Safety Precautions

Read the safety precautions thoroughly for safe use of

the product and become familiar with correct use before

handling the product.

Safety precautions are classified into the following four

categories in this manual: WARNING, CAUTION and

NOTE.

Failure to heed the information indicated by this

symbol may lead to dangerous conditions,

possibly resulting in death or serious bodily

injuries.

Failure to heed the information indicated by this

symbol may lead to dangerous conditions,

possibly resulting in minor or light bodily

injuries and/or substantial property damage.

NOTE Offers important information for your under-

standing and handling of the product.

WARNING and CAUTION are given in Safety

Precautions and the section where injury or damage is

anticipated. NOTE is given only in the section that

requires additional information.

Failure to heed the information, even though its symbol

is , may cause serious results depending

on the situation. Since all WARNING and CAUTION

contain important factors, always observe their

precautions.

The converter system is used to drive machinery in

various places, so it is impossible to anticipate all the

situations where troubles will be caused by potential

factors. Therefore, observe also the safety precautions

needed for inverters, motors, equipment, and the places

of use.

Remarks:

- Serious bodily injuries include loss of eyesight,

injury, burn (hot or cold), electric shock, fracture of a

bone, poisoning or the like. All of these cause

aftereffect and require hospitalization or attendance

at the hospital for a long term for cure.

- Minor and medium injuries indicate burns and

electric shock that does not require hospitalization or

long-term visiting care.

- Damage to the property means enlargement loss

concerning breakage of property and damage to the

equipment.

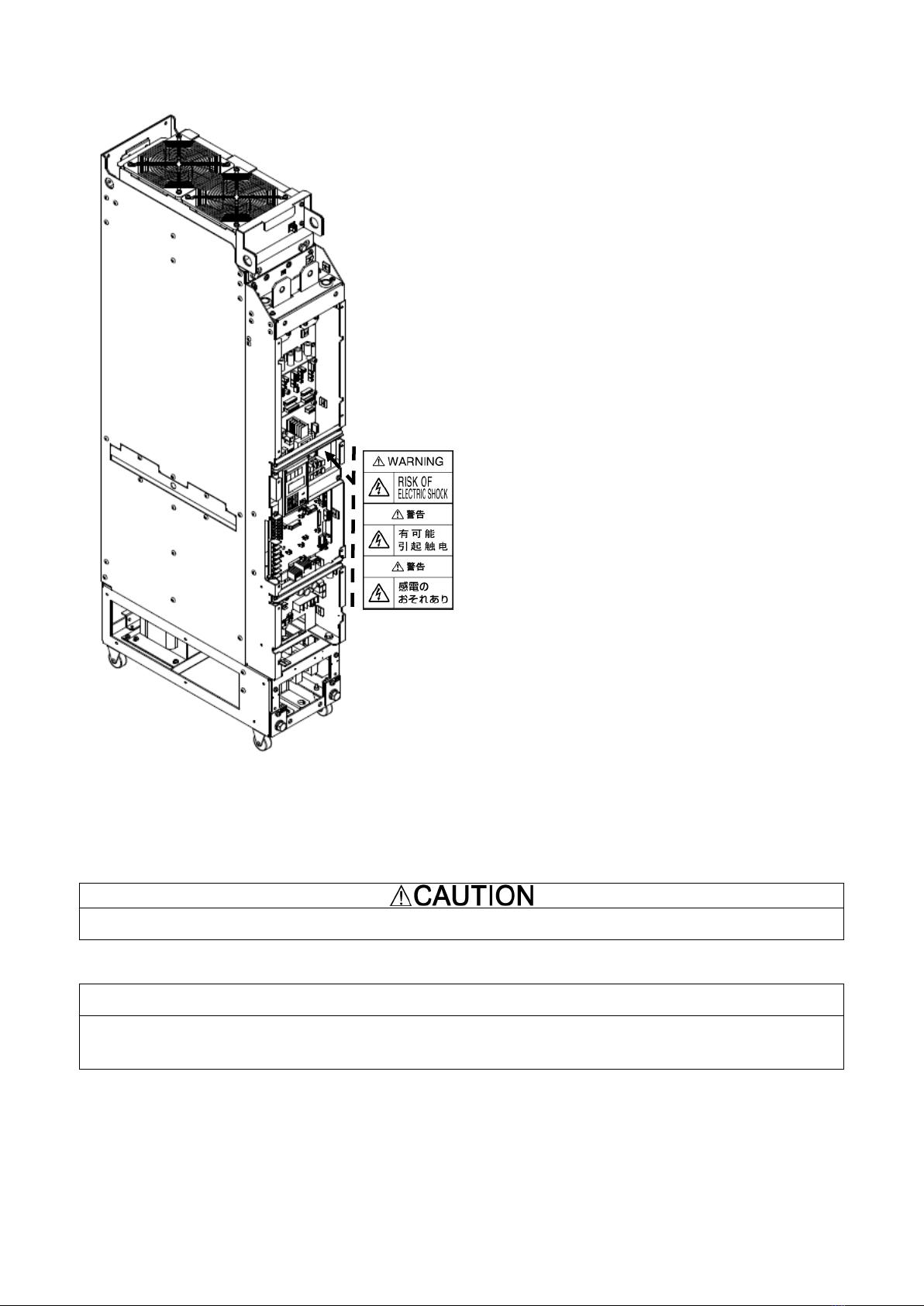

• Peripheral devices such as the filter stack, filtering resistors and reactors, and boosting reactors as well as the

heat sink become hot. NEVER touch these devices while the power is ON and immediately after the power is

turned OFF until they cool down.

Burns and injuries may result.

• Mount the fro

nt cover or the like without fail on the peripheral devices to keep them away from the reach of

people.

Electric shock or injury may result.

ii