The Porta-Flex 200/400 are welding fume extraction units. Designed to capture dangerous fumes/gases and particles

produced by the welding process, at source. These by-products are captured via the magnetic nozzle and removed by the

internal cartridge lter. Our Porta-Flex models are for light welding use only.

Safe Operation

1. Check the power supply cable for damage, if any damage is visible, it must only be replaced by the manufacturer or

qualied electrician to avoid a hazard.

2. Check that the extraction hose is not split or damaged, as this will reduce the eciency of the unit.

3. To protect against electrical shock, do not immerse the power supply cable, plug or extractor in water or other liquid.

4. Our fume extractors are designed for interior use only and should not be used outside in wet conditions.

BEFORE USE

OPERATION

1. Place the Porta-Flex on a sturdy, level surface and connect the 2.5m extraction hose to the intake port on the front

cover.

2. Connect the other end of the 2.5m extraction hose to the magnetic exible nozzle.

3. Plug power supply cable into a suitable electrical socket and turn on power switch (200), or both switches (400),

located on side of unit. Please ensure that the power cable is not a trip hazard to anyone.

4. Position the magnetic exible nozzle to draw welding fumes AWAY from the operator (see section 4 - Quick Start

Guide). For exact capture distance, please refer to certification. Make sure the extraction hose is not kinked or trapped,

as this will reduce extraction eciency.

5. On completion of welding, turn o the Porta-Flex and disconnect the power supply plug from the socket.

6. Disconnect the extraction hose from both the magnetic nozzle and the unit. Both the power supply cable and the

extraction hose can be wound around the carry handle for storage (see section 6 - Quick Start Guide).

Routine Maintenance

ALWAYS wear the correct RPE when replacing the cartridge lter or cleaning the spark trap. Due to the carcinogenic

nature of the waste material, RPE must include a fully tted mask (with correct lters), disposable overalls and

gloves. Replacing the cartridge lter must be carried out OUTDOORS to minimise the risk of inhalation of any dust

etc. The Porta-Flex must be disconnected from the power supply BEFORE undertaking any maintenance.

All Porta-Flex 200 or 400 units should be COSHH tested at least every 14 months, to ensure compliance to HSE 258.

Fumex Ltd have a team of dedicated COSHH engineers who operate all over the UK, please call us for details.

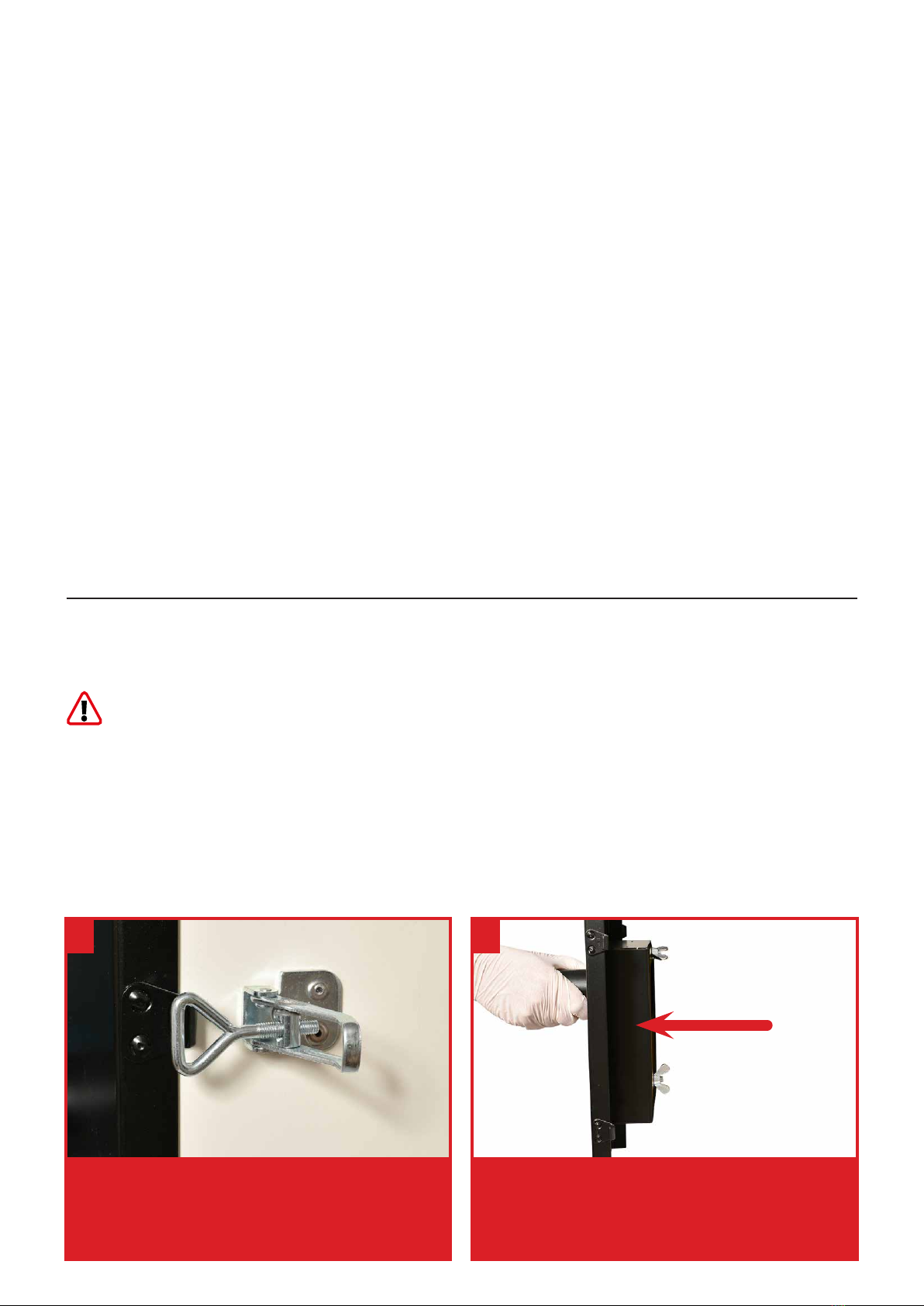

CLEANING THE SPARK TRAP

1

To access the spark trap, release the four toggle

fasteners and unhook the front cover.

The spark trap is located behind the inlet port on the front cover. It should be regularly checked and cleaned as necessary.

2

Carefully remove the front cover and combined

spark trap (arrowed). To check the spark trap,

remove the two wing nuts and clean if required.

4