www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Installation Manual

U-AIS TRANSPONDER

Model FA-150

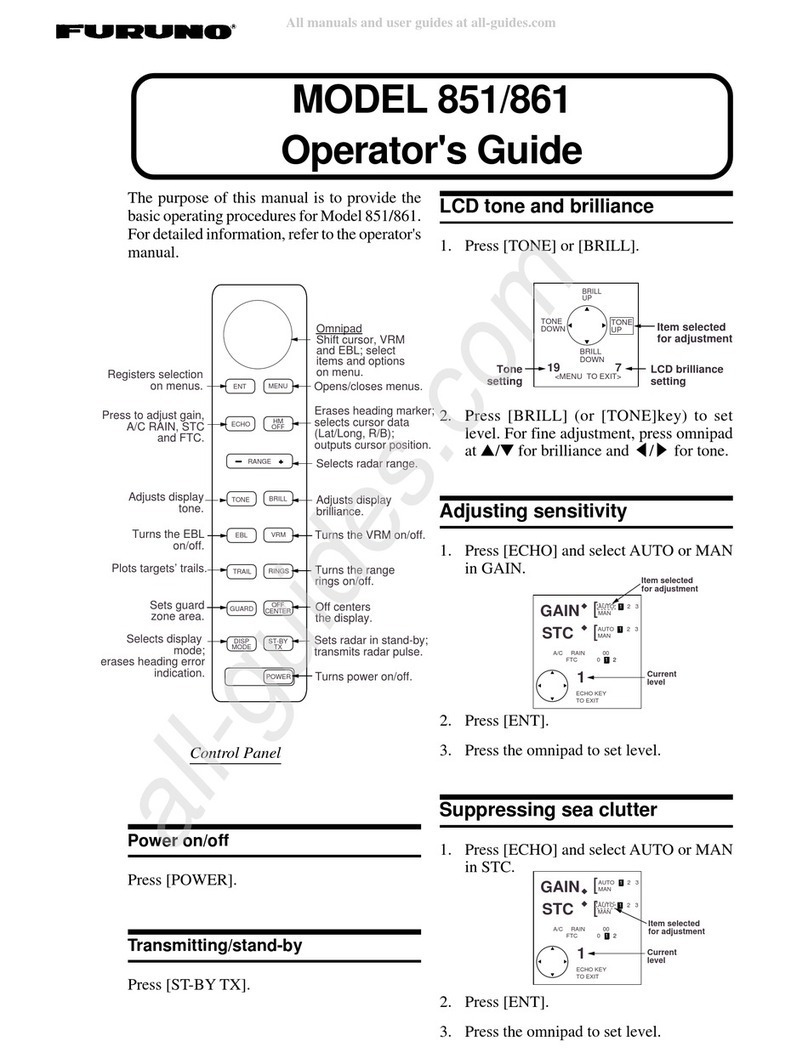

SAFETY INSTRUCTIONS ................................................................................................ i

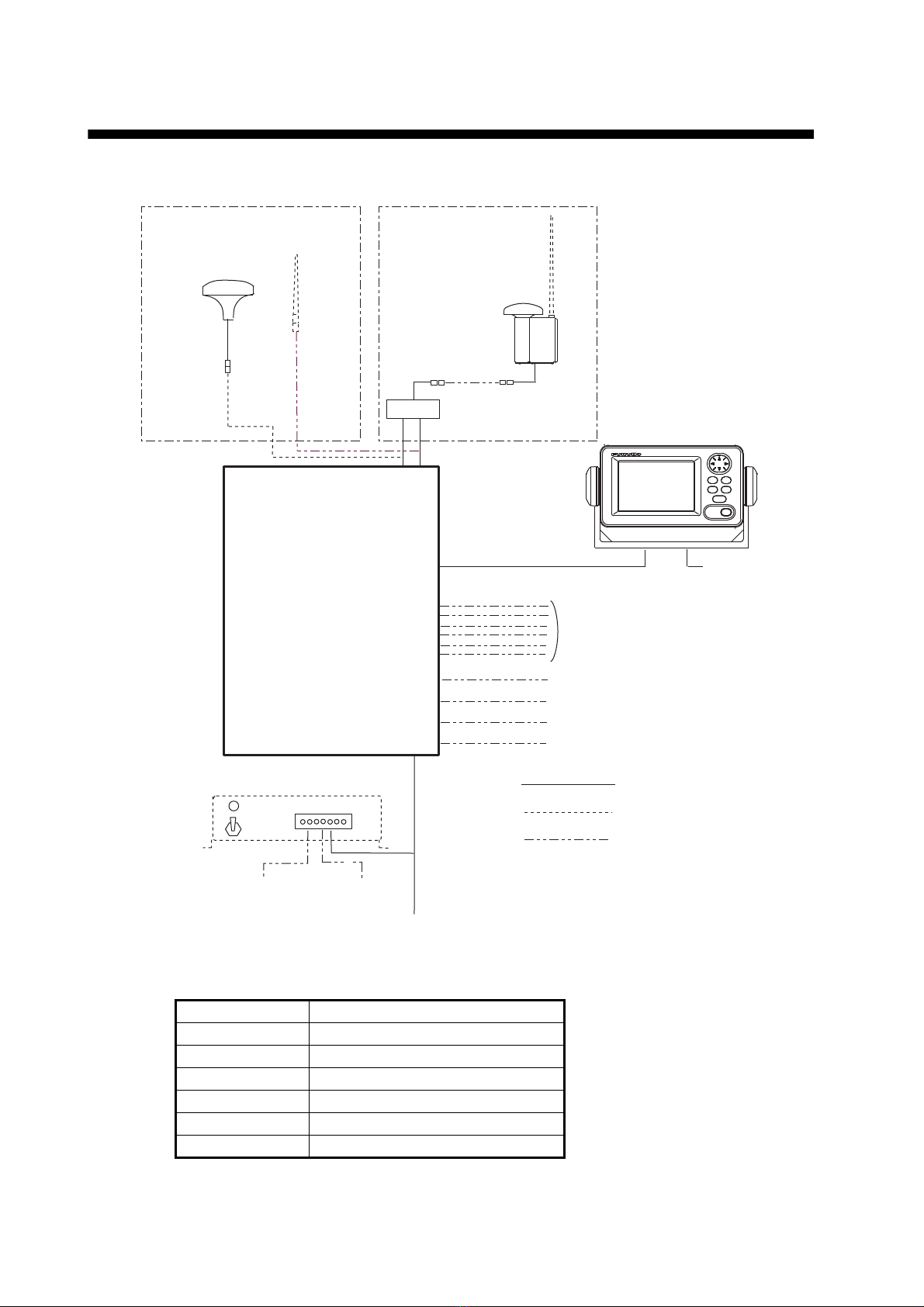

SYSTEM CONFIGURATION ........................................................................................... ii

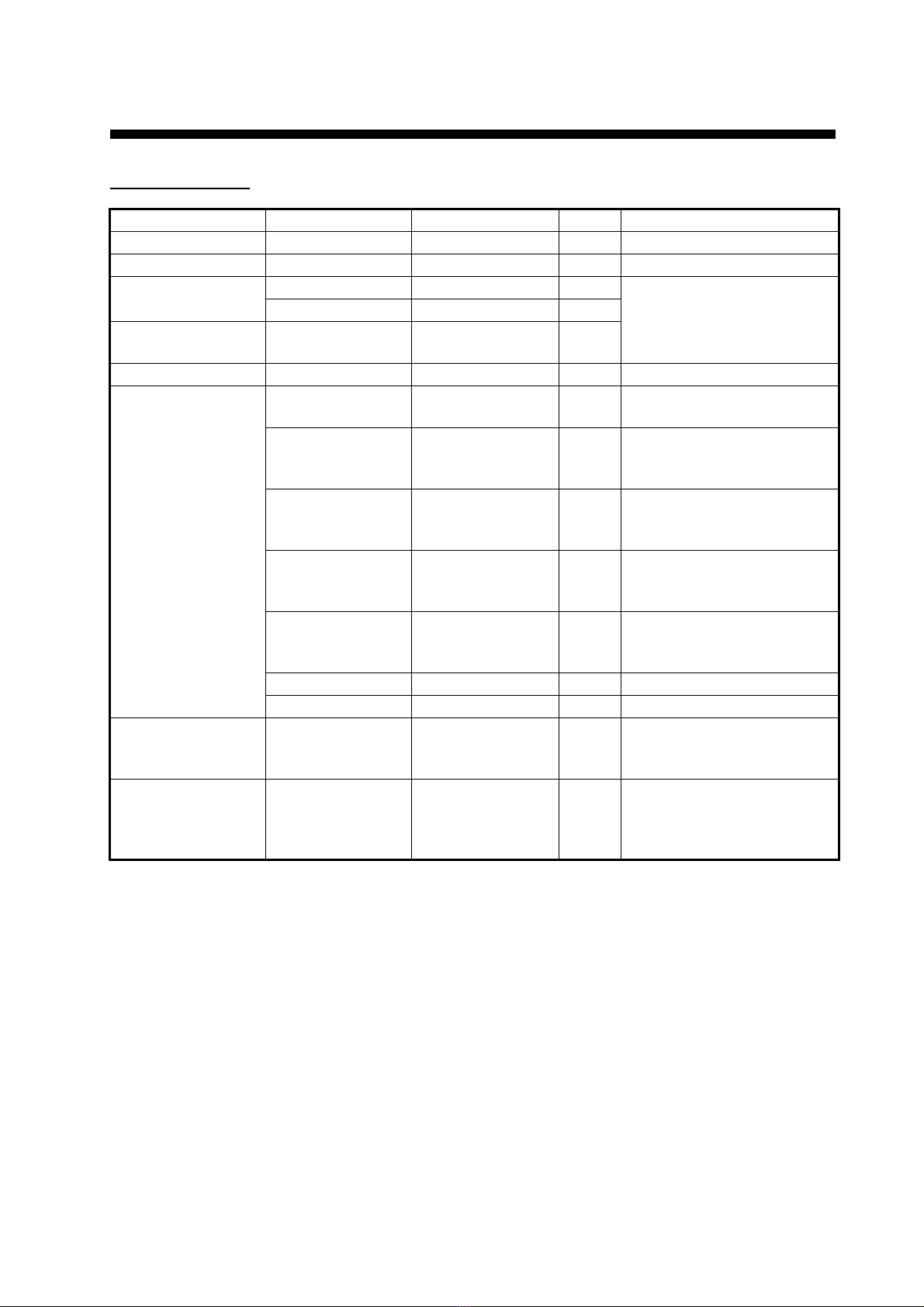

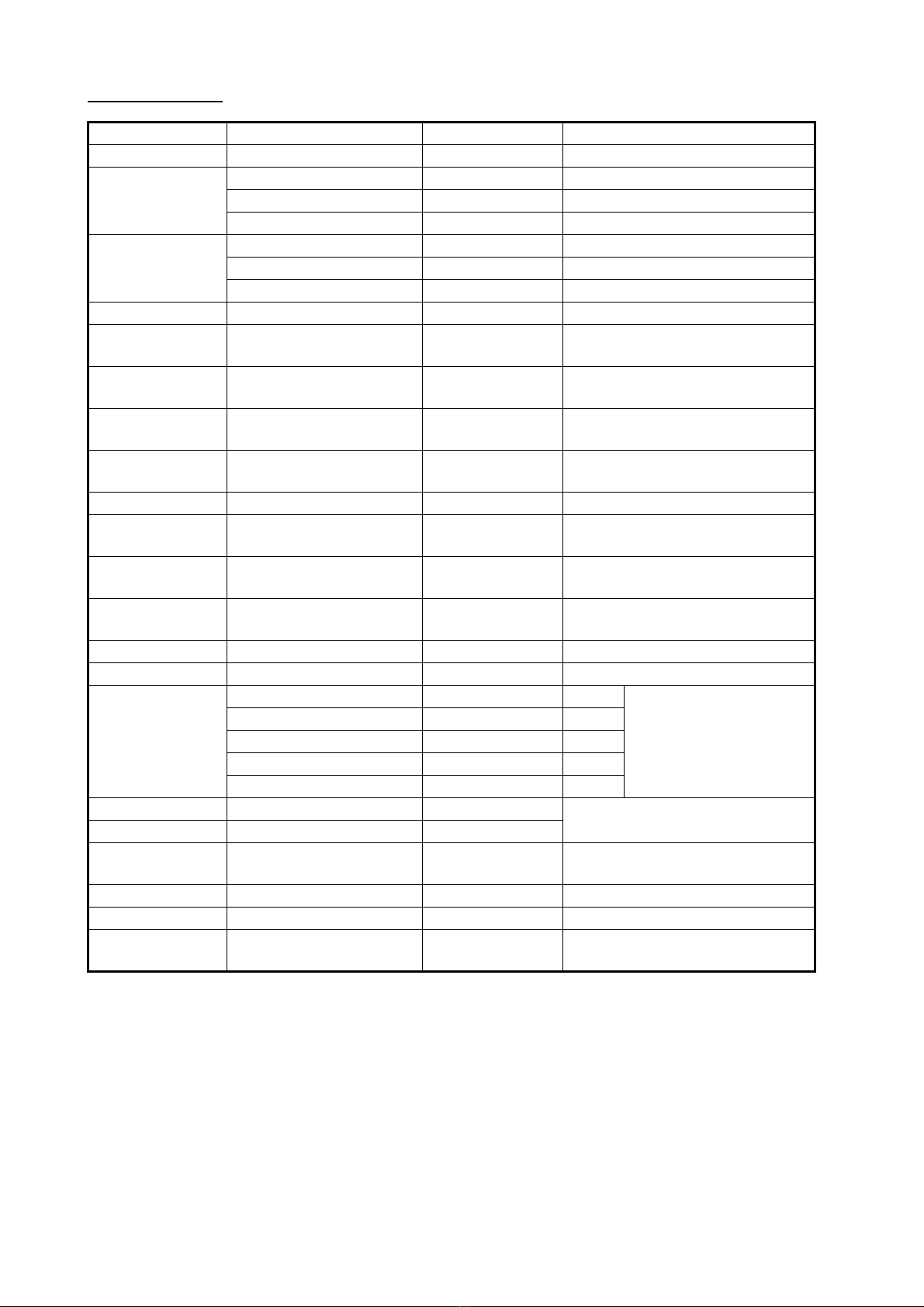

EQUIPMENT LISTS........................................................................................................ iii

1. MOUNTING..............................................................................................................1-1

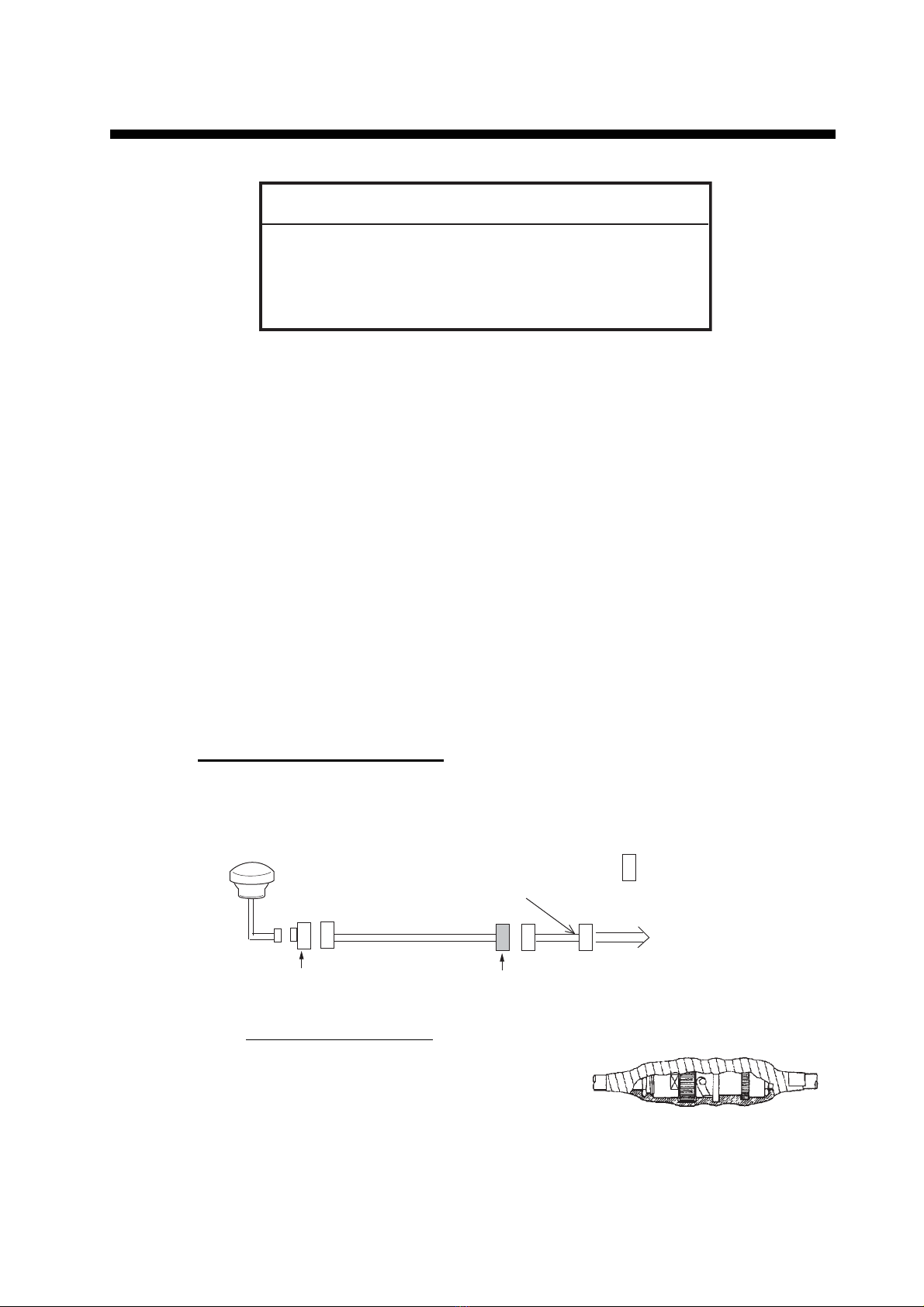

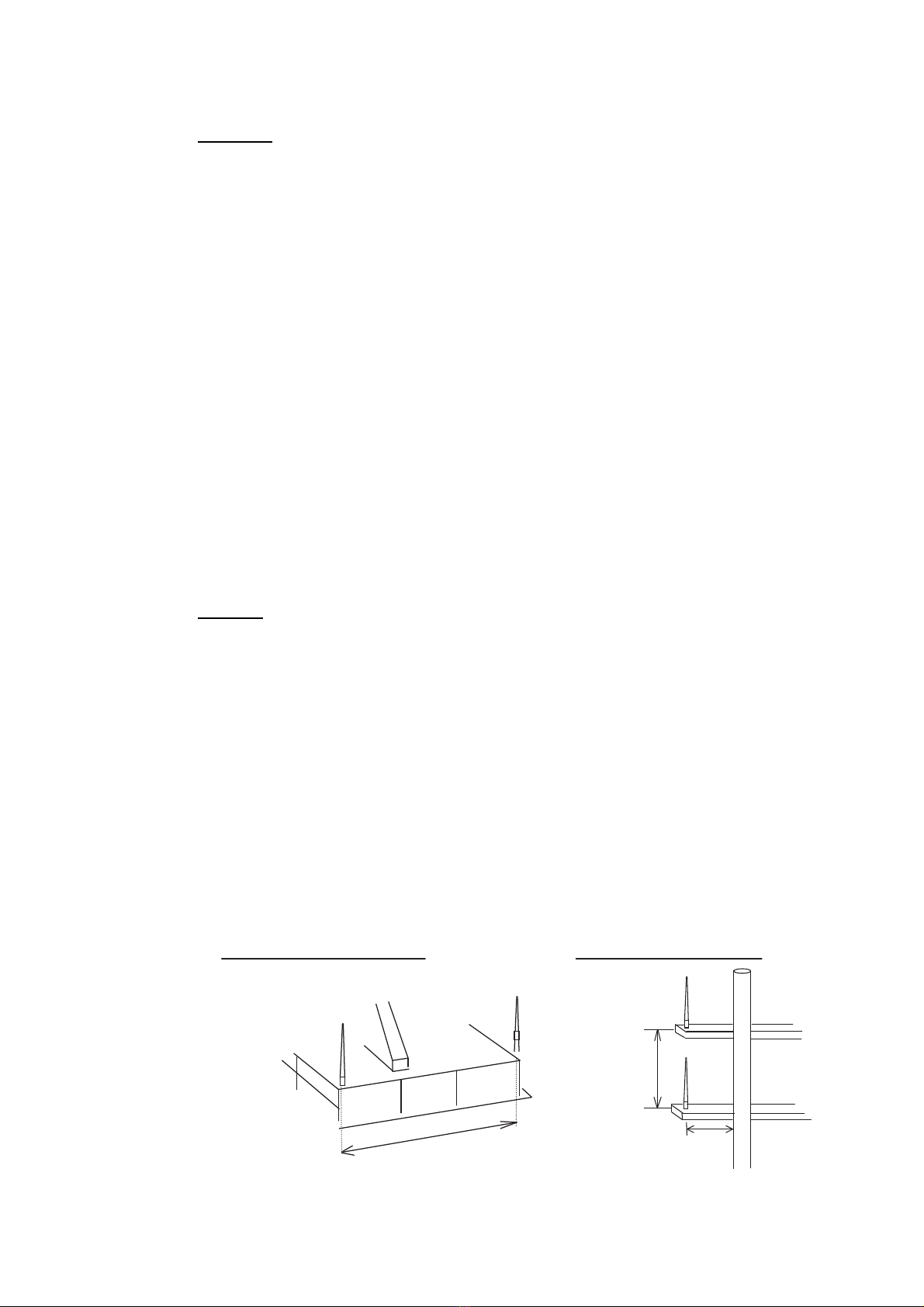

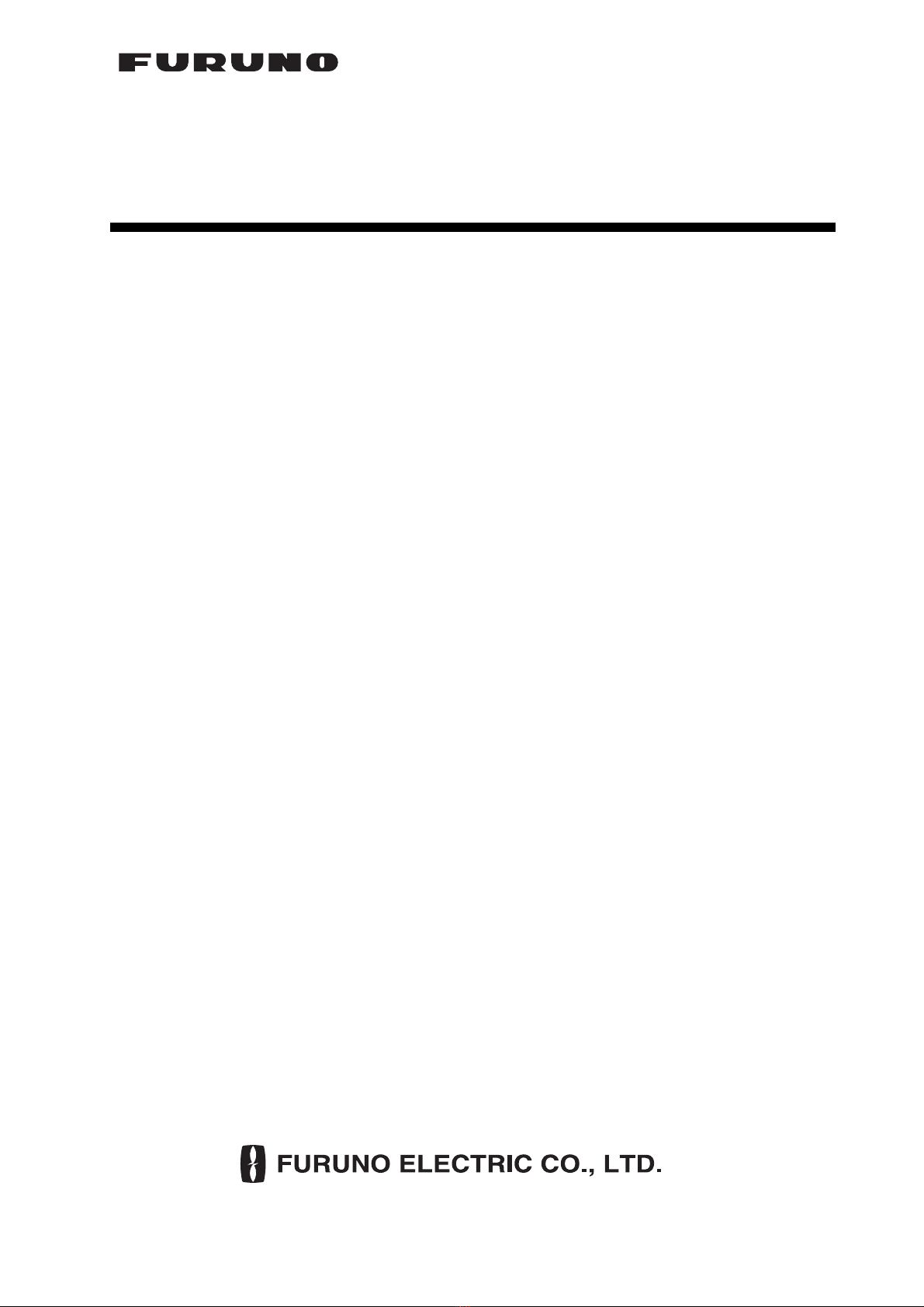

1.1 Antenna Units ....................................................................................................................1-1

1.2 Monitor Unit........................................................................................................................1-7

1.3 UAIS Transponder .............................................................................................................1-9

1.4 Power Supply (option)......................................................................................................1-10

1.5 Pilot Plug (option).............................................................................................................1-10

2. WIRING....................................................................................................................2-1

2.1 Connection.........................................................................................................................2-1

2.2 Changing Ship’s Mains Specifications...............................................................................2-4

3. SETTING AND ADJUSTMENT ...............................................................................3-1

3.1 Inland AIS Specific Settings...............................................................................................3-1

3.2 How to Set MMSI, IMO No., Name and Call Sign..............................................................3-4

3.3 How to Set GPS Antenna Position.....................................................................................3-5

3.4 How to Set Ship Type ........................................................................................................3-6

3.5 How to Set I/O Port............................................................................................................3-6

3.6 How to Set Long Range Channel ....................................................................................3-10

4. ATTACHING LAN KIT (OPTION)............................................................................4-1

5. IEC 61162-1/2 DATA SENTENCES ........................................................................5-1

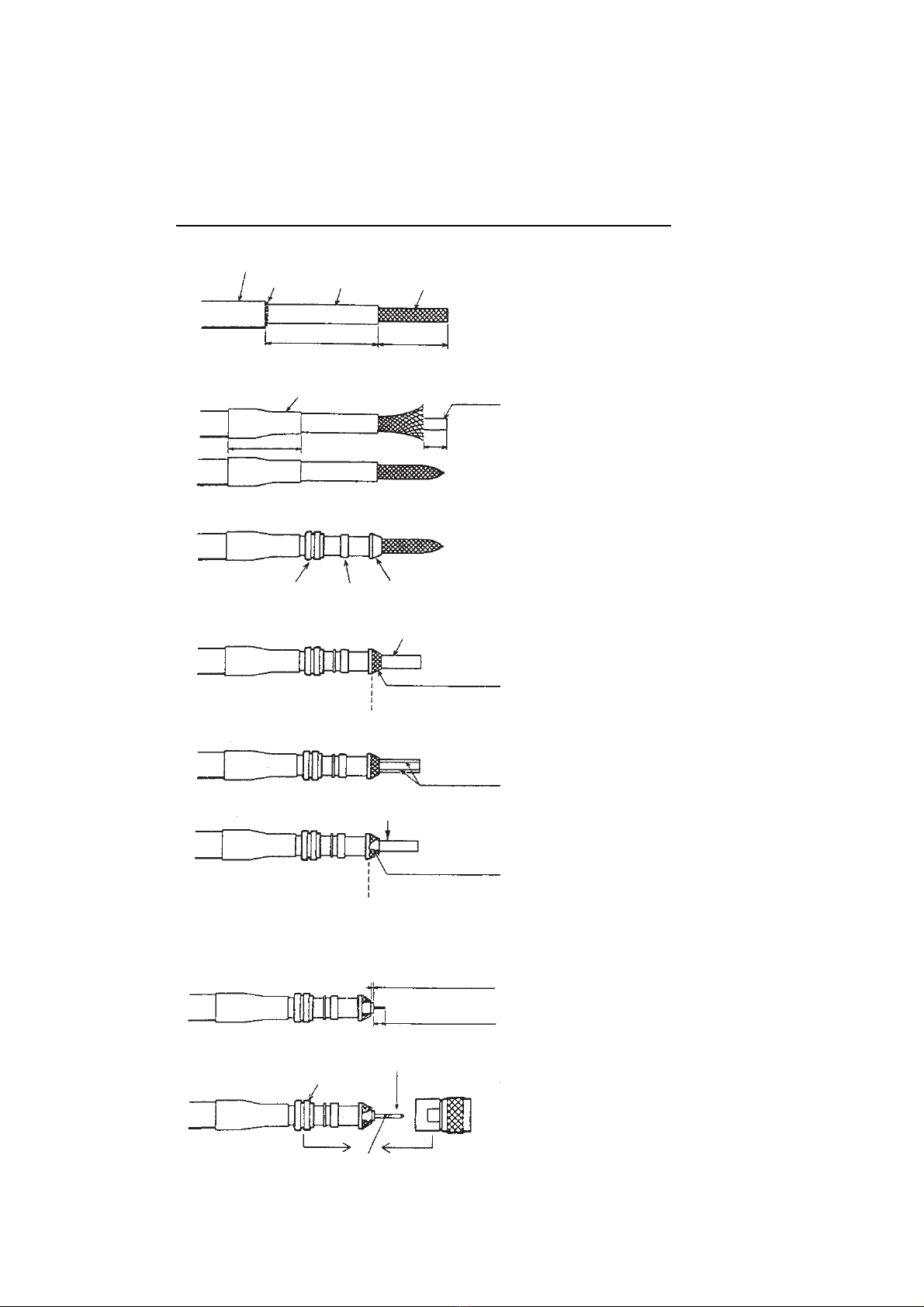

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1