8

INTRODUCTION ......................................................................................................................... 4

EMC COMPLIANCE ................................................................................................................... 5

CLASSIFICATION OF SAFETY INSTRUCTIONS ..................................................................... 6

IMPORTANT RECOMMENDATIONS .......................................................................................... 7

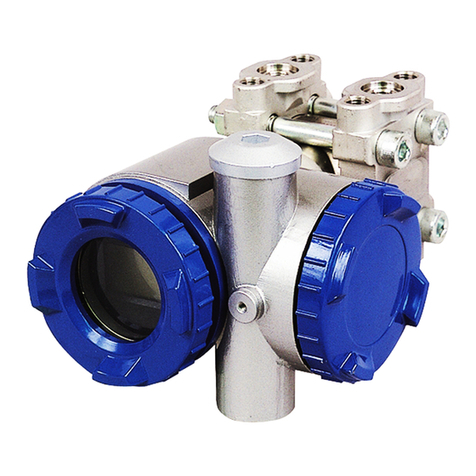

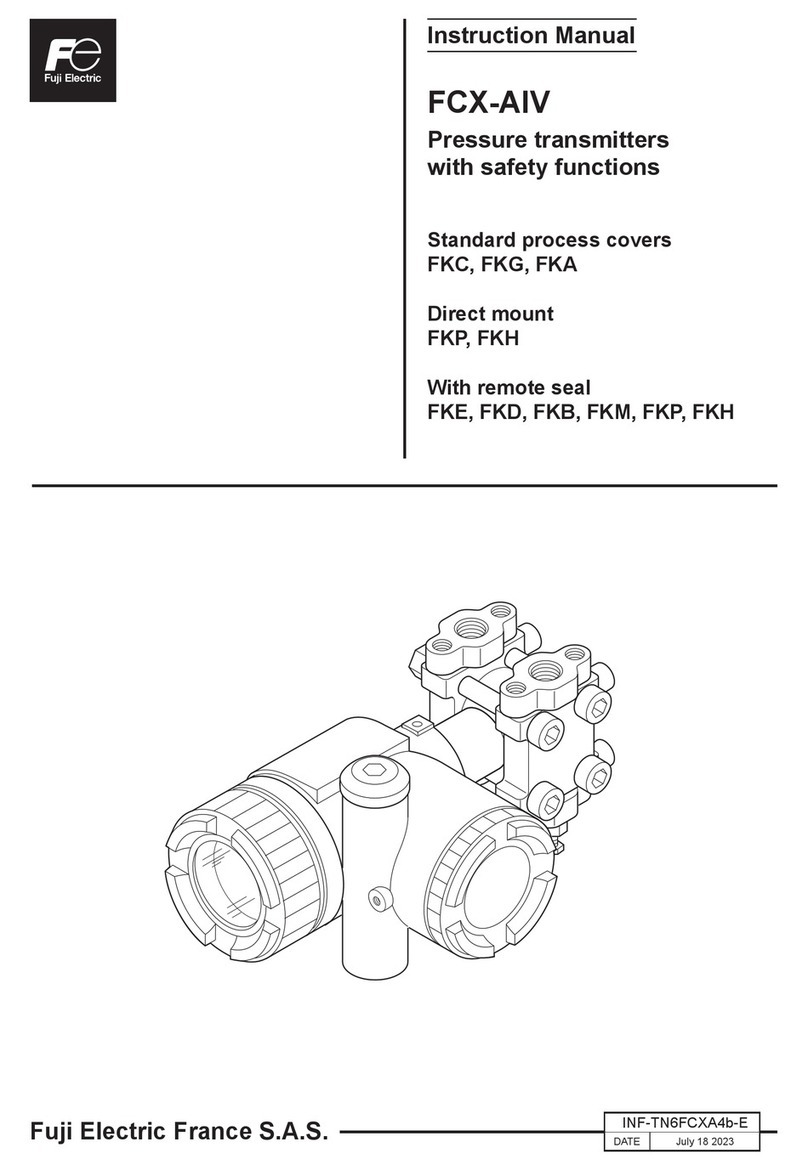

1. DESCRIPTION ......................................................................................................................... 9

2. THE CONSTITUENT ELEMENTS ........................................................................................ 10

3. INSTALLATION AND CONNECTIONS ............................................................................... 12

3.1 Installation ............................................................................................................... 12

3.2 Connection mechanism ............................................................................................ 17

3.2.1 Differential pressure and ow transmitters (FKC) ............................................ 17

3.2.2 Effective (FKG) and absolute (FKA) pressure transmittors .............................. 21

3.2.3 Level transmitters (FKE) ................................................................................... 23

3.2.4 Installation of the transmitters with separators (FKB, FKD, FKM) .................... 26

3.2.5 Relative pressure transmitters with separator (FKB)

Absolute pressure transmitters with separator (FKM) ...................................... 29

4. ELECTRICAL CONNECTIONS ........................................................................................... 31

4.1 - Wiring procedure ..................................................................................................... 32

4.2 Supply voltage and load resistance .......................................................................... 33

4.3 Earthing .................................................................................................................... 34

5. COMMISSIONING AND STOPPAGE .................................................................................. 35

5.1 Preparation for the commissioning ........................................................................... 35

5.2 Operating mode ........................................................................................................ 36

5.3 Deactivation .............................................................................................................. 37

6. ADJUSTMENTS & SETTINGS ............................................................................................ 39

6.1 Settings with the FXW mobile communicator ........................................................... 39

6.2 Adjustment procedure with aid of external screw ..................................................... 59

6.3 Procedure for adjusting the measuring range .......................................................... 60

6.4 Local adjustments from the digital display ................................................................ 61

7. MAINTENANCE ................................................................................................................... 64

7.1 Periodic Inspection ................................................................................................... 64

7.2 Troubleshooting ........................................................................................................ 64

7.3 Replacement of defective parts ................................................................................ 66

7.4 Settings after replacement of the amplier or of the measuring cell ........................ 69

ANNEXES:

A1. SURGE PROTECTOR ....................................................................................................... 70

A2. CALIBRATION .................................................................................................................. 72

A3. INITIAL STATE OF THE PARAMETER SETTINGS ......................................................... 74

TABLE OF CONTENTS