2 Allow sufficient cooling time

Cooling temperature is important when using an impulse sealer. After

the film is heated, the film must be cooled with the frame and pressure

lever in the closed position. If cooling temperature is extremely lower,

the working efficiency will come down. So please set the appropriate

cooling temperature according with the film. Set the cooling time more

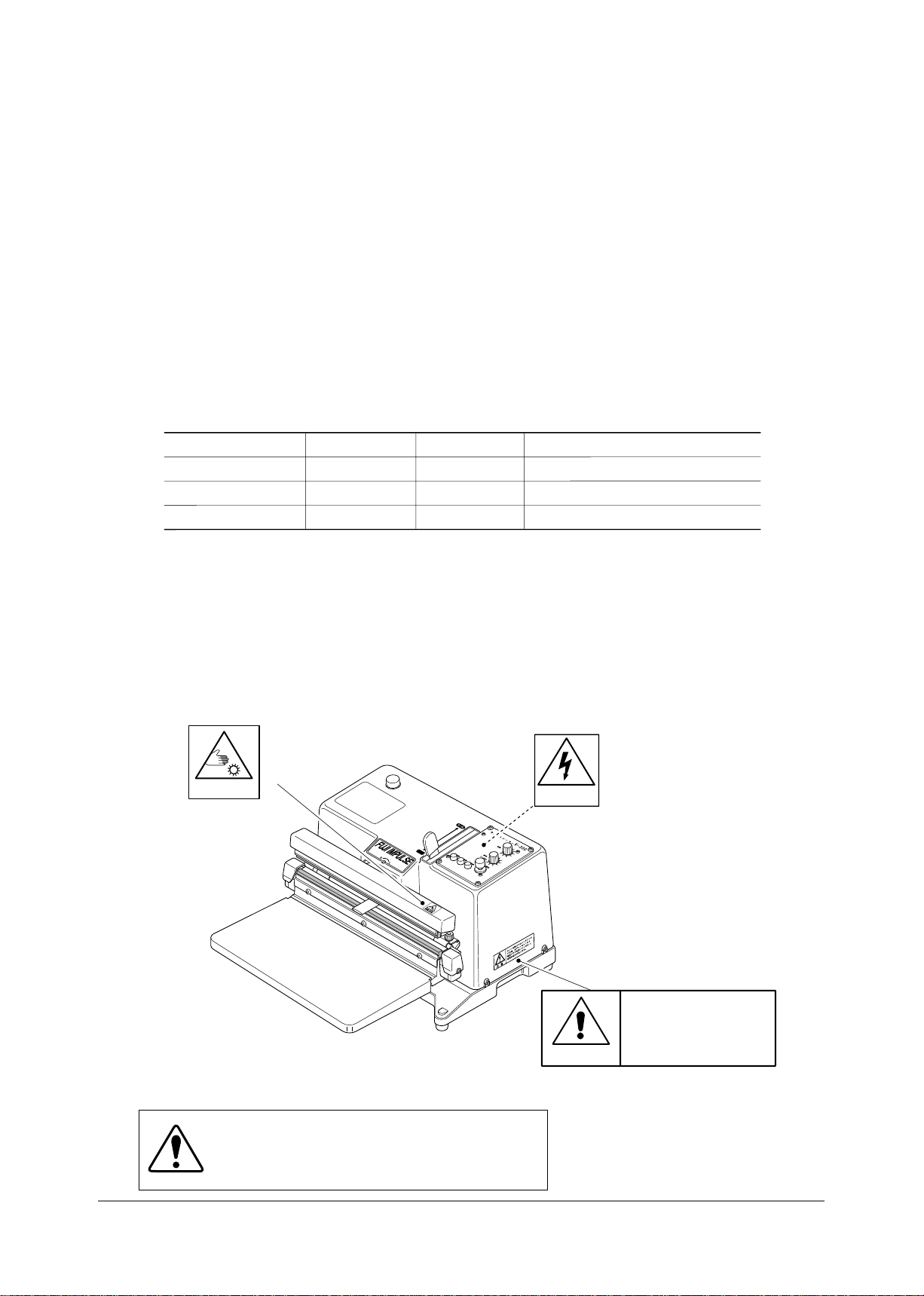

3 When the teflon, Silicone rubber becomes damaged

The teflon, silicone rubber will start to wear with use. Once they are

damaged, it will be difficult to achieve smooth and strong seals.

Thoroughly read how to replace the parts and be careful when doing so.

4 Prolonged operation

The temperature of sealing section will become high if the machine is

operated for a long time. Since sealing conditions will change, shorten

the heating time and lengthen cooling time appropriately.

5 Adjust sealing presure to make tight seal.

Follow the instruction to adjust sealing pressure, see the page 22.

6 Dust in the sealing area.

Dust will prevent attainment of a smooth seal. It will also cause

damager to parts of the heater.

Before using the machine, clean the sealing area.

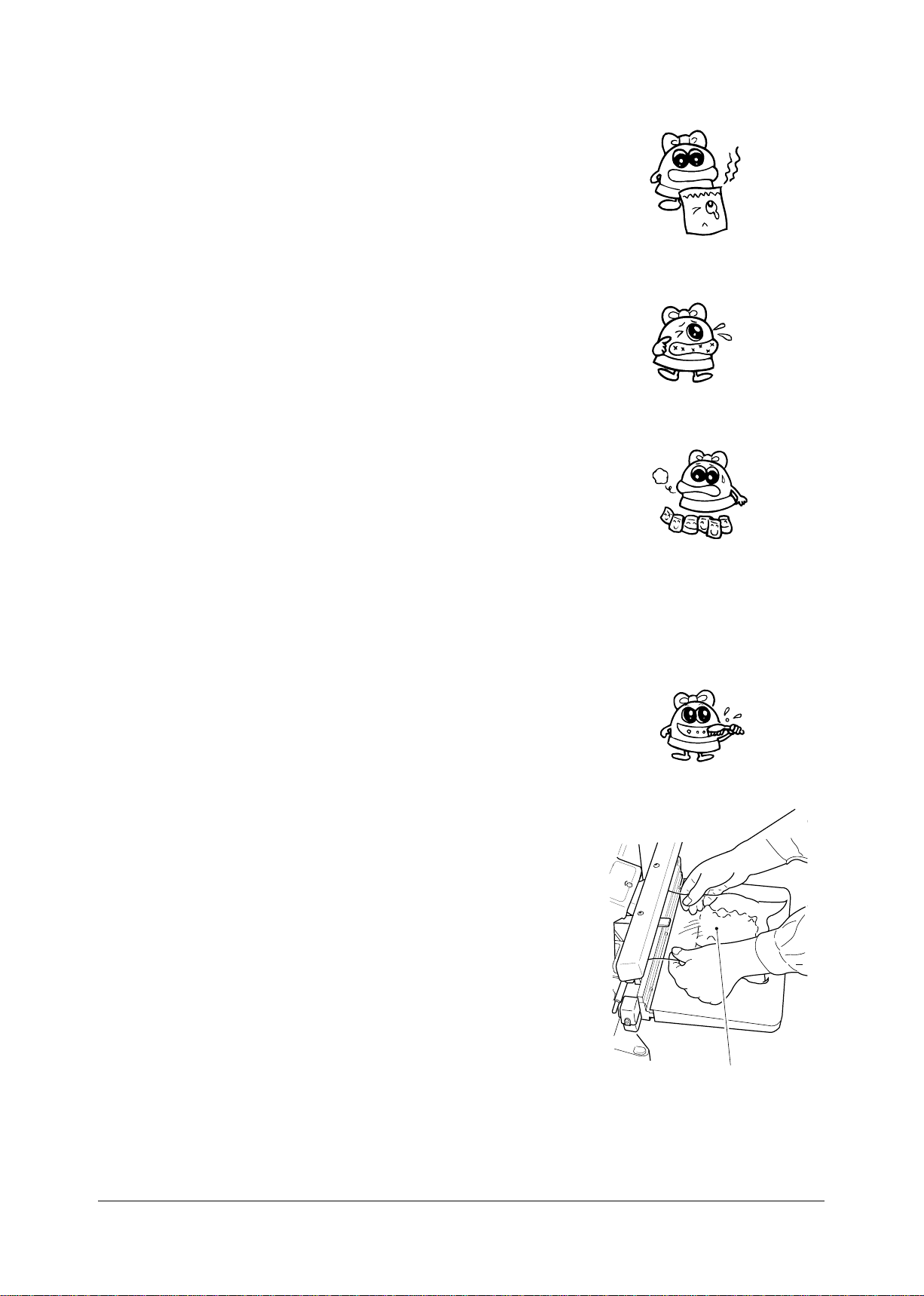

7 When vacuum sealing liquids or powders, regular maintenance of

the nozzle is necessary.

Particularly when sealing sticky liquids, the nozzle should be regularly

flushed with water and allowed to air dry. When flushing the nozzle,

water will pass through the filter and be discharged outside the unit,

so please ready a container to catch the water coming from the hose.

If the blockage in the nozzle is particularly severe, refer to the

instructions on page 21 on how to remove the nozzle. Remove as

illustrated and clean thoroughly.

Wet a sponge with water and place it

inside the pouch. Press the vacuum

button to flush the water from the

sponge through the nozzle. Repeat

this 2 - 3 times to loosen the blockage.

than 1.5 times of the heating time.

V-300 series Operating Instructions