© SP Industries, Inc. MNL-008-A Rev. 009

iii

Contents

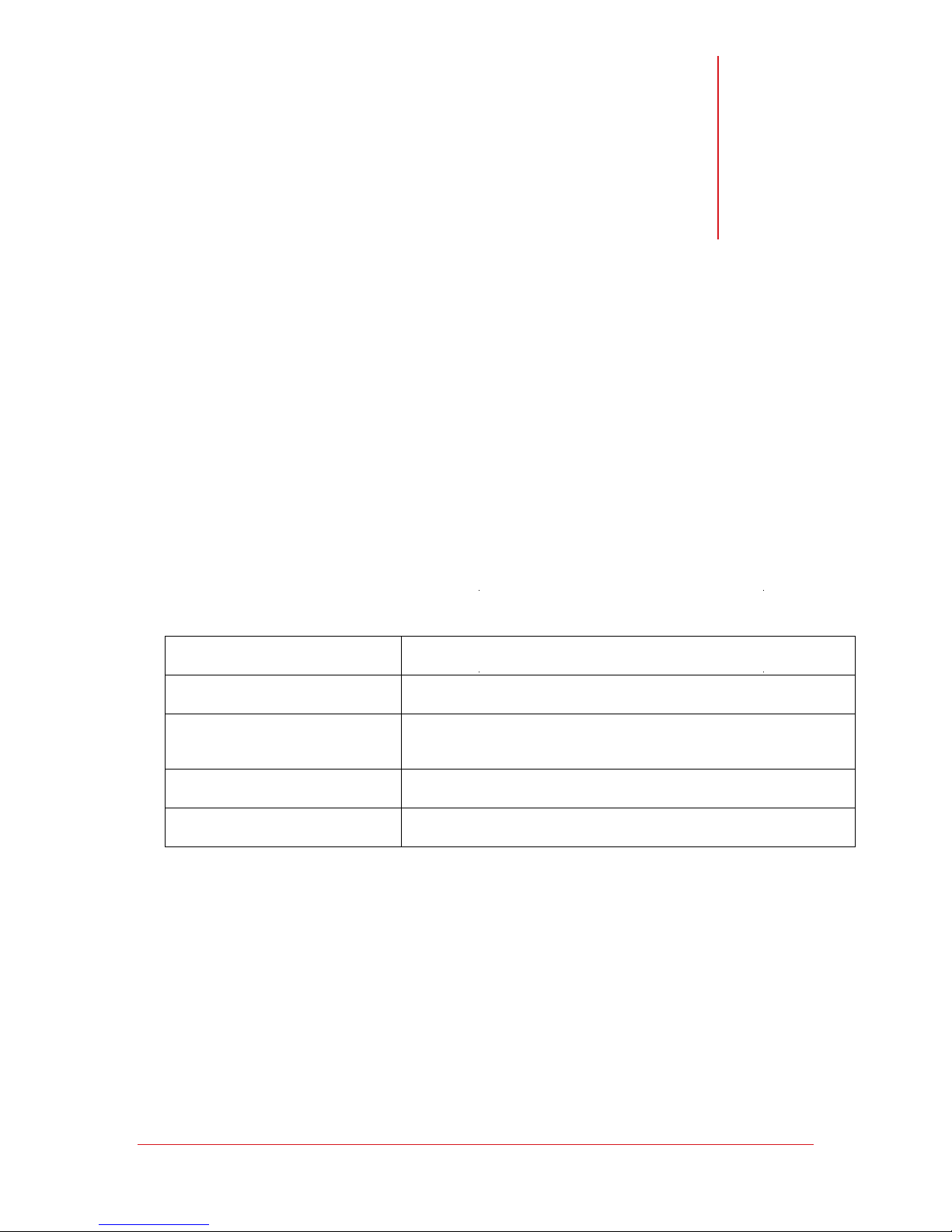

Contents........................................................................................................................................ iii

Important Symbols........................................................................................................................ 4

Foreword ........................................................................................................................................ 5

Safety Precautions...................................................................................................................................... 5

Inspection ................................................................................................................................................... 6

Introduction.................................................................................................................................... 7

Model Number Identification .................................................................................................................... 7

Installation...................................................................................................................................... 8

Physical Location..................................................................................................................................... 8

Ambient Air Requirements ....................................................................................................................... 8

Selecting a Process Fluid ........................................................................................................................... 9

Process Fluid Properties.........................................................................................................................10

Electrical Requirements.............................................................................................................................11

High pressure Bypass Hook-Up (Accessory).............................................................................................12

Connect to the Process .............................................................................................................................13

Operation...................................................................................................................................... 14

User Menu .................................................................................................................................... 16

User Menu Layout .....................................................................................................................................17

Proportional Control Menu.........................................................................................................................18

Span Menu ................................................................................................................................................19

Miscellaneous Menu ..................................................................................................................................20

Communications Menu ..............................................................................................................................21

High Fluid Temperature .............................................................................................................................22

Low Fluid Temperature..............................................................................................................................23

PID Tuning.................................................................................................................................................24

IT and DT...................................................................................................................................................25

CCT ...........................................................................................................................................................25

CPB ...........................................................................................................................................................26

HPB, CPB, AND DB ..................................................................................................................................27

RS-232 Communications Programmer's Reference ................................................................ 28

Maintenance................................................................................................................................. 42

Troubleshooting .......................................................................................................................... 47

Service.......................................................................................................................................... 50

FTS Warranties and Service Agreements .................................................................................................50

Standard Warranty.....................................................................................................................................51

Service Options .........................................................................................................................................52

Extended Warranty: ................................................................................................................................52

Preventative Maintenance: .....................................................................................................................52

Service Contract: ....................................................................................................................................52

Return of FTS Equipment ..........................................................................................................................53