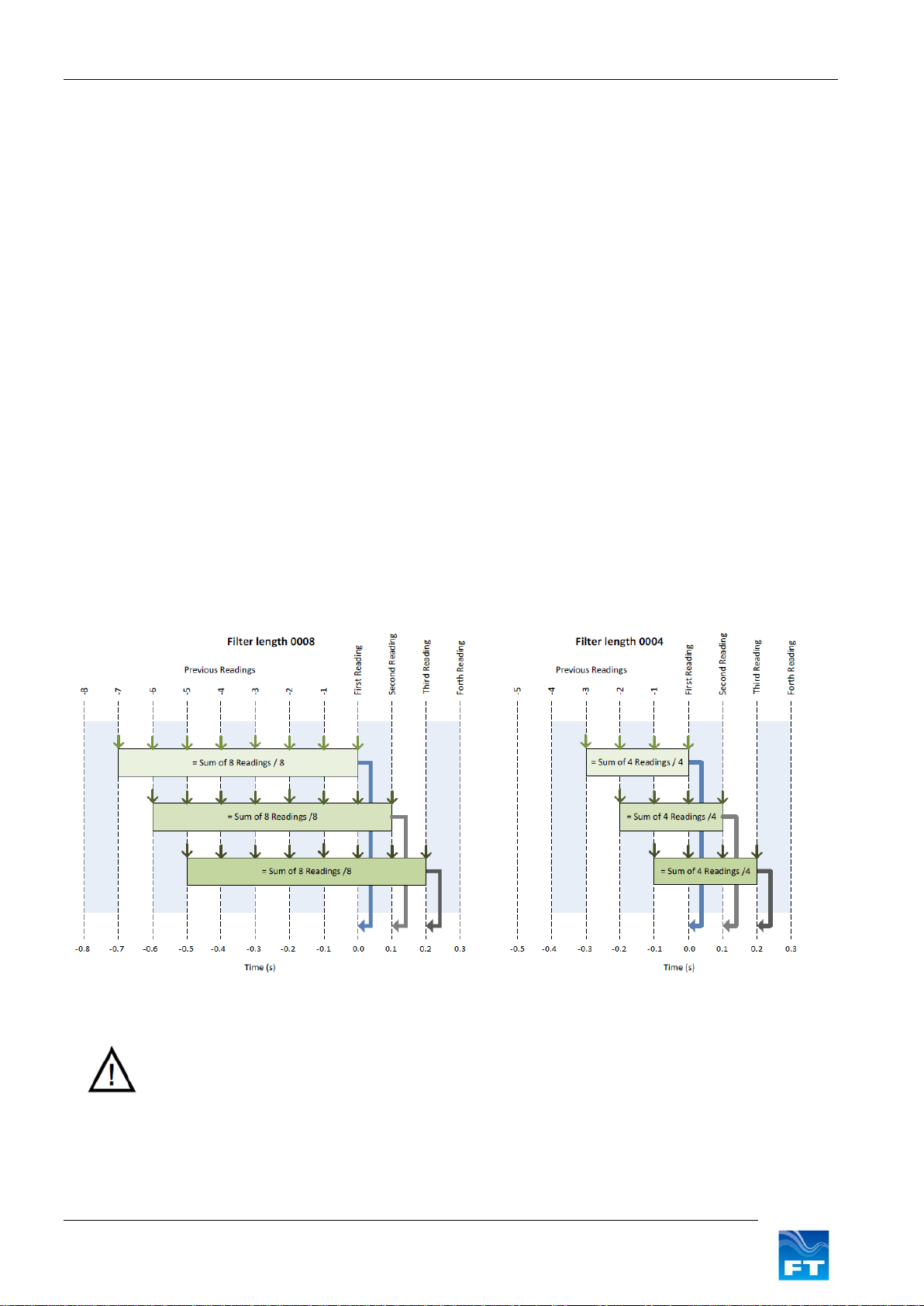

6.4.9 FL.2: Set or Query Filter Lengths....................................................................................46

6.4.10 FL.3: Set or Query the Selective Filter........................................................................47

6.4.11 HT.1: General Heater Settings...................................................................................48

6.4.12 HT.2: Delay Heater Settings ......................................................................................49

6.4.13 HT.3: Limit Heater Settings.........................................................................................50

6.4.14 ID: Set or Query the Listener & Talker Identifiers.......................................................51

6.4.15 MM: Reset or Query the Min/Max Recorded Wind Speed..........................................52

6.4.16 OS: Overspeed Warning Scheme..............................................................................53

6.4.17 PR: Query the Parameter Report................................................................................54

6.4.18 RS: Reset the Sensor .................................................................................................55

6.4.19 SN: Query the Serial Number and Platform Version ..................................................56

6.4.20 SV: Query the Software Version.................................................................................57

6.4.21 UC.1: General User Calibration Settings....................................................................58

6.4.22 UC.2: Clear User Calibration Table Record................................................................59

6.4.23 UC.3: Set User Calibration Table Record...................................................................60

6.4.24 UC.4: Save and Read User Calibration Table............................................................61

6.4.25 UC.5: Set & Query User Calibration Table Label .......................................................62

6.4.26 US: Set or Query Saved Parameters..........................................................................63

6.4.27 WV Polar: Query the Wind Velocity Reading..............................................................65

6.4.28 WV NMEA: Query the Wind Velocity Reading............................................................66