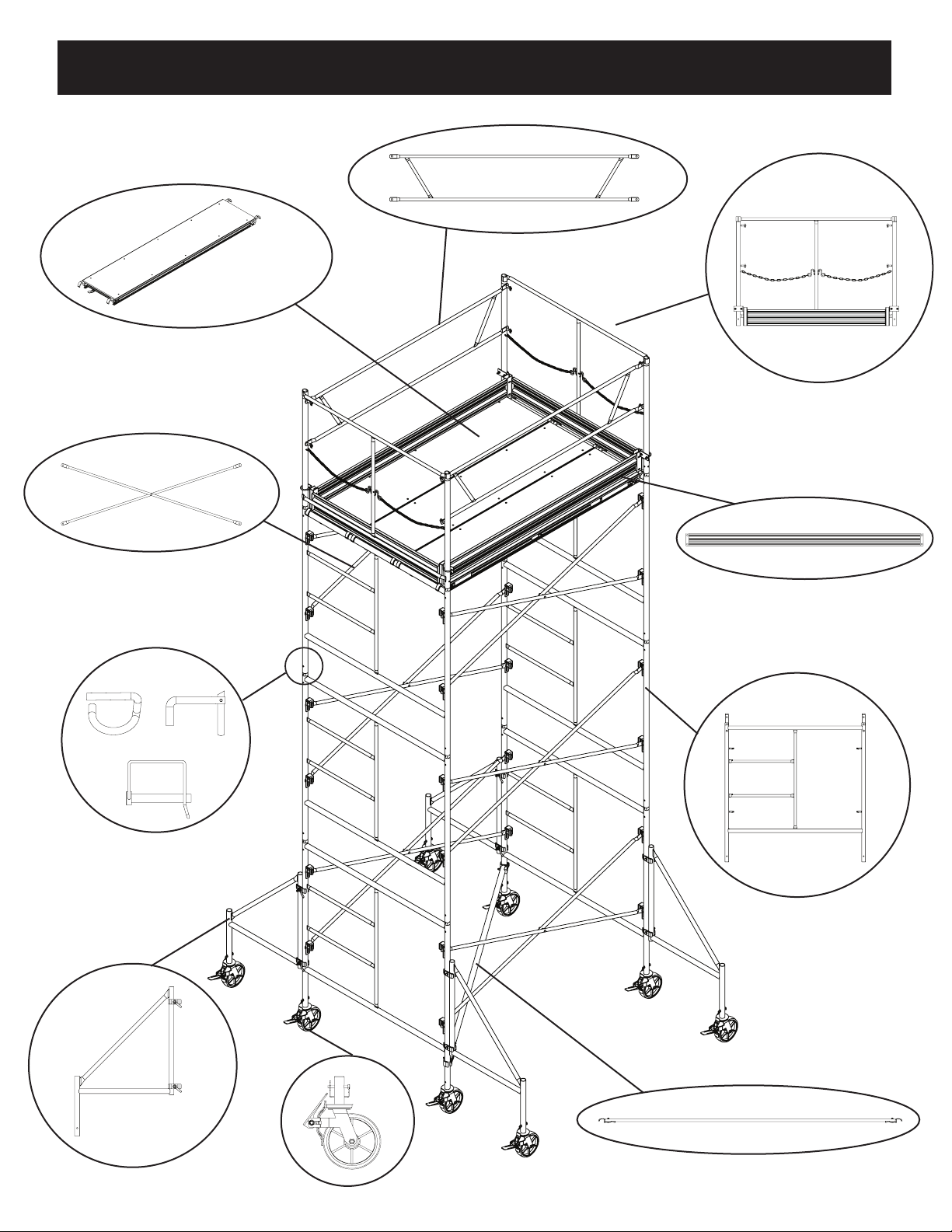

TOWER INFORMATION

2

Metal conducts electricity. Do not use this equipment in areas where contact may be

made with power lines or other live electrical circuits. Failure to comply with the preceding

warning will result in serious personal injury or death.

WARNING

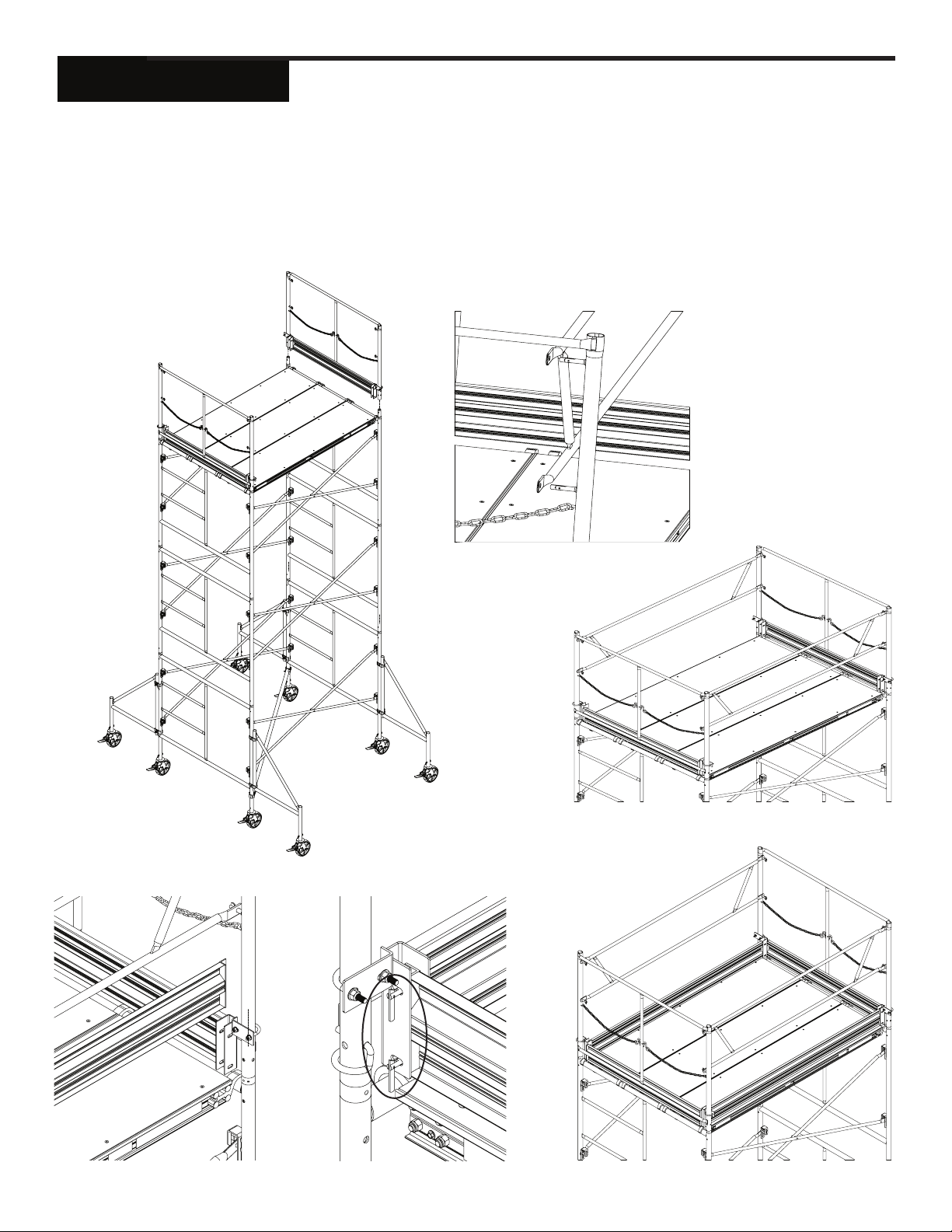

A Rolling Tower should only be used on solid, level and clear oor areas. Do not use on soil or unlevel

surfaces. Check for overhead obstrucons which may interfere with the tower.

Bil-Jax, Inc. recommends that all users of this equipment be supplied with safety informaon and OSHA rules

and regulaons. This informaon must be thoroughly read and understood before using the equipment. If

you have not been provided with OSHA regulaons or safety literature, please call 419-445-8915 before use.

NOTE: All OSHA , state and local codes and regulaons pertaining to this equipment should be obtained, read, and

thoroughly understood before aempng to erect or use this equipment. Persons under the inuence of drugs, alcohol,

or prescripon medicaon should not be on or near this equipment. Common sense should be implemented at all mes

during the erecon and use of this equipment. DO NOT USE THIS EQUIPMENT IN AREAS WHERE EQUIPMENT OR USER

MAY COME IN CONTACT WITH LIVE POWER SOURCE.

• Inspect scaold daily or before each use.

• Do not exert horizontal force from on top of a

free-standing scaold.

• Do not climb or stand on cross braces or

horizontal braces.

• Do not swing around corner of scaold to

enter plaorm from the cross brace side.

• Do not use boxes, ladders, or other means to

increase working height.

• Do not stand or sit on guard rails.

• Do not use bricks, boxes, concrete blocks, or

any other unstable objects under scaold leg.

• NEVER ride a moving scaold.

• Do not move scaold by applying a pulling or

pushing force at or near the top.

• Do not use braces as a plaorm support.

• Do not use personnel brackets (side brackets) on a

rolling tower.

• Use approved access ladder or stairs to climb

scaold. Properly erected step type end frames

will provide “equivalent, safe access” as required

by OSHA.

• When hoisng material or using side brackets,

scaold must be restrained from pping by guying,

tying to a permanent structure or other acceptable

means.

• Restrict loading to safe working loads. If unsure of

safe load limit, consult your scaold dealer.

• If you have not been provided with OSHA regulaons

or safety literature, or for any quesons concerning

the safe use of this equipment, call 419-445-8915

before use.

IMPORTANT: CAUTION