1.0 INTRODUCTION..........................................................................................................................1

2.0 SAFETY .......................................................................................................................................2

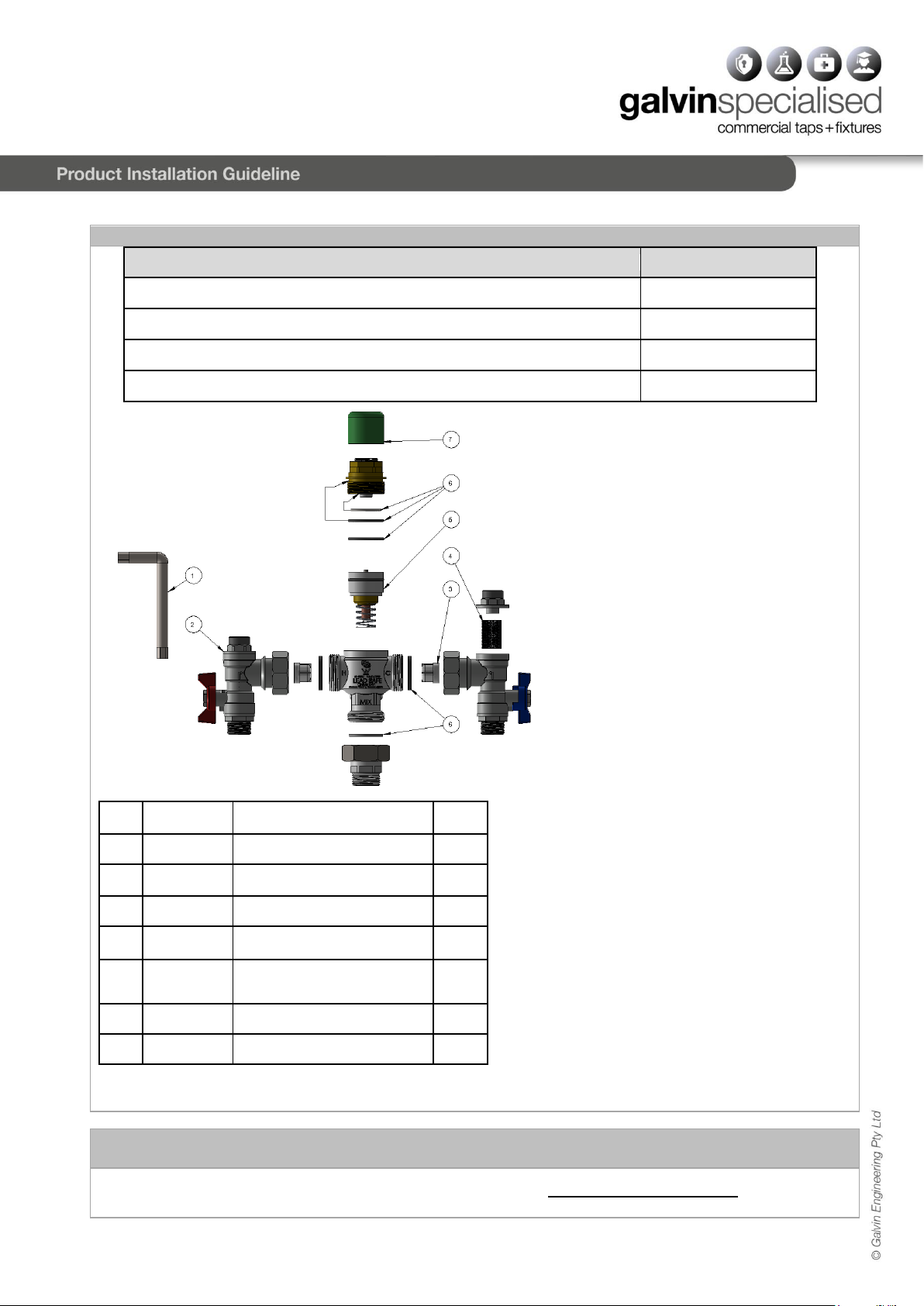

3.0 DESCRIPTION.............................................................................................................................2

4.0 DIMENSIONS...............................................................................................................................2

4.1 TECHNICAL DATA......................................................................................................................3

4.2 FLOW SIZING GRAPH................................................................................................................3

5.0 WATER SUPPLY CONDITIONS.................................................................................................4

5.1 INTRODUCTION..........................................................................................................................4

5.2 SUPPLY PRESSURE REQUIREMENTS....................................................................................4

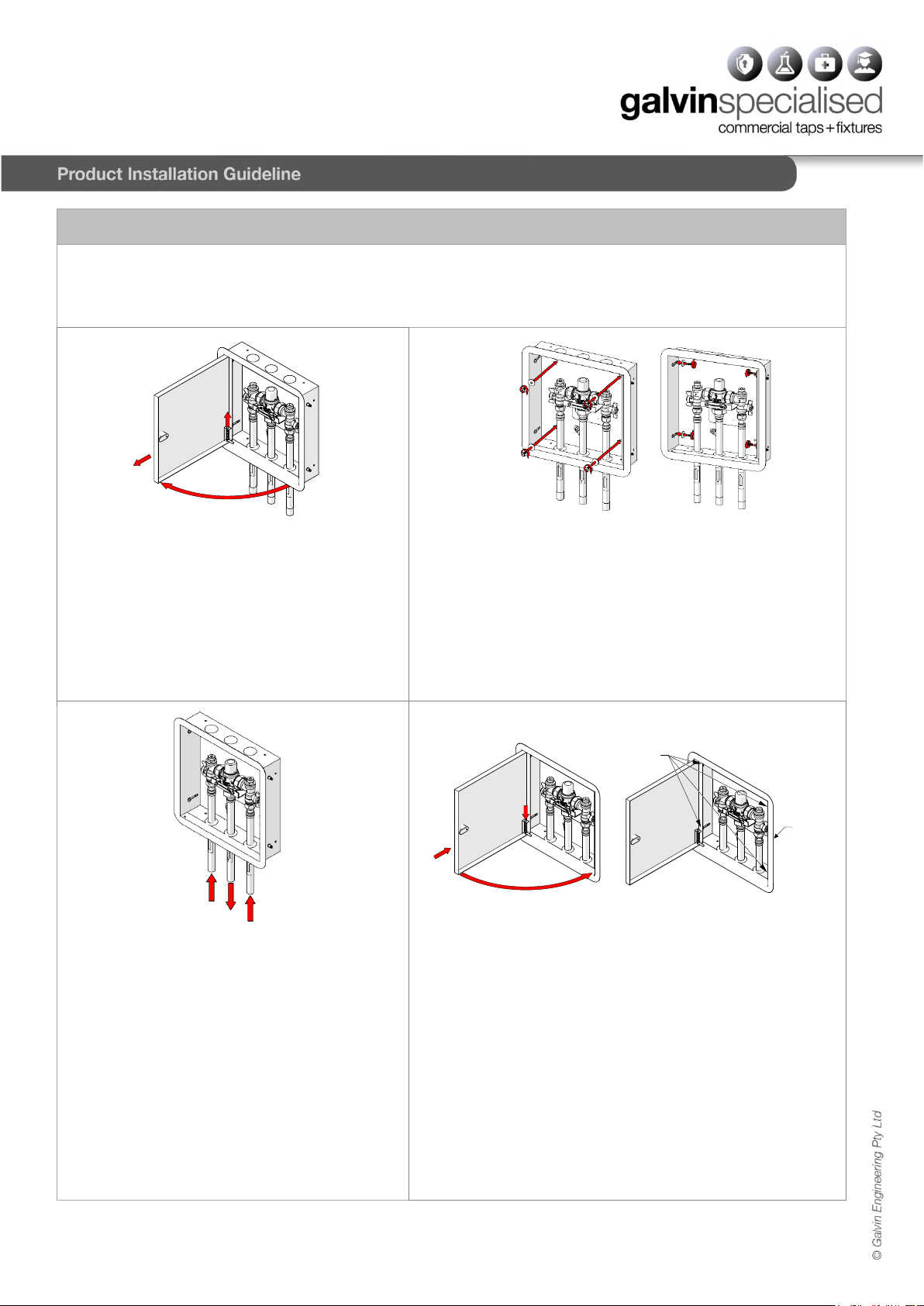

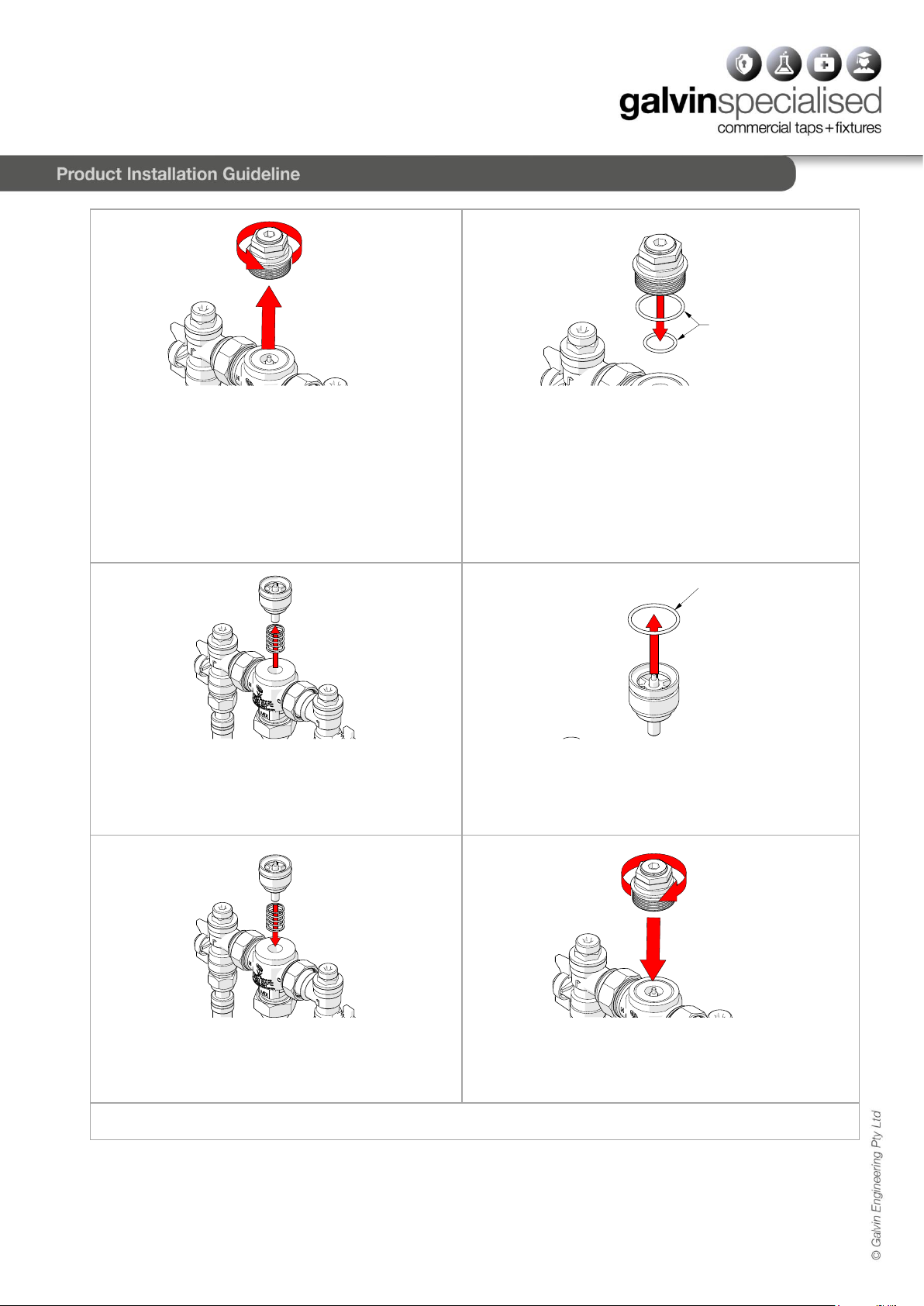

6.0 INSTALLATION...........................................................................................................................5

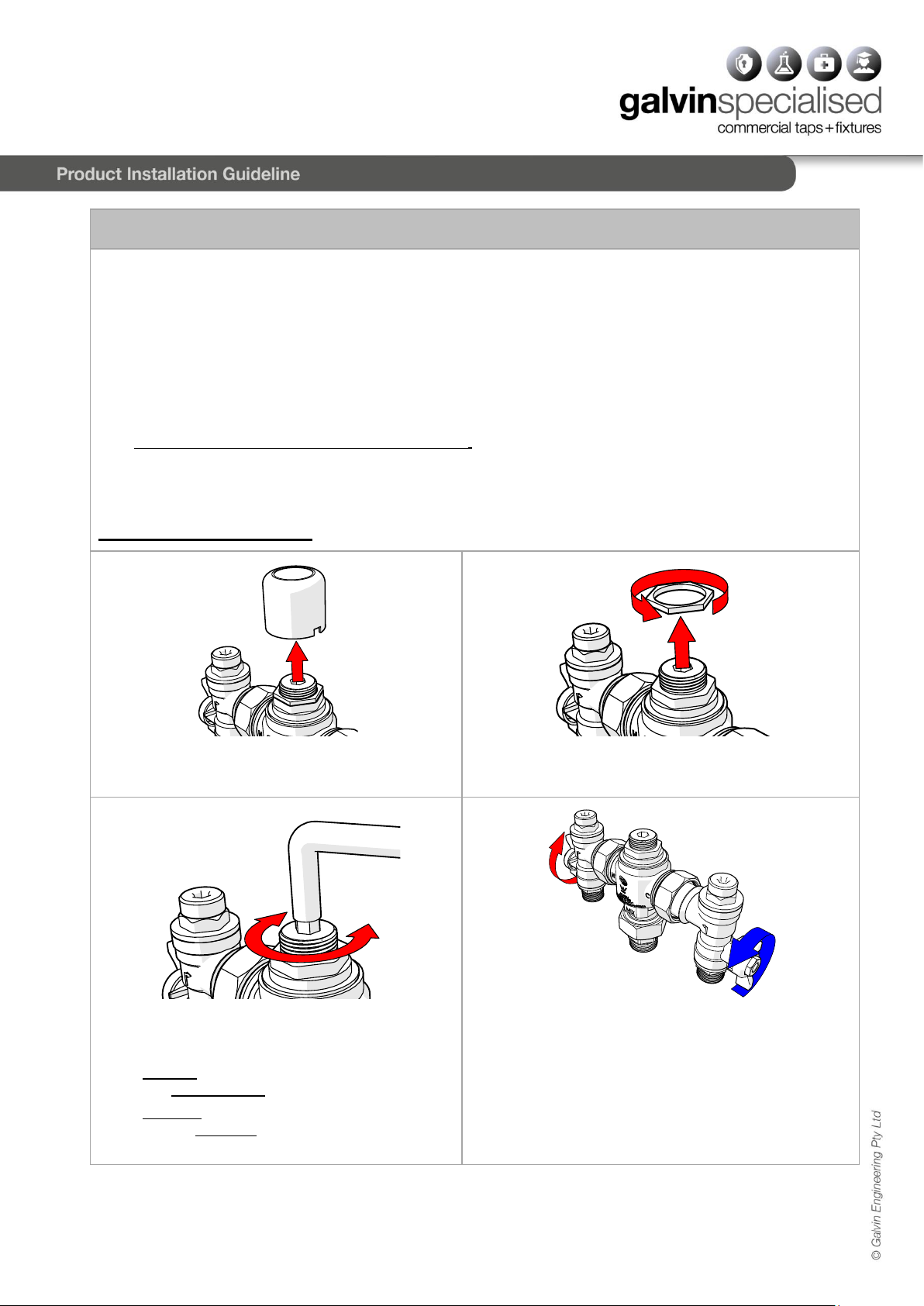

7.0 COMMISSIONING .......................................................................................................................6

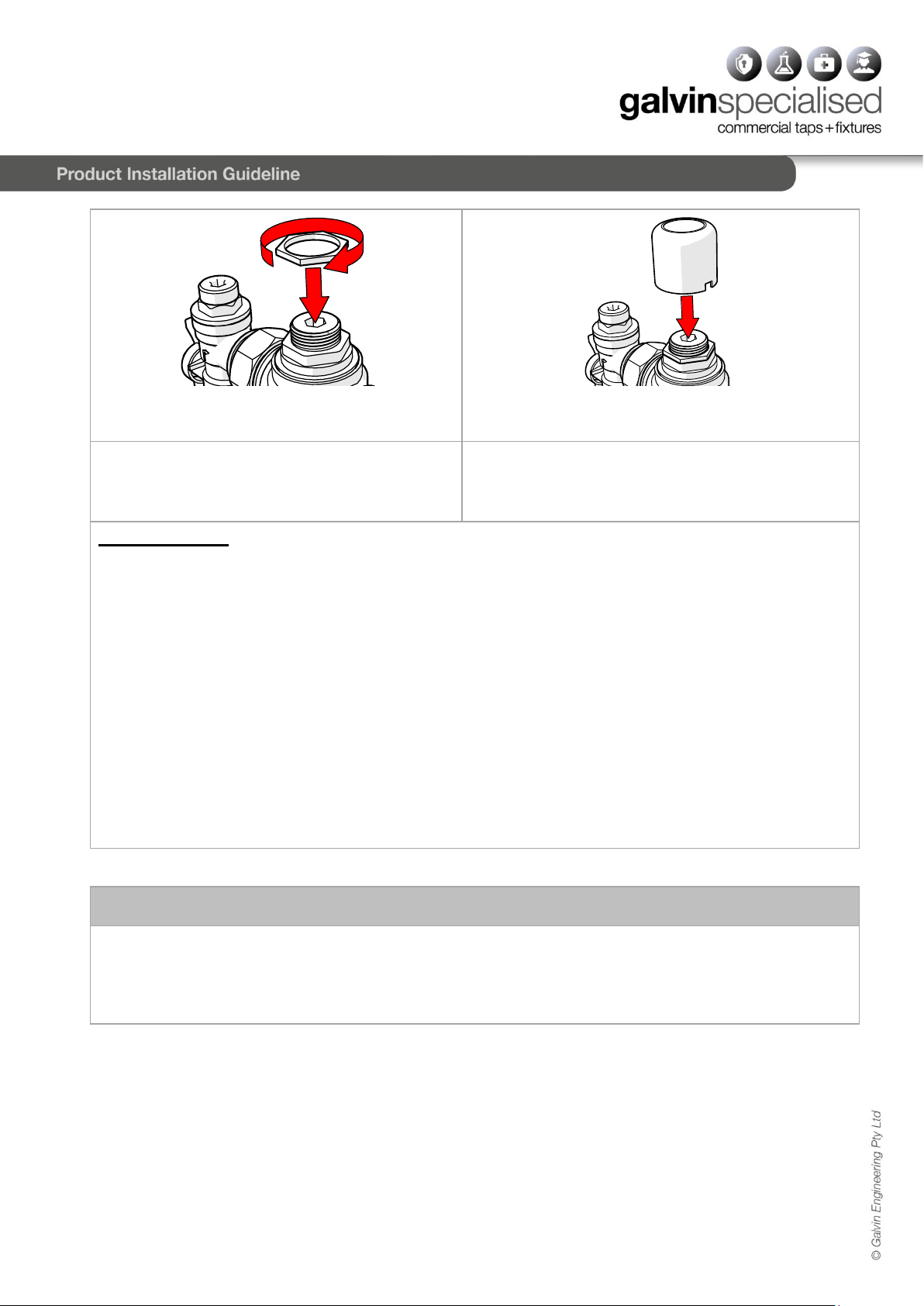

8.0 MAINTENANCE AND SERVICING.............................................................................................7

9.0 DISINFECTION..........................................................................................................................10

10.0 WARRANTY...........................................................................................................................11

11.0 TROUBLESHOOTING...........................................................................................................12

12.0 APPENDIX .............................................................................................................................13

−CliniMix®Thermostatic Mixing Valve Cabinets are designed to protect users from scalding or cold water

shock by providing tempered water to the desired outlets.

−This stainless steel hinged cabinet kit is a lockable cabinet with 20mm copper fittings (2 in and 1 out), which

allows secure installation and safe, simple maintenance of thermostatic mixing valve.

−Flat faced connections allow removal of the valve without disturbing the pipework.

−In the event of either hot or cold water supply failure the valve will shut down.

−Suitable for installation in low pressure systems and will operate with a working pressure as low as 20kPa.

−Units come complete with right angle isolating ball valve, non-return valve and strainer assemblies.

−Can be installed in any configuration with the water outlet in the horizontal or vertical position, and inlet

connections can be rotated to suit inlet pipework.

−Complies with the requirements of AS/NZS 4032.1 Thermostatic Mixing Valves.