1 Specifications ………………………………………………………………………………………… 5

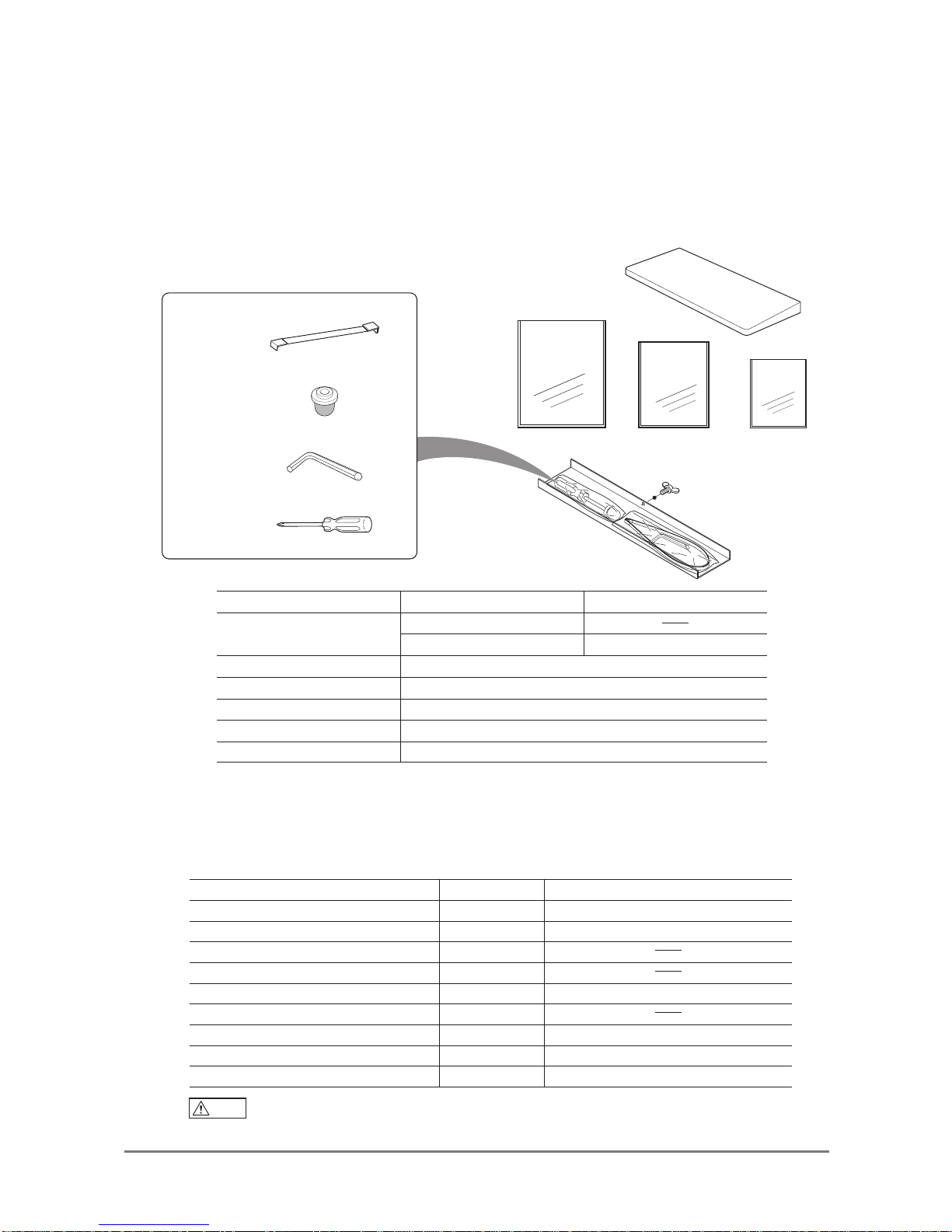

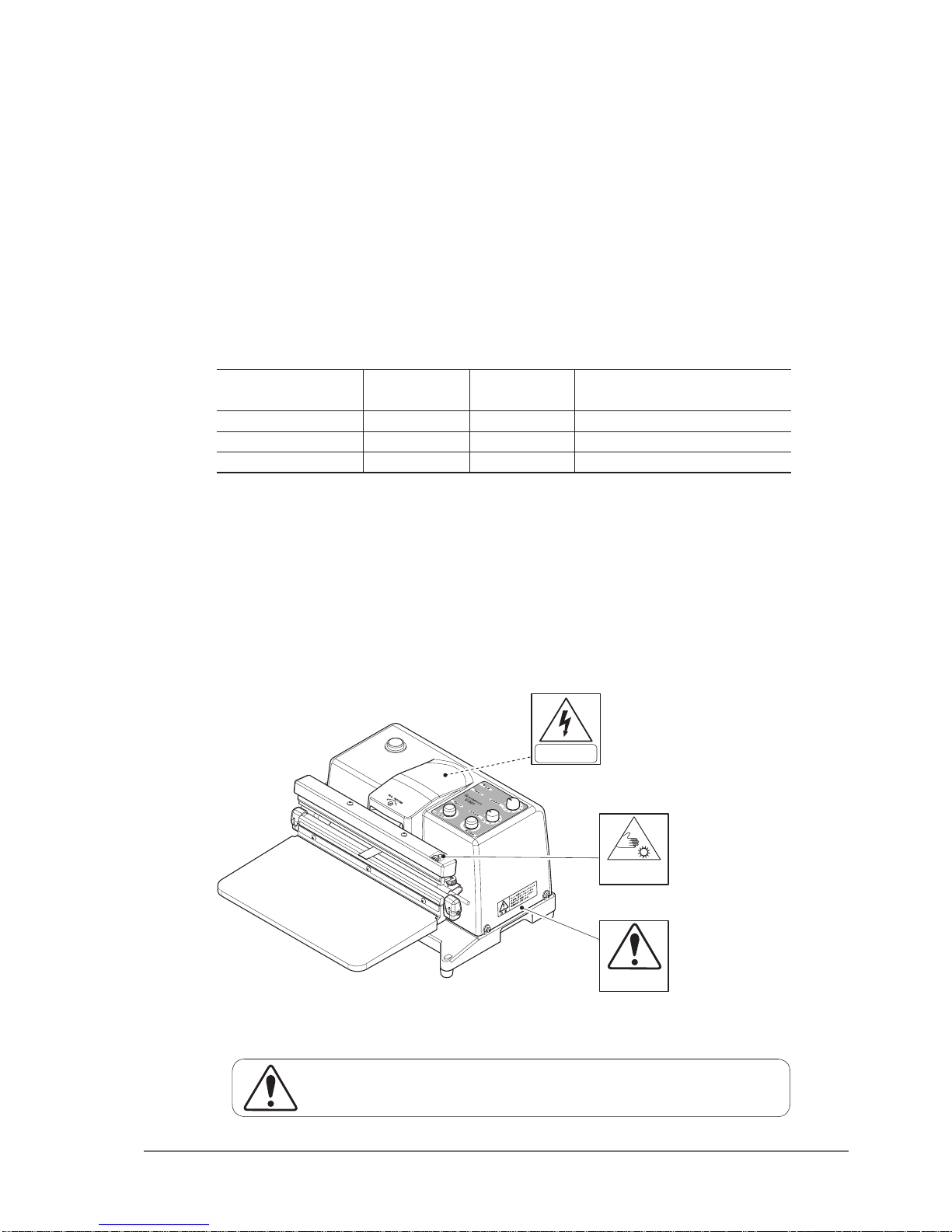

2 Accessories …………………………………………………………………………………………… 6

3 Replacement parts …………………………………………………………………………………… 6

4 Proper operating boundaries for the V-301 series ……………………………………………… 7

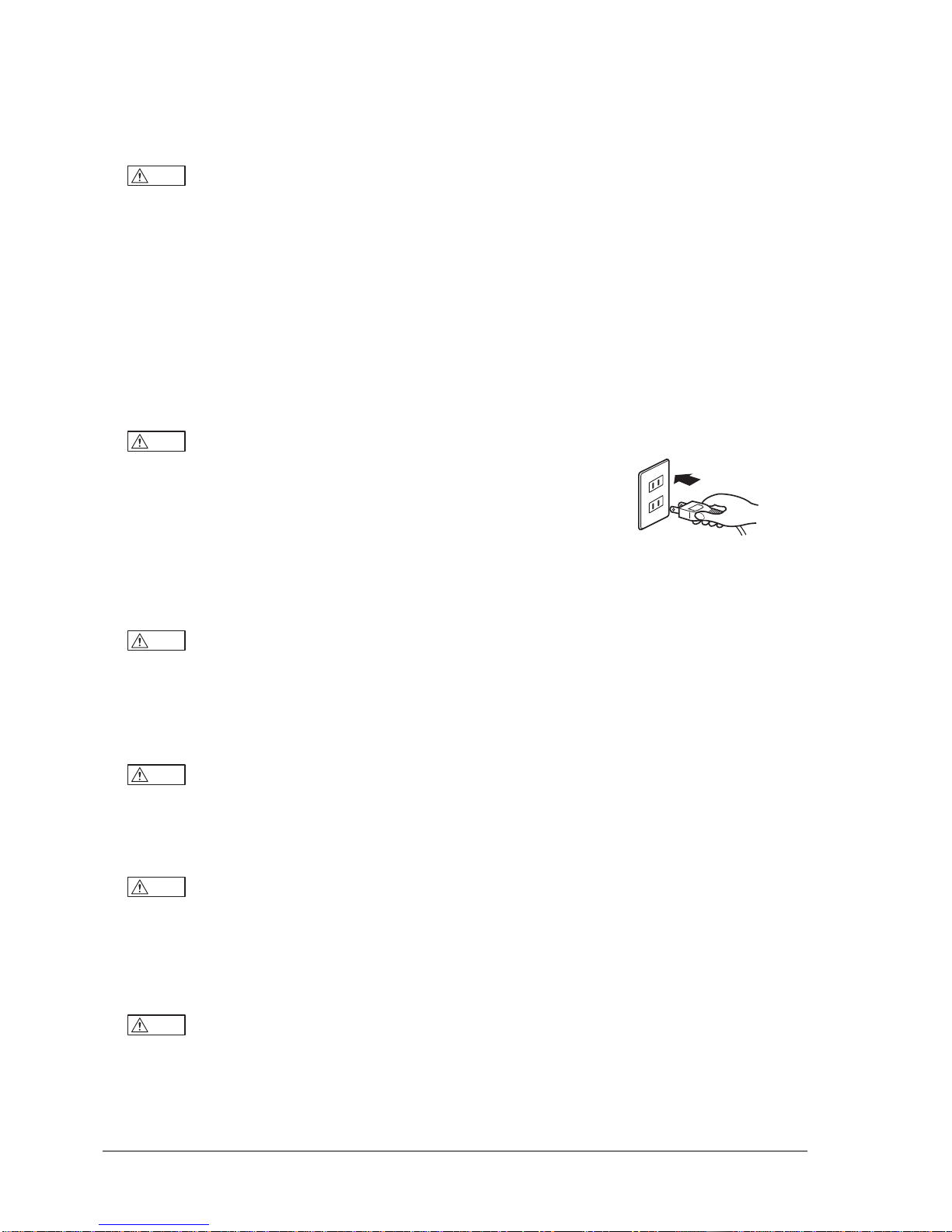

5 Warning - Caution label location and content …………………………………………………… 7

6 Operating precautions ………………………………………………………………………………… 8

For safety operating ………………………………………………………………………………………………………………………… 8

For smooth operation ……………………………………………………………………………………………………………………… 10

Other safeguards …………………………………………………………………………………………………………………………… 11

7 Major parts and functions ………………………………………………………………………… 12

8 Proper use of the sealer …………………………………………………………………………… 13

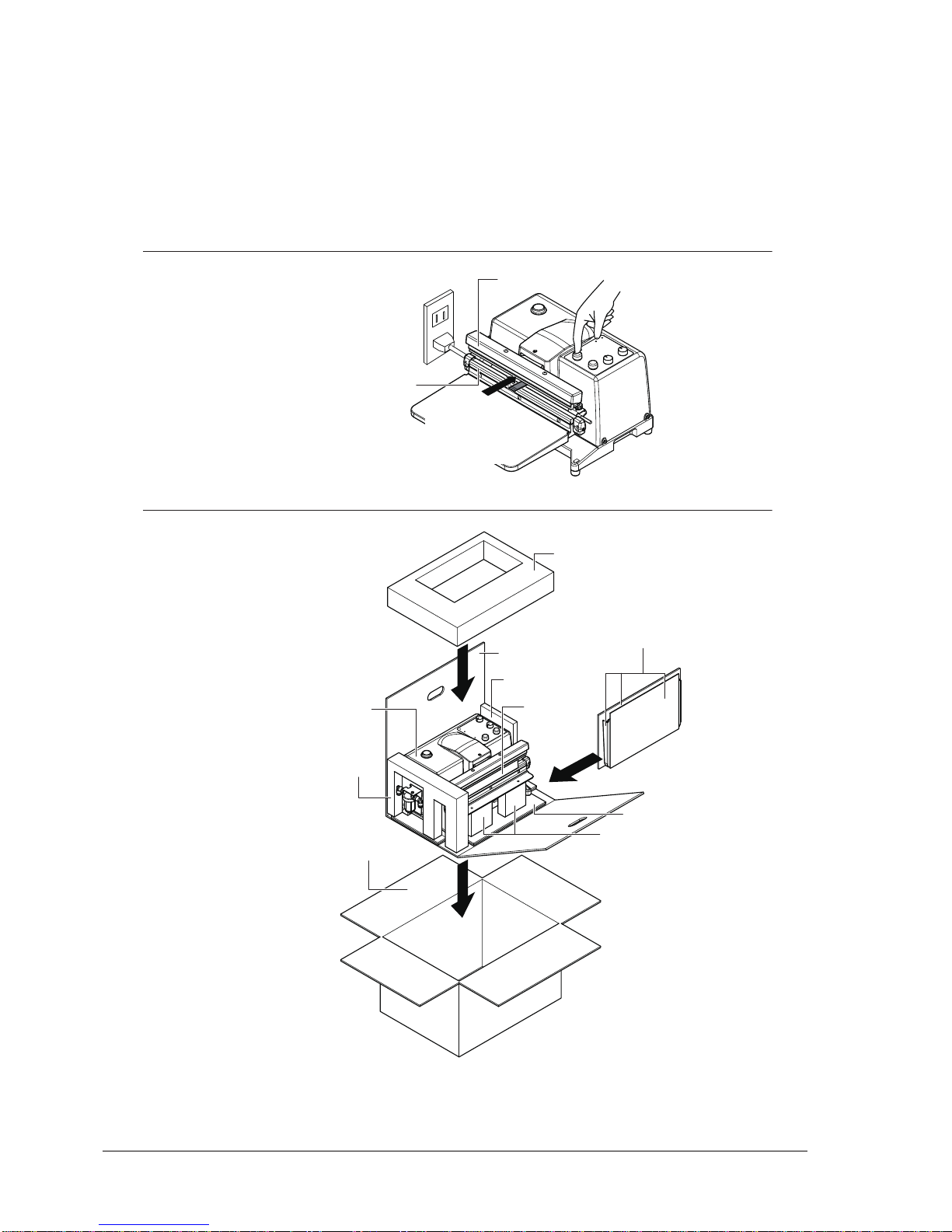

8-1 Set up the machine ………………………………………………………………………………………………………………… 13

8-2 Install the table ……………………………………………………………………………………………………………………… 13

8-3 Connect the power cord …………………………………………………………………………………………………………… 13

8-4 Turn on the power …………………………………………………………………………………………………………………… 13

8-5 Adjust the sealing conditions ……………………………………………………………………………………………………… 14

8-6 Advance the nozzle ………………………………………………………………………………………………………………… 14

8-7 Set the pouch ……………………………………………………………………………………………………………………… 15

8-8 Push the table ……………………………………………………………………………………………………………………… 15

8-9 Push the vacuum start button …………………………………………………………………………………………………… 15

8-10 Press the table further down …………………………………………………………………………………………………… 16

8-11 Cooling process …………………………………………………………………………………………………………………… 16

8-12 Sealing is complete ……………………………………………………………………………………………………………… 16

8-13 Turn off the power switch ………………………………………………………………………………………………………… 17

8-14 Check after the operation ………………………………………………………………………………………………………… 17

9 Safety measurement and Error message ……………………………………………………… 17

10 When air flushing is desired ……………………………………………………………………… 18

11 How to remove the hoses ………………………………………………………………………… 18

12 Replacing he routine maintenance parts ……………………………………………………… 19

12-1 Slide the teflon sheet …………………………………………………………………………………………………………… 20

12-2 Change the heating element …………………………………………………………………………………………………… 20

12-3 Change the glass tape, sarcon sheet ………………………………………………………………………………………… 22

12-4 Change the silicone rubber (white)……………………………………………………………………………………………… 22

12-5 Clean the filter and replace the cartridge ……………………………………………………………………………………… 23

12-6 Replace the nozzle ……………………………………………………………………………………………………………… 24

12-7 Clean or replace the nozzle coupler …………………………………………………………………………………………… 25

13 Adjust the sealing pressure ……………………………………………………………………… 26

14 Electric diagram …………………………………………………………………………………… 27

V-301 Electric diagram …………………………………………………………………………………………………………………… 27

V-301-10D Electric diagram …………………………………………………………………………………………………………… 27

15 Common problems and solutions ………………………………………………………………… 28

Table of contents