Powerex • 100 Mundy Memorial Drive • Mount Juliet, TN 37122 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN599400AV • 21 October 2020

Page 2 of 12

Scroll Basemount Compressor

Operating & Maintenance Manual

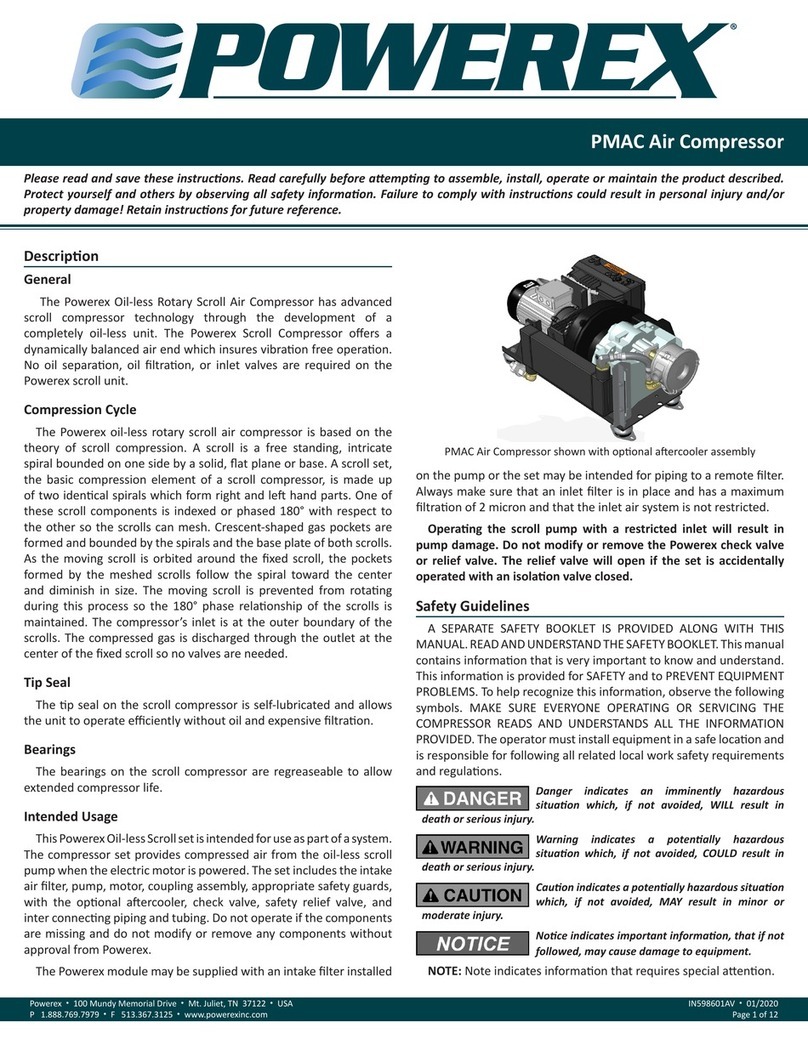

Description

The Powerex Oil-less Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oil-less unit. The Powerex

design permits a continuous 100% duty cycle. No oil

the Powerex scroll unit.

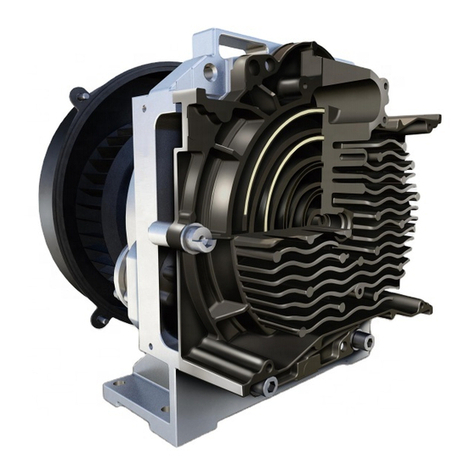

Compressor Cycle

The Powerex oil-less rotary scroll air compressor is

compression element of a scroll compressor, is made

up of two identical spirals which form right and left

hand parts. One of these scroll components is indexed

or phased 180° with respect to the other so the scrolls

can mesh. Crescent-shaped gas pockets are formed

follow the spiral toward the center and diminish in size.

The moving scroll is prevented from rotating during

this process so the 180° phase relationship of the

scrolls is maintained. The compressor’s inlet is at the

scroll so no valves are needed.

Tip Seal

Bearings

Intended Usage

This Powerex Oil-less Scroll set is intended for use

as part of a system. The compressor set provides

compressed air from the oil-less scroll pump when the

electric motor is powered. The set includes the pump,

and a pressure relief valve. Do not operate the set with

place and that the inlet air system is not restricted.

Operating the scroll pump with a restricted inlet will

result in pump damage. Do not modify or remove the

Powerex check valve or relief valve. The relief valve

will open if the set is accidentally operated with an

isolation valve closed.

Safety Guidelines

This manual contains information that is very

important to know and understand. This information

is provided for SAFETY and to PREVENT EQUIPMENT

Danger indicates an imminently

hazardous situation which, if not

avoided, WILL result in death or serious injury.

Warning indicates a potentially

hazardous situation which, if not

avoided, COULD result in death or serious injury.

Caution indicates a potentially

hazardous situation which, if not

avoided, MAY result in minor or moderate injury.

Notice indicates important

information, that if not followed,

special attention.

any application of air for human consumption, you

ANSI and/or Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES IN THE EVENT

THE COMPRESSOR IS USED FOR THE PURPOSE