2

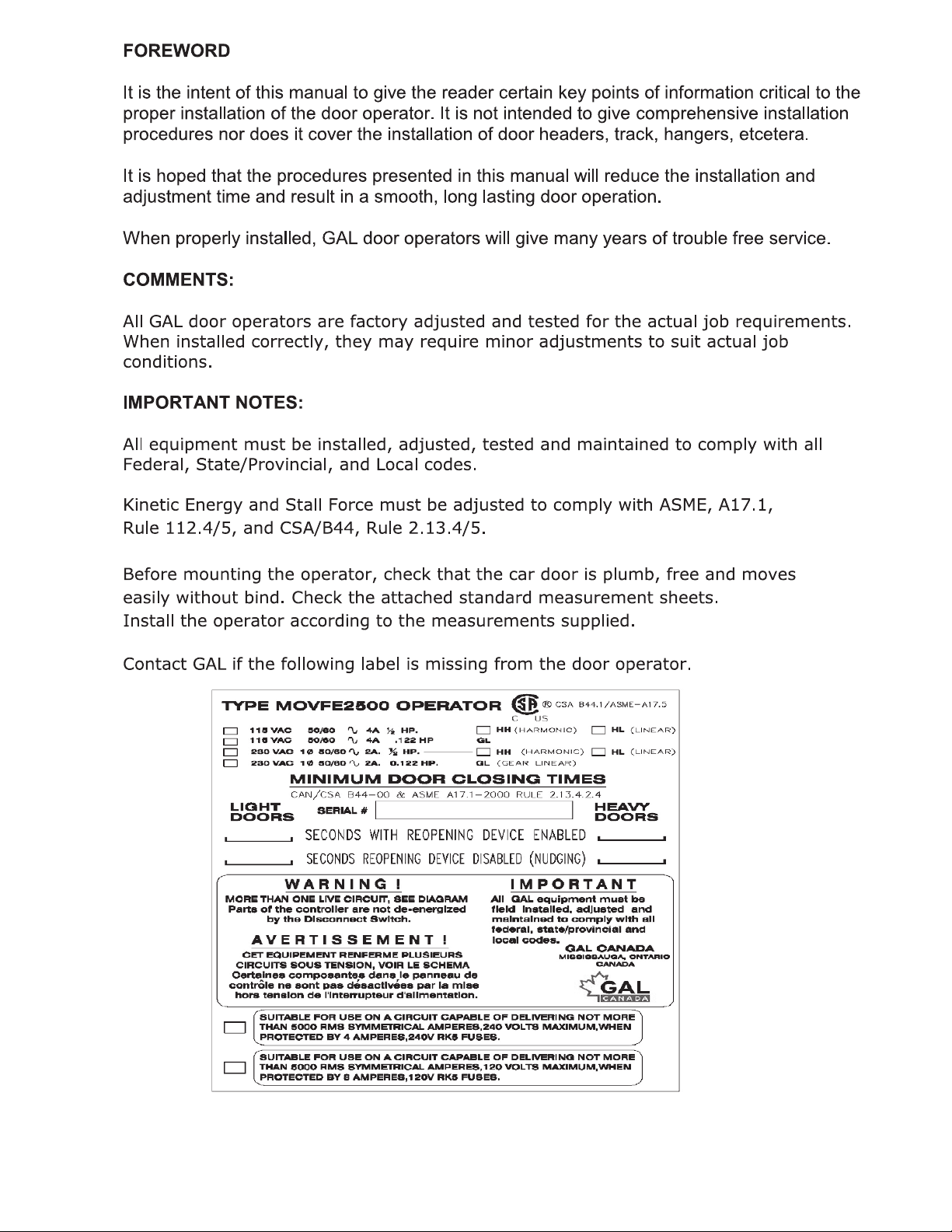

SAFETY STANDARDS:

xCSA Certified. B44.1/ASME- A17.5

xComplies with the following CE and IEEE safety standards of

EN61000-4-2, EN61000-4-3 EN61000-4-4, EN61000-4-5, EN61000-4-6, EN61000-4-8,

and IEEE STD C62.45-1992

xEMC conformity report is available

A POWERFUL SYSTEM:

x230VAC and 115VAC power supply versions are available

xVariable voltage, variable frequency (VVVF) drive

xA ½ HP AC motor is used to accommodate for most of door loads, friction, and wind pressure

HARMONIC AND LINEAR MODELS ARE AVAILABLE:

xThree models of VFE2500 are currently available:

¾VFE2500-HH : Heavy duty Harmonic model

¾VFE2500-GL : Light duty Linear model

¾VFE2500-HL : Heavy duty Linear model

NON-CONTACT SENSORS:

xOptical sensors and Hall-effect sensors for final limits, door protection monitor, and narrower

door limit.

CONVENIENCE INDICATORS:

xLight Emitting Diodes (LEDs) on the main board are used to indicate status of all important

functions:

Door open, close, nudging, heavier, narrower input signals,

Door open, and close directions,

Open, and close slowdown,

Obstruction detection signal,

Stall reverse,

Frequency failure,

DOL, DCL, AUX (Narrower door), and DPM (Door Protection Monitor)* output signals,

Door-width learning completion.

UNIVERSAL INPUTS AND OUTPUTS:

xUniversal inputs accept control signals in form of contacts or signal voltages;

from 24-230V AC or DC.

xOutput contacts, rated at 10Amp, 230VAC, include:

Door Close Limit (DCL),

Door Open Limit (DOL),

Re-Open (RE-OPEN),

Door Protection Monitor (DPM),

Auxiliary/Narrower Door (AUX),

Edges Timeout (ET)

xAll input modules, output relays, and connectors are pluggable for easy replacement.

KEYPAD (PARAMETER UNIT):

xKeypad programming with LCD display is available to adjust, monitor, copy, change

parameters, upload parameter sets, and to learn the door width distances.

xDefault parameter sets are ready for all ECI operator models.

xDifferent parameter sets for heavier door and narrower door are available for proper

adjustments to comply with codes.

xThe ability to copy (read) and download (write) parameter sets enables reduced setting time

on similar door operators.

2