Gatan Solarus 950 Guide

Gatan, Inc.

5794 W. Las Positas Blvd.

Pleasanton, CA 94588 Tel. (925) 463-0200

Fax. (925) 463-0204

Solarus 950

Gatan Advanced Plasma System

Owner’s Manual and User’s Guide

Part Number: 950.82001

July 2011

Revision 5

ii Solarus 950 Owner’s Manual and User’s Guide

APS Solarus 950 Owner’s Manual iii

Preface

About this Guide

This provides information on operation and basic maintenance of the Solarus

950 Advanced Plasma system.

The following typographical conventions are used for special comments:

NOTE:Recommendations for getting the best performance from the

equipment.

Disclaimer

Gatan, Inc., makes no express or implied representations or warranties with

respect to the contents or use of this manual, and specifically disclaims any

implied warranties of merchantability or fitness for a particular purpose. Gatan,

Inc., further reserves the right to revise this manual and to make changes to its

contents at any time, without obligation to notify any person or entity of such

revisions or changes.

Copyright and Trademarks

© 2007 Gatan, Inc. The Gatan logo is a registered trademark of Gatan, Inc.

The product names AutoFilter, BioScan, Clipring, DigiPEELS, DigiScan, Digi-

talMicrograph, DigitalMontage, Duo Mill, DuoPost, Gatan LowDose, GIF,

Hexlok, Hexring, HotHinge, MSC, PECS, PIPS, Toggle Tilt, and Whisperlok

are trademarks belonging to Gatan, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written

permission of Gatan, Ltd.

The text and graphics are for the purpose of illustration and reference only. The

specifications on which they are based are subject to change without notice.

CAUTION:Precautionary notes and advice to avoid personal injury or damage to

the equipment.

!

iv APS Solarus 950 Owner’s Manual

Returns

If there is a need to return equipment to the factory, please call Gatan to obtain a

Returned Merchandise Authorization Number (RMA #). This RMA number must

appear on your shipping document, to help in tracking and to ensure that proper

actions will be taken to repair or replace your equipment.

Support

Gatan, Inc. provides free technical support via phone, fax, and email. Contact the

USA, Canada &

Latin America Corporate Headquarters

Western USA Sales

Central USA & Latin America Sales

5794 W. Las Positas Blvd.

Pleasanton, CA 94588

Tel: +1 (925) 463-0200

Fax: +1 (925) 463-0204

Contact: [email protected]

Gatan, Inc.

Eastern USA Sales

780 Commonwealth Drive

Warrendale, PA 15086

Tel: +1 (724) 776-5260

Fax: +1 (724) 776-3360

Contact: [email protected]

Asia & Pacific Rim Nippon Gatan

3F Sakurai building

2-8-19 Fukagawa, Koto-ku

Tokyo 135-0033, Japan

Tel: +81 3 5639 2772

Fax: +81 3 5639 2763

Contact: [email protected]

Gatan Singapore

10 Eunos Road 8

#12-06

Singapore Post Centre

Singapore 408600

Tel: (65) 6293 3160

Fax: (65) 6293 3307

Contact: wchuang@gatan.com

APS Solarus 950 Owner’s Manual v

Europe Gatan GmbH, München, Germany

Ingolstadterstr. 12

D-80807 München

Germany

Tel: +49 89 358084-0

Fax: +49 89 358084-77

Contact: [email protected]

Gatan UK

25 Nuffield Way

Abingdon

OX14 1RL

UK

Tel: +44 1235 540160

Fax: +44 1235 540169

Contact: [email protected]

Gatan France

Division de ROPER Scientific SAS

8, rue du Forez

ZI petite montagne Sud - CE 1702

91017 EVRY Cedex

Tel: + 33 1 69 11 03 69

Fax: + 33 1 64 97 19 67

Contact: [email protected]

vi APS Solarus 950 Owner’s Manual

Solarus 950 Owner’s Manual and User’s Guide vii

Table of Contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Copyright and Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Overview 1

Features 3

Plasma Recipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Touch Screen User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Description and Specifications 6

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety and Serviceability 9

Cautionary Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation Recommendations for Gatan Customers—Flammable and

Oxidizing Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installation and Setup 12

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Configuring Gas 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Purging the Gas Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connecting Exhaust Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Connecting Vent Gas Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Testing With Air as a Plasma Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Loading Samples in the Solarus 950 22

Loading TEM Samples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Loading SEM Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

viii Solarus 950 Owner’s Manual and User’s Guide

Removing the Ion Shield 24

Operating the Gatan Advanced Plasma System 25

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Creating Custom Recipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintenance 38

Maintenance Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Troubleshooting 47

Spares and Consumables 48

Battery Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Solarus 950 Owner’s Manual and User’s Guide ix

List of Figures

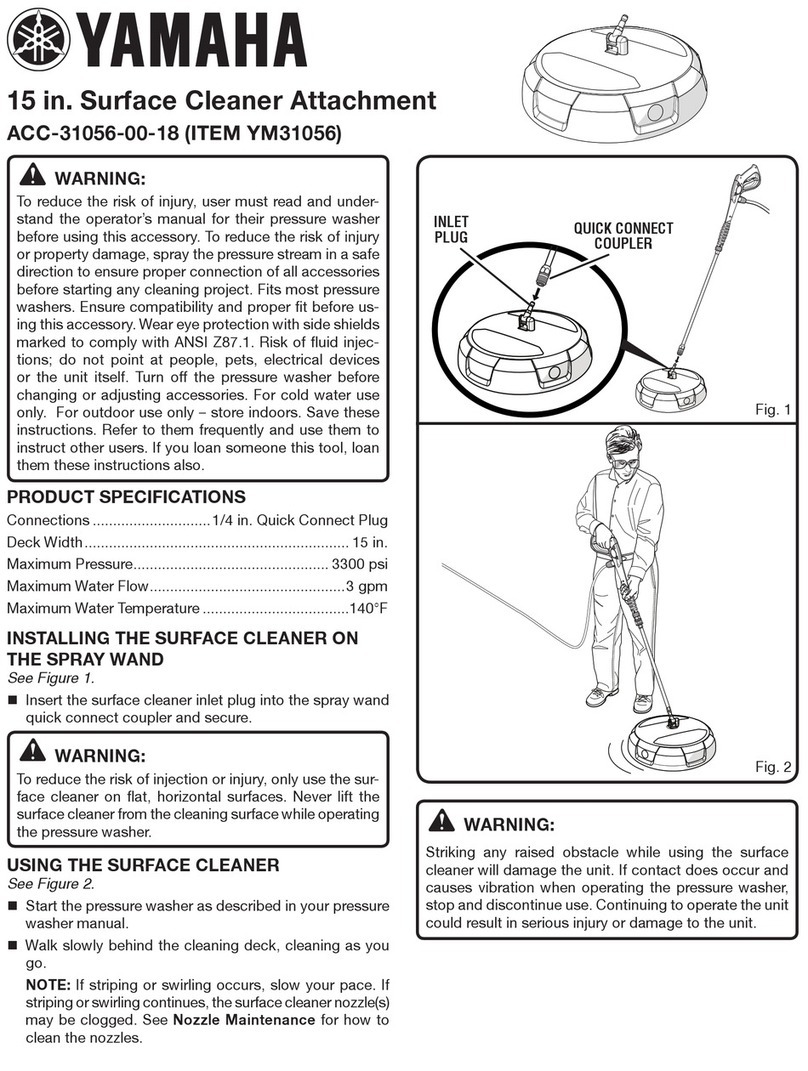

Figure 1 Gatan Advanced Plasma System, model Model 950. . . . . . . . . . . . . . . .2

Figure 2 Gatan Advanced Plasma System, front-accessible components . . . . . . . . . .6

Figure 3 Gatan Advanced Plasma System, rear panel . . . . . . . . . . . . . . . . . . . .7

Figure 4 Solarus 950 rear panel gas connection detail. . . . . . . . . . . . . . . . . . . 12

Figure 5 Gas line to filter connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6 Two-tank cleaning configuration. . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7 Three-tank cleaning configuration . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8 Two-tank purging configuration . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9 Air testing configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10 Loading TEM holder, holder adapter, and plug . . . . . . . . . . . . . . . . . 22

Figure 11 TEM holder and adapter in place. . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 12 Top-loading SEM chamber, side view . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13 Sample loaded in SEM chamber . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 14 TEM holder-adapter with ion shield removed . . . . . . . . . . . . . . . . . . 24

Figure 15 System in idle state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 16 System initiating vacuum state. . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 17 System introducing gases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 18 Applying RF power to the unit . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 19 Cleaning in process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 20 Plasma cleaning complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21 Venting the chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 22 System ready for next sample . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 23 Recipe options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 24 Access to Pirani gauge calibration button . . . . . . . . . . . . . . . . . . . . 45

Figure 25 Example maintenance report . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 26 Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

xSolarus 950 Owner’s Manual and User’s Guide

Solarus 950 Owner’s Manual and User’s Guide 1

Gatan Advanced Plasma System

Owner’s Manual and User’s Guide

Overview

Optimal imaging and microanalysis in electron microscopy requires a clean, well-

prepared specimen. This is especially important for FEG TEM, because specimen

contamination rates tend to increase as probe size decreases and beam current

density increases. The high performance now possible with the FESEM under-

scores the need for eliminating hydrocarbon contamination, especially for those

applications involving low voltage, high-resolution operation.

An RF-generated gas plasma cleaning process, originating within the semi-

conductor industry for wafer cleaning, has been known and available for some

time. A version of this technique was adapted for EM applications by Nestor

Zaluzek at Argonne National Laboratory and University of Chicago (US Patent

5,510,624, dated April 23, 1996).

The Solarus Advanced Plasma System expands this process to a new level.

Solarus is a low power hydrogen and oxygen radical generator producing glow-

discharge plasma within the generator housing. The hydrogen and oxygen radicals

disperse from the generator by convection, passing over and around the specimen/

specimen holder tip to clean hydrocarbons from the surfaces. The process pro-

duces H2O, CO2, and CO gases that are pumped away by the vacuum system.

Solarus incorporates a multi-stage diaphragm pump backing a turbomolecular

drag pump to assure fast, reliable pumping. The pump package enables pump and

vent cycles of less than two minutes. With cleaning times of 1-2 minutes, the full

Solarus 950 cleaning cycle takes less than four minutes.

2Solarus 950 Owner’s Manual and User’s Guide

ƒigure 1 Gatan Advanced Plasma System, model Model 950

Solarus 950 Owner’s Manual and User’s Guide 3

Features

The Solarus 950 is unique in automatically managing all critical plasma parame-

ters, offering a reliable one-touch cleaning solution. With this system, every user

can obtain consistent, high quality results.

The Gatan Advanced Plasma System consists of four main elements:

Oplasma recipes

Ohardware

Oelectronics

Osoftware

These elements are integrated into a highly flexible system that allows a great deal

of control over the sample cleaning process.

Plasma Recipes

Gatan provides cleaning recipes developed to maximize contamination removal

rates while minimizing damage to even the thinnest TEM samples. These recipes

have been tuned for efficiency using a mass spectrometer and crystal and thick-

ness monitors, tuned for minimal sputtering and sample damage using Langmuir

probes, and exhaustively verified with TEM and SEM samples in a wide variety

of conditions.

The unique H2/O2 recipe prevents or reduces buildup of contamination after about

one minute of cleaning. Even the worst burned-on contamination takes less than

ten minutes to clean. Holey carbon films have been cleaned in this recipe for more

than nine minutes without damage. Alternate Ar/O2 (Ar 75% - O2 25%) recipes

can also be selected.

The two primary gas chemistries used are H2/O2 and Ar/O2.

H2/O2

Gatan has found this chemistry to provide superior cleaning rates, less sputtering

damage, and significantly less sample heating than Ar/O2over a wide range of

samples.

Ar/O2(option)

This is the traditionally used process gas combination in electron microscopy.

Gatan has not yet found a processing advantage to Ar/O2over H2/O2, but some

sites may have restrictions on the use of pure H2or O2. An optional third mass

flow controller and a supply of Ar 75%/O 25% is required to use this recipe.

The use of this recipe requires optional hardware.

4Solarus 950 Owner’s Manual and User’s Guide

Air

Air can be used as a substitute for Ar/O2in a pinch. Some concerns exist about

forming C-N compounds that won’t volatilize and remain on the sample.

NOTE:Any of the cleaning chemistries can be used to treat carbon films that

have become hydrophobic.

Cl2/Br2

Other Gases

Please contact Gatan for compatibility of other gases.

Hardware

The Gatan Advanced Plasma System hardware offers fast cycle times and a broad

range of sample cleaning options. Both TEM and SEM samples can be accommo-

dated.

TEM Samples

Two front ports on the Solarus 950 accept TEM adapters compatible with all side-

entry TEM or SEM specimen holders. For slightly faster cleaning, use the left

port.

SEM Samples

A top-loading chamber accepts multiple SEM stubs and large irregular-shaped

samples.

Electronics

The electronics subsystem offers a powerful RF power supply, an auto-tuning RF

match network, and mass flow controllers.

RF Source

The Solarus 950 contains a 65 Watt RF power supply (13.56 MHz) with an auto-

tuning network to assure effective plasma coupling to the generator and chamber.

The RF supply is CE certified to comply with FCC guidelines.

The auto-tuning network is critical for achieving consistent results. It measures

the amplitude and phase of the forward and reflected power and automatically

minimizes reflected power. This ensures that the power delivered to the plasma is

CAUTION:Donot useCl2/Br2withthealuminum GatanAdvancedPlasmaSystem

chamber!

!

Solarus 950 Owner’s Manual and User’s Guide 5

consistent, even as the impedance varies due to aging, odd sized samples, or

changes in gas pressure or species.

Vacuum/Gas Pumping

A two-stage variable-speed diaphragm pump (electronic speed control) backs a 70

liters/second turbo molecular drag pump.

Chamber

The chamber is 3.5” in diameter x 2.0” deep, and includes multiple entry ports. A

front viewing port displays plasma when activated. An inline electromagnetic

valve isolates the vacuum pump from the chamber, resulting in less than one

minute pump down and less than a ten-second vent cycle.

Mass Flow Controllers

Mass flow controllers accurately gauge gas levels to achieve superior and repeat-

able cleaning results.

Touch Screen User Interface

A touch screen interface to the Solarus 950 software offers one touch operation

through user-programmable recipes, providing greater flexibility and repeatability

than competitive products.

Simple Four-Step Cleaning

1. Load a sample, either from the front (TEM holders) or top (stand-alone

TEM/SEM samples)

2. Select a recipe for TEM, STEM, SEM or carbon film cleaning using either

H2/O2or Ar/O2plasma cleaning.

3. Touch START to begin the cleaning cycle.

4. Touch VENT to vent the chamber and permit sample removal.

6Solarus 950 Owner’s Manual and User’s Guide

Description and Specifications

The Solarus 950 consists of a single self-contained unit as shown in the following

photos.

ƒigure 2 Gatan Advanced Plasma System, front-accessible components

The front of the unit contains a touch screen for executing all actions, two TEM

holder ports, and a viewing port. The door to the top-loading specimen chamber is

on the top of the unit, above the TEM holder ports.

All gas and venting connections are made at the rear of the unit. The rear panel

also contains the on/off power switch, connectors for power cable, USB ports and

network cable, and a storage area for the DP locking screw mentioned in the

unpacking instructions.

Solarus 950 Owner’s Manual and User’s Guide 7

ƒigure 3 Gatan Advanced Plasma System, rear panel

Physical Specifications

NOTE:Although the instrument is a compact bench-top system, it is relatively

heavy and should not be lifted by a single individual.

SPECIFICATION VALUE

Weight 145 lbs/65 kg (see Note)

Dimensions The system requires a stable bench with a surface area of:

O39 inches (1m) in length

O24 inches (62cm) in depth

O18 inches (46cm) in height

Clearance Allow clearance on both sides for ventilation, and to the rear

for gas line connections and ventilation.

Do not block the fan vents.

Power 100-240 VAC, 50/60 Hz, 1000 Watts

A molded power cord is supplied to fit the local

standard power socket. Be sure to use a properly grounded AC

outlet.

Maximum Ambient

Temperature 35 degrees Celsius

8Solarus 950 Owner’s Manual and User’s Guide

Gas Requirements

NOTE:All gas connections are compression fittings (1/8 inch OD Tube),

4.5 grade is 99.995% pure (50 PPB).

Gas Used During Cleaning (Standard Gatan Recipes)

NOTE:* sccm = standard cubic centimeters per minute

For example, a 2 cubic foot (~57 liter) lecture bottle of H2will last for ~147 hours

of continuous use. An 80 cubic foot (~2265 liter) bottle of O2will last for ~1373

hours of continuous use.

GAS PURITY PSI

O2Grade = 4.5 25 psi (1.7 bar)

H2Grade = 4.5 25 psi (1.7 bar)

Ar (option) Grade = 4.5 25 psi (1.7 bar)

GAS USAGE

H2/O2H2= 6.4 sccm*

O2= 27.5 sccm

Ar/O2Ar = 35.0 sccm

O2= 11.5 sccm

Solarus 950 Owner’s Manual and User’s Guide 9

Safety and Serviceability

Cautionary Notes

Servicing

The turbo-molecular drag pump and diaphragm pumps require periodic mainte-

nance. Please see the individual operator manuals of these instruments (included

in the shipping crate) for instructions. See the maintenance section in this manual

for instructions to remove these pumps from the instrument.

CAUTION:UnplugtheACmainscablebeforeopening the system, toavoid electric

shock. Dangerous high voltages and currents may be present inside the case

during operation. Do not reach your hands inside the system while the power is on

or if the AC mains cable is plugged in.

CAUTION:High pressure cylinders can be dangerous when not properly secured.

Be sure all cylinders are secured according to applicable safety codes..

CAUTION:TheRFpowersupplycangenerate85Wattsof power,whichcancause

burns if the live conductors are touched. Do not operate the unit unless the RF

cables arepluggedin properly. Do not defeat the safety mechanisms and touch the

RF antenna when the system is attempting to generate a plasma.

CAUTION:Hydrogen and Oxygen are combustible gasses. During normal

operation these gasses are fully combusted in the plasma and are not a danger. If

the gas supply connections or lines leak into an enclosed space, it is possible for

a dangerous concentration to accumulate. It is important to install and maintain

these connections properly in order to prevent leaks.

!

!

!

!

10 Solarus 950 Owner’s Manual and User’s Guide

Installation Recommendations for Gatan Customers—Flammable and

Oxidizing Gases

Hydrogen Guidance

OEnclosure/Cabinet: Store a lecture bottle of hydrogen within a one hour fire

barrier such as a “semiconductor type” rated lecture bottle gas cabinet. Secure

the compressed gas cylinder inside cabinet.

OSeismic Bracing and Mechanical Integrity: Ensure that the enclosure is

seismically braced in accordance with applicable Building Codes and that the

distribution line is properly braced between the cabinet and the Solarus 950.

OGas Detection: Install listed and/or approved hydrogen gas monitoring for

the lecture bottle gas cabinet providing both local and remote alarm

annunciation.

ODistribution System: Piping, tubing, valves, and fitting shall be compatible

with flammable gases and be of adequate strength and durability to withstand

the pressure expected.

OGrounding and Bonding: Provide for appropriate grounding and bonding to

minimize the potential for static electricity buildup.

OMaintenance and Inspections: Place safety critical equipment such as flam-

mable gas detection and grounding on a periodic calibration and test schedule.

Oxygen Guidance

OCompressed gas cylinder: Secure oxygen compressed gas cylinders to a

fixed object with one or more restraints stored upright with valve end up. Pro-

tect compressed gas cylinder valves from physical damage, by using valve

caps and ensure compressed gas cylinder caps are in place when not in use

ODistribution System: Ensure oxygen piping is free from oil residues and for-

eign material. Oil-free and noncombustible materials must be used for leak

testing oxygen lines.

OSegregation: Store oxygen compressed gas cylinder separately from incom-

patible materials, such as hydrogen gas. Note: If hydrogen gas cylinder is

located within a 1-hour rated fire barrier such as a semiconductor type gas

cabinet, then adequate segregation is provided. If no enclosure is used for

hydrogen, then the oxygen compressed gas cylinder shall be located at least

20 feet away.

Oxygen Guidance Applicable to both Hydrogen and Oxygen

OLeak Testing: Conduct pressure leak testing of delivery piping and associated

fittings prior to introducing hydrogen to the Solarus 950.

Table of contents

Other Gatan Ultrasonic Jewelry Cleaner manuals