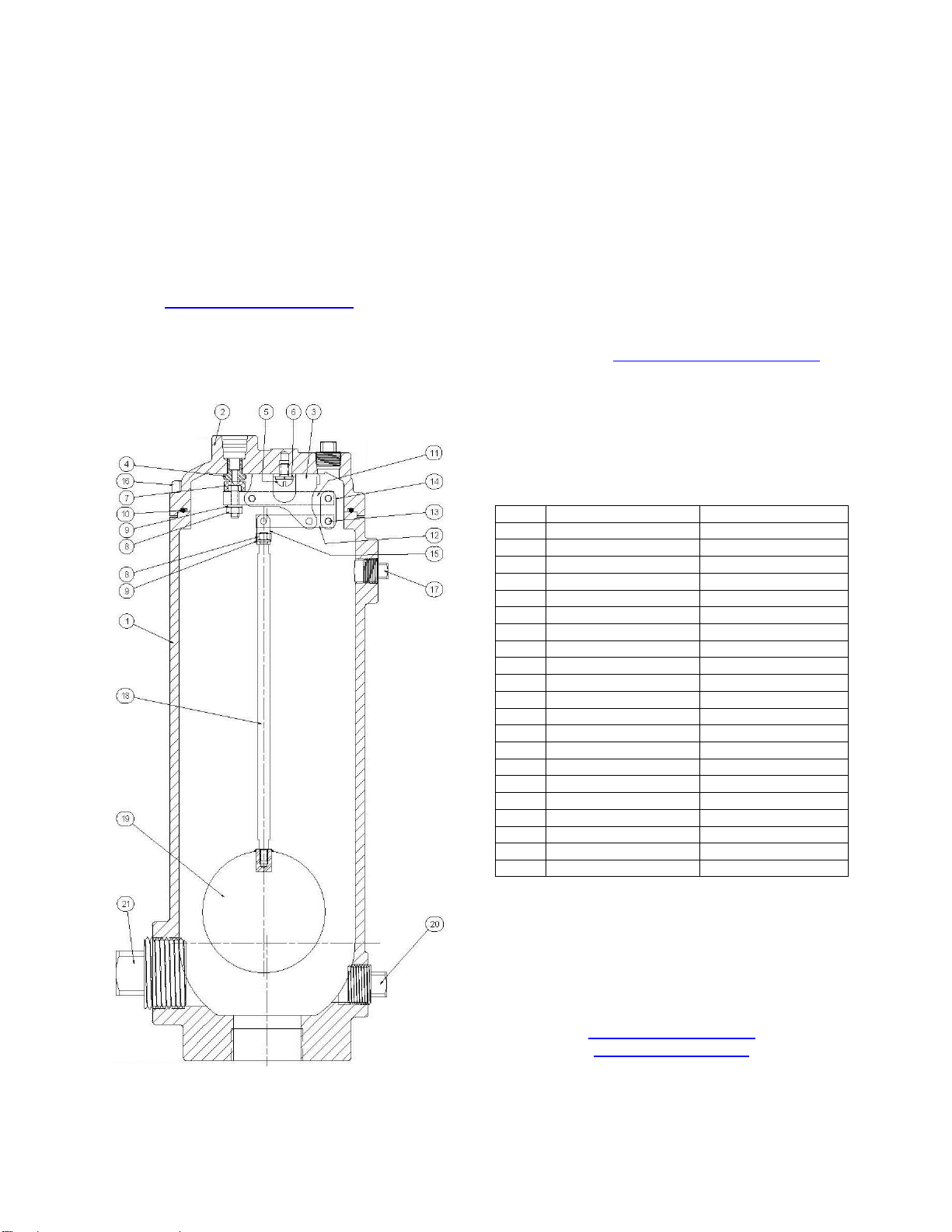

(3). The float and linkage will be free from the

cover.

Remove the spring pins (13) connecting the

valve links (14) to the float arm (12). Remove

the spring pin (13) from the pivot link (15) and

the hex nut (8) and lock washer (9). Unscrew the

float rod (21) from the float ball (20). It may be

necessary to apply some heat to these threaded

connections as they are secured with Loctite.

Remove the hex nut (8) and lock washer (9) and

unscrew the orifice button (7) from the lever arm

(11).

Remove the bracket screw (5) to remove the

leverage bracket (3). Using a hex socket

remove the orifice (4) from the cover.

Inspect all parts for wear and damage. Minor

scratches and dents in the float are normal.

Some floats may contain sand for added weight

but if water is detected replace the float.

Carefully clean the orifice of scale. Replace

damaged parts.

REASSEMBLY

Clean all parts especially seating and sealing

surfaces before reassembling valve. Worn parts

should be replaced during re-assembly.

Apply Loctite©PST thread sealant to orifice (4)

and thread into cover. Torque to 22 ft-lbs

(maximum).

Install bracket (3), bracket screws (5) and lock

washers (6) and tighten.

Thread orifice button (7) all the way into lever

arm (11) and install hex nut (8) and lock washer

(9) but do not tighten. Connect the lever arm

(11) and float arm (12) to the bracket (3) using

two spring pins (13).

Adjust the orifice button (7) so that the end of

the lever arm (11) nearest the orifice button is

about 1/16” (1.6mm) farther from the cover than

the opposite end when the orifice button (7) is

gently resting on the orifice (4). Secure by

tightening hex nut (8).

Install valve links (14) and spring pins (13) to

connect the float arm (12) to the lever arm (11).

Apply Loctite 263 to one end of float rod threads

and Install lock washer (9) and float rod (21) into

float ball (20) and tighten. Apply Loctite 263 to

the threads on the other end of float rod. Install

pivot link (15), lock washer (9) and hex nut (8)

on opposite end of float rod (19) and tighten.

Attach pivot link (15) to float arm (12) using

spring pin (13).

Verify free movement of linkage mechanism and

that the orifice button (7) presses against the

orifice (4) when the float rises and pulls away

when allowed to fall.

Lubricate and place O-ring (10) in cover (2) and

carefully place cover (2) on body (1) ensuring o-

ring is retained. Install the cover bolts (16) and

tighten in an alternating pattern.

Carefully introduce pressure and check for

leaks.

BACKFLUSHING INSTRUCTIONS

Follow all local cross-connection and safety

codes and regulations!

To determine if a GA Industries sewage air valve

needs cleaning or backflushing:

•Close the inlet isolating valve then slowly

open the ½” flushing ball valve (if installed)

or slowly remove the pipe plug at the top

of air valve to relieve internal pressure.

•Open the 1” blow off ball valve (if installed)

or remove the pipe plug near the bottom.

Liquid should freely drain from the valve

body. If it does not, then the valve is likely

in need of cleaning or backflushing.

To clean a GA Industries sewage air release

valve equipped with backflushing attachments:

•Close the inlet isolating valve and then

slowly open the ½” flushing valve to

relieve internal pressure.

•Open the 1” blow off valve

•Connect the ½” flushing valve to a

pressurized source of clean water using

the rubber hose provided with the

backflushing attachments.

•Introduce flushing water until liquid runs

freely from the blow off valve.

•Shut off and disconnect the supply of

clean water and close the blow off and

flushing valves.

•Slowly open the inlet isolating valve. The

air release valve should exhaust air and

then close tightly