Section 2. Treatment Process Overview

Fuji Clean’s “contact filtration” treatment is a simple, well engineered process that consists of a controlled, circuitous

flow train through anaerobic and aerobic chambers and in direct contact with assorted proprietary fixed film medias

on which biological digestion of organic matter occurs. Media is also designed and positioned to provide mechanical

filtration of process wastewater.

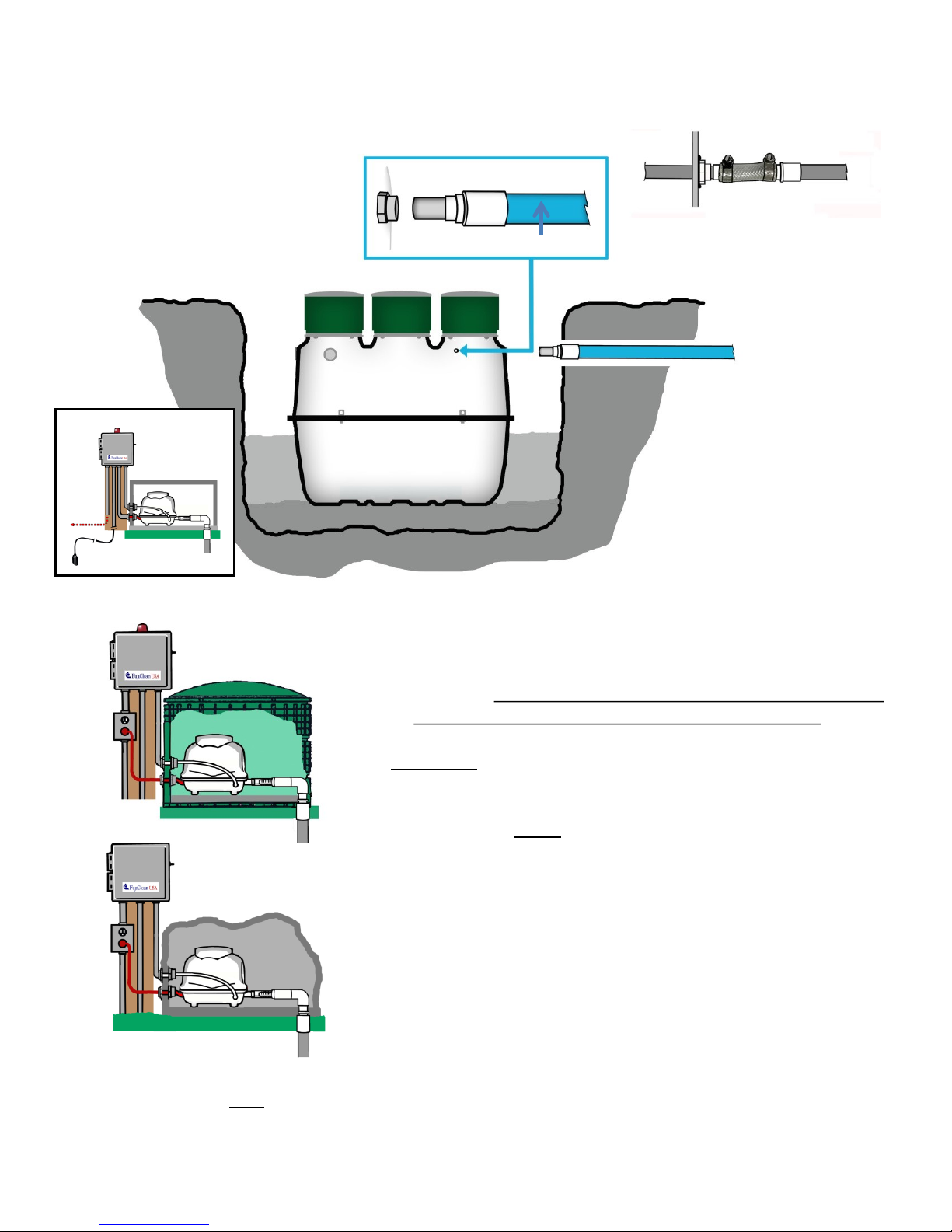

The system includes two air lift pumps (see diagram below) The Recirculating Airlift Pump returns process water and

sludge from the aerobic zone to the sedimentation chamber, recirculating 2-4 times inflow per day for CE models and

4-6 times inflow for CEN (enhanced denitrification) models. The Effluent Airlift Pump is designed to help equalize flow

and discharge treated effluent.

Outlet

Air

Sludge Transfer

(Recirculating air lift

pumpback) See airlift

pump info below.

Chamber 3B. Disinfection Chamber (final zone before

discharge –option for chlorination tablet disinfection)

Chamber 1.

Sedimentation

Chamber (separates

solids and greases)

Chamber 3. Aerobic Contact

Filtration Chamber

(both board and cylindrical hollow

mesh media) oxygen rich zone for

aerobic microbe digestion activity,

solids filtration and nitrification of

ammoniac nitrogens to nitrates

Powered by the FujiMACRII Series

Blowers State-of-the-art linear

diaphragm air blowers manufactured

by Fuji Clean Co sized to provide

about 2.8 cubic feet per minute to

most residential systems.

Chamber 2. Anaerobic Contact

Filtration Chamber (spherical-

skeleton filter media) organic matter

decomposition by micro-organisms,

suspended solids captured and

nitrates are denitrified

Chamber 3A. Storage Chamber (settling zone)

Two Air Lift Pumps. One

Recirculating Air Lift pump sending

process water and solids back to

Chamber 1, and one Effluent Air

Lift Pump for measured discharge

of treated effluent. (See airlift

pump info below).

Airlift Pumps. This generic illustration

shows the mechanics of the “airlift

pumps” used in this system, which are

simple pipe conduits through which

pressurized air (from blower) is

introduced at the bottom and by fluid

pressure, water is carried up the pipe

by ascending bubbles.

Flow Equalization

When water level

exceeds LWL, treated

water is discharged

through Chamber 3B

via the Effluent Air Lift

pump. If water level

exceeds HWL, then

treated water is also

discharged through an

overflow effluent weir.

Overflow Effluent Weir

During treatment,

water level fluctuates

between high and

low water levels

Inlet

5