- 1 -

Preface

We thank you very much for purchasing Fuji’s NO2/NO

Converter.

●Please read this instruction manual thoroughly

before installing, using and applying maintenance

this device.

Damage or accident may be caused when

mishandled.

●Specification of this NO2/NO converter may alter

without notice for modification.

●Do not remodel or modify this NO2/NO converter

without the manufacturer’s permission. Fuji Electric

will not accept any liability whatsoever for any

trouble or accident caused by such modification.

●Operator of the NO2/NO converter should keep this

instruction manual.

●Operator should keep this instruction manual near at

hand at all times, after thoroughly reading it.

Safety precautions

Please read the safety precautions written as bellow

before use, for correct use of the converter.

Please observe cautions stated bellow, for it contains

important information on safety.

CAUTION

CAUTION

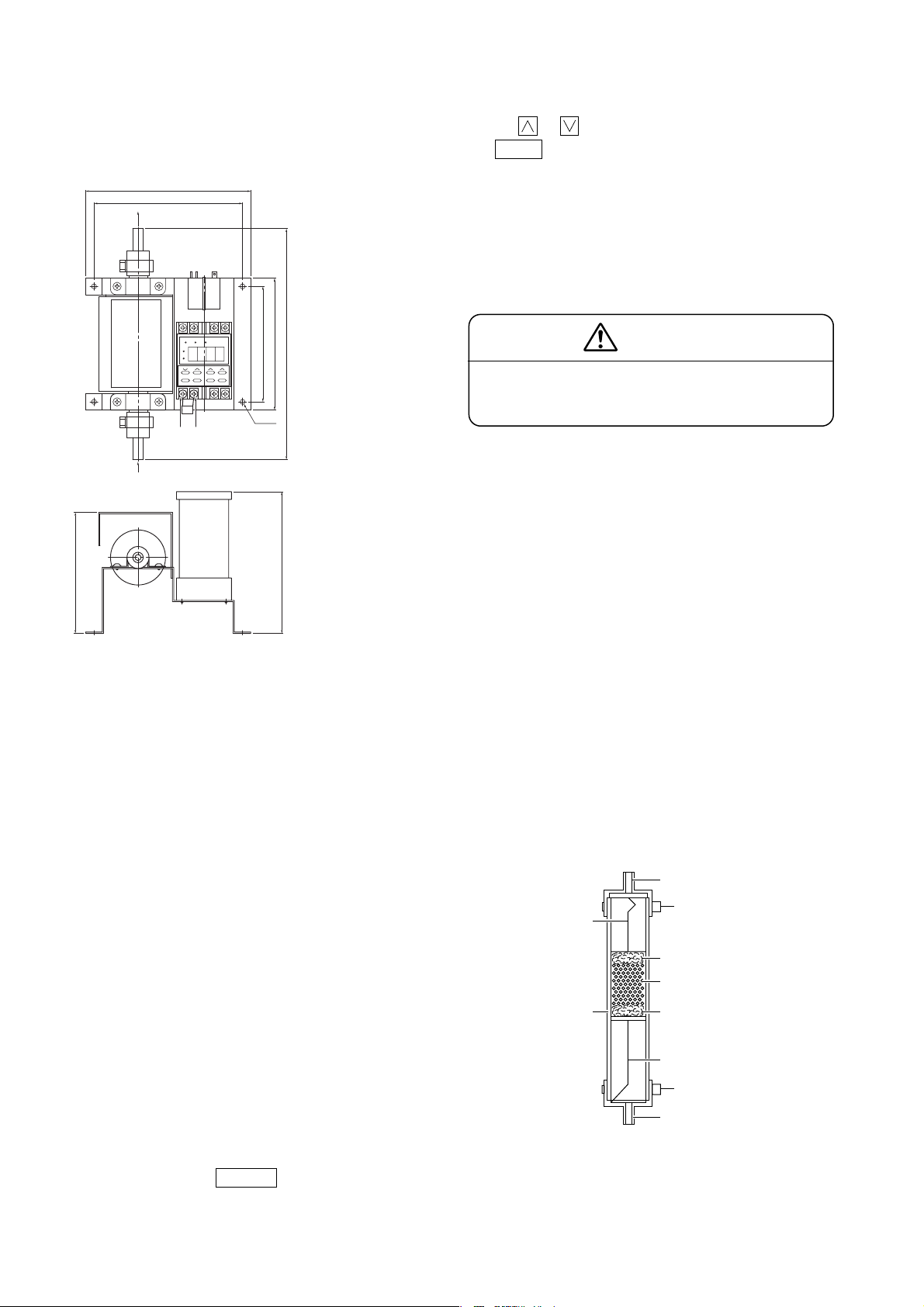

1. Overview

The NO2/NO converter is to be coupled with a NOx gas

analyzer or NH3gas analyzer for flue exhaust. It is

converter using a special catalyst which efficiently

converts NO2in sample gas to NO.

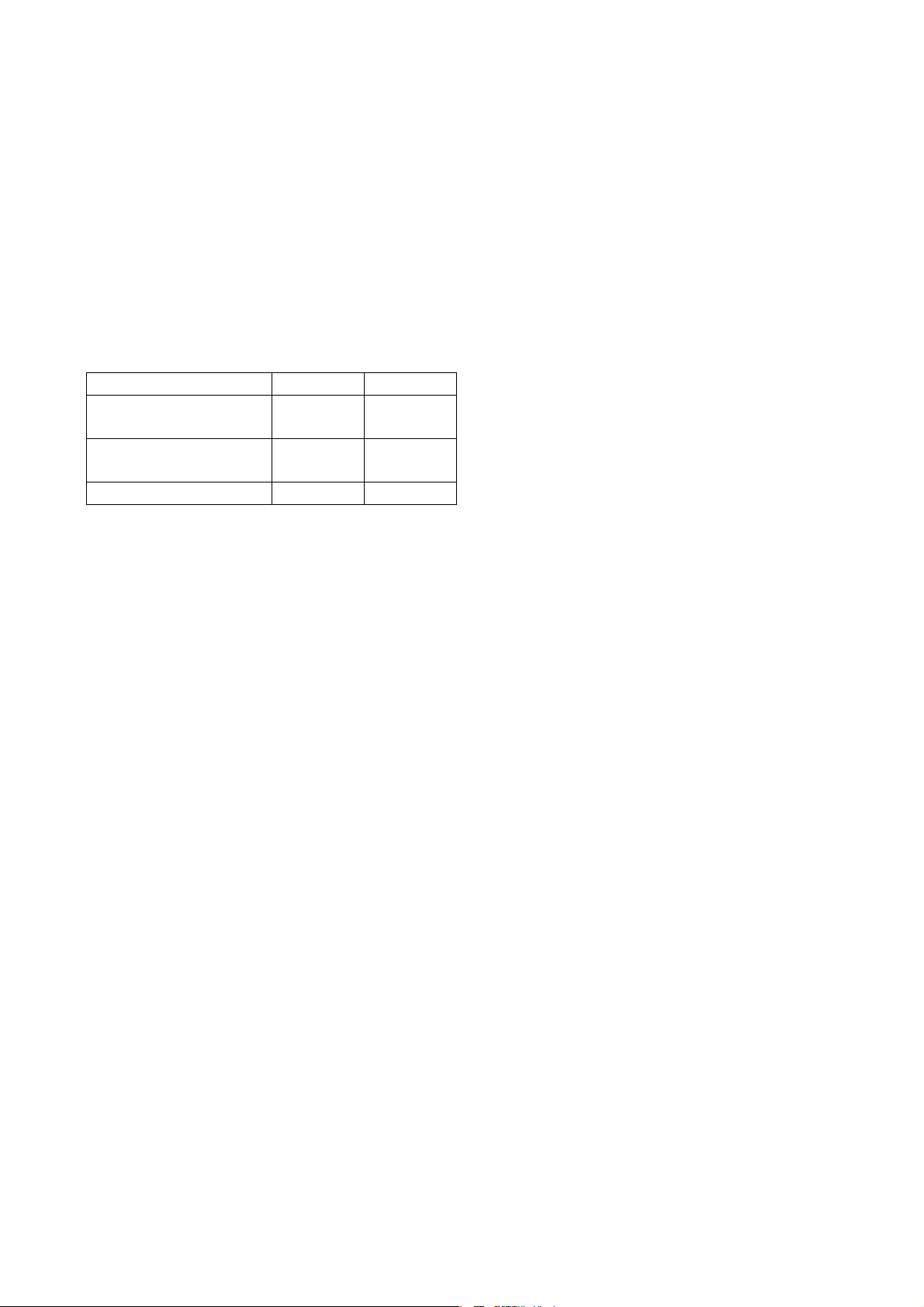

2. Major Specifications

Catalyst : Carbon, replacement required every

8 months (when NO2concentration

is 10 ppm or lower)

Gas flow rate : About 0.5L/min.

Set temperature : 220±10°C

Thermocouple : K

Power supply : 100V AC, 50/60Hz

Power consumption : About 85VA

Material of parts that contact gas

: Ceramic, Viton, Glass wool,

SUS316

Gas inlet/outlet connection method

: Insert Teflon tube φ6 mm/φ4 mm

into Viton connection port of inner

diameter φ5.5 mm. (Withstand

pressure: 10 kPa)

NO2 / NO Converte

INZ-TN1ZDL03-E

INSTRUCTION MANUAL

●Installation, wiring and piping should be carried

out by professionals or suppliers. Incomplete

installation may cause fall of the device, electric

shock or fire.

●Gas analyzer should be turned OFF when wiring,

maintenance or inspection is carried out. This is to

prevent electric shock and injury.

●Use wires with proper wire rods and diameters

that meets this device. Wrong ones may cause

electric shock or fire.

●Do not insert metal rod or fingers to the power

supply terminal. It may cause electric shock.

●Remove any metal objects such as wristwatch

while operating maintenance or inspection. It may

cause electric shock.

●Use pipes with proper material and joints stated in

the instruction manual. It may cause gas leakage.

●Use replacement parts that are specified by the

manufacturer. Otherwise, it may cause

malfunction, electric shock or gas leakage.

●Do not touch the converter section, due to high

temperature. Wear protective gloves while

exchanging catalyst. It may cause burn injury.

Model: ZDL03

Precautions under this mark is stated

when wrong handling may cause

hazardous situation. Possibility of

Medium level damage or injury, and

physical damage is predicted.

CAUTION

Head Office

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fesys.co.jp/eng

Instrumentation Div.

International Sales Div.

No. 1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

Phone: 81-42-585-6201, 6202 Fax: 81-42-585-6187

http://www.fic-net.jp/eng