FRC

P. 2 / 4TNFFRCDd-E

Fuji Electric France S.A.S.

46, rue Georges Besse - ZI du Brézet - F-63039 Clermont-Ferrand Cedex 2 - France

Tél: +33 4 73 98 26 98 Fax: +33 4 73 98 26 99 http://www.fujielectric.fr

SAFETY FEATURES & CAUTIONS

■INTRINSICALLY SAFE APPROVAL

• ATEX

EU-

Type Examination Certificate: KEMA 07ATEX0136 X

II 1G Ex ia IIC T4, T5, T6 Ga

Zone 0

EN 60079-0

EN 60079-11

• IS Data

Ui = 30V DC Uo = 6.4V DC

Ii = 96mA DC Io = 30mA DC

Pi = 720mW Po = 48mW

Ci = 0 µF Co = 20 µF

Li = 0 mH Lo = 10 mH

• Prior to installation, check that the safety class of this

unit satisfies the system requirements.

• A safety barrier must be installed between the unit and

its power supply. Refer to “Installation Diagram” attached

at the end of this manual when selecting a safety barrier.

• The power supply and the safety barrier must be located

in a non-hazardous area.

• Environmental temperature must be within the following

ranges depending upon the required temperature class.

T4 : -40°C ≤ Ta ≤ +80°C

T5 : -40°C ≤ Ta ≤ +65°C

T6 : -40°C ≤ Ta ≤ +50°C

• DO NOT RUB the surface of the plastic enclosure with a

dry cloth. Electrostatic charge generated by the friction

may cause an explosion.

• DO NOT APPLY physical impact or friction onto the

FRC1 enclosure.

• Non-metallic materials (window cement) are contained in

the FRC1/FRC2 enclosure and the user must consider the

performance of these materials with respect to chemicals

which may be present in the hazardous area.

• Be sure to secure the terminal cover after wiring (model

FRC0).

• The wiring method must be in accordance with the electri-

cal parameters described in this manual.

• Be sure to earth the unit (model: FRC1/FRC2).

• The intrinsic safety approval of the model FRC1/FRC2 is

applied to the combination of the outdoor enclosure and

the transmitter. The transmitter must not be separated

or replaced.

• Substitution of components may impair suitability for the

hazardous location and may cause an explosion.

• When metal particles are present in the air, install the

model FRC0 inside an outdoor enclosure.

• For installing the FRC0 in an environment with a high

relative humidity exceeding 0 to 95% RH or in a condens-

ing atmosphere, install the unit inside an outdoor enclo-

sure.

■Model FRC1/FRC2 FLAMEPROOF APPROVAL

• IECEx

Certificate of Conformity: IECEx CML 18.0140X

Ex db IIC T4, T5, T6 Gb

IEC 60079-0

IEC 60079-1

• ATEX

EU-

Type Examination Certificate: CML 18ATEX1277X

II 2G Ex db IIC T4, T5, T6 Gb

Zone 1

EN 60079-0

EN 60079-1

• Threaded joint of cover: UN 3 5

/

8- 12

• Engaged threads ≥ 8

• Prior to installation, check that the safety class of this

unit satisfies the system requirements.

• Environmental temperature must be within the following

ranges depending upon the required temperature class.

T4 : -40°C ≤ Ta ≤ +80°C

T5 : -40°C ≤ Ta ≤ +65°C

T6 : -40°C ≤ Ta ≤ +50°C

• Use suitable heat resistant cable and cable glands for am-

bient temperatures ≥ 70°C

• Before wiring, make sure there is no danger of explosion

in the atmosphere.

• Before opening the enclosure, wait at least for 60 seconds

after the power is removed.

• The cable entry device and stopping plugs for unused ap-

ertures shall be of a certified flameproof type, suitable for

the conditions of use and correctly installed.

•

The cable entry conduit is 1/2 NPT or M20 ×1.5 threaded.

• Six or more cable entry threads must be engaged.

• Squeeze the cable entry and stopping plug into the con-

duit with the proper tool.

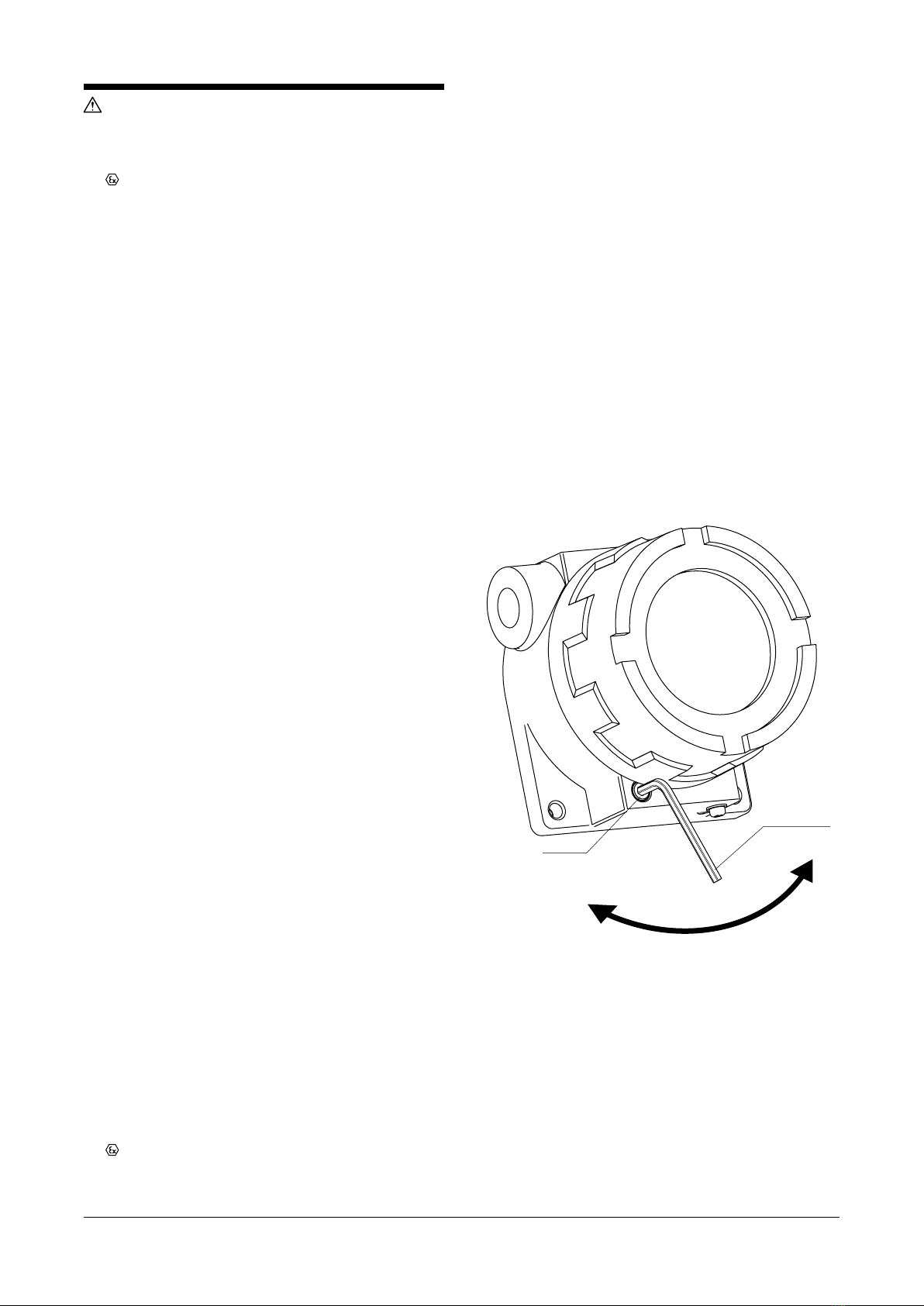

• Before turning the power supply on, be sure to close the

enclosure cover tightly and tighten the fastener as shown

in Figure 1 using a hexagon key wrench. When opening

the enclosure, loosen the fastener first.

Tight

Loosen

Fastener

Hexagon Key

Wrench

Figure 1. Enclosure fastener

• DO NOT RUB the surface of the plastic enclosure with a

dry cloth. Electrostatic charge generated by the friction

may cause an explosion.

• Be sure to earth the unit.

• For external earthing or bonding connection a cable lug

shall be used so that the conductor is secured against

loosening and twisting and that contact pressure is main-

tained.

• The flameproof approval of this unit is applied to the com-

bination of the outdoor enclosure and the transmitter.

The transmitter must not be separated or replaced.

• Substitution of components may impair suitability for the

hazardous location and may cause an explosion.