2

Table of Contents

Introduction....................................................................................3

Caring for your 403 LE..................................................................4

Scanning the 403 LE.....................................................................5

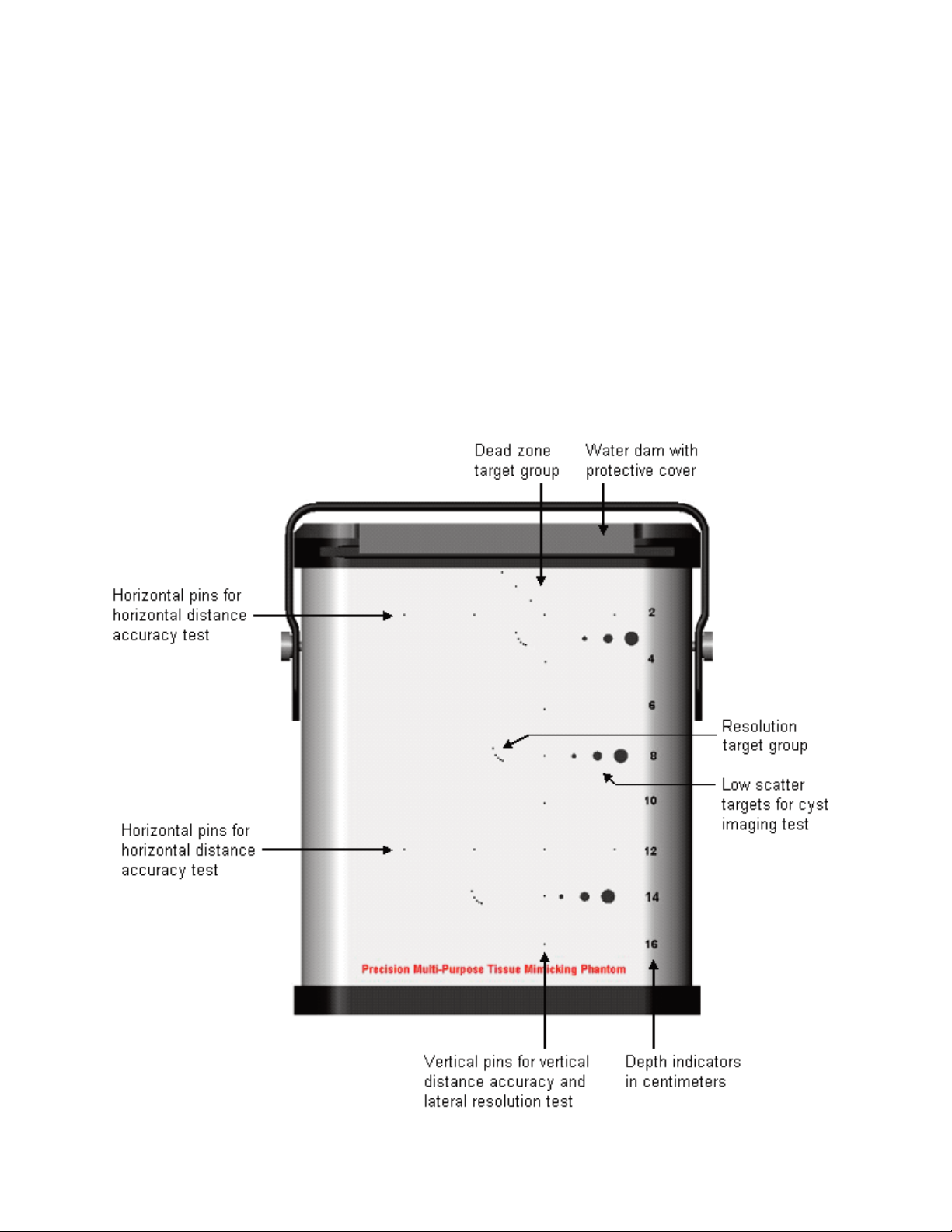

A Guided Tour of the 403 LE........................................................6

Evaluating the Phantom..................................................................7

Target Specifications..................................................................11

Cystic Targets................................................................................11

Pin Targets....................................................................................11

Resolution Target Groups...................................................................11

Phantom Specifications.............................................................13

Physical Specifications.................................................................13

Tissue Mimicking Background Material........................................13

Low Scatter (Anechoic) Cysts.......................................................13

Harmonic Imaging.......................................................................14

Phantom Desiccation...................................................................15

Charts and Graphs.........................................................................15

Product Warranty.........................................................................16

Sales and Service........................................................................17