- 2 -

CONTENTS

INFORMATION REGARDING THIS MANUAL ............................................................................................................................ 4

HOW TO USE THIS MANUAL .................................................................................................................................................... 4

1. SAFETY WARNINGS .............................................................................................................................................................. 4

2. DESCRIPTION OF THE PRODUCT .......................................................................................................................................... 4

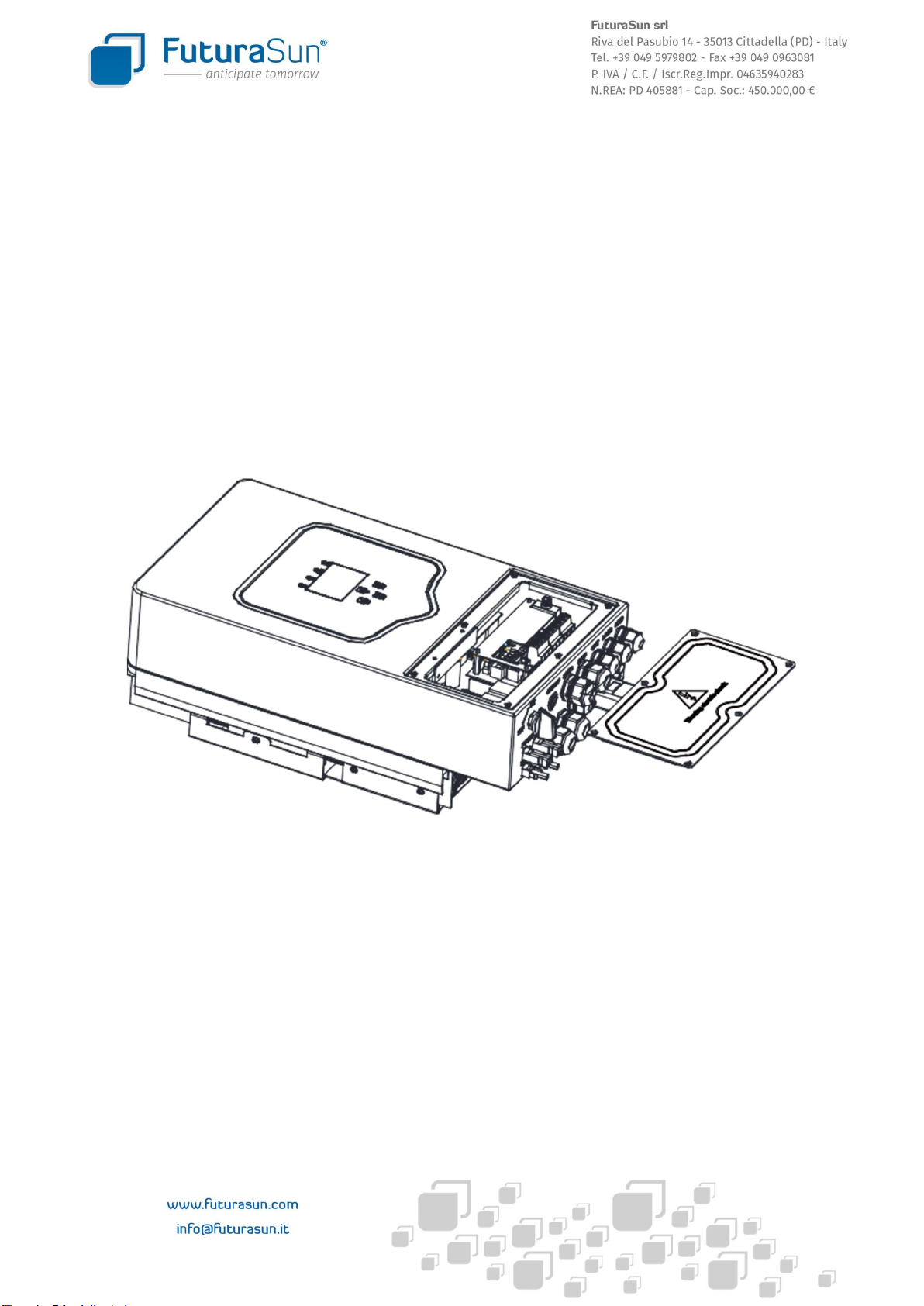

2.1 PRODUCT OVERVIEW .................................................................................................................................................... 5

2.2 PRODUCT DIMENSIONS ................................................................................................................................................. 6

2.3 PRODUCT FEATURES ...................................................................................................................................................... 7

2.4 PRODUCT FEATURES ...................................................................................................................................................... 7

3. INSTALLATION ...................................................................................................................................................................... 8

3.1 LIST OF COMPONENTS................................................................................................................................................... 8

3.2 INSTALLATION INSTRUCTIONS ...................................................................................................................................... 9

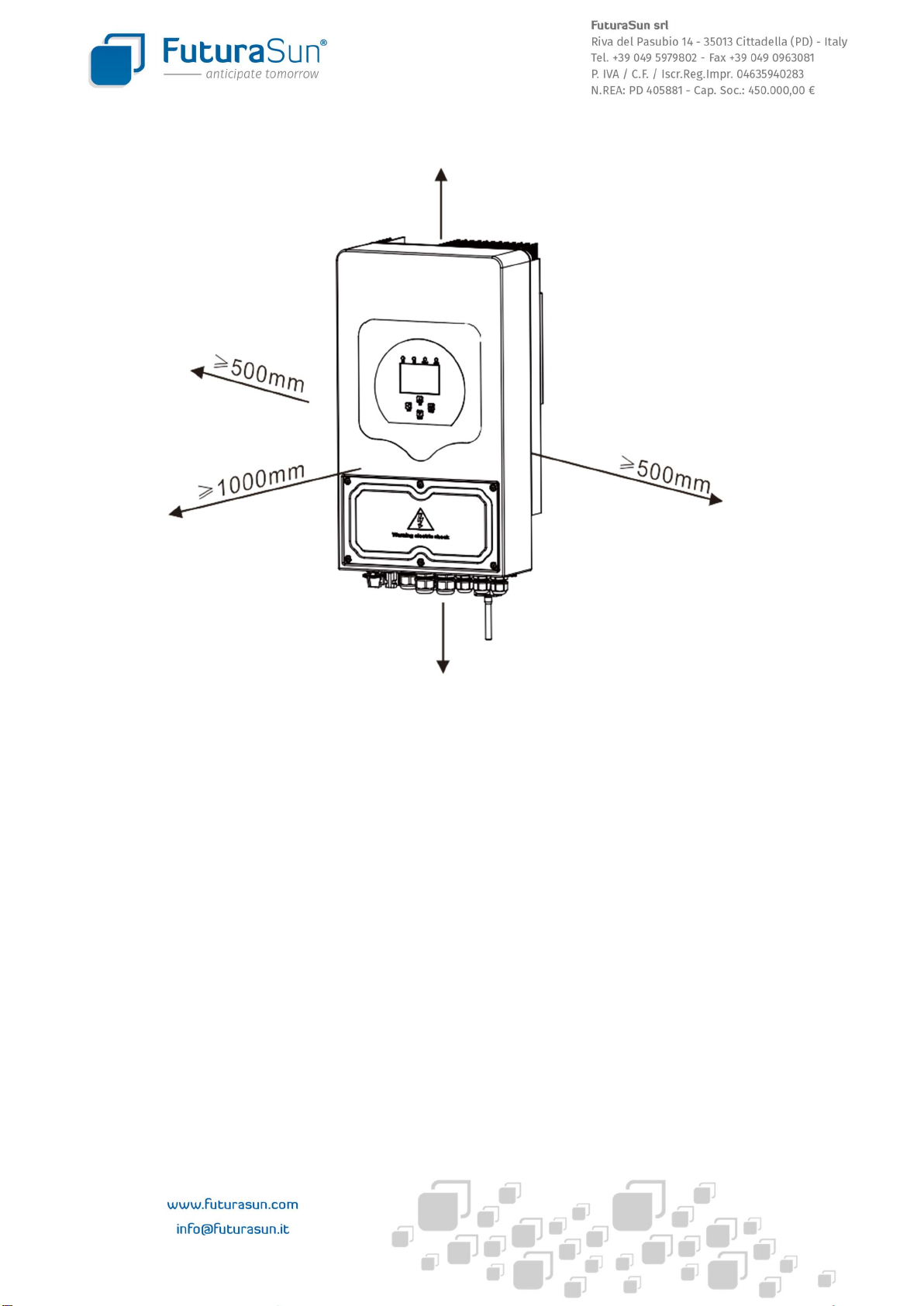

3.2.1 INSTALLATION PRECAUTIONS ................................................................................................................................ 9

3.2.2 SELECTION OF THE INSTALLATION WALL .............................................................................................................. 9

3.2.3 INSTALLING THE INVERTER .................................................................................................................................. 10

3.3 CONNECTING THE BATTERIES ..................................................................................................................................... 11

3.3.1 SPECIFICATIONS OF THE FUNCTION TERMINALS ................................................................................................ 13

3.3.2 CONNECTION OF THE TEMPERATURE SENSOR FOR LEAD/ACID BATTERIES ...................................................... 14

3.4 CONNECTION OF THE GRID AND THE BACKUP LOAD ................................................................................................. 15

3.5 PHOTOVOLTAIC FIELD CONNECTION .......................................................................................................................... 17

3.5.1 PHOTOVOLTAIC MODULE SELECTION AND PHOTOVOLTAIC GENERATOR CONFIGURATION ........................... 18

3.6 CT CONNECTION .......................................................................................................................................................... 19

3.6.1 CONNECTION WITH EXTERNAL METER CHNT DDSU 666 .................................................................................... 20

3.6.2 CONNECTION WITH EXTERNAL METER EASTRON SDM230 ................................................................................ 21

3.7 EARTH CONNECTION ................................................................................................................................................... 21

3.8 WI-FI PLUG CONNECTION ............................................................................................................................................ 22

3.9 DIAGRAM OF TYPICAL CONNECTION .......................................................................................................................... 22

3.10 DIAGRAM OF SINGLE-PHASE CONNECTION WITH PARALLEL INVERTER ................................................................. 23

3.11 DIAGRAM OF THREE-PHASE CONNECTION WITH PARALLEL INVERTER .................................................................. 25

4 OPERATION ......................................................................................................................................................................... 26

4.1 SWITCHING ON USING THE ON/OFF BUTTON ............................................................................................................ 26

4.2 DISPLAY AND SIGNALLING LEDS.................................................................................................................................. 26

5 LCD DISPLAY ICONS ............................................................................................................................................................. 27

5.1 MAIN SCREEN .............................................................................................................................................................. 27

5.1.1 MENU STRUCTURE ............................................................................................................................................... 28

5.2 SOLAR / INVERTER / LOAD / GRID / BATTERY INFORMATION .................................................................................. 29

5.3 ENERGY DATA PAGES AND CURVES ............................................................................................................................ 30