Instruction Manual

Top & Bottom Loading Arms

E2110, E2112, E2022, E2025

E20 , E2 04, E257 , E212 ,

E2 1 , E2121

Rev.: 1

Table of Contents

1 Safety.......................................................................................................................1

1.1 afety Comments.............................................................................................1

1.2 afety ymbols and Notes ...............................................................................2

2 Loading Arm Types ................................................................................................2

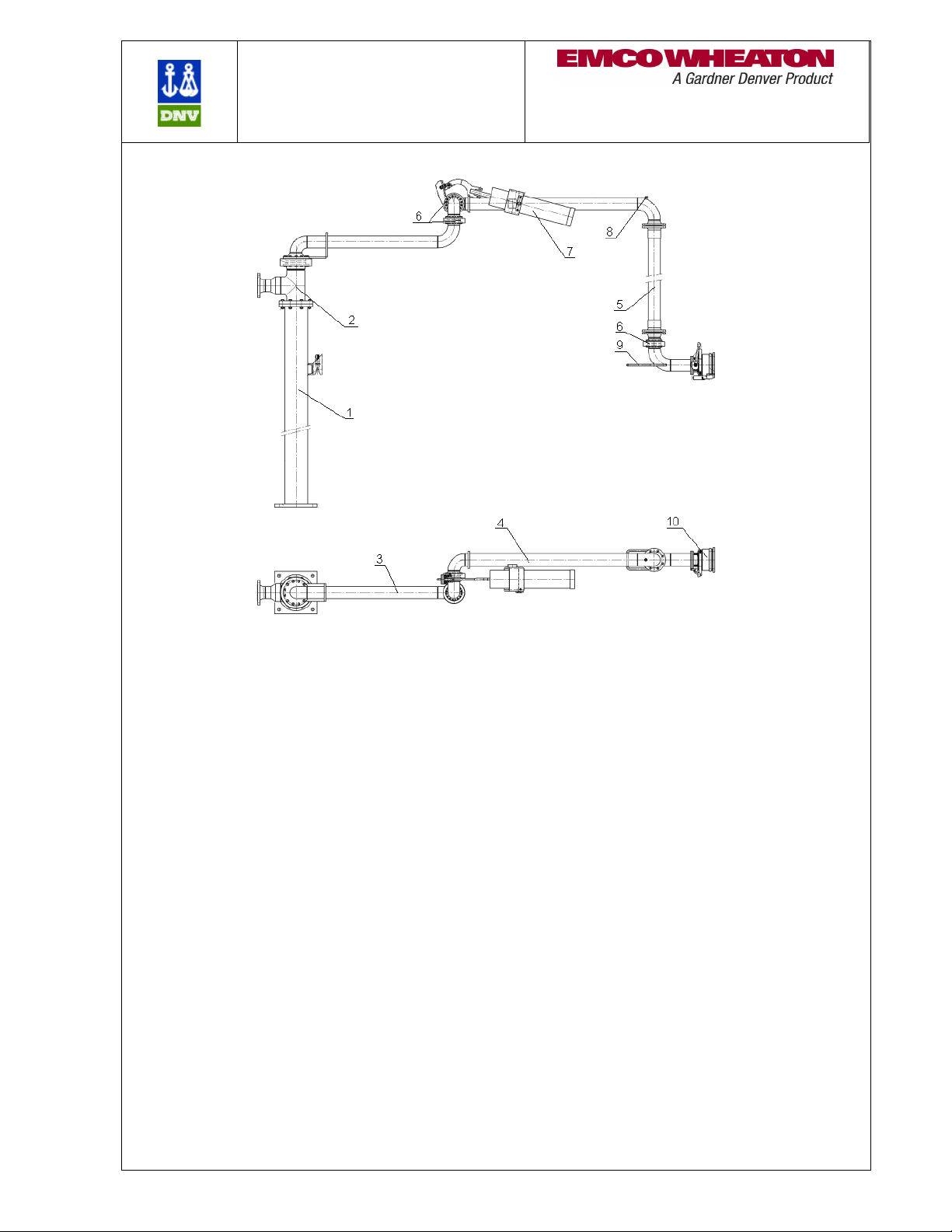

Loading Arm Description.......................................................................................

3.1 Loading Arm.....................................................................................................

3.2 Main Components - Top Loading .....................................................................

3.3 urvey Drawing ................................................................................................4

3.4 Main Components - Bottom Loading ................................................................5

3.5 urvey Drawing ................................................................................................5

4 Warranty ..................................................................................................................6

5 Delivery and Storage ..............................................................................................6

6 Installation...............................................................................................................7

6.1 Installation of the Loading Arm .........................................................................7

6.2 Installation of Feed Lines .................................................................................9

7 Commissioning.......................................................................................................9

8 Operation of the Loading Arm.............................................................................10

8.1 Operation of Loading Arms with Open B-Length............................................10

8.2 Operation of the Loading Arms with Flange/Coupler......................................11

9 Service and Maintenance.....................................................................................11

9.1 afety Comments...........................................................................................11

9.2 pare Parts ....................................................................................................12

9.3 Regular Tests.................................................................................................12

9.4 General Maintenance .....................................................................................12

9.5 ervice Intervals.............................................................................................1

9.6 Lubrication Points at the Loading Arm............................................................1

9.7 Maintenance of wivel Joints .........................................................................14

9.7.1 Maintenance of D2000 wivel Joints.......................................................15

9.8 pring Cylinder Maintenance .........................................................................15

9.9 pring Cylinder Adjustment………………………………………………..…….. 16

9.10 Replacement and Disposal of pring Cylinder .............................................16

9.11 Bolt Connections ..........................................................................................16

9.12 Painting ........................................................................................................16

9.13 Hose.............................................................................................................16

9.14 Couplers.......................................................................................................17

9.15 Electrical Equipment.....................................................................................17

9.16 E0471 Loading Valve….............. ……………………………………………….17

9.17 Other Valve types……… ………………………………………………………...19