Gatan PIPS II 695 Guide

Pr

e

e

cisio

Ow

n

G

5

P

n Io

n

n

er’s

M

G

atan,

I

5

794 W. Las

P

leasanton,

C

n

Poli

s

M

anual

a

I

nc.

s

Positas Bl

v

C

A 94588

s

hing

a

nd Us

e

Part N

u

v

d. Tel.

(

Fax.

PIPS

Syst

e

e

r’s G

u

u

mber 695.

8

Revisi

o

3/15

/

(

925)463-0

2

(925)463-0

2

II

e

m

u

ide

8

2001

o

n 4.0

/

2014

2

00

2

04

2

PIPS II Owners Manual and Users Guide

PIPS II

O

Sy

m

S

s

ym

I

M

in

s

pr

O

wners Ma

n

T

h

m

h

a

e

q

m

bols a

n

Y

o

p

r

S

YMBOL

C

A

m

bol is ma

r

M

PORTAN

T

s

tructions

oduct. Rev

n

ual and Us

e

S

h

is chapter

anual. Gata

n

a

rm to your

s

q

uipment as

w

n

d Atte

n

o

u must be

a

r

ovides vari

o

REFERE

N

IEC 60417

IEC 60417

IEC 60417

IEC 60417

A

UTION -

D

r

ked.

T

- For

please re

f

iew this do

c

e

rs Guide

S

afety

presents a

n

, Inc., reco

s

elf or the e

q

w

ell.

n

tion S

y

a

ware of sa

f

o

us procedu

r

N

CE

-5031 (200

2

-5032 (200

2

-5033 (200

2

-5017 (200

6

D

ocument

a

Re

g

ulator

y

f

er to th

e

c

ument in f

u

Infor

m

summary

o

mmends fo

l

q

uipment. P

y

mbols

f

ety when y

o

r

es that requ

i

2

-10)

2

-10)

2

-10)

6

-08)

a

tion must

b

y

Complia

n

e

R

e

g

ulat

o

u

ll before i

n

m

atio

n

o

f the safe

l

lowing all

s

lease follo

w

o

u install an

d

i

re careful a

t

b

e consult

e

n

ce and

o

r

y

Pamp

h

n

stallin

g

an

d

n

ty symbols

s

afety prec

a

w

all warnin

g

d

use this s

y

ttention to

p

D

D

A

c

u

B

a

l

c

u

E

T

e

d in all c

a

Safet

y

inf

o

h

let provi

d

d

operatin

g

throughou

t

a

utions to pr

g

s marked

o

y

stem. This

G

p

recautions.

D

ESCRIPTI

O

D

irect curre

n

A

lternating

u

rrent

B

oth direct a

n

l

ternating

u

rrent

E

arth (gro

u

ERMINAL

a

ses where

o

rmation

d

ed with

g

this produ

3

t

this

r

event

o

n the

G

uide

O

N

n

t

n

d

u

nd)

this

and

this

ct.

PIPS II

O

Pr

o

O

wners Ma

n

o

duct S

a

R

e

p

r

u

s

c

o

w

i

lo

w

a

a

n

n

ual and Us

e

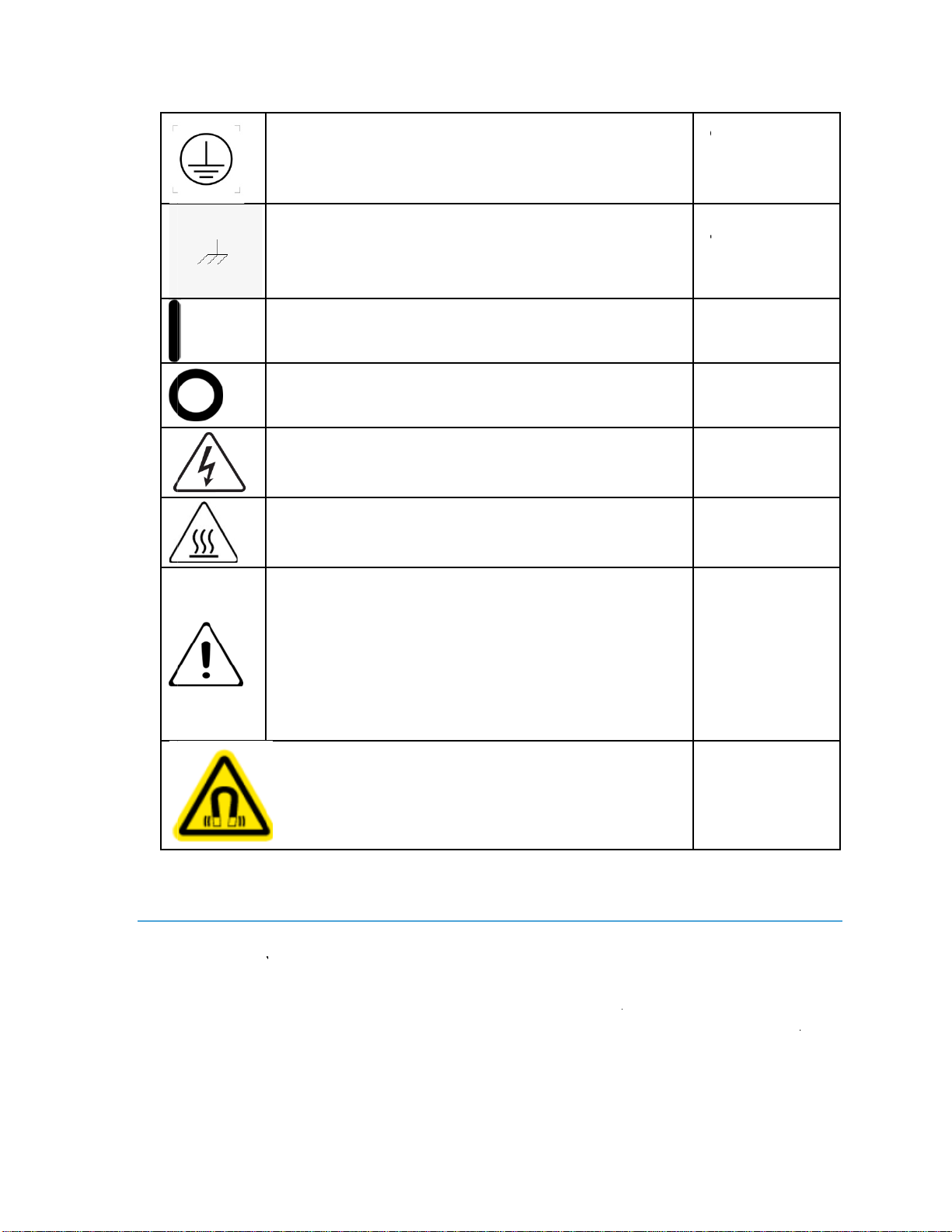

IEC 60417

IEC 60417

IEC 60417

IEC 60417

IEC 60417

ISO 7000-

0

a

fety Inf

o

e

view the f

o

r

oduct, or a

n

s

e the produ

c

o

mponent p

r

i

th safety s

y

cations wit

h

a

rnings and

n

d frequenc

y

e

rs Guide

-5019 (200

6

-5020 (200

2

-5007 (200

9

-5008 (200

9

-5041 (200

2

0

434B (200

4

o

rmatio

o

llowing pr

e

n

y products

t

c

t only as s

p

r

oduct use

r

y

mbols, writ

t

h

in the unit.

instruction

s

y

of your

p

6

-08)

2

-10)

9

-02)

9

-02)

2

-10)

4

-01)

n

e

cautions to

t

o which it

i

p

ecified. Re

a

manuals an

d

t

en warning

Save this d

o

s

marked o

n

p

ower sour

c

avoid injur

y

i

s connecte

d

ad all safet

y

d understan

s, and cauti

o

ocument fo

r

n

the equip

m

c

e matches

P

C

T

F

T

O

O

C

p

e

l

C

s

u

C

d

m

c

o

c

a

s

y

m

C

m

y

and preve

n

d

. To avoid

p

y

informatio

n

n

d the preca

u

o

ns before

a

r

future refe

m

ent. Ensur

e

the voltag

e

P

rotective

C

onductor

T

erminal

F

rame or ch

a

ERMINAL

O

n (Power)

O

ff (Power)

C

aution,

ossibility o

f

l

ectric shoc

k

C

aution,

u

rface

C

aution -

ocumentati

o

m

ust be

o

nsulted in

a

a

ses where

t

y

mbol is

m

arked

C

aution,

m

agnetic fiel

n

t damage t

o

p

otential ha

z

n

provided

i

u

tions asso

c

a

ccessing p

a

rence. Foll

o

e

that the v

o

e

and freq

u

4

a

ssis

f

k

hot

o

n

a

ll

t

his

d.

o

this

z

ards,

i

n the

c

iated

a

rts or

o

w all

o

ltage

u

ency

PIPS II

O

O

wners Ma

n

in

ki

n

p

r

c

a

Da

n

spe

c

Do

N

do

n

To

A

con

d

ma

k

gro

u

Do

n

Dis

c

Sho

u

wip

e

Wa

r

not

ter

m

Ele

c

stati

clot

h

Wh

e

stra

p

disc

h

To

a

an e

n

ual and Us

e

scribed on t

h

n

d through

r

esent. Con

d

a

use fire, ele

c

ng

er: Disco

n

c

ified on the

N

ot Operat

e

n

ot operate t

h

A

void the

R

d

ensing co

n

k

e connectio

n

u

nded plug (

t

n

ot operate

i

c

onnect all e

u

ld a leak o

c

e

to clean u

p

r

nin

g

:To a

v

make conn

e

m

inal. See th

e

c

tronic com

p

c electricit

y

h

ing or wor

k

e

n installing

p

s and ant

h

arge.

a

void injury

x

plosive at

m

e

rs Guide

h

e equipme

n

the openin

d

uctive fore

i

c

trical shoc

k

n

nect power

product's r

a

e

Without

C

h

is product

w

R

isk of Ele

c

n

ditions. W

h

n

s to a grou

n

t

hird groun

d

i

n wet, dam

p

xternal pow

c

cur, remov

e

p

the spill.

v

oid electri

c

e

ctions to t

e

e

product us

p

onents on p

. Ordinary

a

k

environme

the board i

n

i-static ma

t

, fire hazar

d

m

osphere.

n

t's electric

a

gs in the

e

i

gn objects

c

k

, or damag

e

before repl

a

a

ting label.

overs: To a

v

w

ith any re

m

c

tric Shock:

h

en supplyi

n

n

ded main.

A

d

ing pin).

p

, or conden

s

er connecti

o

e

power fro

m

c

al hazards (

e

rminals o

u

er manual f

o

rinted circu

i

a

mounts of

s

nt can dam

a

n

a system,

y

t

s to prev

e

d

, or explos

i

a

l rating lab

e

e

quipment.

D

c

ould prod

u

e

your equip

a

cing fuses

a

v

oid electri

c

m

oved enclo

s

Do not op

e

n

g power

t

A

lways use

a

s

ing conditi

o

o

ns before s

e

m

PIPS. Use

(

heat, shock

u

tside the r

a

o

r correct c

o

i

t boards are

s

tatic electri

a

ge the elect

r

y

ou must u

s

e

nt damage

i

on, do not

o

e

l. Never p

u

D

angerous

v

u

ce a short

c

ment.

a

nd only use

c

shock or

f

s

ure covers

o

e

rate in we

t

t

o the syst

e

a

power cab

l

o

ns.

e

rvicing.

paper towe

l

and/or fire

h

a

nge specifi

e

o

nnections.

e

extremely

s

city genera

t

r

onic equip

m

s

e anti-static

due to e

o

perate this

u

sh objects

o

v

oltages m

a

c

ircuit that

c

value

f

ire hazard,

o

r panels.

t

, damp, or

em

, always

le with

a

l

s or Kem

h

azard), do

e

d for that

s

ensitive to

t

ed by your

m

ent.

grounding

e

lectrostatic

product in

5

o

f any

a

y be

c

ould

6

PIPS II Owners Manual and Users Guide

Preface

Copyright and Trademarks

© 2007 Gatan, Inc. The Gatan logo is a registered trademark of Gatan, Inc.

The product names AutoFilter, BioScan, Clipring, DigiPEELS, DigiScan,

DigitalMicrograph, DigitalMontage, Duo Mill, DuoPost, Gatan LowDose,

GIF, Hexlok, Hexring, HotHinge, MSC, PECS, PIPS, Toggle Tilt, and

Whisperlok are trademarks belonging to Gatan, Inc.

The PIPS is protected by US Patents 4,272,682; 5,009,743; and 5,472,566.

Other patents are pending.

Disclaimer

Gatan, Inc., makes no express or implied representations or warranties with

respect to the contents or use of this manual, and specifically disclaims any

implied warranties of merchantability or fitness for a particular purpose.

Gatan, Inc., further reserves the right to revise this manual and to make

changes to its contents at any time, without obligation to notify any person or

entity of such revisions or changes.

Support

Gatan, Inc. provides free technical support via phone, fax, and electronic mail.

To reach Gatan technical support, contact the facility nearest you, or send

USA, Canada and

Latin America Field Service

Gatan, Inc.

5794 W. Las Positas Blvd.

Pleasanton, CA 94588

Tel. +1 (925) 224-7360

Toll Free: +1 888-887-3377

Fax. +1 (925) 463-0204

Contact:service @gatan.com

Parts and Consumables

Gatan, Inc.

5794 W. Las Positas Blvd.

Pleasanton, CA 94588

Tel. +1 (925) 224-7314

Fax. +1 (925) 463-0204

Contact:service @gatan.com

7

PIPS II Owners Manual and Users Guide

Factory Service

Gatan, Inc.

780 Commonwealth Drive

Warrendale, PA 15086

Tel. +1 (724) 779-2552

Toll Free: +1 888-778-7933

Fax. +1 (724) 776-3360

Contact:service @gatan.com

Asia and Pacific Rim Nippon Gatan

Hibarigaokaminamikan 6F

3-27-11 Yato-cho, Nishi-Tokyo-Shi

Tokyo 188-0001 Japan

Tel: 011-81-424-38-7230

Fax: 011-81-424-38-7228

Contact:[email protected]

Gatan Singapore

10 Eunos Road 8

#12-06

Singapore Post Centre

Singapore 408600

Tel: (65) 6293 3160

Fax: (65) 6293 3307

Contact: [email protected]

Europe Gatan GmbH, München Germany

Ingolstadterstr. 12

D-80807 München

Germany

Tel. +49 89 358084-0

Fax. +49 89 358084-77

Contact: [email protected]

Gatan UK

25 Nuffield Way

Abingdon, OX14 1RL

United Kingdom

Tel. +44 1235 540160

Fax. +44 1235 540169

Contact: [email protected]

8

PIPS II Owners Manual and Users Guide

Gatan France

3bis, Chemin du Haut Breuil

78113 GRANDCHAMP

FRANCE

Tel : 33 1 34 94 44 07

Mobile : 33 6 80 13 51 39

Fax : 33 1 34 87 16 68

Contact: [email protected]

Returns

If there is a need to return equipment to the factory, please call Gatan to obtain

a Returned Merchandise Authorization Number (RMA #). This RMA number

must appear on your shipping document, to help in tracking and to ensure that

proper action will be taken to repair or replace your equipment.

9

PIPS II Owners Manual and Users Guide

Table of Contents

Safety Information....................................................................................................................... 3

Symbols and Attention Symbols ............................................................................................. 3

Product Safety Information ..................................................................................................... 4

Preface......................................................................................................................................... 6

Copyright and Trademarks...................................................................................................... 6

Disclaimer................................................................................................................................ 6

Support..................................................................................................................................... 6

Returns..................................................................................................................................... 8

Table of Contents........................................................................................................................ 9

List of Figures ........................................................................................................................... 12

List of Tables............................................................................................................................. 16

1. Overview......................................................................................................... 17

1.1. Features of the Precision Ion Polishing System.............................................. 17

1.2. Main Work Chamber ...................................................................................... 20

1.3. Vacuum System.............................................................................................. 21

1.4. Electrical system............................................................................................. 24

1.5. The Standard Operating Mode........................................................................ 25

2. Installation....................................................................................................... 26

2.1. Site Requirements........................................................................................... 26

2.2. Unpacking....................................................................................................... 27

2.3. Installation....................................................................................................... 28

3. Operation......................................................................................................... 34

3.1. Graphical User Interface (GUI)...................................................................... 34

3.2. Start-up Procedure .......................................................................................... 59

3.3. Specimen Loading and Unloading.................................................................. 61

3.4. Specimen Viewing.......................................................................................... 63

3.5. Shutter Control................................................................................................ 64

3.6. Specimen Rotation.......................................................................................... 64

3.7. Centering the x-y Stage................................................................................... 65

3.8. Centering the Point of Interest........................................................................ 66

3.9. Gun Gas-flow Adjustment.............................................................................. 69

10

PIPS II Owners Manual and Users Guide

3.10. Aligning the Beam.......................................................................................... 71

3.11. Ion-beam Modulation...................................................................................... 75

3.12. Manual Shutdown Procedure.......................................................................... 78

4. Specimen Preparation ..................................................................................... 79

4.1. Disk Preparation.............................................................................................. 79

4.2. Specimen Mounting........................................................................................ 88

4.3. Ion-beam Milling............................................................................................ 95

5. Routine Maintenance and Servicing............................................................... 98

5.1. Cleaning the Viewing Port.............................................................................. 98

5.2. Cleaning the Airlock Vacuum Seals............................................................... 99

5.3. Cleaning the Specimen-mount Assembly..................................................... 101

5.4. Cleaning the Cold-cathode Gauge Tube....................................................... 104

5.5. Cleaning the Shutter...................................................................................... 106

5.6. Care of Penning Ion Guns............................................................................. 108

5.7. Removing the Cover..................................................................................... 118

5.8. Replacing the MDP Oil Cartridge................................................................. 119

5.9. Diaphragm Pump Maintenance..................................................................... 120

5.10. Cleaning the Work Chamber ........................................................................ 121

5.11. Cleaning the Shutter Piston........................................................................... 122

5.12. Motor Drive Replacement............................................................................. 123

5.13. Replacing the Stage Encoder........................................................................ 124

5.14. Replacing the Sample Mount........................................................................ 126

5.15. Replacing the Bellows Assembly ................................................................. 128

5.16. Cleaning the Rotate-Shaft Quad-seal............................................................ 131

5.17. Checking the Specimen Height..................................................................... 131

5.18. Replacing the Gas Manifold ......................................................................... 134

5.19. Replacing a Mass Flow Controller (MFC) ................................................... 137

5.20. Replacing the Touchscreen........................................................................... 139

5.21. Replacing the High Voltage Power Supply.................................................. 141

5.22. Replacing the Control PCAs (CPU, I/O)...................................................... 142

5.23. List of O-Rings ............................................................................................. 145

5.24. List of Cables................................................................................................ 146

6. Trouble Shooting .......................................................................................... 147

7. PIPS II Options............................................................................................. 148

11

PIPS II Owners Manual and Users Guide

7.1. Cold Stage Option......................................................................................... 148

7.2. End-point Detection...................................................................................... 160

7.3. Digital Zoom Microscope Option................................................................. 163

7.4. Motorized Gun Tilt....................................................................................... 183

Gatan Hardware Product Warranty............................................................... 187

12

PIPS II Owners Manual and Users Guide

List of Figures

Figure 1-1 PIPS II, basic system, front view................................................. 17

Figure 1-2 Work chamber, top view............................................................... 20

Figure 1-3 Work chamber, cross-section view............................................... 21

Figure 1-4 Vacuum system............................................................................. 22

Figure 1-5 Gas-control system...................................................................... 23

Figure 2-1 View of connections on rear of cabinet........................................ 28

Figure 2-2 Camera system mount onto the PIPS II. ...................................... 29

Figure 2-3 Microscope front to back alignment. ............................................ 32

Figure 2-4 Microscope left to right alignment................................................ 33

Figure 3-1 Milling page.................................................................................. 34

Figure 3-2 Setting the milling duration........................................................... 35

Figure 3-3 Setting the modulation mode. ....................................................... 36

Figure 3-4 Setting the language..................................................................... 37

Figure 3-5 Recipes page.................................................................................. 38

Figure 3-6 Status bar, showing a recipe is running......................................... 38

Figure 3-7 Status bar, showing a recipe is completed successfully................ 39

Figure 3-8 Edit recipe page............................................................................. 40

Figure 3-9 Adding a recipe step...................................................................... 41

Figure 3-10. Deleting a recipe step................................................................. 41

Figure 3-11 Copying a recipe. ........................................................................ 42

Figure 3-12 Creating a new recipe: enter the name........................................ 42

Figure 3-13 Alignment page........................................................................... 43

Figure 3-14 Camera page................................................................................ 44

Figure 3-15. Viewing page. ............................................................................ 45

Figure 3-16 General Settings page.................................................................. 46

Figure 3-17 Setting the gas inlet used for the guns........................................ 46

Figure 3-18 Choosing the calibration table used for the Argon gas inlet...... 47

Figure 3-19. Milling sectors........................................................................... 48

Figure 3-20 Heaters settings page................................................................... 49

Figure 3-21 Auto-terminator page.................................................................. 49

Figure 3-22 Gas flow calibration.................................................................... 50

Figure 3-23 Motorized guns calibration. ........................................................ 51

Figure 3-24 Properly aligned stage in the Home position. ............................. 52

Figure 3-25 Stage home position calibration.................................................. 52

Figure 3-26 Temperature sensor calibration.................................................. 53

Figure 3-27 Pressure calibration..................................................................... 53

Figure 3-28 Foreline gauge calibration........................................................... 54

Figure 3-29 Cold Cathode gauge calibration................................................. 54

Figure 3-30. Vacuum page.............................................................................. 55

Figure 3-31 Gun Readings.............................................................................. 56

Figure 3-32 Gun Tilt page............................................................................... 57

Figure 3-33 Network page.............................................................................. 57

13

PIPS II Owners Manual and Users Guide

Figure 3-34 Software maintenance page......................................................... 58

Figure 3-35. Software configuration page...................................................... 59

Figure 3-36 Clock page................................................................................... 59

Figure 3-37 Milling page................................................................................ 60

Figure 3-38 Lowering the stage...................................................................... 62

Figure 3-39 Specimen mount in raised and working positions....................... 62

Figure 3-40 Camera page................................................................................ 63

Figure 3-41 Viewing page. ............................................................................ 64

Figure 3-42 Specimen mount raised and in the Home position...................... 65

Figure 3-43 x-y alignment, steps 7 (left) and 8 (right). .................................. 67

Figure 3-44 x-y alignment, steps 10 (left) and 11 (right). .............................. 68

Figure 3-45 x-y alignment, step 12................................................................. 68

Figure 3-46 x-y alignment, steps 14 (left) and 15 (right). .............................. 69

Figure 3-47 Operating characteristics of the PIG........................................... 70

Figure 3-48 X and Z-alignment device screws............................................... 72

Figure 3-49 Alignment ellipse observed in the beam..................................... 73

Figure 3-50 Gun knob with gun alignment knobs installed........................... 75

Figure 3-51 Modulation modes....................................................................... 77

Figure 3-52 Beam modulation........................................................................ 77

Figure 4-1 Gatan model 601 ultrasonic cutting tool....................................... 79

Figure 4-2 Gatan model 659.00001 disk punch.............................................. 80

Figure 4-3 Gatan model 623 disk grinder....................................................... 81

Figure 4-4 Disk grinding: initial and final...................................................... 81

Figure 4-5 Sample disk after dimple grinding (not to scale).......................... 81

Figure 4-6 Gatan model 656 dimple grinder................................................... 82

Figure 4-7 Specimen disc geometry. .............................................................. 84

Figure 4-8 Cross section specimen preparation.............................................. 86

Figure 4-9 Cross section specimen preparation.............................................. 87

Figure 4-10 Cross section specimen preparation............................................ 88

Figure 4-11 DuoPosts, glue type and clamp type........................................... 89

Figure 4-12 Clamp-type post and loading dock.............................................. 89

Figure 4-13 Mounting a sample, steps 1 and 2............................................... 91

Figure 4-14 Mounting a sample, Steps 4 and 5. ............................................. 91

Figure 4-15 Mounting a sample, step 8. ......................................................... 92

Figure 4-16 Graphite holder............................................................................ 93

Figure 4-17 Graphite holder loading dock...................................................... 93

Figure 5-1 Viewing port and o-rings. ............................................................. 99

Figure 5-2 Specimen mount removal............................................................ 103

Figure 5-3 Specimen-mount and window assembly..................................... 103

Figure 5-4 Cold-cathode gauge tube............................................................. 105

Figure 5-5 Cleaning the shutter..................................................................... 107

Figure 5-6. Removal and disassembly of ion guns....................................... 109

Figure 5-7 Ion source and magnet assembly................................................. 110

Figure 5-8 Removal of anode assembly and anode cup insulator. .............. 111

Figure 5-9 Removing anode cup assembly/front pole piece........................ 111

Figure 5-10 Focus electrode assembly......................................................... 117

14

PIPS II Owners Manual and Users Guide

Figure 5-11 Cover removal.......................................................................... 118

Figure 5-12 Molecular drag pump removal................................................. 120

Figure 5-13 Shutter servicing........................................................................ 123

Figure 5-14 Motor Drive Removal............................................................... 124

Figure 5-15 Replacing the encoder.............................................................. 126

Figure 5-16 Sample mount removal. ........................................................... 127

Figure 5-17 Whisperlok assembly............................................................... 129

Figure 5-18 checking the specimen height. .................................................. 132

Figure 5-19 Correct beam angle setting........................................................ 133

Figure 5-20 Sample height adjustment......................................................... 134

Figure 5-21 Gas manifold assembly............................................................ 135

Figure 5-22 MFC removal. Unplugging the power/signal cable from the

MFC.............................................................................................................. 138

Figure 5-23 MFC removal. Loosening the M3 screw that secures the MFC.

....................................................................................................................... 138

Figure 5-24 Touch display assembly........................................................... 140

Figure 5-25 Connections for touch display.................................................. 140

Figure 5-26 HVPS location.......................................................................... 141

Figure 5-27 Removing cables from the I/O PCA. ....................................... 142

Figure 5-28 PCA assembly.......................................................................... 143

Figure 5-29 PCA connector locations and associated cable part numbers.. 144

Figure 7-1 System with Cold Stage installed............................................... 149

Figure 7-2 Settings Page............................................................................... 152

Figure 7-3 Sample and cold conductor temperature over time..................... 154

Figure 7-4 Sample and cold conductor temperature over time..................... 155

Figure 7-5 Interior chamber showing the cold conductor with new brushes.156

Figure 7-6 Open chamber showing access to cold stage. ............................. 158

Figure 7-7. Dewar Assembly installed in manifold..................................... 159

Figure 7-8 Autoterminator sensor top view.................................................. 161

Figure 7-9 Autoterminator shown in working position................................ 162

Figure 7-10 Autoterminator page.................................................................. 163

Figure 7-11 System with digital zoom microscope. .................................... 164

Figure 7-12 DM environment....................................................................... 165

Figure 7-13 DM open image series............................................................... 167

Figure 7-14 DM standard tools..................................................................... 168

Figure 7-15 DM main menu. ........................................................................ 169

Figure 7-16 DM Histogram Window............................................................ 175

Figure 7-17 DM ROI menu........................................................................... 175

Figure 7-18 DM Slice tool............................................................................ 178

Figure 7-19 DM Slice player. ....................................................................... 178

Figure 7-20 DM video compression............................................................. 179

Figure 7-21 DM Ion Polish Control window................................................ 179

Figure 7-22 DM Ion Polish Camera Control window. ................................ 180

Figure 7-23 DM PIPS II record options window.......................................... 181

Figure 7-24 Camera page.............................................................................. 182

Figure 7-25 PIPS II with motorized gun tilt................................................ 183

15

PIPS II Owners Manual and Users Guide

Figure 7-26 Gun tilt settings......................................................................... 184

Figure 7-27 Motorized gun assemblies........................................................ 185

Figure 7-28 Gun tilt maintenance screen..................................................... 186

Figure 7-29 Gun tilt calibration screen........................................................ 186

16

PIPS II Owners Manual and Users Guide

List of Tables

Table 1 Polishing wheel diameter versus dimple depth.................................. 82

Table 2 Optimum initial specimen disc thickness.......................................... 83

Table 3 Typical Milling rates.......................................................................... 96

Table 4 Bulk/rim thickness vs. minimum milling angle................................ 96

Table 5 PIPS II milling parameters................................................................ 97

Table 6 Maintenance Operations.................................................................... 98

PIPS II

O

1.1

.

1

1

O

wners Ma

n

T

h

be

e

x

fo

F

i

.

Fea

.1.1. Dual

I

o

(

P

a

n

w

i

c

a

s

o

s

p

a

n

a

v

.1.2. Opti

m

T

h

a

n

ual and Us

e

h

e Model 6

9

e

nch-top sy

s

x

ceptionally

r PIPS II so

f

gure 1-1 PI

P

tures o

f

Ion Sourc

n polishing

P

IGs). The o

p

n

d both hav

e

i

thin this ra

n

a

pable of ve

r

o

that the x-

p

ecimen. T

h

n

gles in a r

e

v

ailable as a

n

m

um Gun

D

h

e gun’s io

n

result, gun

e

rs Guide

1.

9

5 Precisio

n

s

tem desig

n

large, clean

,

f

tware versi

o

P

S II, basic

s

f

the Pr

e

e

is done b

y

p

erating an

g

e

the ability

n

ge. The PI

G

r

y high thin

n

and z-align

h

ese feature

s

e

asonably s

h

n

optional f

e

D

esign

n

optics has

v

maintenanc

e

Ove

rv

n

Ion Polis

h

n

ed to prod

u

,

electron-tr

a

o

n 1.6.

s

ystem, fron

t

e

cision I

y

two vari

a

g

le of each

g

to center t

h

G

s incorpo

r

n

ing rates.

E

m

ent drives

s

make it

p

h

ort time.

M

e

ature.

v

irtually eli

m

e

is reduce

d

r

view

h

ing Syste

m

u

ce high-q

u

a

nsparent ar

t

view.

I

on Poli

s

a

ble-angle,

m

g

un, ± 10°, i

h

e beam on

t

r

ate powerf

u

E

ach gun is

can be use

d

p

ossible to

t

M

otorized o

p

m

inated cat

h

d

, specimen

m

(PIPS II

™

u

ality TEM

eas. This m

a

s

hing S

y

m

iniature P

s independe

t

o the speci

m

u

l rare-earth

mounted in

d

to center

t

t

hin speci

m

p

eration of

b

h

ode-apertu

r

contaminat

™

) is a co

m

specimens

a

nual was

w

y

stem

enning ion

nt of one a

n

m

en at any

magnets a

n

a universal

t

he beams

o

m

ens at ver

y

b

eam tilt an

g

r

e erosion a

n

ion from t

h

17

m

pact,

with

w

ritten

guns

n

other

angle

n

d are

joint

o

n the

y

low

g

le is

n

d, as

h

e ion

18

PIPS II Owners Manual and Users Guide

guns is minimized, and gun consumables have been eliminated. The new

focus electrodes in each gun have improved the low energy spot size, keeping

the spot size approximately constant across all beam energies. This results in

dramatically faster milling rates at low energy, such that it is now practical to

mill to perforation at energies as low as 100 eV.

1.1.3. Gas Flow Optimization

The optimum gas flow for all beam energies is calibrated at the factory, and

may be selected by using the automatic gas flow option. The gas flow of each

gun may also be set manually.

1.1.4. Compact Vacuum System

Specimen contamination is reduced with an oil-free vacuum system consisting

of a molecular drag pump (MDP) backed by a 2-stage diaphragm pump (DP).

Additionally, a liquid-nitrogen trap is available to further reduce contaminants

and water vapor.

1.1.5. Touch-screen Interface

Operation of the system is controlled by the user via a touch-screen interface,

which is customer selectable between several languages.

1.1.6. Versatile Sample Holders

The Gatan specimen post, for single-sided milling, and the DuoPost, for

double-sided milling, eliminate transfer of material onto the specimen by

secondary sputtering from the specimen platform and provide excellent

thermal contact with the specimen to prevent specimen overheating. Lastly,

both specimen posts allow the specimen to have an unobstructed view of the

ion beam and thus ion polishing can be performed at angles approaching 0°.

In order to allow for centering the thin section at the rotation axis the sample

mount includes a manual x-y stage. This allows the user to compensate for a

sample that is mounted off-axis in the post.

1.1.7. Stereo Microscope

An optional optical stereo microscope is used to inspect the specimen in its

working position at any time during the thinning process to achieve very

precise control over the final stage of specimen thinning. This feature is

especially important for insulators and semi-conductors since these materials

are transparent to light and the interference-fringe technique can be used to

control the final specimen thickness in the region of interest to an accuracy of

about ±10 nm.

19

PIPS II Owners Manual and Users Guide

1.1.8. Digital Zoom Microscope System

The Digital Zoom Microscope is a system option. This system uses a digital

camera connected to an external PC. The camera is mounted on the system

and allows for in-situ observation of the sample. In addition, the supporting

software allows for manual/automated acquisition of images, typically one

automated image per rotation. The external PC can also be used for remote

control of the PIPS II system, via remote desktop type software.

1.1.9. Autoterminator

This can be provided as an optional feature and uses the amount of light

transmitted through the sample. Milling is stopped when this reaches a

previously set value.

1.1.10. WhisperlokTM Stage

Quick specimen exchange (<30 sec) is achieved using a miniaturized version

of Gatan’s pneumatically controlled Whisperlok™. The specimen can be

easily transferred and viewed at frequent intervals during the final moments of

the thinning process.

20

PIPS II Owners Manual and Users Guide

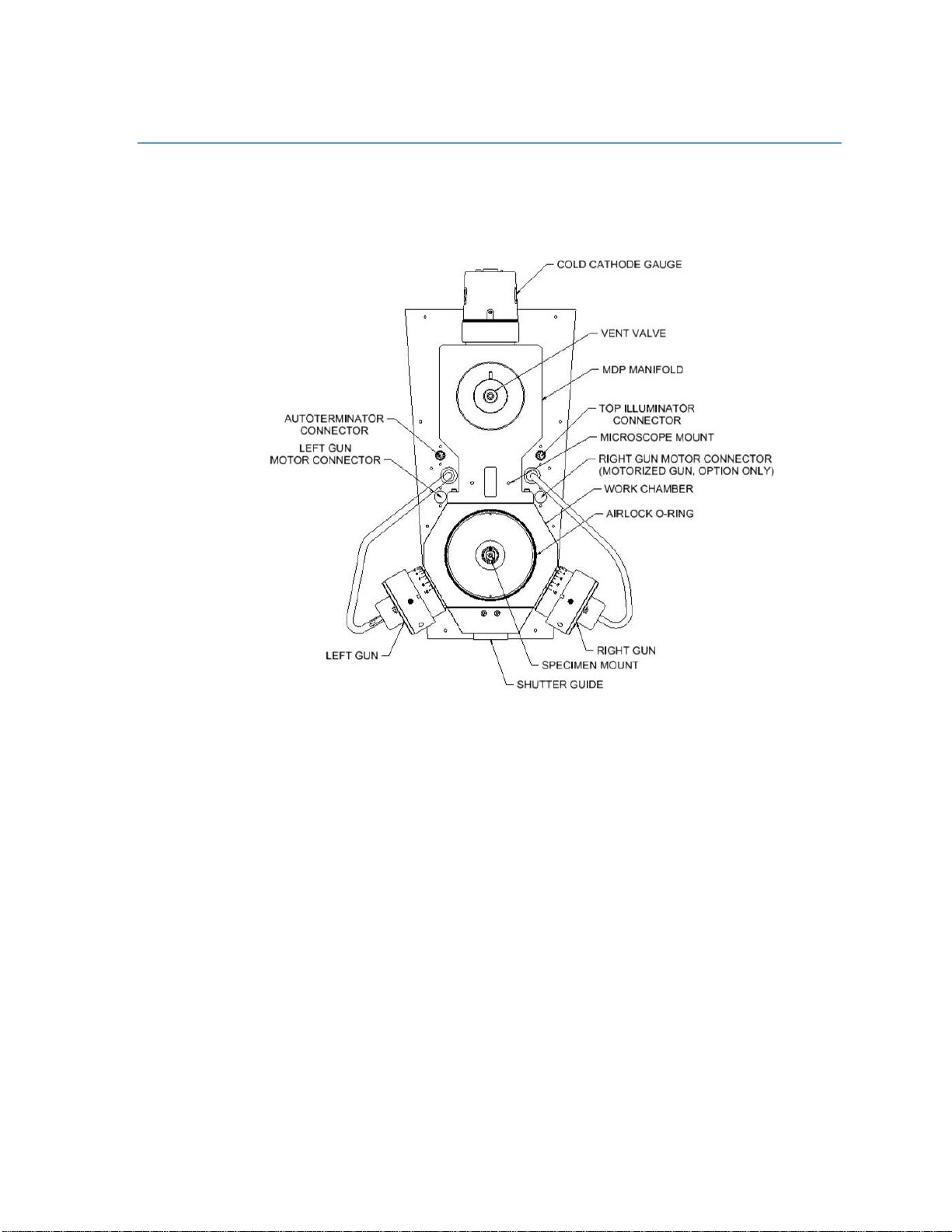

1.2. Main Work Chamber

Figure 1-2 is a top view of the PIPS II main Work Chamber. The figure shows

the right and left PIGs. The Airlock cover is removed to reveal the main

Airlock O-ring and a top view of the specimen mount.

Figure 1-2 Work chamber, top view.

Figure 1-3 is a cross-sectional view through the main Work Chamber of the

PIPS II. The Airlock cover is in place with the specimen in its working

position at the center of the Chamber.

Specimens are mounted on posts that plug into the specimen mount and can

be milled on both surfaces with proper orientation of the PIGs. One of the

PIGs is shown inclined at a positive angle (+10°) to the horizontal (beam

incident to the top surface of sample). By simply grasping the gun knob and

rotating it, the gun angle can be reduced down through 0° continuing on to a

negative angle (-10°, beam incident to the bottom surface of sample).

The Shutter is shown in its inserted position, which prevents sputtered

material from depositing on the specimen Viewing Port.

Table of contents

Other Gatan Ultrasonic Jewelry Cleaner manuals