05

Before using the equipment, check the

conditionof the tool for any damage, for

example oil leakage or loosen components.

Such damage could cause severe physical injuries during use.

保证产品的 安 全,不要随意乱扔 或 防止

高处掉落。 不 要用于操作说明书 上 注明

以外的其他 用 途。不要交给未经 培 训的

人员操作本 产 品。

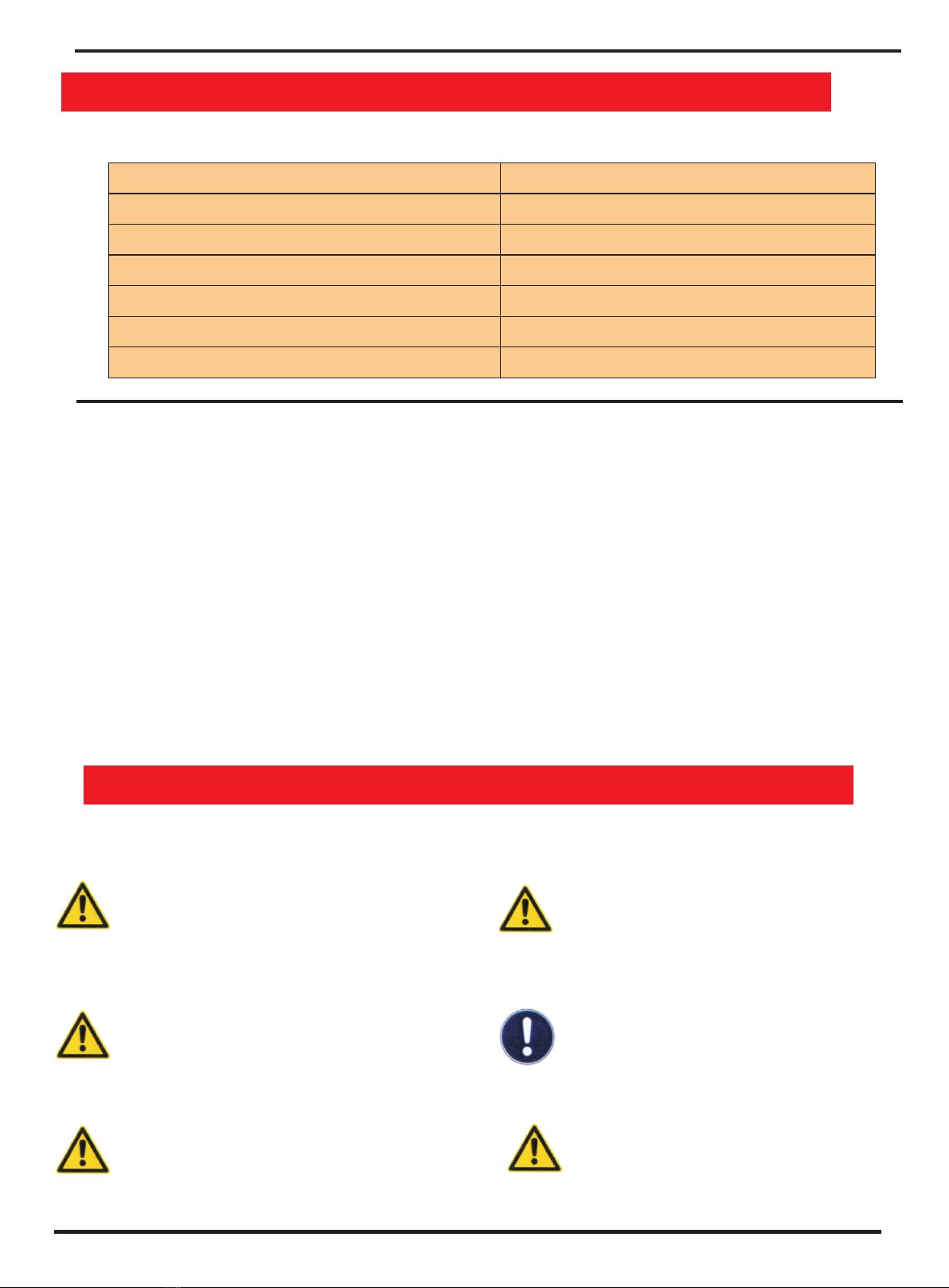

4.Warnings and Important Notices

Press capacity max

Input voltage

Battery Capacity

Stroke

Ambient temperature

Safety Requirement

Main machine weight

60 kN

220V

3.0Ah

33mm

5-50 C°/ 41 122°F-

Safety glasses,Face Shield

3.0kg

3.2 Technical Data

6.

7.Motor stops quickly, ensuring high security for user.

8.Starts quickly and die heads are 180° rotatable.

9.The safety valve can automatically or manually resewhen it reaches a certain pressure.

10.Alerts to recharge when the battery is running low.

Piston with infinitely variable speeds.

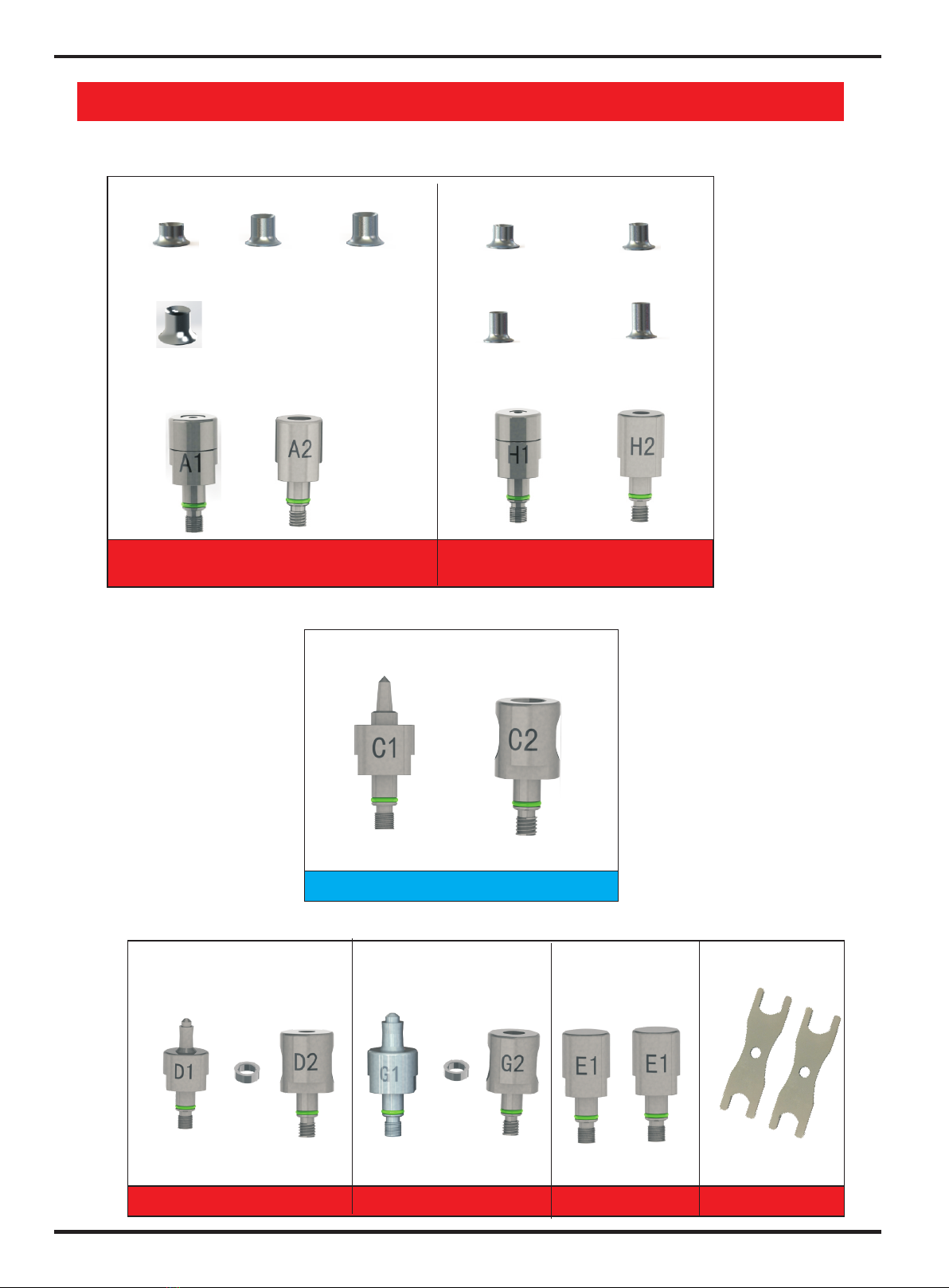

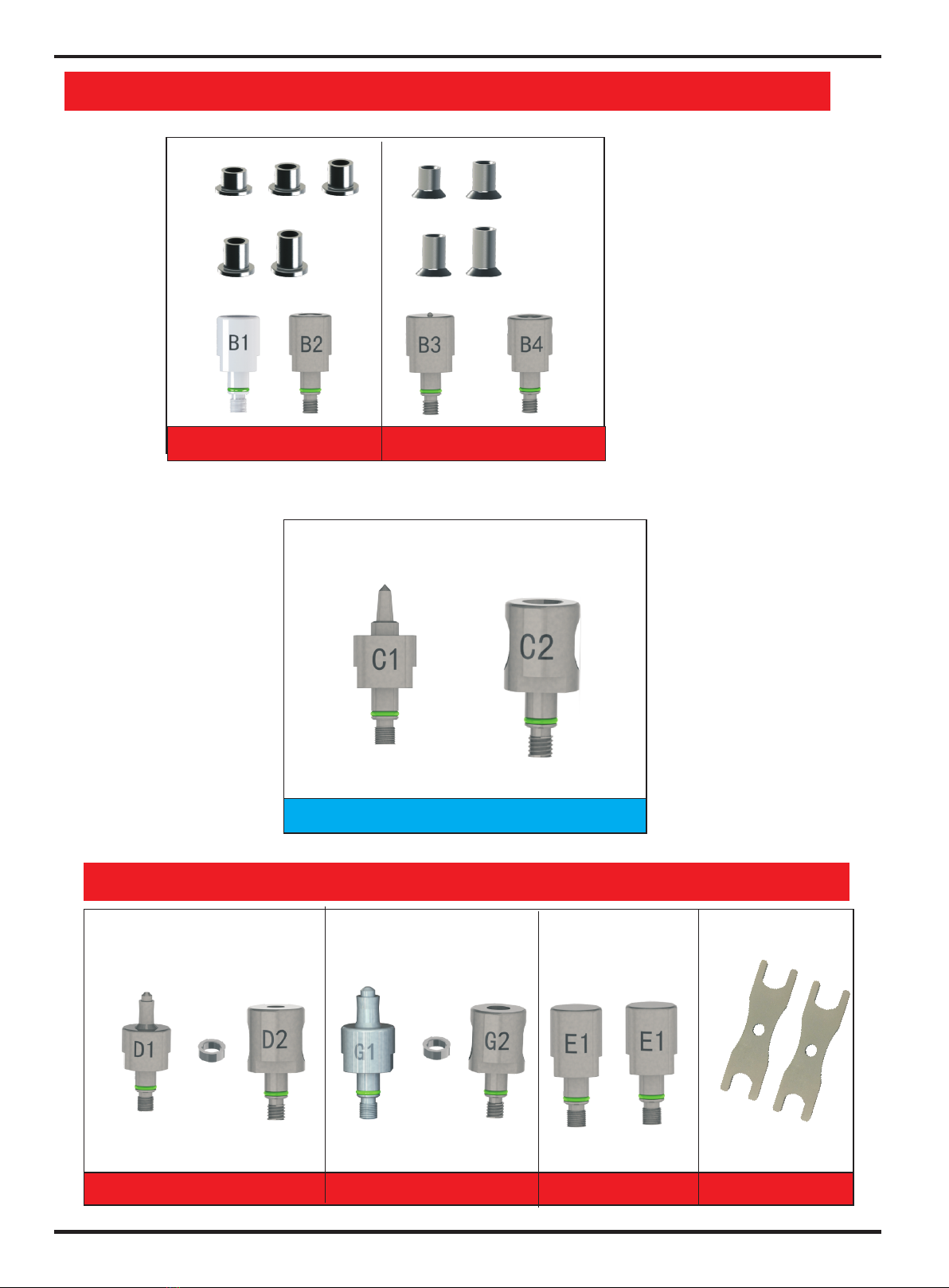

1.Available for removing rivets.

2.Available for sheet shaping and flattening.

3.Available for self-piercing riveting

4.Available for semi-tubular riveting.

5.Available for piercing.

3.3 & FeaturesApplications

Use only manufacturer's suggested replacement parts and

consumablesThe warranty shall not apply to equipment

which has been used for operation outside of the

specifications for the equipment,such as using the

equipment with other consumables oraccessories that

are not supplied by the manufacturer.There is a risk of

damage to the equipment and to the safety of users.

Using non-genuine accessories/consumables

Use only original accessories/consumables.

is a safety hazard.

Do not throw the tool or allow it to fall.

Never misuse the tool or let it to

untrained personnel.

The tool must only be used in temperature

5C(41F) and 50C(122F).

The tool must never be used in

potentially explosive areas.