FFI Tech Dept. v 09.11.06 Measurements in Millimeters. 1” = 25.4mm 3 of 11

AGB Unitop

Model 1455-3 Door Lock

Installation Guide

1.0 Basic Information

Congratulations on your purchase of this innovative product from AGB. Unitop® is a registered

trademark of Alban Giacomo spa (AGB). The Unitop door lock complies with EU standards.

The Unitop model 1455-3 door lock can be assembled and installed by experienced personnel

without difficulty by using this installation guide. This shall be verified in the case of complaints.

Arbitrary modifications and changes to the Unitop lock or its accessories are not permitted.

Installation of products that are not original AGB products and the use of parts that have not been

approved by AGB may negatively affect the given design characteristics of the locking device. All

repairs must be conducted by authorized specialists and with original spare parts. The

manufacturer will not accept liability for damages caused by failure to observe these instructions.

This will also void warranty claims in any form.

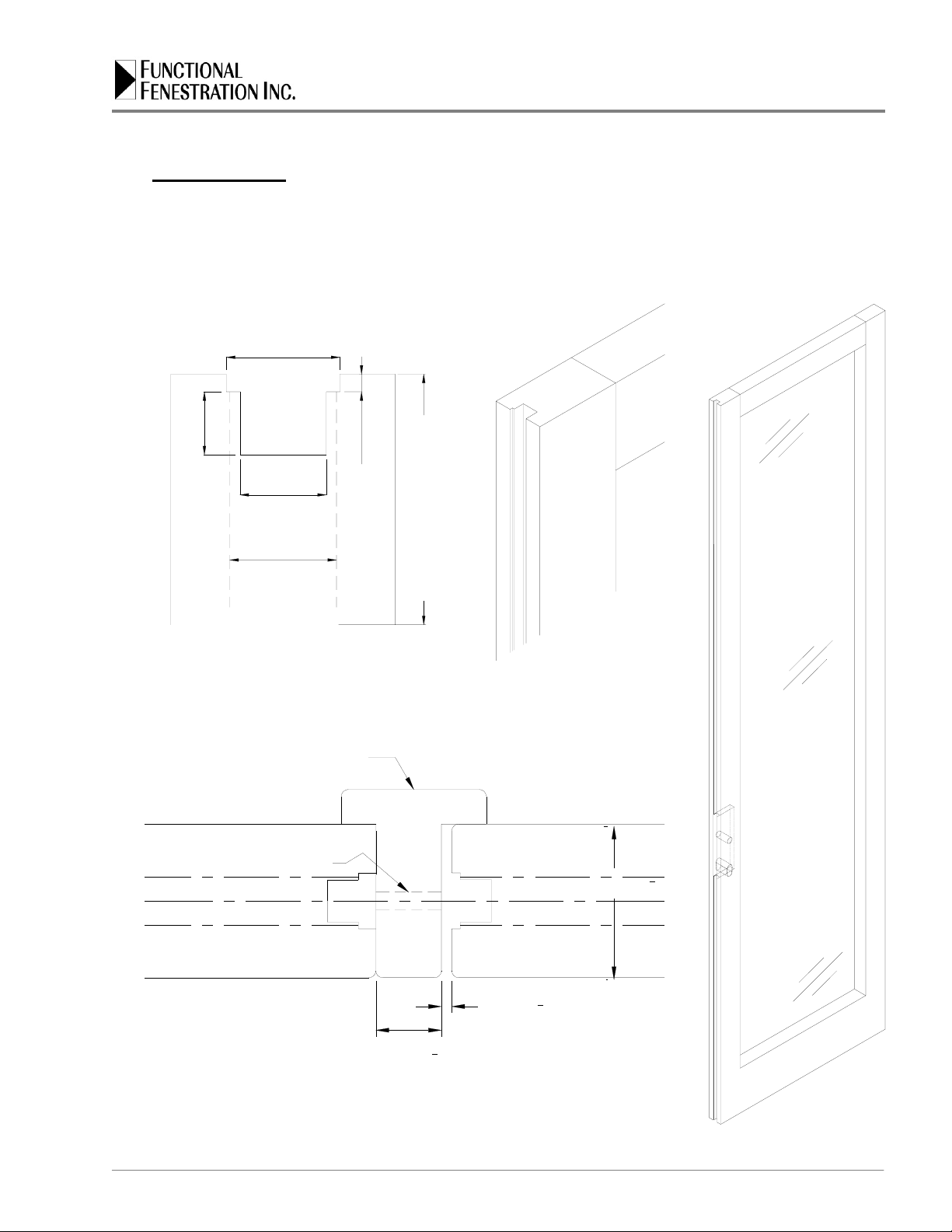

1.1 Technical Data

Type: Lift Lever Operation.

Door Height: min=1800mm; max. =3658mm

Faceplate: width=16 mm; thickness=2.5mm; length=1920 mm + upper shootbolt & extensions.

Lockbox Backsets: 35, 40, 45, 50, & 55mm.

Lockbox Depth: backset + 18mm.

Spindle Size: 8mm square.

Spindle Centers: 92mm.

Handle Height: set at 1050mm (standard); may be lowered to a minimum 948mm.

Shoot-bolt Throw: 15mm

Material: steel.

Finishes: yellow bichromate & silver zinc.

2.0 General Description

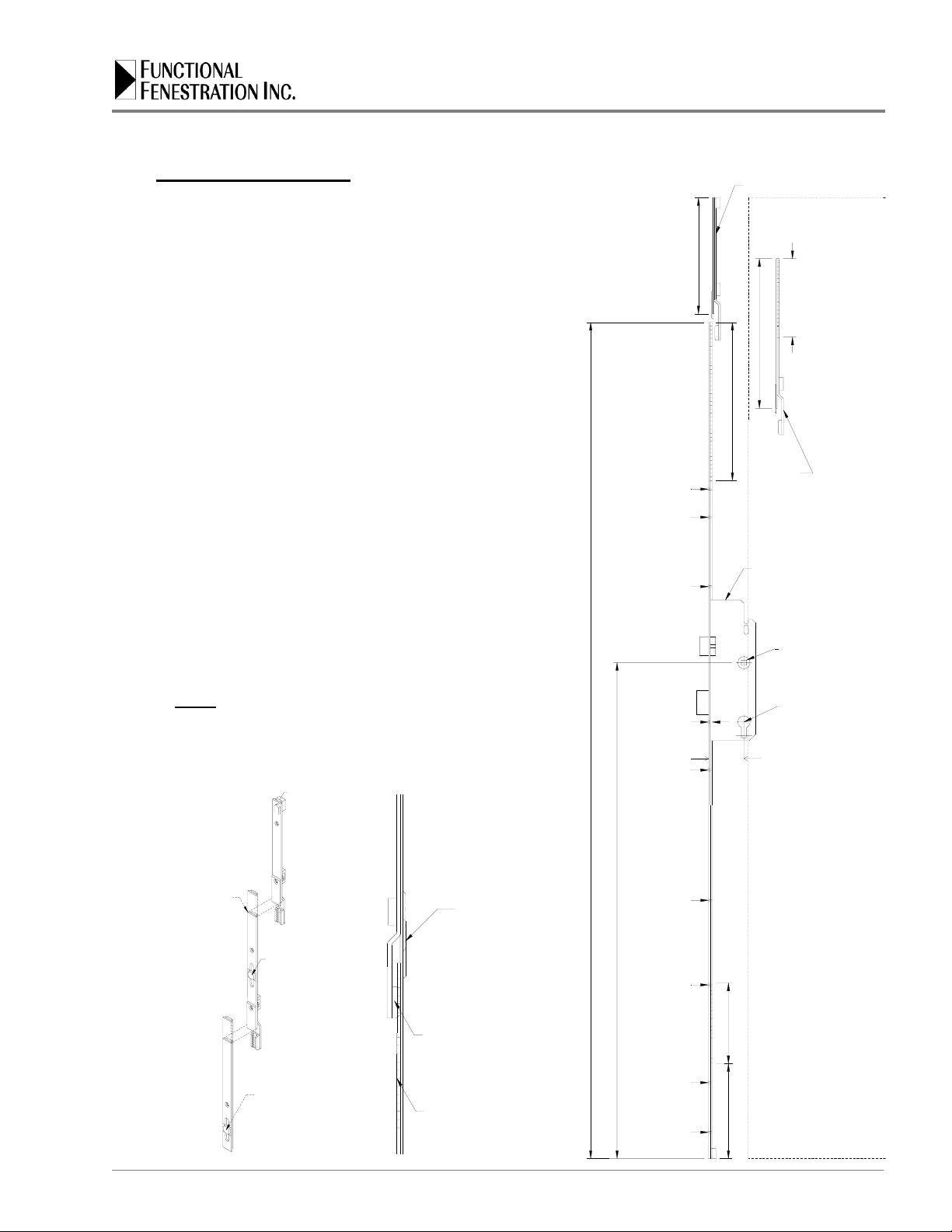

The Unitop Model 1455-3 is a multiple locking device (door lock) for swinging doors. This door

lock is designed for the securing of the “active” (primary) door in a swinging double-door

(“French”) system. This door lock ensures that the active door is securely locked by means of a

central latch & deadbolt that inserts into the inactive door along with two vertical “shoot-bolts”, one

that secures the top of the door to the head jamb and one that secures the bottom of the door to

the sill. A reverse mechanism, contained in the lock case, allows the upper and lower drive rods

to move in opposite directions. The reverse gearbox commonly installed at the end of one rod is

thus eliminated. The locking is more secure and the mechanism is simpler and more practical.

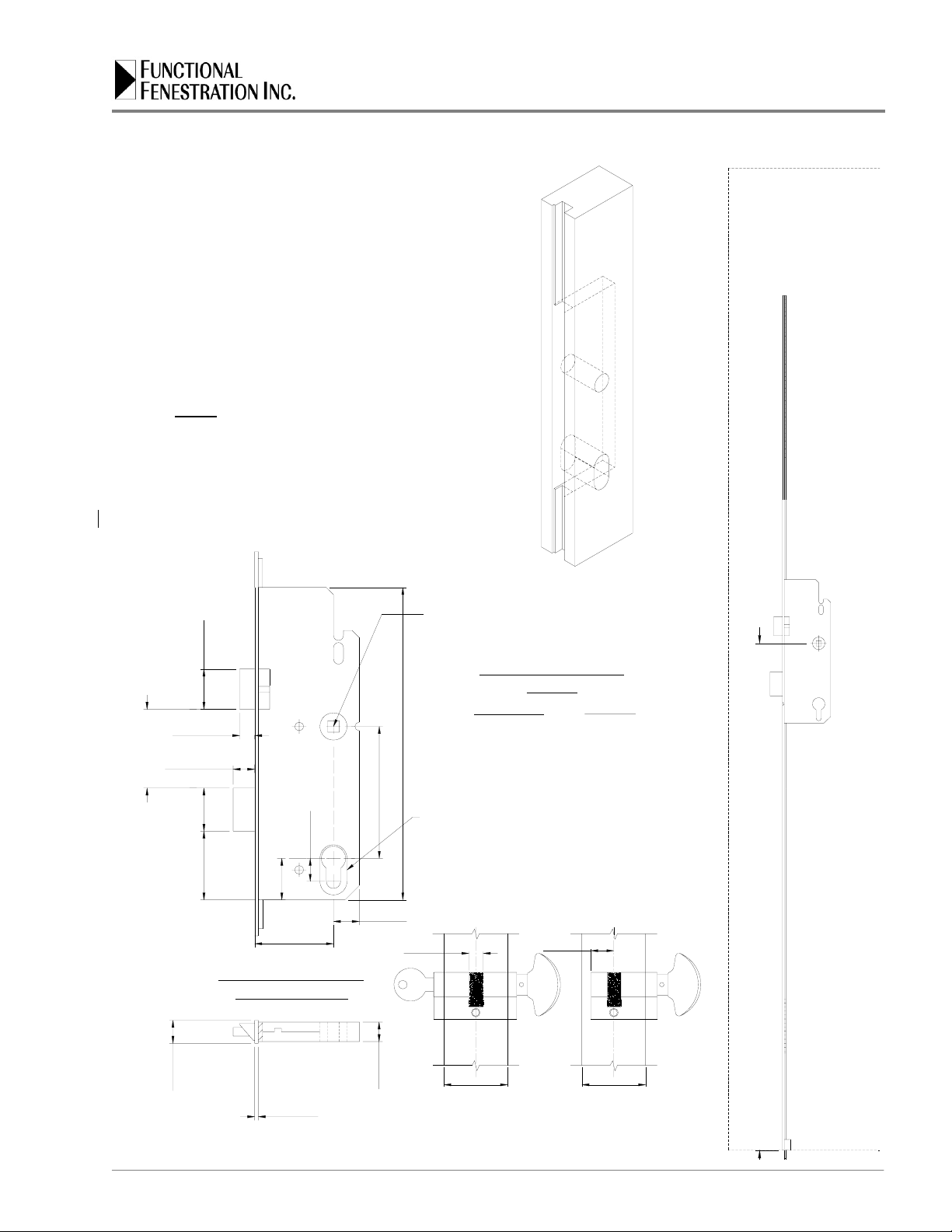

The lock is not handed and is easily reversed with a screwdriver. Its self-adjusting spring latch is

inclined and rounded on both sides. This shape guarantees a perfect closing of the door. An

upward motion of a lever style handle only engages the deadbolt and shoot-bolts.They are

disengaged by downward motion of the handle. The handle may be locked from movement by the

use of a manually activated European lock cylinder (optional).

The Unitop lock is suitable for all types of door materials. The door lock-stile must be milled or

equipped with a “Euro” hardware groove for mounting of the locking hardware. The door head

jamb and sill must be able to accept a “thimble” type keep for receiving of the shoot-bolts. The

Unitop model 1455 lock may be installed in private homes, public and commercial buildings.