4 INF-TN6FCXA4b-E

GENERAL SAFETY INSTRUCTIONS

For your own safety and the correct use of the FCX-AIV pressure transmitters, please carrefuly

read the following general recommendations:

1. The risks related to a non-respect of the instructions

povided in this manual are ranked and identied as follow:

2. Applications in hazardous locations (potentially explosive atmospheres)

FCX-AIV serie

and protection modes.

transmitters.

Please refer to the dedicated datasheet for further details on protection mode and related

parameters.

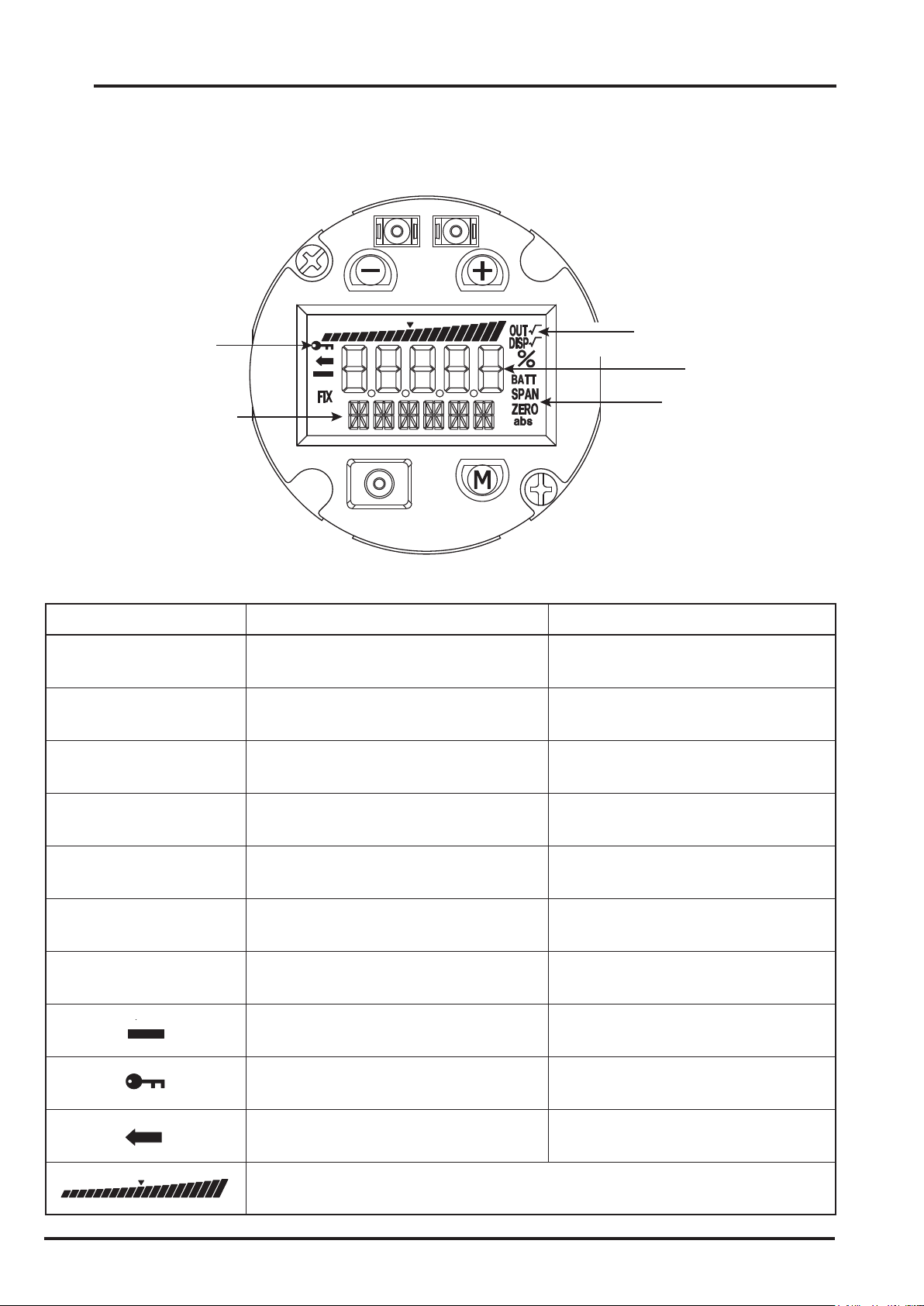

3. Magnetic stick (contacless setting)

• Do not use this magnetic stick if you have a medical device such as a pacemaker.

•

4. Safety Instrumented Systems

to IEC 61508 and IEC 61511 standards.

For evaluation of your safety instrumented system, please refer to the FCX-AIV Safety Manual

(TN5A5137) for further details on FMEDA results, failure rates and expected product lifetime.

instructions are not followed.

or physical damage can happen.

Important instructions to be respected.

General observations concerning the product,

product handling and correct use of the transmitter.

DANGER

CAUTION

WARNING

INDICATION