1-1

1. Forward

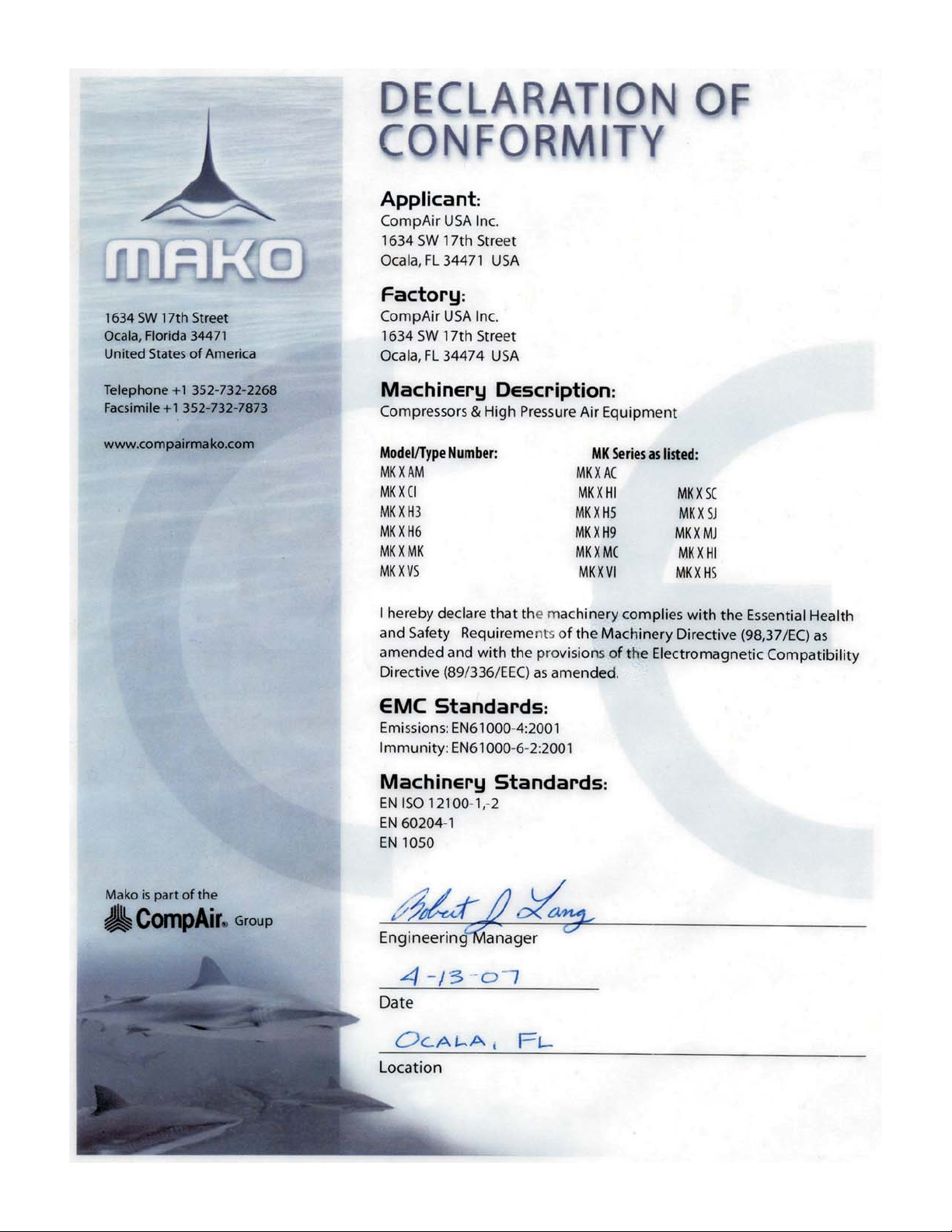

fig. 1.1-1 CE

1.2 Intended Use

This unit has been constructed in

accordance with state-of-the-art technology

and recognized safety regulations.

Nevertheless, its use may constitute a risk

to life and limb of the user or third persons

or cause damage to the machine or to other

material property, if

- it is not used as intended,

- it is operated by unqualified personnel

- it is improperly modified or changed

- the safety regulations are not observed

Therefore, any person entrusted with the

operation, maintenance or repair of this unit

must read and follow all safety regulations

in this manual. If required, this has to be

acknowledged by signature.

1.1 Notes On The Unit

Certificate Of Conformity

MAKO units are the result of many years of

research and development. This experience

combined with high quality standards

guarantee the manufacture of breathing air

charging systems which will provide a long

service life, high reliability and cost-

effective operation.

This unit and its accessories as supplied by

MAKO conform to the basic health and

safety requirements included in the

Machinery Directive 98/37/EC and the EMC

Directive 89/336/EEC. The compliance with

these directives is signified by the "CE

mark" (See fig. 1.1-1)

in addition,

- relevant accident prevention regulations

- generally recognized safety regulations

- national safety regulations

have to be observed.

This system must be operated under

technically perfect conditions and in

accordance with its intended use and the

instructions set out in the operating manual.

This system must be operated only by

safety-conscious personnel who are fully

aware of the dangers involved in the

operation of this system. If any functional

problem is detected or suspected stop the

operation of this system. Report the

problem to the appropriate maintenance or

service personnel. The problem must be

resolved before the system is returned to

operation.

Operating the unit within the limits of its

intended use also involves observing the

instructions set out in the operating manual

and complying with the inspection and

maintenance directives.

Carefully performed maintenance is

imperative, this ensures that your unit can

meet all the requirements for which it was

intended. It is therefore imperative to

adhere to the specified maintenance

intervals and to carry out the maintenance

work with deliberate care, especially when

the unit is utilized under harsh operating

conditions.

Please contact your authorized MAKO

distributor in the case of malfunctions or

when spare parts are required. Our fully

trained personnel will ensure that all repairs

are carried out properly. Using only genuine

MAKO spare parts. Genuine MAKO spare

parts are manufactured utilizing state-of-

the-art technology, thus guaranteeing the

continued reliable performance of the unit.

1.3 Maintenance

Servicing