GASSONIC GASSSONIC MM0100 User manual

InstallatIon and User GUIde for

GasssonIC MM0100 /eH6028

UltrasonIC Gas leak deteCtors

teCHnICal doCUMentatIon

t

InstallatIon and User GUIde for

GasssonIC MM0100 /eH6028

UltrasonIC Gas leak deteCtors

From serial number: 056-001

Gassonic MM0100 / EH6028

Index

Page:

1. Introduction ................................................................................................................................... 4

2. Description of Gassonic MM0100 / EH6028 ............................................................................... 4

3. Installing the Detector

3.1. Area Monitored by Gassonic MM0100 / EH6028 ...................................................... 4

3.2. Environmental Conditions ........................................................................................... 5

3.3. Mounting the Detector ............................................................................................... 5

3.4. Cable Connections ..................................................................................................6-7

4. Power Requirements ...................................................................................................................... 8

5. Adjustments

5.1. Adjustable Alarm Level Settings .................................................................................. 8

5.2. Alarm Delay & Cut-on Frequency Settings

5.2.1. Gassonic EH6028 .......................................................................................... 9

5.2.2. Gassonic MM0100 ......................................................................................... 9

5.2.2.1 Alarm Delay..................................................................................................... 9

5.2.2.2 Cut-on Frequency ........................................................................................... 9

6. Operating the Equipment

6.1. Trip Output Data ......................................................................................................... 10

safetY ConsIderatIons

WARNINGS

• Switchoffallequipmentbeforeconnectingordisconnectingthem.Failuretodosocould

damage the equipment.

• TheGasLeakDetectorsGassonic MM0100 / EH6028 areintrinsicallysafeunits

(EEx ib IIC T6). The voltage and current levels at the detector must be limited by Ex approved

isolators/barriers. Failure to do so may result in an explosion.

• Precautionsshallbetakentoavoidelectrostaticchargingofthedivice.

• OnlyoriginalGassonicscrewswithisolatorsshouldbeusedtotightenthelid.

aBoUt tHIs InstallatIon GUIde

ThisinstallationguidedescribeshowtoinstalltheGassonicMM0100/EH6028GasLeakDetector

andtellsyouhowtoadjustittothelocalconditions.

Copyright @ 2004 Gassonic

Allrightsreserved.Nopartofthispublicationmaybereproducedordistributedinanyform,orbyanymeans,

withoutpriorconsentinwritingfromGassonic,Ballerup,Denmark.

InstallationandUserGuideforUltrasonicGasLeakDetectors Page 4

1. IntrodUCtIon

ThisinstallationguidedescribeshowtoinstallUltrasonicGasLeakDetectorsGassonicMM0100/EH6028

andhowtomakethenecessarychecksandadjustmentstoensureoptimalperformance.

2. desCrIptIon of GassonIC MM0100 / eH6028

TheGassonicMM0100/EH6028detectsleaksfrompressurisedgassystemsbysensingtheairborne

ultrasoundproducedbythegasescaping.ThisdetectionmethodisOmni-directional.Itcanfunctionin

extremeweatherconditionsandisidealformonitoringleaksfromvalvesandangesincomplexpipeline

systems,bothonshoreandoffshore.

TheGassonicMM0100detectorhasanadjustablealarmtriggerlevelsetting(7levels,from44to104dB

in10dBsteps)andaninternaladjustablealarmdelayfrom0–480seconds.Iftheinternalalarmdelay

issettozero,analarmdelayofatleast15secondsshouldbeintroducedatthecontrolsystem.These

functionsenablethedetectortorecogniseleaksmoreeasilyandpreventtheoccurrenceoffalsealarms.

TheGassonicEH6028detectorhasanadjustablealarmtriggerlevelsetting(10levels,from54to99dB

in5dBsteps)andnointernalalarmdelay.Itisnecessaryforanalarmdelayofatleast15secondstobe

introduced at the control system.

Ex approved isolators must be used to limit the current and voltage to the detector. These isolators need

tobeinstalledinthenon-hazardousarea.ThedetectorssatisesATEX–EEx ib IIC T6andUL/ULC–Class

1/Div. 1/ Group ABCD classifications. It is certified by DEMKO (certificate no. DEMKO 02 ATEX 131173X

andULFile/NO.E228468).CopiesofthecerticatesareavailableonrequestfromyourlocalGassonic

representative.

3. InstallInG tHe deteCtor

3.1. Area Monitored by Gassonic MM0100 / EH6028

Sound in Air:

Soundpressurelevels(SPL)decreaseby

approximately6dBeachtimethedistance

is doubled.

This means that if a gas leak generates

aSPLof100dBat1metretheSPLwill

dropby6dBeverytimethedistancefrom

thegasleakisdoubled.Asillustratedin

thediagram,theSPLat2metreswillbe

94dB.

Page 5Gassonic MM0100 / EH6028

Although these calculations are for ideal conditions, where there are no obstacles or reecting walls

betweentheleakandthedetector,theyprovidereliableguidelinesastothenumberofdetectorsrequired

andwherethemightbepositioned.

Werecommendthatthedetectorshouldbepositionedinlineofsighttoandwithin8–12metresradius

fromthepossibleleak,toaccuratelydetectleaksof0.1kg/sec.(e.g.4mmleaksizeat735psi).Thismay

dependentonlocalconditions(backgroundnoiseetc.).

3.2. envIronMental CondItIons

WARNING!Inordertokeepthedetectorandthejunctionboxintrinsicallysafe,thevoltageandcurrent

levels must be limited by Ex approved isolators/barriers placed in the non-hazardous area. MTL isolators

arementionedindrawingBR6008onpage8.However,anyisolators,withthecorrectspecications,can

be used.

Corrosion Resistant:

Thedetectorshavebeentestedwithsaltcontamination,followedby30cyclesoftheKesterwicktest

withupto100%relativehumidityand0.21SO2percycle(accordingtoDIN50018-SFW0.25W).The

GassonicMM0100/EH6028havebeentestedandfoundtocomplywithIP66accordingtoIEC529

second edition: 1989-11.

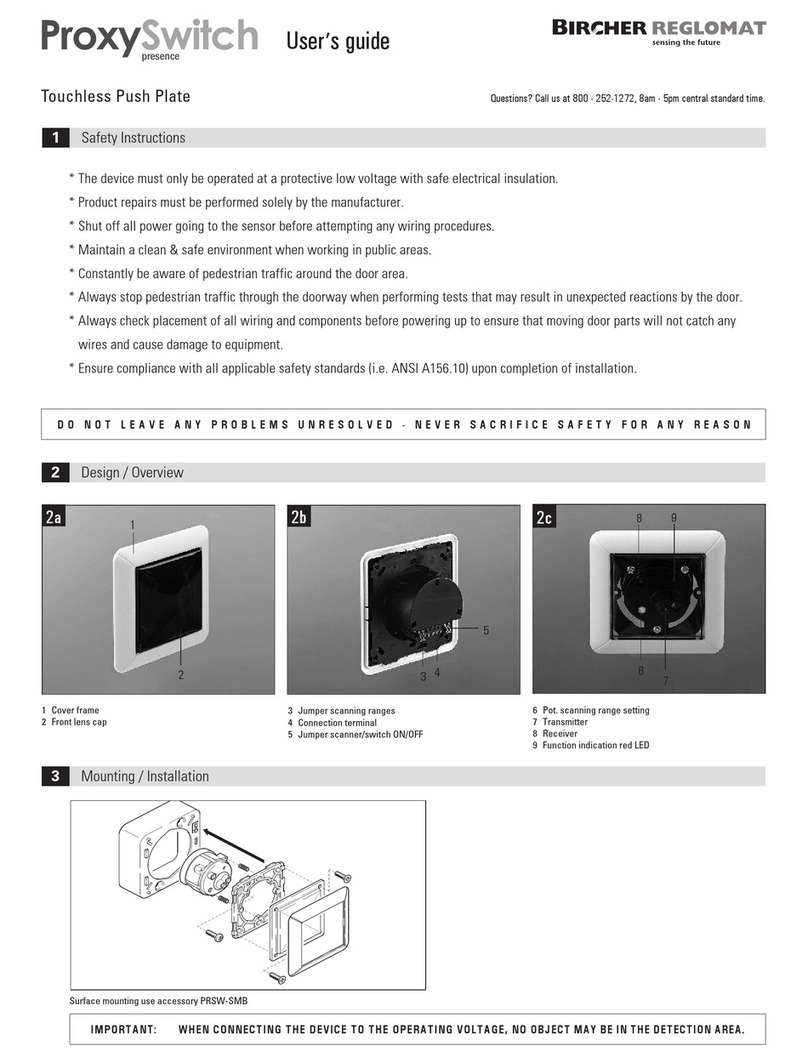

3.3. MoUntInG tHe deteCtor

TwoM8stainlesssteelboltsattachedtothedetector’slidareusedtoxtheGassonicMM0100/EH6028

initsoperatingposition.Thedetectorscanbemountedtoafree-standingpoleorwall,usingthemountain

bracketUA1352.Itispossibletomountthedetectorsnotonon-vibratingstructuralbeamsorcable-trays.

Themicrophoneshouldfacedownwards,andiftiltingofthedetectorisneeded,thisangleshouldnot

exceed 45°.

InstallationandUserGuideforUltrasonicGasLeakDetectors Page 6

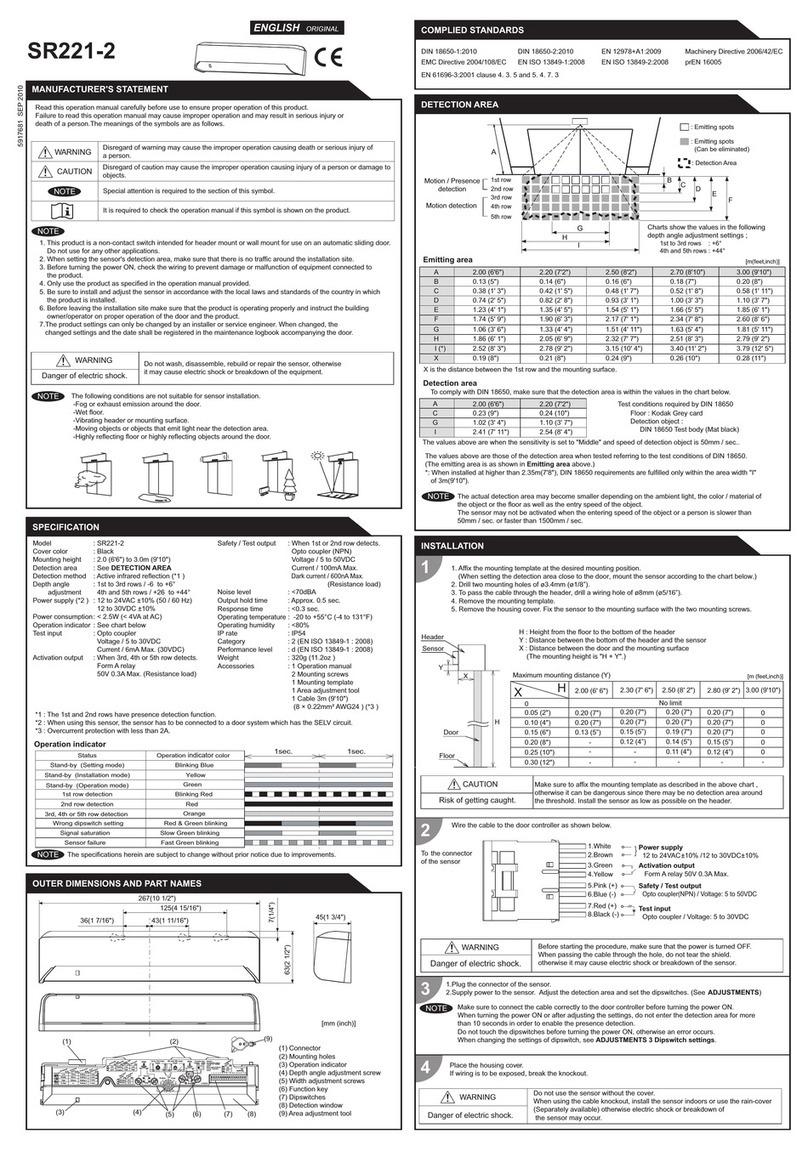

3.4. CaBle ConneCtIons

1

-

1

1

7

4

4

10

2

11

2

2

8

5

11

3

12

3

3

9

6

12

13

14

Safe Area

Installation Example Drawing for

MM0100 Family, with MTL Isolators

Hazardous Area

MTL5025

MTL5011

O/P

PWRCHL

20-35 VDC

Supply

Voltage

On/Off Relay Output

DCS-System or

Fire & Gas Panel

Earth

Glan Type:

HAWKE 501/453/UNIVA/B/WXYZ

BFOU(C) 250V 2x2x0,75

Armour

Inside MM0100

Pair 1

Power Supply

13-24 VDC

Pair 2

Alarm Relay

Output

Internal

Relay

Blue

Black

Blue

Black

1KW

484W

10KW

Relay Status Output from MTL5011

MM0100 Normal, No alarm: Relay open.

MM0100 Gas Leak alarm or Power drop: Relay closed.

6 metres of cable attached

to the detector from factory.

Pair 1

Blue - position 1

Black - position 2

Pair 2

Blue - position 3

Black - position 4

Drain wire- position 5

Collective screen and drain wire cut back and insulated.

Detector Relay and NAMUR Output Status:

Normal: No Alarm, Relay Switched, Output = 1.28kW ±1%.

Trigger: Alarm, Relay Open, Output = 10kW ±1%.

BR6008

Drawn By:

Documentation No.:Rev.:

Date:

RELATED

Authorised Person:

Documentation

Level:

15

SN

220302

Junction Box (optional)

1702

Gas Leak Detector

MM0100,

MM0100-EH6028

Power supply Vmax/Ui: 28 Vdc

Power supply Imax/Ii: 100 mA

Li: < 0,01 mH

Ci: <10 nF

Class I/Div.1/Group ABCD

Earth

Earth

Pi: 750 mW

IS Earth

Any isolators with the correct specifications can be used.

Installation Example Drawing for

Gassonic MM0100 Family, with MTL Isolators

Page 7Gassonic MM0100 / EH6028

Thedetectorisdeliveredasasealedunitttedwithasixmeter,2-pair,

collectivescreen,steel-braided,halogen-free,mudresistant,reresistantcable.

Pair 1 PowerSupplyInputs:

Blue:13–28VDC

Black:GND

Pair 2 Trip Outputs:

Blue&Black:AlarmRelayOutput.

Collective screen and drain wire: IS Earth

Armour: Earth

Thebraidedcablemustbefastenedatleastevery0.5m.

InstallationandUserGuideforUltrasonicGasLeakDetectors Page 8

4. power reqUIreMents

Thedetectorsarepoweredbyanexternal24VDCsupply(min.13VDC,max.28VDC).Themaximum

powerconsumptionofonedetectorisapproximately30mA.Thedetectorsmustbeelectricallyconnected

via certified barriers placed outside the hazardous area.

Intrinsicallysafespecications:

Vmax/Ui = 28 Vdc Imax/Ii = 100 mA Li = 0.01 mH Ci = 10 nF Pi = 0.75 W

5. adjUstMents

5.1. Adjustable Alarm Level Settings

TheGassonicMM0100/EH6028isequippedwithanadjustableAlarmTriggerLevel.

This should be adjusted to suit the local conditions.

The alarm has ten level settings:

GASSONIC MM0100 GASSONIC EH6028

Level Setting Trip SPL (dB) Level Setting Trip SPL (dB)

0,1&2 44 054

354 159

464 264

574 369

6 84* 4 74

794 5 79*

8 & 9 104 684

789

894

999

*Factorysettings(unlessotherwisespecied)

TheDetectorsshouldbeadjustedsothatthealarmlevelisatleast6dBabovethenormalbackground

noise level in the area to be monitored.

Abuilt-ingreenLED,positionedbesidetheattenuatorindsidethedetector,helpsyoutondthecorrect

level setting.

Adjusting the Alarm Level

1.UsinganAllen-key,removethescrewatthebottomofthedetector.

2.Using a small, at-blade screwdriver set the attenuator to the highest position. Adjust the level

downwardsuntilthegreenLEDlights.Increasethesettingtoatleastthenextattenuatorposition.The

detectornowhasthecorrectalarmlevelsetting.

3.ReplacethescrewandsecureitrmlyusingtheAllen-key.Itisimportantthatthescrewistightand

sealedtopreventwaterenteringthedetector.

Page 9Gassonic MM0100 / EH6028

5.2. alarM delaY & CUt-on freqUenCY settInGs

5.2.1 GASSONIC EH6028

The Alarm Delay and Cut-on Frequency settings are fixed in the Gassonic EH6028.

These values are:

Alarm Delay: 0 seconds Cut-on frequency: 25 kHz

5.2.2 GASSONIC M0100

TheGassonicMM0100isequippedwithanadjustableAlarmLevel,AlarmDelayandaCut-onFrequency.

These should be adjusted to suit the local conditions.

5.2.2.1. Alarm Delay

TheGassonicMM0100isttedwithanAlarmDelayfunction.Thiscanpreventshortdurationultrasound

noiseevents,whichexceedthealarmlevel,fromtriggeringthealarm.Gasleaksnormallyproducean

almost constant ultrasound level. The detector may be subjected to short duration ultrasound noise

events,suchasair-valves,sirensorloudbangs,whichexceedthealarmlevel.Byadjustingthealarmdelay

toaperiodlongerthantheseeventsitwillbeabletoilluminatefalsealarms.

Thealarmdelayissetusingthedipswitchesinsidethedetector.Thetimedelaysandthecorresponding

dipswitchpositionsareshownbelow:

Dip On. Delay

1 0

2 15 sec*

3 30 sec

4 2 min

5 4 min

6 8 min

* Factory settings

Thetime-delayistypicallysetbetween15secondsand2minutes.However,thisdependsentirelyonthe

durationofthenoiseevents.Thealarmdelaycanbesetupto8minutes.

Ifadelaylongerthan8minutesisnecessary,anexternaldelayunitcanbeadded.

5.2.2.2. Cut-on Frequencies

Thedetectorcanalsobesetsothatitignoresfrequenciesbelowadenedlevel.TheH.P.ltercontrols

this“cut-on”option.Thefrequencyisdenedusingthedipswitcheslabelled7and8.

DIP7 DIP8 Freq.(kHz)

On On 25*

Off On 20

On Off 15

Off Off 10

* Factory settings

InstallationandUserGuideforUltrasonicGasLeakDetectors Page 10

Adjusting the DIP Switches:

1.UnscrewthefourscrewsinthetopoftheGassonicMM0100,andremovethelid.

2.Unscrewthesixscrewsonthemetalplatelocatedunderthelidandremovetheplate.Thedipswitches,

illustratedbelow,arenowvisible.

3.Usingasmall,at-bladescrewdriver,changethepositionsofthedipswitchestosuityourmeasuring

site requirements.

4.Replacetheplateandsecureitwiththesixscrews.

5.ReplacethelidandsecurethefourscrewsusinganAllen-key.

6. operatInG tHe eqUIpMent

6.1. Trip Output Data

Theonlyoutputfromthedeviceisatripoutput.Thishastwostates:

Normal:1.28kΩ±1%

Alarm:10kΩ±1%(Nopoweroranultrasoundlevelabovethepresettriggerlevel)

GASSONIC A/S

Energivej 42 A

DK-2750Ballerup

Denmark

Tel +45 44 700 910

Fax +45 44 700 911

mail@gassonic.com

www.gassonic.com

GasssonIC MM0100 /eH60288

From serial number: 056-001

BB6016-03

CAPITOLCOPENHAGEN+4545800831

This manual suits for next models

1

Table of contents

Other GASSONIC Security Sensor manuals