0-2

TABLE OF CONTENTS

8. HOW TO REFER TO WORKING

RANGE CHART AND RATED LOAD

CHART

Working range chart ……………………… 8- 1

Rated load chart …………………………… 8- 2

9. DESCRIPTION OF EACH

CONTROL DEVICE

Overwinding alarm ………………………… 9- 1

Automatic stop for overwinding …………… 9- 2

Boom angle chart ………………………… 9- 4

Warning horn ……………………………… 9- 8

Retaining mechanism for slinging wire rope

…9-8

Automatic stop for leaving minimum wire rope

(With wire rope retaining roller) …………… 9- 8

10. HOW TO OPERATE CARRIER

Designation of each control lever

and its location …… 10- 1

Preparation before operation ……………… 10- 3

Precautions before operation

(air-bleeding procedures) … 10- 6

How to operate …………………………… 10- 7

How to Crawl ……………………………… 10-10

How to fasten carrier when in transportation

… 10-15

11. HOW TO OPERATE CRANE

Designation of each control lever

and its location … 11- 1

Preparation before operation ……………… 11- 3

Inspection before starting crane operation … 11- 4

Procedures to set up outriggers …………… 11- 6

How to operate boom for derricking

(raising and lowering) … 11-15

How to hoist and lower the hook …………… 11-16

How to telescope boom …………………… 11-18

How to slew boom ………………………… 11-20

How to store crane ………………………… 11-22

Procedures for storing hook………………… 11-23

How to store outriggers …………………… 11-25

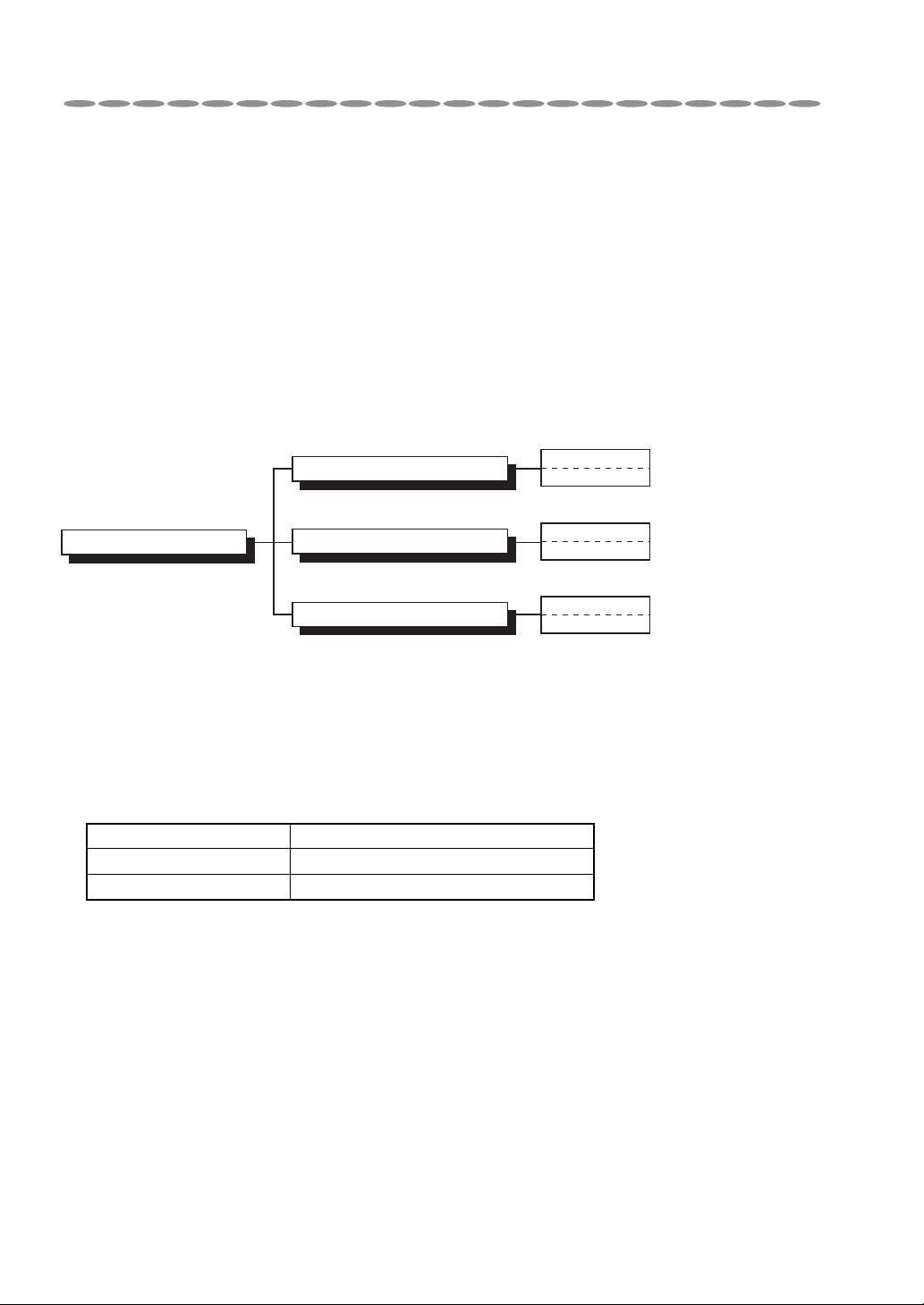

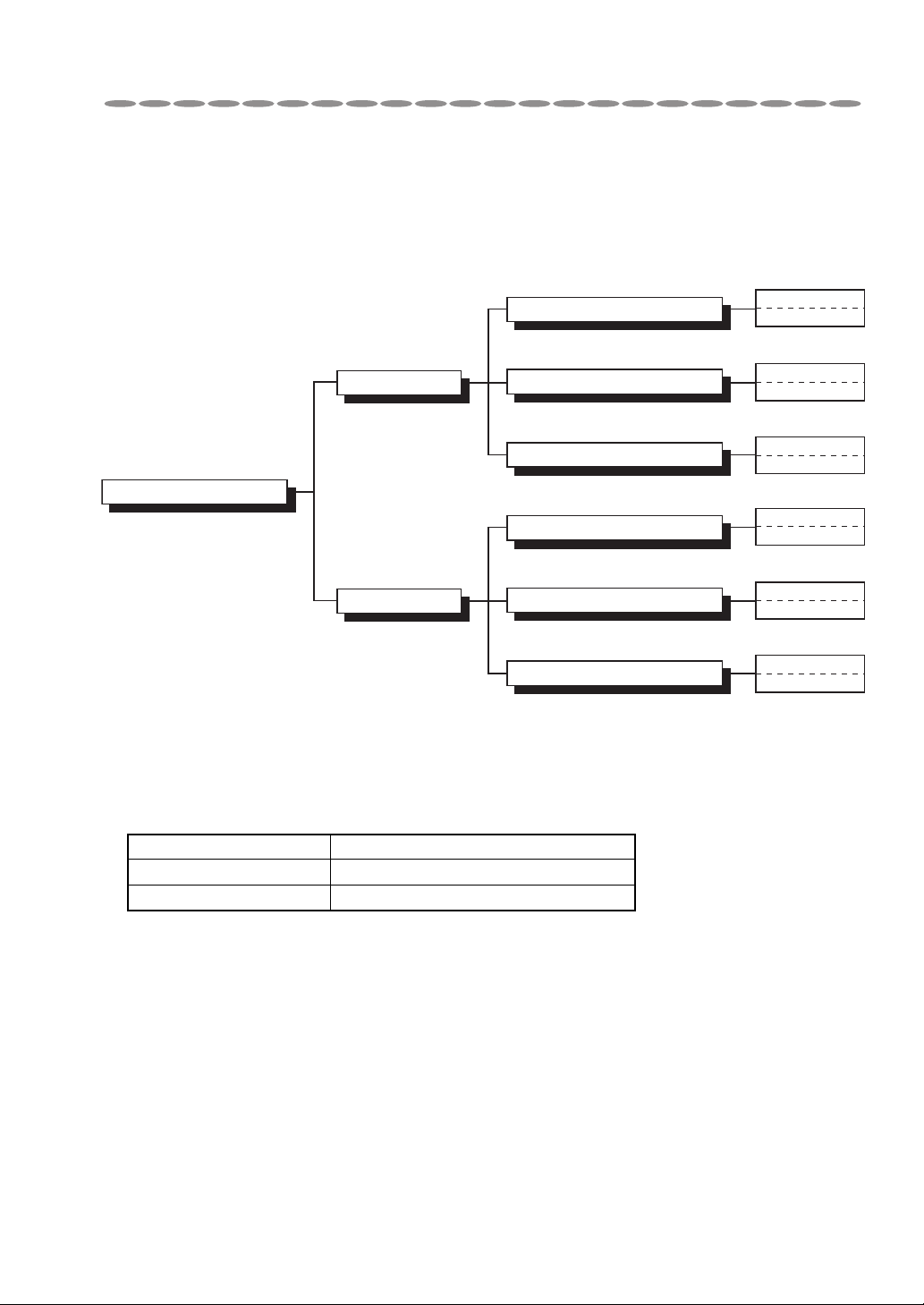

SETUP OF THIS MANUAL

URW370C4 series ………………………… 0- 4

URW500C4 series ………………………… 0- 5

URW547C4 ……………………………… 0- 6

1. FOR SAFETY OPERATION

Request to customers ……………………… 1- 1

2. SAFETY PRECAUTIONS ON

CARRIER OPERATION

Before operation …………………………… 2- 1

During operation …………………………… 2- 2

When loading and unloading ……………… 2- 4

After operation …………………………… 2- 4

3. SAFETY PRECAUTIONS ON

CRANE OPERATION

Before operation …………………………… 3- 1

During operation …………………………… 3- 2

After operation …………………………… 3- 4

4. DESCRIPTION OF CARRIER

EQUIPMENT ……………………… 4

-

1

5. DESCRIPTION OF CRANE

EQUIPMENT ……………………… 5

-

1

6. NAME PLATES

Description of name plates ………………… 6- 1

Stickers in detail …………………………… 6- 2

7. DEFINITION OF TERMS

Outrigger extension………………………… 7- 1

How boom-sections are extended ………… 7- 6

Net rated load ……………………………… 7-10

Rated load ………………………………… 7-10

Lifting capacity …………………………… 7-10

Working radius …………………………… 7-10

Boom length ……………………………… 7-10

Boom angle………………………………… 7-10

Lift above ground ………………………… 7-10