2GIC-TL - Rev. 00 - Jan/23

1. To the owner 3

2. To the operator 4 to 14

3. Data sheet 15 to 17

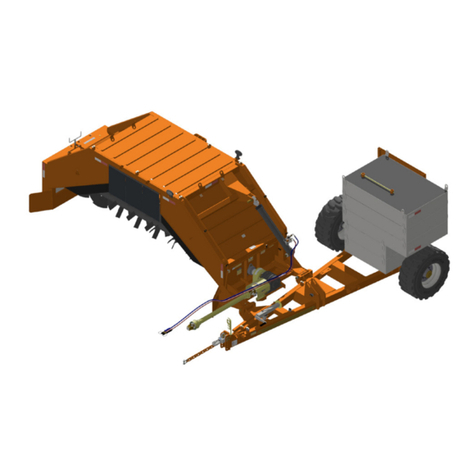

4. Components 18

5. Assembly 19 to 36

Using the set of wrenches 19

Assembly of bearings and spacer spools 20

Disc gangs assembly sequence 21 & 22

Assembly of the disc gangs on the frame 23

Scrapers assembly 24

Frames junction assembly / Junction extension assembly 25

Wheel support assembly 26

Wheel locks and cylinder assembly 27

Stop assembly 27

Drawbar assembly 28

Drawbar articulation set assembly 29

Opening system assembly 30

Transport bar assembly 31

Hydraulic circuit ducts and valves assembly 32

Hydraulic circuit assembly 33 to 36

6. Set-up instructions 37 to 44

Preparing the tractor / Preparing the equipment 37 & 38

Hitching to the tractor - hydraulic cylinder / Hitching to the tractor 38 & 39

Jack position 40

Procedures to transport the equipment 41 to 43

Hitching to the tractor to operate the disk harrow 44

7. Adjustments and operations 45 to 52

Cutting depth 45 & 46

Tractor position related to the previous pass - lateral displacement 47

Fixation holes on the hitch bar 48

Drawbar articulation extensor adjustment / Junction extension adjustment 48

Ways to start the harrowing 49

Direction of the maneuvers 50

Operations - important points 51 & 52

8. Maintenance 53 to 63

Lubrication / Lubrication points 53 to 55

Wheel support hubs lubrication 56

Hydraulic cylinder maintenance / assembly 57 & 58

Hydraulic safety 59

Troubleshooting guide 60 & 61

Disk harrow maintenance 62

Tires ination 63

9. Important data 64 to 66

Hourly income calculation 64

Average income table 65

Torque table 66

10. Important 67

Table of contents