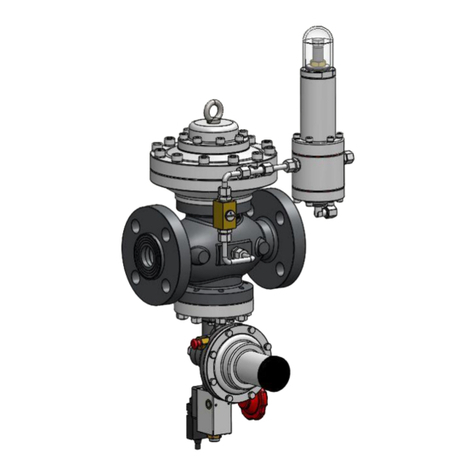

GasTeh 121 Quick guide

REGULATOR NISKOG PRITISKA BEZ I SA

BLOKADNIM MEHANIZMOM TIP: 121

(blokada od: - visokog pritiska –VP

- visokog i niskog pritiska - VNP)

SAFE USE GUIDE

UPUTSTVO ZA MONTA@U, RUKOVANJE I ODR@AVANJE

LOW GAS PRESSURE REGULATOR WITH OR

WITHOUT INCORPORATED SAFETY SHUT-OFF DEVICE

TYPE: 121

(shut-off device: - for high pressure –VP

- for high and low pressure –VNP)

GT-121-02 1

INTRODUCTION

This Safety use guide provides instructions and safety informations on pressure equipment so as to avoid

any foreseeable risk during the use. For any information refer to regulator type: 121 see Technical manual

(GT-121-01).

UVOD

Uputstvo za rukovanje, montažu i održavanje pruža informacije i instrukcije za bezbedan rad kako bi se

izbegli mogući rizici pri upotrebi. Za ostale informacije vezane za tehničke karakteristike pogledati

Tehnički katalog (GT-121-01).

GENERAL REMARK

Regulators type: 121 and type 121-BV are devices whose function is to maintain the value of the controlled

pressure within its tolerance field irrespective of disturbance pressure.

Regulators type: 121 and type 121-BV are direct acting regulators in which the net force required to move

the control member is supplied by the controlled pressure.

Regulators type: 121 and type: 121-BV are designed and manufactured according to EN 334.

Conformity to Directive 2014/68/EC and CE marking of pressure regulator and relevant accessory requires

installation on system with minimum requirements according to: EN 12186 and EN 12279.

Only accessories produced and labeled by GasTeh can be incorporated to regulators type: 121 and type:

121- BV as additional pressure accessories (e.g. filters, silencers, etc.).

For problems with regulators type: 121 and type 121-BV with incorporated pressure accessories produced

by other manufacturers, GasTeh will not be responsible.

OPŠTE PRIMEDBE

Regulatori pritiska tip:121 i tip:121- BV su uređaji čija je funkcija obezbeđivanje konstantne vrednosti

izlaznog pritiska u okviru regulacione grupe, nezavisno od promene ulaznog pritiska.

Regulatori pritiska tip:121 i tip:121- BV su regulatori direktnog dejstva kod kojih se sila potrebna za

održavanje konstantnog pritiska dobija iz samog pritiska koji se kontroliše.

Regulatori pritiska tip:121 i tip:121- BV su konstruisani i proizvedeni u skladu sa EN 334.

Usklađenost sa direktivom 2014/68/EC i CE označavanje regulatora pritiska i odgovarajućih uređaja

zahteva instalaciju na sisteme u skladu sa odredbama EN 12186 i EN 12279.

Kao dodatni uređaji pod pritiskom dodati regulatorima pritiska tip:121 i tip:121-BV, moraju se koristiti

isključivo oni proizvedeni od strane GasTeh-a (npr: filteri, prigušivači, itd.).

Za probleme nastale korišćenjem dodatnih uređaja drugih proizvođača na regulatorima pritiska tip:121 i

tip:121- BV, GasTeh neće biti odgovoran.

GT-121-02 2

PED CATEGORIES AND FLUID GROUP

Regulators type 121 and type 121- BV are classified as differential strength regulators, and marking for

these types of regulators is the symbol DS.

Regulators type 121 and type 121- BV are fail-to-open regulators.

Fail- to- open stand- alone regulators cannot be used as a safety accessory according to

PED 2014/68/EC to protect downstream pressure equipment.

According to PED 2014/68/EC gas pressure regulators type 121 and 121- BV depending of their size are

in the following groups:

Size

Category

Fluid group

DN25

Art.3.3

1

DN32

I

1

DN40

I

1

DN50

II

1

All sizes with

slam-shut

IV

1

Table 1.

Safety shut- off device type: GT.BM.VNP.02.65.P.Z. or type: GT.BM.VP.02.65.P.Z., incorporated in

regulator type: 121- BV, conform to PED 2014/68/EC Article 3.3 and were designed and manufactured

according to sound engineering practice (SEP) and they are not CE marked .

KATEGORIJE I GRUPE FLUIDA PREMA PED DIREKTIVI

Regulatori pritiska gasa tip 121 i tip: 121- BV spadaju u klasu regulatora koji sadrže elemente projektovane

za pritiske (PSD) koji su manji od projektnog pritiska (PS). Na tablici nose oznaku DS.

Regulatori pritiska tip 121 i tip 121- BV su u izvedbi u otkazu otvoreni.

Regulator pritiska sa izvedbom u otkazu otvoren prema direktivi PED 2014/68/EC se ne može koristiti

kao sigurnosni uređaj.

Prema PED 2014/68/EC regulatori pritiska tip: 121 i tip: 121- BV, zavisno od dimenzija, spadaju u sledeće

grupe:

Dimenzija

Kategorija

Grupa fluida

DN25

Art.3.3

1

DN32

I

1

DN40

I

1

DN50

II

1

Svi regulatori sa

blokadnim meh.

IV

1

Tabela 1.

GT-121-02 3

Blokadni mehanizami tip: GT.BM.VNP.02.65.P.Z. i tip: GT.BM.VP.02.65.P.Z., ugrađeni na regulatore tip:

121- BV, prema direktivi PED 2014/68/EC spadaju u kategoriju Art. 3.3. i projektovani su i proizvedeni u

skaldu sa Sound Engineering Practice (SEP) i ne označavaju se CE znakom.

SPECIFIKACIJA REGULATORA TIP: 121 I TIP: 121-BV

Nazivne dimenzije: DN25, DN32, DN40, DN50

Klasa pritiska: PN16, PN25, ANSI 150

Projektni pritisak (PS): 25 bar

Maksimalni radni pritisak: 19 bar

Opseg izlaznog pritiska: 0,02 ÷0,5 (1) bar

Klasa temperature: 2 (-20°C ÷+60°C)

Navedene maksimalne temperature i pritisci ne smeju biti prekoračeni!

Regulator pritiska ne zahteva dodatni sigurnosni uređaj instaliran pre regulatora za zaštitu od prevelikog

pritiska u odnosu na projektni pritisak PS, kada je redukciona stanica pre regulatora projektovana za

maksimalni pritisak jednak ili manji od 1.1 x PS.

Regulatori tip 121 i tip 121- BV se ne koriste kao monitori, i nisu opremljeni sa indikatorima položaja

otvorenosti.

REGULATOR TYPE: 121 AND TYPE: 121-BV SPECIFICATION

Available size : DN25, DN32, DN40, DN50

Nominal pressure: PN16, PN25, ANSI 150

! WARNING !

Design pressure (PS): 25 bar

Maximum operating pressure: 19 bar

Range of outlet pressure: 0,02 ÷0,5 (1) bar

Temperature class: 2 (-20°C ÷ +60°C)

Maximum temperatures and pressures above mentioned should not be exceeded!

Pressure regulator does not require any safety accessory installed upstream for protection against

overpressure compared with design pressure PS, when reducing station installed upstream is sized for a

max downstream incidental pressure MIPdis less or equal 1,1 x PS.

Regulators type 121 and type 121- BV are not used as stand- by monitor and are not equiped with any

external visual device which indicates wheather the control member is in the closed or in fully open

position.

! UPOZORENJE !

GT-121-02 4

MARKING OF REGULATOR TYPE: 121 AND TYPE: 121-BV /

OZNAČAVANJE REGULATORA TIP: 121 I TIP: 121-BV

The nameplate shall contain all basic informations about mentioned products. / Tablica regulatora mora

sadržati sve potrebne informacije o osnovnim karakteristikama regulatora.

Table 2. / Tabela 2.

NOTE 1:

- for regulator dimension DN25 (art.3.3 acc. to PED 2014/68/EC): - (nothing)

- for regulators DN32 and DN40 (category I acc. to PED 2014/68/EC): CE sign

- for regulator dimension DN50 (category II acc. to PED 2014/68/EC): CE sign and NB2028

- for all regulators wit slam-shut (category IV to PED 2014/68/EC): CE sign and NB2028

PRIMEDBA 1:

- za regulator DN25 (art.3.3 po direktivi PED 2014/68/EC): - (ništa)

- za regulatore DN32 i DN40 (kategorija I prema direktivi PED 2014/68/EC): CE

- za regulator DN50 (kategorija II prema direktivi PED 2014/68/EC): CE i 2028

-za sve regulatore sa blokadnim mehanizmom (kategorija IV prema direktivi PED 2014/68/EC): CE i 2028

List of symbols:

Wds –specific set range

pds –set point

pdo –relief valve –set pressure

ds–nozzle diameter

AC –accuracy class

SG –lock-up pressure class

SZ –class of lock-up pressure zone

Type –DS (differential strenght)

Temp. class –2 (-20°C ÷+60°C)

Regulator in failure –OPEN

pmax –maximum operating pressure

PS –allowable pressure

PSD –specific maximum allowable pressure

Lista simbola:

Wds –posebno područje podešavanja izlaznog pritiska

pds –izlazni pritisak regulatora

pdo –pritisak otvaranja –odušni ispusni ventil

ds–prečnik sedišta

AC –klasa tačnosti

SG –klasa pritiska zatvaranja

SZ –zona pritisaka zatvaranja

Tip –DS (differential strenght)

Temp. klasa –2 (-20°C ÷+60°C)

Regulator u otkazu - OTVOREN

pmax –maksimalni radni pritisak

PS –maksimalni dozvoljeni pritisak

PSD –specifični maksimalni dozvoljeni pritisak

GT-121-02 5

SPECIFIKACIJA BLOKADNOG MEHANIZMA TIP: GT.BM.VNP.02.65.P.Z I

TIP: GT.BM.VP.02.65.P.Z

Nazivne dimenzije: DN25, DN32, DN40, DN50

Klasa pritiska: PN16, PN25, ANSI 150

Projektni pritisak (PS): 5 bar

Maksimalni radni pritisak : 1 bar

Blokadni mehanizam se instalira na regulator sa maksimalnim radnim pritiskom 19 bar. Maksimalni radni

pritisak blokadnog mehanizma je maksimalni izlazni pritisak iz regulatora.

Opseg pritisaka blokiranja:

- za visoke pritiske: 0.03 ÷ 1 bar (klasa tačnosti AG 2.5)

- za niske pritiske: 0.002 ÷ 0.3 bar (klasa tačnosti AG 5)

Vreme odziva: ≤1s

Temperature class: 2 (-20°C ÷+60°C)

SAFETY SHUT- OFF DEVICE TYPE: GT.BM.VNP.02.65.P.Z. AND

TYPE: GT.BM.VP.02.65.P.Z SPECIFICATION

Available size: DN25, DN32, DN40, DN50

Nominal pressure: PN16, PN25, ANSI 150

! WARNING !

Maximum operating pressure: 1 bar

Design pressure (PS): 5 bar

Safety shut- off device is installed on regulator with maximum operating pressure 19 bar. Maximum

operating pressure for safety shut-off device is maximum regulator outlet pressure.

Set range:

- for high pressure: 0.03 ÷ 1 bar (accuracy group AG 2.5)

- for low pressure: 0.002 ÷ 0.3 bar (accuracy group AG 5)

Response time : ≤1s

Temperature class: 2 (-20°C÷ +60°C)

! UPOZORENJE !

GT-121-02 6

MARKING OF SAFETY SHUT-OFF DEVICE TYPE: GT.BM.VNP.02.65.P AND TYPE:

GT.BM.VP.02.65.P / OZNAČAVANJE BLOKADNOG MEHANIZMA ТIP: GT.BM.VNP.02.65.P I

TIP: GT.BM.VP.02.65.P

The nameplate shall contain all basic informations about mentioned products. / Tablica mora sadržati sve

potrebne informacije o osnovnim karakteristikama blokadnog mehanizma.

Table 3./ Tabela 3.

List of symbols:

Wdso - specific set range for over-pressure monitoring

Wdsu –specific set range for under-pressure monitoring

pdso –set point for over-pressure monitoring

pdsu –set point for under-pressure monitoring

Funct. class –A (closed in case of failure)

Type –IS (integral strenght)

Temp. class –2 (-20°C ÷+60°C)

pmax –maximum operating pressure

PS –allowable pressure

PSD –specific maximum allowable pressure

Lista simbola:

Wdso - područje podešavanja nadpritiska

Wdsu –područje podešavanja podpritiska

pdso –pritisak aktiviranja –gornji

pdsu –pritisak aktiviranja –donji

Funkc. klasa –A (u otkazu zatvoren)

Tip –IS (integral strenght)

Temp. klasa –2 (-20°C ÷+60°C)

pmax –maksimalni radni pritisak

PS –maksimalni dozvoljeni pritisak

PSD –specifični maksimalni dozvoljeni pritisak

OVERPRESSURE PROTECTION

The recommended maximum allowable pressures are stamped on the regulator nameplate.

If actual version hasn´t a built-in safety shut-off device, some type of overpressure protection is needed.

The regulator should be inspected for damage after any overpressure condition.

ZAŠTITA OD PREVISOKOG PRITISKA

Preporučeni maksimalni dozvoljeni pritisci su naznačeni na tablici regulatora.

Ako regulator nema ugrađen blokadni mehanizam, mora se predvideti neka druga vrsta zaštite od

previsokog pritiska.

Posle svakog prekoračenja pritiska, potrebno je izvršiti pregled regulatora zbog mogućih oštećenja.

GT-121-02 7

TRANSPORT, PACKING AND HANDLING

Established transport and handling procedures shall be folowed to avoid any damage during transporting

and handling of those equipment. The packing for transportation of equipment are designed and shaped to

avoid damage to any part. After packing is open, check that no damage occured to any position. If damage

occured inform the suplier and keep original packing.

TRANSPORT, PAKOVANJE I RUKOVANJE

Prilikom transporta rukovoditi se uspostavljenim procedurama, kako bi se sprečila moguća oštećenja

opreme prilikom transporta. Kutije za transport su tako projektovane i oblikovane da se izbegnu bilo kakva

oštećenja prilikom transporta. Posle otvaranja, proveriti opremu i ukoliko se uoče oštećenja obavestiti

dobavljača. Originalno pakovanje sačuvati.

INSTALLATION

Only qualified person shall install or service a regulator.

! WARNING !

All means for venting have to be provided in the assemblies where the pressure equipment is installed

(according to EN 12186 and EN12279).

All means for draining have to be provided in the equipment installed before regulators and safety

shut-off devices (according to EN 12186 and EN 12279).

Before proceeding with installation, commisioning or maintence, operators must:

- examine the safety provisions applicable to the installation in which they must work

- obtain the authorisations necessery for working when so requested

- use the necessary means of individual protection

- ensure that the area in which they operate is fitted with the means of collective protection envisaged and

with the necessary safety indications

Before installating the regulator it is necessary to ensure that:

- clean out all pipelines and check that regulator is clean and is not damaged during transport

- that regulator can be fitted into the space provided

- the upstream and downstream piping is in the same level

- the inlet and outlet flanges are parallel and clean

- make shure that data on regulator plate is compatible with operating requirements

- make shure that arrow on regulators body and flow are in the same directions

Pressure regulators shall be instaled in non- seismic area and hasn´t to undergo fire and must be provided

cathodic protection and electrical isolation.

GT-121-02 8

Recomended installation:

Picture 1. / Slika 1.

Installation / Ugradnja

Regulator can be mounted in other position if required (consult GasTeh personel for advice).

Before start-up regulator, impulse connections must be connected with the main pipeline. This connections

shoud be made using stainless steel or cooper pipe with minimum internal diameter of 8 mm.

MONTAŽA

Montažu mogu da vrše samo stručna i osposobljena lica. Pogledati sliku 1.

! UPOZORENJE !

Ventilacioni vodovi moraju biti obezbeđeni u sistemima gde se instalira gasna oprema (EN 12186 i EN

12279)

Vodovi za odmuljenje moraju biti obezbeđeni na opremi pre regulatora i blokadnog

mehanizma ( EN 12186 i EN 12279).

Pre početka izvođenja montaže, pregleda ili održavanja, lice mora da:

- proveri sigurnosne uslove koji se odnose na instalaciju u kojoj treba da radi

- ukoliko je potrebno, pribavi sve dozvole za rad

- koristi neophodnu zaštitnu opremu

- obezbedi da prostor u kome se radi ima uređaje za opštu bezbednost i uređaje za sigurnosnu indikaciju

Pre montaže regulatora potrebno je obezbediti:

- očistiti cevovode, proveriti da li je regulator čist i da nije oštećen prilikom transporta

- da se regulator može postaviti na predviđeno mesto

- da su ulazni i izlazni cevovodi saosni

- da su ulazna i izlazna prirubnica paralelne i čiste

- proveriti podatke na tablici regulatora, da li se slažu sa zahtevanim radnim parametrima

- proveriti da li je smer proticanja gasa istog smera kao i strelica na telu regulatora

Oprema pod pritiskom mora biti instalirana na mestima neugroženim seizmičkom aktivnošću, ne sme biti

izložena požaru i mora biti obezbeđena električna izolovanost i katodna zaštita.

Regulator može biti montiran i u drugim položajima (konsultovati tehnička lica GasTeh-a)

Pre puštanja u rad regulatora i blokadnog mehanizma, impulsni vodovi moraju biti povezani sa impulsnim

priključcima na cevovodu. Impulsni vodovi treba da se izvedu cevima od nerđajućeg čelika ili bakarnim

cevima unutrašnjeg prečnika najmanje 8 mm.

GT-121-02 9

COMMISSIONING

After installation check that the inlet/outlet on/off valves , by-pass and other lines are closed.

The regulator and safety shut-off device is factory set at approximately the midpoint of the pressure

requested, so an initial adjustment may be required to give the desired results.

With proper installation completed, slowly open the inlet valve.

To relatch safety shut-off device, remove handle (H) from lower blocade housing (B) (see Picture A.).

Rotate handle and screw it onto rod (R) (see Picture B.). Slowly pull handle to the moment when gas

flow through pad unit and keep it in this position several seconds until pressures stabilize, then

completely move handle in open position and release it (see Picture C.). Properly worked safety shut-off

device remain latched. Then unscrew handle from rod and screw it into blocade housing.

Slowly open the outlet valve and monitor pressure with a pressure gauges.

Picture A. / Slika A. Picture B. / Slika B. Picture C. / Slika C.

PUŠTANJE U RAD

Nakon instalacije, proveriti da li su ulazna/izlazna slavina, by-pass linije i ostale linije zatvoreni. Regulator

i blokadni mehanizam su fabrički podešeni na sredinu zahtevanog opsega pritisaka, tako da je možda

potrebno eventualno malo podešavanje da bi se ostvario zahtevani pritisak. Nakon uspešno izvedene

instalacije, polako otvoriti ulaznu.

Deblokiranje blokadnog mehanizma vrši se na sledeći način (prikazano na slikama A., B. i C.). Skinuti

ručni potezač (H) sa donjeg kućišta blokade (B) (videti sliku A.). Okrenuti ručni potezač i navrnuti ga na

osovinicu (R) (videti sliku B.). Polako povući ručni potezač toliko da gas može da prestrojava kroz pečurku

blokade i zadržati ga nekoliko sekundi u tom položaju dok se pritisci ne izjednače, onda izvući ručni potezač

do kraja, zatim pustiti potezač (videti sliku C.). Ispravan blokadni mehanizam ostaje u zabravljenom

položaju. Odvrnuti ručni potezač sa osovinice i ponovo ga uvrnuti u donje kućište blokade.

Polako otvoriti izlaznu slavinu i pratiti pritisak pomoću manometara.

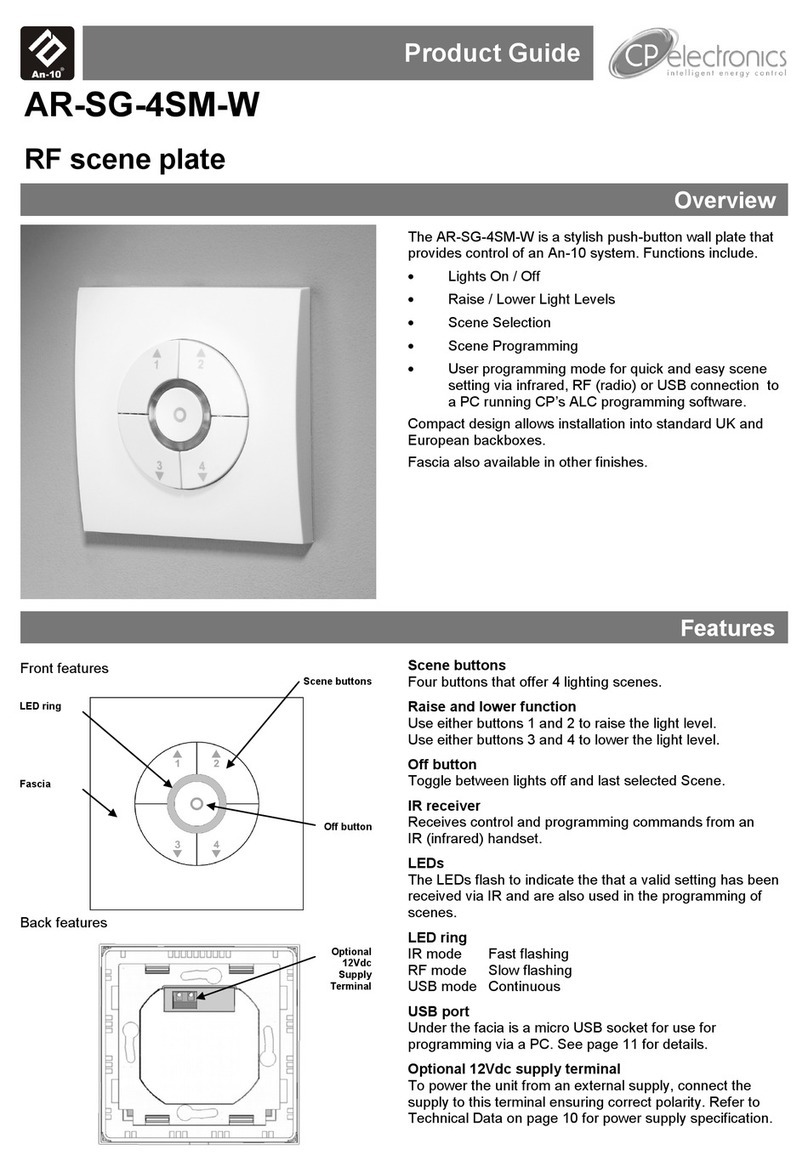

ADJUSTMENT (Picture 2.)

To change the outlet pressure, remove the cover (18) from upper housing (23) and turn the adjusting screw

(17) clockwise to increase outlet pressure or counter clockwise to decrease outlet pressure. Setting pressure

monitor with a test gauge downstream the regulator.

PODEŠAVANJE (Slika 2.)

Za podešavanje izlaznog pritiska potrebno je prvo skiniti poklopac (18) sa kućišta opruge (23). Okretanjem

pritezača opruge (17) u smeru kazaljke na satu dolazi do povećanja izlaznog pritiska, dok okretanjem u

suprotnom smeru, izlazni pritisak opada. Podešavanje pritiska se prati na manometru iza regulatora.

GT-121-02 10

DECOMMISSIONING

WARNING! To avoid personal injury resulting from sudden release of pressure, isolate the regulator from

all pressure before attempting disassembly and release trapped pressure from the regulator and pressure

line.

In case of disassembly of main pressure retaining parts for checks and maintance procedures, exernal and

internal tightnes tests have to be done according applicable codes.

ISKLJUČIVANJE

UPOZORENJE! Da bi se izbegle povrede radnika nastale neočekivanim povećanjem pritiska, potrebno je

regulator izolovati od svih mogućih pritisaka, i nakon toga ispustiti pritisak iz regulatora i linije.

Nakon demontaže glavnih delova regulatora koji su izloženi pritisku, potrebno je uraditi ispitivanje

nepropusnosti u skladu sa primenjenim standardima.

CHECKS AND MAINTENANCE

WARNING! Maintenance should be carried out only by qualified, skilled personnel.

It is recommended that the regulator be periodicly checked in order to ensure its proper functioning. The

frequency of inspection/checks and replacement depends upon severity of service conditions and upon

applicable standards and regulations. Regulator and its pressure accessories are subjected to wear and must

be inspected periodicly and replaced as necessary. Before carrying out maintenance, be sure that no gas

under pressure is trapped in the regulator. First close inlet and outlet valve and then release gas from the

line by opening the vent line.

Maintenance operations do not require removal the body from the line.

When carrying out maintenance procedures, replace all rubber parts.

Regulator drawing and specifications are required to start with maintenance.

Checking regulator

Slowly close the outlet valve and check pressure with a test gauge downstream the regulator. If the system

is functioning properly, an increase in outlet pressure will be noticed due to lock-up pressure, after which

pressure will stabilize. If pressure value is constant, in range of lock-up pressure class (SG), regulator is

functioning properly. If outlet pressure increase, more than defined in lock-up pressure class (AG), slowly

close inlet valve and call service personel from GasTeh to carry out general maintenance of regulator. For

checking function of regulator, slowly close outlet valve, and open relief valve downstream

the regulator, and check pressure oscilating. If presure is constant, regulator is functioning properly. If

pressure value oscillates, slowlyclose inlet valve and call service personel from GasTeh to carryout general

maintenance of regulator.

General maintenance of regulator

General maitenance of regulator is possible in following order (see regulator drawing - Picture 2.):

- remove screws (32) and washers (33) from body (01)

- disassembly body (01) and diaphragm housing (07)

- check pad unit (03)

- unscrew nozzle (02), check O-ring (45), if necessary, replace nozzle

- remove cover (18), unscrew adjusting ring (17) and remove spring (38)

- remove screws (32), nuts (33) and washers (34) from diphragm housings

- remove upper diaphragm housing (22)

GT-121-02 11

- remove diaphragm assembly and check diaphragm (12)

- check all seals from removed parts

- remove screws (49) and washers (50)

General maintenance of safety shut-off device is possible in following order (see safety shut-off device

drawing - Picture 3.):

- safety shut-off device is previously disassembled from regulator body

- check pad unit (15) and replace if neccesary

- remove cover (20), unscrew adjusting ring (10) and (11), and remove springs (26) and (27)

- remove screws (21),

- remove upper housing (09)

- remove and check diaphragm (18) assembly

- remove screw (24) and remove subassembly I

- remove handle (07) and retaining ring (36)

- remove rod guide (04) and (05)

- remove and check rod (03)

- check all seals from removed parts

General maintenance of subassembly of safety shut-off device (see subassembly drawing –Picture

4.)

- remove reataining ring (09) and lever washer (08)

- remove lever (05)

- and unscrewlock carrier cover (06)

- remove spring housing (02) and rod (01)

- remove elastic washer (10) and check tooth (03)

- check spring (07) and all other parts for damages

Reassembling

Reassemble parts by carrying out steps mentioned above in reverse order. Take care that:

- all seals are lubricated

- diaphragm are properly fitted in housing

- all screws are tightened

- check leaks with soapy water

Setting

After reassembling the equipment, set the outlet pressure in following order:

- install pressure gauge downstream of regulator

- set outlet pressure by rotating adjusting ring (17)

- if necessary replace spring (38)

- set safety shut-off device pressure

PREGLEDI I ODRŽAVENJE

UPOZORENJE! Održavanje mogu da izvode samo stručna i osposobljena lica.

GT-121-02 12

Preporučuje se povremena provera rada regulatora kako bi se obezbedilo njegovo ispravno funkcionisanje.

Učestanost pregleda i zamena delova zavisi od više uslova i primenjenih regulativa i standarda. Delovi

regulatora izloženi su habanju i moraju periodično biti kontrolisani i zamenjeni ukoliko je potrebno. Pre

početka kontrolisanja proveriti da regulator nije pod pritiskom. Zatvoriti ulaznu i izlaznu slavinu i preko

ispusnog voda isprazniti liniju.

Za operacije održavanja regulatora na terenu, regulator nije neophodno skidati sa linije.

Prilikom izvođenja održavanja potrebno je sve delove od gume zameniti novim.

Prilikom izvođenja održavanja potrebno je imati uputsvo za rukovanje sa crtežom regulatora i spiskom

sastavnih delova.

Pregled regulatora

Prilikom pregleda regulatora, polako zatvoriti izlaznu slavinu iza regulatora i kontrolisati vrednost pritiska

pomoću manometra iza regulatora. Ako je vrednost pritiska konstantna, i u okviru zatvorne grupe (ZG),

rad regulatora je ispravan. Ukoliko vrednost izlaznog pritiska raste izvan granice zatvorne grupe (ZG),

rad regulatora nije ispravan i potrebno je zatvoriti ulaznu slavinu pre regulatora. Regulator je potrebno

servisirati i u tom slučaju pozovite stručno osoblje iz GasTeh-a. Za proveru rada regulatora, zatvorite

izlaznu slavinu iza regulatora i pomoću odušne slavine posle regulatora, otvaranjem iste, proveriti rad

regulatora. Ukoliko je rad regulatora bez oscilacija, rad je ispravan. Ukoliko rad regulatora ima oscilacije,

regulator je potrebno servisirati i u tom slučaju pozovite stručno osoblje iz GasTeh-a.

Održavanje regulatora

Održavanje regulatora se vrši sledećim redosledom (pogledati crtež regulatora – Slika 2.):

- skinuti vijke (32) i podloške (33) sa tela regulatora (01)

- odvojiti telo (01) i kućište membrane (07)

- prekontrolisati pečurku (03)

- odvrnuti diznu (02), proveriti o-prsten (45) i po potrebi zameniti diznu

- skinuti poklopac (18), odviti pritezač opruge (17) i izvaditi oprugu (38)

- skinuti vijke (32), navrtke (33) i podloške (34) sa kućišta membrane

- skinuti kućište membrane gornje (22)

- skloniti membranski sklop i proveriti membranu (12)

- proveriti zaptivke i zaptivne površive na svim rastavljenim delovima

- skinuti vijke (49) i podloške (50)

Održavanje blokadnog mehanizma

Održavanje blokadnog mehanizma se vrši sledećim redosledom (pogledati crtež blokadnog mehanizma

–Slika 3.):

- blokadni mehanizam je prethodno skinut sa tela regulatora

- proveriti pečurku (15) i zameniti po potrebi

- skinuti poklopac (20), odviti pritezače opruga (10) i (11), i izvaditi opruge (26) i (27)

- skinuti vijake (21),

- skinuti gornje kućište (09)

- skinuti membranski sklop, proveriti membranu (18)

- skinuti vijak (24) i skloniti podsklop I

- skinuti ručni potezač (07) i seger (36)

- skinuti vođice trna (04) i (05)

- skinuti i proveriti trn (03)

- proveriti zaptivke i zaptivne površive na svim rastavljenim delovima

GT-121-02 13

Održavanje podsklopa I blokadnog mehanizma (pogledati crtež podsklopa I – Slika 4.)

- skinuti seger (09) i podlošku poluge (08)

- ukloniti polugu (05)

- skinuti poklopac nosača brave (06)

- skinuti kućište opruge (02) i trn (01)

- skinuti elastičnu čiviju (10) i proveriti zubac (03)

- proveriti oprugu (07) i proveriti oštećenost ostalih delova

Montaža posle održavanja

Sklopiti sastavne delove regulatora i blokadnog mehanizma redosledom suprotnim od gore navedenog.

Obratiti pažnju da:

- sve zaptivke budu namazane mašću

- membrana bude ispravno postavljena u kućištu membrane

- svi vijci budu dovoljno pritegnuti

- proveriti nedozvoljeno isticanje gasa pomoću sapunice

Podešavanje posle montaže

Posle montaže, potrebno je podesiti vrednost izlaznog pritiska na sledeći način:

- postaviti manometar na liniju iza regulatora

- podesiti izlazni pritisak okretanjem pritezača opruge (17)

- ukoliko je potrebno zameniti oprugu odgovarajućom

GT-121-02 14

TROUBLE-SHOOTING / MOGUĆI PROBLEMI

In table 4. are showed possible problems with regulator and safety shut-off device that can arise over time.

U tabeli 4. prikazani su mogući problemi koji mogu da nastanu pri radu regulatora i blokadnog mehanizma.

REGULATOR (Picture 2.)/ REGULATOR (Slika 2.)

PROBLEM / PROBLEM

POSSIBLE CAUSES /

MOGUĆI UZROCI

REMEDY/ REŠENJE

No tightnes(Q=0) /

Ne zaptiva (Q=0)

Internal tightnes/

Unutrašnje zaptivanje

Nozzle (02) or Pad unit (03)

damaged / Dizna (02) ili pečurka

(03) oštećena

Replace / Zameniti

Diaphragm (12) damaged /

Membrana (12) oštećena

Replace / Zameniti

O-ring (45) damaged /

O-prsten (45) oštećen

Replace / Zameniti

Internal parts oscilating /

Oscilovanje unutrašnjih delova

Friction of the rod (4) and rod

guide (6) / Trenje između trna (4) i

vođice (6)

Clean or replace, put lubricant /

Očistiti ili zameniti, podmazati

No tightnes (Q>0) /

Ne zaptiva (Q>0)

External tightnes/

Spoljašnje zaptivanje

O-ring (46) or (47) damaged /

O-prsten (46) ili (47) oštećen

Replace / Zameniti

Diaphragm (12) damaged /

Membrana (12) oštećena

Replace / Zameniti

Outlet pressure decrease / Izlazni

pritisak opada

Inlet filter is clogged / Filter na

ulazu je zaprljan

Clean the filter cartridge/ Očistiti

filter

Regulator capacity is low / Kapacitet

regulatora nije zadovoljavajući

See Technical manual (tables 4-7) /

Videti tehnički katalog (tabele 4-7)

Outlet pressure increase /

Izlazni pritisak raste

Diaphragm (12) is damaged /

Membrana (12) je oštećena

Replace / Zameniti

Nozzle (02) and pad unit (03) are

damaged / Dizna (02) i pečurka (03)

su oštećene

Replace / Zameniti

Dirt on nozzle (02)/ Nečistoće na

dizni (02)

Clean / Očistiti

No flow through regulator /

Nema protoka kroz regulator

Regulator is not properly installed /

Regulator nije dobro instaliran

See Installation in this manual /

Pogledati u prospektu Ugradnja

SAFETY SHUT-OFF DEVICE (Pictures 3. and 4.)/ BLOKADNI MENANIZAM (Slike 3. i 4.)

No tightnes (Q>0) /

Ne zaptiva (Q>0)

O-ring (29- 34) damaged (Pic.3.)/

O-prsten (29- 34) oštećen (Slika 3.)

Replace / Zameniti

Diaphragm (18) damaged (Pic.3.)/

Membrana (18) oštećena (Slika 3.)

Replace / Zameniti

Safety shut-off device doesn´t

work /Blokadni mehanizam ne

radi

Pressure improperly setted (Pic.3.)/

Pritisak aktiviranja nije dobro

podešen (Slika 3.)

Adjust springs (26) and (27) by

adjusting rings (10) and (11) /

Podesiti opruge (26) i (27)

okretanjem pritezača (10) i (11)

Safety shut-off device improperly

work /Blokadni mehanizam ne radi

ispravno

Friction between rod (03) and rod

guide (04) and (05) (Pic.3.)/ Trenje

između trna (03) i vođica trna (04) i

(05) (Slika 3.)

Clean or replace, put lubricant /

Očistiti ili zameniti, podmazati

Safety shut-off device is

activated (is not possible to

deactivate) / Blokadni

mehanizam je aktiviran i ne može

se deaktivirati

Tooth (03) is stacked in lock carier

(04) (Pic.4.)/ Zubac (03) je

zaglavljena u nosaču brave (03)

(Slika 4.)

Clean or replace /

Očistiti ili zameniti

Table 4. / Tabela 4.

GT-121-02 15

REGULATOR DRAWING / CRTEŽ REGULATORA

Picture 2. / Slika 2.

Table 5. / Tabela 5.

010203040506

0708

09

21301039111213

14 15

35

43

36

37

16

38

23

17

18

34

33

32

48

19

44

20

45

46

47

32

33

31

40

44

22

41

42

28

27

24

S u ba sse m b ly 0 1

49

50

10

25

26

29

52.

Elastic washer / Elastična podloška

S270MC

51.

Screw / Zavrtanj

Class 8.8

50.

Elastic washer / Elastična podloška

CS270MC

49.

Screw / Zavrtanj

Class 8.8

48.

Impulse connection / Impulsni priključak

S235JR

47.

“O”- ring sealer / “O” - prsten

80NBR 14.1

46.

“O”- ring sealer / “O” - prsten

80NBR 14.1

45.

“O”- ring sealer / “O” - prsten

80NBR 14.1

44.

Nut / Navrtka

Class 5

43.

‘O”-ring sealer / “O” - prsten

80NBR 14.1

42.

Washer- wide / Podloška – široka

S235JR

41.

Screw / Zavrtanj

Class 8.8

40.

Impulse pipe / Impulsna cev

P235TR1

39.

Elastic pin / Elastična čivija

S270MC

38.

Regulator spring / Opruga regulatora

Spring steel wire

37.

Vent valve spring / Opruga odušnog ventila

Spring steel wire

36.

Elastic washer / Elastična podloška

S270MC

35.

Screw / Zavrtanj

Class 8.8

34.

Nut / Navrtka

Class 5

33.

Elastic washer / Elastična podloška

S270MC

32.

Screw / Zavrtanj

Class 8.8

31.

Elastic pin / Elastična čivija

S270MC

30.

Elastic pin / Elastična čivija

S270MC

29.

Vent valve screw / Vijak dsajnog ventila

CW614N

28.

Retaining ring / Uskočnik

S270MC

27.

Vent valve diaphragm / Membrana

razrezana

745 YG 290

Po

s

Part name / Naziv pozicije

Material

26.

Vent valve body / Telo disajnog ventila

ABS

25.

Vent valve washer / Pločica disajnog ventila

CW614N

24.

Distancer / Podmetač

CW614N

23.

Spring housing / Kućište opruge

AlSi10Mg

22.

Upper diaph. housing / Kuć. membrane

gornje

AlSi10Mg

21.

Pin / Osovinica

X5CrNi18-10

20.

Spring support / Podmetač osig. opruge

ABS

19.

Central screw / Centralni zavrtanj

S235JR

18.

Cover / Poklopac

ABS

17.

Adjustment ring / Pritezač opruge

S235JR

16.

Locking nut / Priteznica

CW614N

15.

Central guide / Centralna vođica

CW614N

14.

Spring support / Podmetač opruge

DC01

13.

Diaphragm plate / Tanjir membrane

DC01

12.

Rolled diaphragm / Rolovana membrana

745 YG 290

11.

Lever pusher / Potiskivač poluge

CW614N

10.

Spacer / Rolnica

CW614N

09.

Lever / Poluga

DC01

08.

Rod extension / Nastavak trna

S235JR

07.

Lower diaph. housing / Kuć. membrane

donje

AlSi10Mg

06.

Rod guide / Vođica trna

CW614N

05.

Rod guide carrier / Nosač vođice trna

EN AW 2030

04.

Rod / Trn

X5CrNi18-10

03.

Pad unit / Pečurka

S235JR

02.

Nozzle / Dizna

CW614N

01.

Body / Kućište regulatora

ASTM A

352LCB

Pos

Part name / Naziv pozicije

Material

GT-121-02 16

SAFETY SHUT-OFF DEVICE DRAWING / CRTEŽ BLOKADNOG MEHANIZMA

(In previous drawing marked as Subassembly 01) / (U prethodnom crtežu označeno Subassembly 01)

Picture 3. / Slika 3.

Table 6. / Tabela 6

S ubassem bly II

08

15

06

37

21

03

28 05 34 31 01 25 35 24 29 04 32

36

33

07

02

18

14

12

23

22

27

26

09 20 11 10 19 13

30

S ubassem bly I

19.

Upper spring support / Podmetač opruge gornji

S235JRG2

18.

Diaphragm / Menbrana

745 YG 290

17.

16.

15.

Pad unit / Pečurka

CW614N

14.

Diaphragm support / Podmetač mrembrane

DC01

13.

Spring carrier / Nosač opruga

EN AW 2030

12.

Spring support / Podmetač opruge

CW614N

11.

Adjusting ring VP / Pritezač opruge VP

S355J2G3

10.

Adjusting ring NP / Pritezač opruge NP

CW614N

09.

Upper housing / Kuć. blokade gornje

EN AW 2030

08.

Trigger spring support / Podmetač opr. okid.

S235JRG2

07.

Handle / Ručni potezač

CW614N

06.

Rod extension / Nastavak osovinice

CW614N

05.

Rod inlet guide / Ulazna vođica osovinice

CW614N

04.

Rod guide / Vođica osovinice

CW614N

03.

Rod / Osovinica

X5CrNi18-10

02.

Diaphragm carrier / Nosač membrane

EN AW 2030

01.

Lower blockade housing / Kuć. blokade donje

AlSi10Mg

Pos.

Part name / Naziv pozicije

Material

37.

Retainer ring / Seger

S270MC

36.

Retainer ring / Seger

S270MC

35.

Ermeto joint / Ermeto spoj

S235JR

34.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

33.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

32.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

31.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

30.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

29.

“O”-ring sealer / „O“ – prsten

80NBR 14.1

28.

Trigger spring / Opruga okidanja

Spring steel

wire

27.

Spring NP / Opruga NP

Spring steel

wire

26.

Spring VP / Opruga VP

Spring steel

wire

25.

Ball / Kuglica

100Cr2

24.

Screw / Zavrtanj

Class 8.8

23.

Elastic washer / El. podloška

S270MC

22.

Nut / Navrtka

Class 8

21.

Screw / Zavrtanj

Class 8.8

20.

Cover / Poklopac

ABS

Pos.

Part name / Naziv pozicije

Material

GT-121-02 17

SAFETY SHUT-OFF DEVICE SUBASSEMBLY DRAWING / CRTEŽ PODSKLOPA

BLOKADNOG MEHANIZMA

(In previous drawing marked as Subassembly I) / (U prethodnom crtežu označeno Subassembly I)

Picture 4. / Slika 4.

Table 7. / Tabela 7.

08 09

01

05

06

02

04

10

03

11

07

11.

Spring / Opruga

Spring steel wire

10.

Elastic washer / Elastična čivija

S270MC

09.

Retaining ring / Uskočnik

S270MC

08.

Lever washer / Podloška poluge

CW614N

07.

Spring / Poklopac nosača brave

Spring steel wire

06.

Lock carrier cover / Poklopac nosač brave

CW614N

05.

Lever / Poluga

CW614N

04.

Lock carrier / Nosač brave

CW614N

03.

Tooth / Zubac

X20Cr13

02.

Spring housing / Kućište opruge

CW614N

01.

Rod / Trn

X5CrNi18-10

Pos.

Part name / Naziv pozicije

Material

GT-121-02 18

SAFETY SHUT-OFF DEVICE SUBASSEMBLY II DRAWING / CRTEŽ PODSKLOPA II

BLOKADNOG MEHANIZMA

(In previous drawing marked as Subassembly II) / (U prethodnom crtežu označeno Subassembly II)

Picture 5. / Slika 5.

Table 8. / Tabela 8.

Note/ Napomena:

For inlet pressure of 0,5 to 1 bar a reduction ring is installed / Za ulazne pritiske od 0,5 do 1 bar

ugrađuje se redukcioni prsten.

For all regulators of type 121 and 121-BV, the reduction ring is the same / Za sve regulatore tipa

121i 121-BV redukcioni prsten je isti.

Material for reducing ring is S235JRG2. / Materijal za redukcioni prsten je 235JRG2.

03

04

02

01

05

R educing ring

05.

“O”-ring sealer / „O“ - prsten

NBR80 14.1

04.

Spring / Opruga

51CrV4

03.

Button / Dugme

X20Cr13

02.

Body / Telo

CW614N

01.

Rod / Trn

X5CrNi18-10

Pos.

Part name / Naziv pozicije

Material

GT-121-02 19

SPARE PARTS

For spare parts see specification list in Table 5, 6, 7 and 8. (also see Picture 2, 3, 4 and 5.)

The following description should be used when ordering spare parts:

- Type of regulator

- Serial number and year of manufacture

- Type of fluid

- Position No.

- Quantity

Spare parts storage shall be done by proper procedures according to national standards to avoid any damage

of spare parts. Space for storage spare parts shall be dry, with normal temperature and with enough space

to avoid mechanical or any other damage of spare parts.

REZERVNI DELOVI

Spisak delova možete pogledati tabeli 5, 6, 7 i 8 (kao i na slikama 2, 3, 4 i 5.)

Prilikom poručivanja rezervnih delova navesti:

- tip regulatora

- serijski broj i godinu proizvodnje

- tip fluida

- broj pozicije

- količinu

Skladištenje rezervnih delova treba da je u skladu sa domaćim standardima, kako bi se izbegla oštećenja rezervnih

delova. Prostor za skladištenje treba da je bez vlažnosti, sa prosečnom temperaturom i sa dovoljno prostora da se

izbegnu bilo kakva oštećenja rezervnih delova.

"GasTeh" d.o,o.

Kralja Petra I b.b.

22320 Indjija

Serbia

tel/fax: +381022/561-630

e-mail: office@gasteh.com

www.gasteh.com

This manual suits for next models

1

Table of contents

Other GasTeh Controllers manuals