5|284|28

!

WARNINGS

• DANGER TO LIFE AND ACCIDENT RISK FOR CHILDREN AND INFANTS!

• RISK OF SUFFOCATION! Never allow children to play with the packaging material or film

unsupervised!

• RISK OF SWALLOWING and SUFFOCATION! Keep children and infants away from the

location when you are assembling the product because the consignment includes

small parts.

• CAUTION! Metal parts and metal profiles can have sharp edges so there is a

RISK OF CUTS and INJURIES! Wear protective/work gloves when opening the shipping

carton and when checking the parts against the parts list.

• WARNING! The product is not a climbing frame or an item of play equipment. Children

should be supervised at all times!

• RISK OF TIPPING and SUFFOCATION! Do not place objects on the product, use it to pull

yourself up, climb underneath it or climb into the packaging.

• WARNING! Strong sunlight can lead to the temperature inside the closed, unventilated

greenhouse rising to a level that poses a hazard to health. Ensure that there is

sufficient ventilation when people are inside and do not remain inside for too long.

• ACCIDENT RISK! Always ensure that the ladders are in a secure position.

• WARNING! Film is combustible! Do not expose it to heat sources or open flames!

SAFETY INSTRUCTIONS

• Assemble the greenhouse at a location that is sheltered from the wind (e.g. on

the lee side of a building, depending on the main wind direction).

• The greenhouse is to be used for the intended purpose only and as a stationary

installation. It must therefore be anchored to a suitable supporting surface.

• ATTENTION! Always ensure that the anchors are secured in the ground.

• CAUTION! Do NOT assemble the greenhouse in windy weather!

• CAUTION! It is dangerous to leave a semi-assembled greenhouse exposed to the

weather. In particular, the partially mounted film can provide a large surface that

functions like a sail in windy weather.

• CAUTION! It takes at least 2 people to assemble the greenhouse.

• CAUTION! RISK OF CUTS and INJURIES! Always wear protective/work gloves when

handling the product. The metal parts can have sharp edges and corners.

• Only use robust tools that are suitable for manual work.

• ATTENTION! When it is windy the greenhouse door(s) and side vents have

to be kept closed.

• ATTENTION! The greenhouse is not designed to support snow loads. Always remove

snow. Otherwise the greenhouse may collapse! Alternatively, if the greenhouse is empty,

the film can be removed during the winter.

• ATTENTION! If the film is not correctly tensioned on the frame it is possible that

rainwater will collect on the roof and exert a load on it. Remove the water pockets

from the greenhouse roof.

• Dispose of the packaging material and any remaining film safely and properly.

!

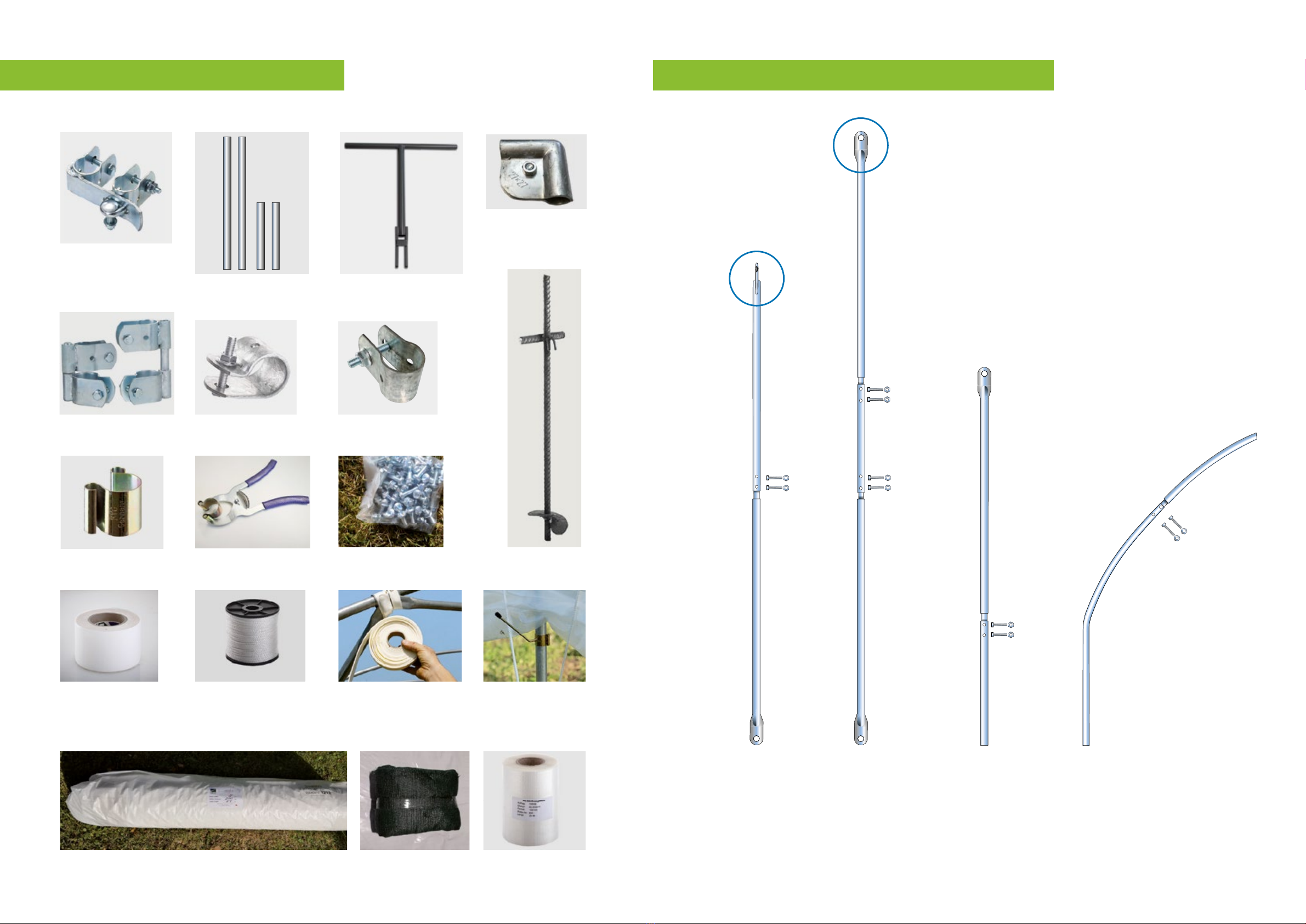

Required tools (not supplied)

• Protective/work gloves

• Sledgehammer

• Pipe wrench

• Ratchet (13mm socket) & 13mm

combination wrench

• Allen key IS5

• (Mason‘s) cord

• Carpet knife

• Scissors

• Trestle

• Spirit level

• Tape measure/folding rule

• Small wooden board

• 2-3 people for assembly

• 2 small (step)ladders

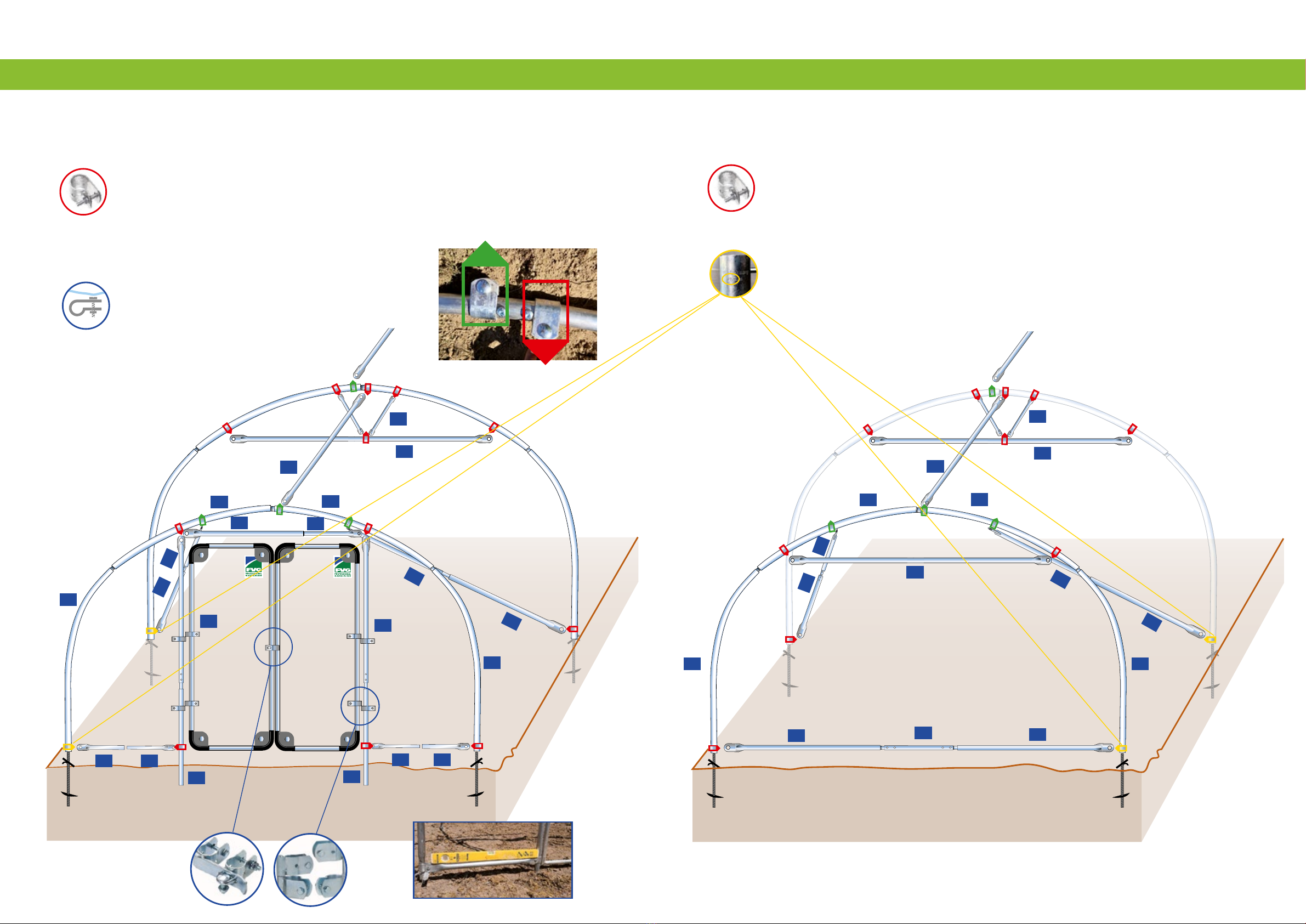

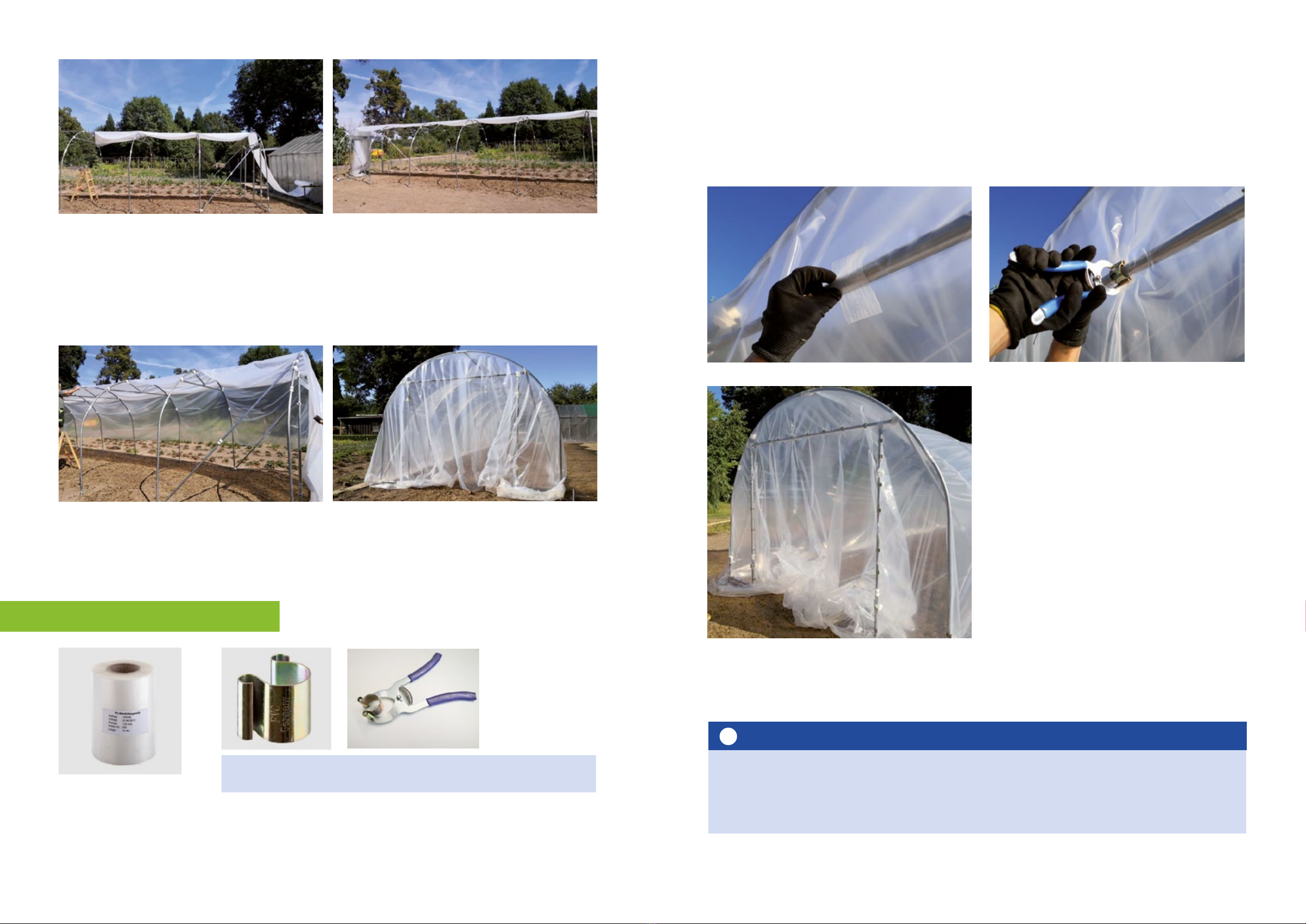

!General assembly instructions

• Read all sections of the instructions for use thoroughly before starting to

assembly the product.

• The user is responsible for obtaining any necessary planning permission or

building law approvals.

• The Römi

®

Start-Up can be set up in different positions and locations. This

involves

adapting and adjusting the individual tunnel elements to the specific

location. We cannot provide any precise measurements for that reason. Instead

,

we use approximate information or phrases such as „adjust to requirements“.

• Tunnel components that are exposed to direct sunlight can heat up and

cause burns. When assembling and using the tunnel, please avoid contact

with hot parts.

• Initially, the bolt clamps slide up and down the tubes. Therefore, always

ensure that the bolt clamps are at the correct position on the arch before

screwing them into place. Once they have been screwed into place, the bolt

clamps cannot be slid over the screw connections.

•

General care instructions are included in every roll of film. We recommend

that you read them carefully.

• It is impossible to assemble the film on the frame without folding it. The folds

have to be arranged so that no troughs form where water can collect.

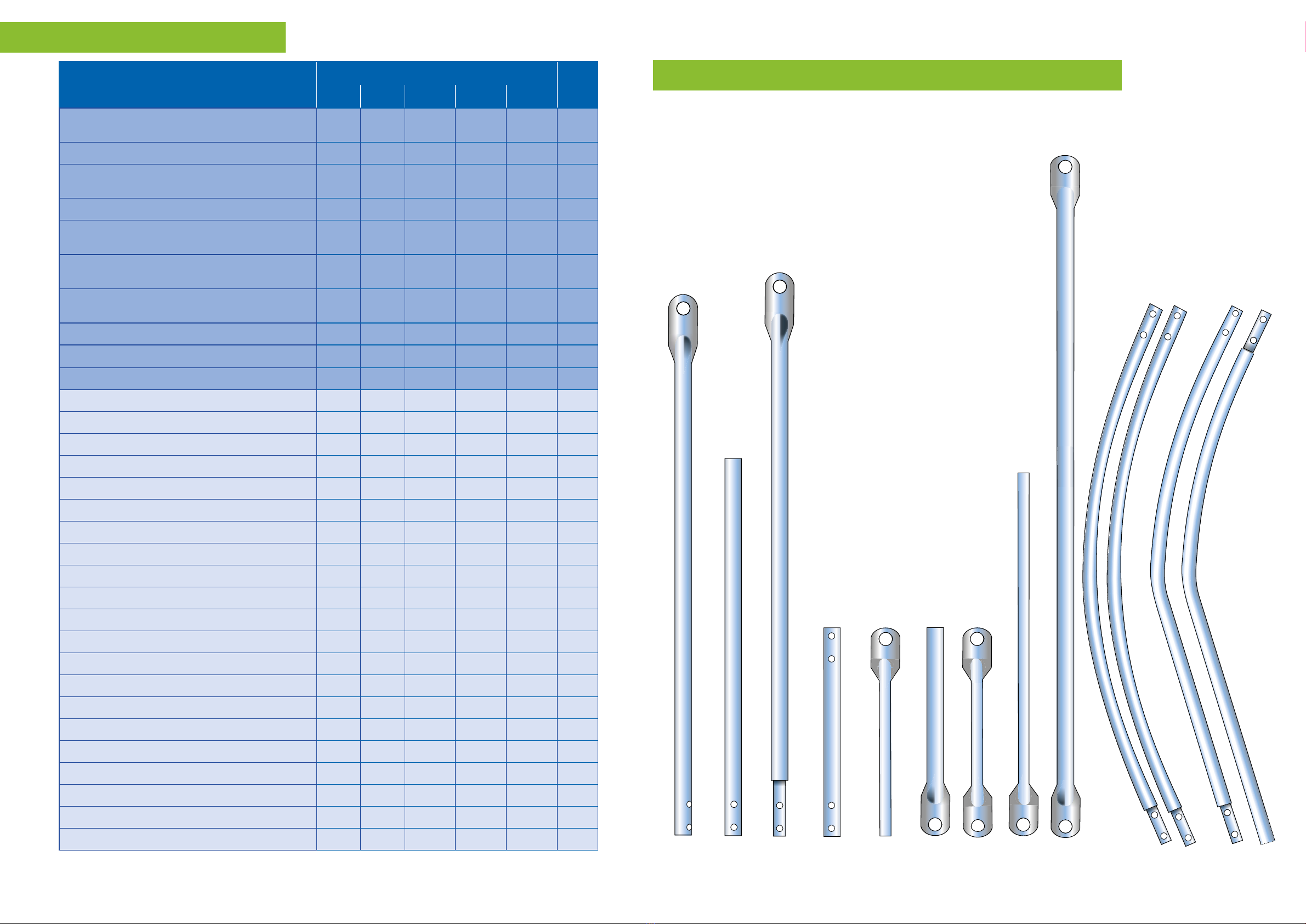

• Don’t combine the parts for one arch with the parts for another arch. We

commend the successive assembly of the arches and that only one

package/ bundle is opened at a time.

• Don’t worry if your

MiniRömi

®

Start-Up

is initially not perfectly aligned and looks

a little crooked. These slight flaws can be remedied in the assembly process.