Foreword

READ THIS MANUAL carefully to learn how to operate

and maintain your machine correctly. Failure to do so

could result in personal injury or equipment damage.

This manual and the safety signs on your machine may

also be available in other languages. (See your Waratah

dealer to order.)

THIS MANUAL SHOULD ALWAYS remain with the

machine, even if you sell the machine. It provides

detailed operating and maintenance instructions as well

as safety information and equipment data.

MEASUREMENTS in this manual are given in both

metric and imperial equivalents. Use only correct

replacement parts and fasteners. Fasteners may

require a specic metric or inch wrench.

RIGHT-HAND AND LEFT-HAND sides are determined

by facing in the direction of forward travel.

WRITE PRODUCT IDENTIFICATION NUMBERS in the

machine numbers section on page 3-2-1. Accurately

record all numbers to help in tracing the machine should

it be stolen. Your dealer also requires these numbers for

ordering of parts. File the identication numbers in a

secure place off the machine.

WARRANTY is provided as part of Waratah New

Zealand Limited’s (“Waratah’s”) support program for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained

below.

Waratah will back its products where defects appear

within the warranty period. Waratah may also provide

eld improvements at times, often without charge, even

if the product is out of warranty. If the equipment is

abused, or modied to alter its performance from

published specications, the warranty will become void

and eld improvements may be withheld.

T7M7G6M,00004BA-19-10OCT21

Copyright

These original instructions are the property of Waratah

New Zealand Limited.

All information, illustrations, and specications provided

in this manual are based on the latest information

available at the time of publication. We reserve the right

to make changes at any time and without notice.

COPYRIGHT © 2022

WARATAH NEW ZEALAND LIMITED

Tokoroa, New Zealand

All rights reserved.

Issue date: May 2022

T7M7G6M,0000807-19-30MAY22

General Information

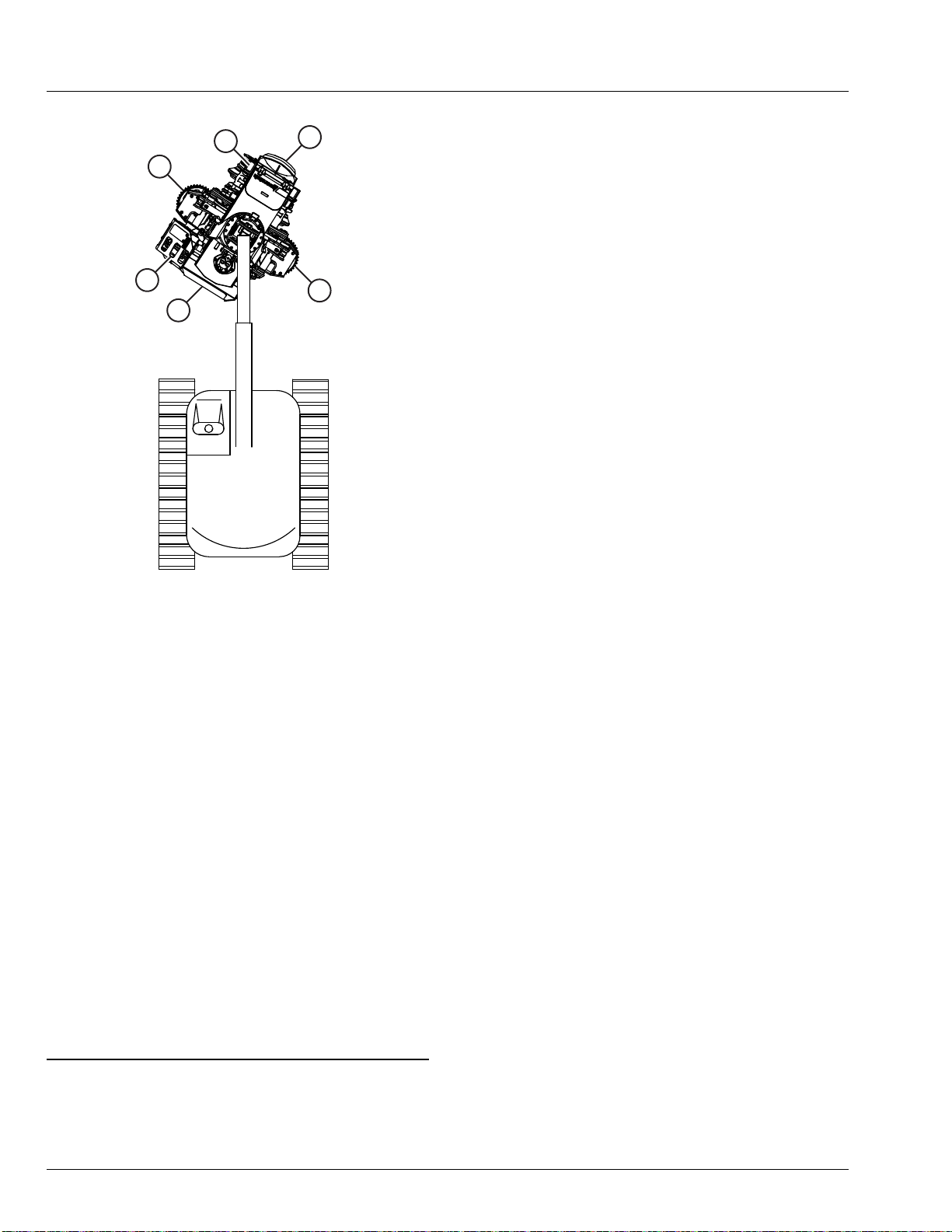

This manual contains instructions for the maintenance

of the HTH616C SIII harvester head. If you have

questions about the instructions, please consult your

local dealer for more detailed information.

Every effort was made to ensure that the information

contained in this manual was accurate at the time of

publication. Waratah, however, accepts no responsibility

for any errors or consequences arising from them.

Waratah also reserves the right to revise product

specications, instructions, etc. as required by ongoing

product improvements and updates.

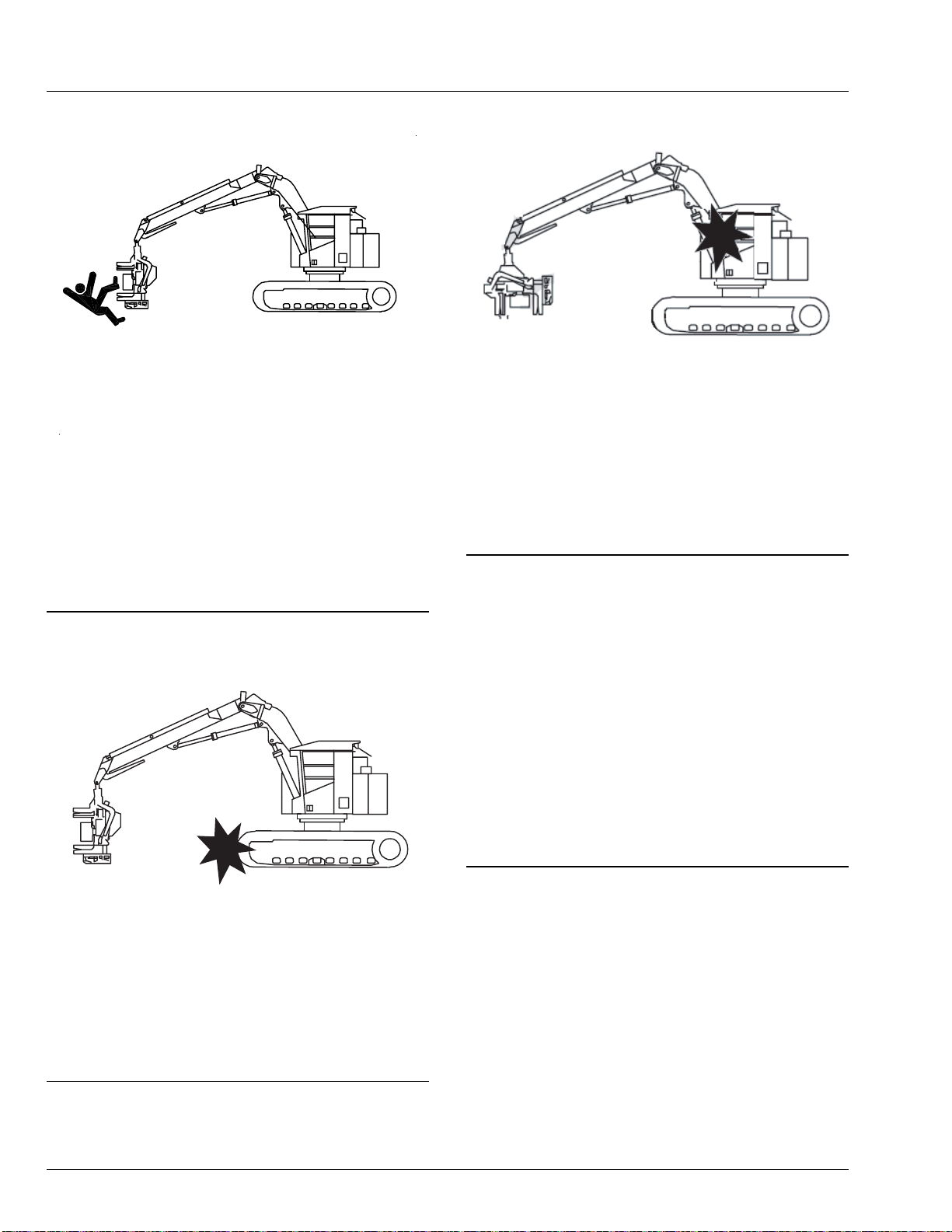

All service and repairs should be carried out by qualied

service personnel, or an authorized repair shop with

suitable tools and lifting devices, using Waratah-

approved parts. Waratah takes no responsibility for

damages that may arise through instructions not being

followed or through improper use of the product.

T7M7G6M,0000363-19-18AUG21

Manual Replacement

When re-ordering this manual, quote the part number

“WA135210” and the date of publication.

T7M7G6M,0000364-19-28FEB20

Warranty

Terms: Unless otherwise stated, Waratah New Zealand

Limited (‘Waratah’) warrants each new attachment to be

free of failure caused by defective material or

workmanship for a period of one (1) year or two

thousand (2000) hours, whichever rst occurs, following

date of delivery of the product to the original retail

customer (user).

Warranty coverage for parts on Waratah’s forestry

attachments is for 12 months from the date of

installation by a Waratah-approved dealer, or 180 days

from the date of delivery if the customer buys the part

over the counter.

Interruptions: Only one warranty interruption, lasting

no more than six (6) months, will be accepted during the

warranty period.

Validity: To validate this warranty, attachment

installation must be done by an authorised dealer on a

carrier that meets Waratah’s specications, prescribed

pre-delivery and start-up inspections must be

completed, and the customer must complete, sign, and

submit a Warranty Registration Form to the selling

Waratah Distribution Centre (WDC).

Obligations: Waratah’s sole obligation under this

warranty is limited to repairs of failures due to faulty

workmanship, or the repair or replacement of defective

parts. These actions are without charge, whether in the

eld, or at Waratah’s factory, warehouse, or an

General

0-1-1