TR-CL180 Lens Controller -User Manual

14.3 Command structure 27

14.4 General commands 29

14.5 Analog mode commands 32

14.6 Waveform commands 34

14.7 Programmable step commands 39

14.8 Command summary 41

15 TR-CL180 reference information 42

15.1 Specifications and ratings 42

15.2 Restrictions 43

15.3 Event codes 43

15.4 Error codes 44

TR-CL180 Lens Controller -User Manual

4Getting started

Before you use this product, make sure that you have read and

understood Section 5, Safety (or Section 6, Sicherheit,or Section 7,

Sécurité)and Section 15.1, Specifications and ratings,and that you have

checked the TR-CL180 fulfils your requirements.

Mount the TR-CL180 (see Section 8, Mounting the TR-CL180)and

connect it up (see Section 9, Connecting the TR-CL180), as required.

Set up the TR-CL180 for the desired operation as described in Section

13, Webpage configuration or Section 14, Configuration commands.

We recommend that you visit www.gardasoft.com for application notes

on this product.

There is also asupport web page there, which has information on trouble-

shooting problems.

4.1 TR-CL180 features - a summary

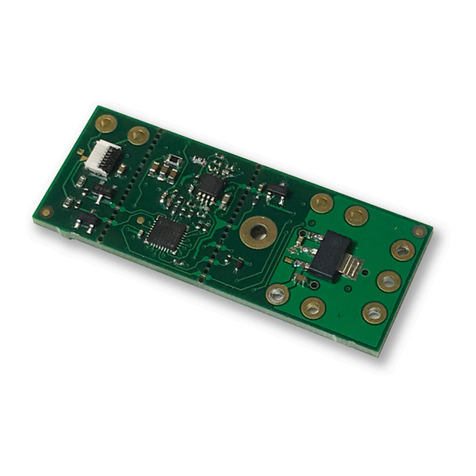

The TR-CL180 product is asingle channel lens controller for use in

machine vision applications. It works with the following ranges of Optotune

lenses:

EL-10-30

EL-16-40

4.2 GigE VisionTM

The TR-CL180 is GigE Vision™ compatible. This means that any

compatible GigE Vision client image processing software (for example,

CVB, LabVIEW, Halcon) allows the user to view and change controller

settings. GigE Vision is an industry standard protocol running on Ethernet

which provides easy configuration and control of cameras and other

devices.

The TR-CL180 is the first non-streaming device to become available

(at the time of publishing this manual), so some packages may not support

non-streaming devices yet. If your package does not work with the

TR-CL180 then please inform the manufacturer or Gardasoft.

—5—