Gates Magnum Coulter Disk User manual

June 2014

Magnum Coulter Disk

124756

Operator’s Manual

®

1 124756 / 6-2014

TABLE OF CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Owner Registration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Basic Warranty Repair Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Exceptions to this Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Gates Coulter Disk Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety During Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety During Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Decal Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Safety Light Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

OPERATION & MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Tractor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Transport to Field Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Start-Up And Hydraulic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Side to Side Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Front to Back Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Coulter Gang Angle Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Working Depth Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Optional Harrow and Rolling Basket Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Transporting from the Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Coulter Disk Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Coulter Disk Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

PROPER BOLT USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3 124756 / 6-2014

FOREWORD

Preface

This Operator and Parts Manual contains information pertaining to the operation, maintenance and adjustments of your

Gates Manufacturing product. To obtain the maximum service, read the manual provided thoroughly. Your Gates

Manufacturing product is designed to give you years of satisfaction. Taking the time to protect it against rust, wear and by

replacing worn parts will add longer life and trade-in value to your product.

Disclaimer

Gates Manufacturing, Inc.’s policy is to improve and develop our products on a continuing basis. We reserve the right to

make changes or add improvements at anytime without incurring any obligation to make such changes on machines

previously sold.

Gates Manufacturing, Inc. recommends that operators READ and UNDERSTAND the Operator’s Manual before using the

machine and should review the machine’s Operator’s Manual annually.

Contact Information

Gates Manufacturing, Inc.

8710 33rd Ave. NW

Lansford, ND 58750

Phone: 701.784.5434

Fax: 701.784.5444

E-mail: [email protected]

www.gatesmfg.net

Owner Registration Information

Bring this information when ordering parts.

Name________________________________________

Address______________________________________

City__________________________________________

State/Prov.____________________________________

Mail Code_____________________________________

Size_________________________________________

Serial Number_________________________________

Date Purchased________________________________

Dealer________________________________________

124756 / 6-2014 4

WARRANTY

Gates Manufacturing, Inc. warrants its new, unused agricultural equipment, to be free of defects in material and

workmanship, when properly assembled, at time of delivery to the first retail purchaser.

Basic Warranty Repair Period

Gates will repair or replace, at its option, without charge for parts any Gates Manufactured part that is found to be

defective for a period of two years. Return of the defective part will be the responsibility of the customer to the dealer

or Gates Manufacturing. It is the dealer’s responsibility to hold the part for inspection by Gates Manufacturing.

Replacement parts are warranted for a period of one year from date of purchase, providing the bill of sale accompanies

warranty claim.

Labor is covered during the first year of warranty only, and at a reasonable rate to be determined by Gates

Manufacturing, Inc. Labor during the second year is not covered.

Exceptions to this Warranty

In no event shall the owner be entitled to recover for incidental, special or consequential damages such as, but not

limited to; loss of profit or revenue, inconvenience of cost of rental of replacement equipment.

Hydraulic hose will be one warranty only.

Blades and springs will be one year warranty only prorated by wear subject to Gates Manufacturing appraisal.

Tires and cylinders will be the manufacturers responsibility.

The buyer of a Serial Numbered Gates product must be reported to Gates Manufacturing, Inc. by the dealer to initiate

warranty.

Use of Gates Manufacturing products for rental units will be warranted for a one year period only.

Mileage and travel time.

Hydraulic Oil.

Repair, maintenance, and service items not related to defects.

• Loss or damage during shipment.

• Failure resulting from lack of or improper maintenance.

• Damage caused by operator abuse, negligence or improper operation.

• Damage due to accidents.

Gates® Manufacturing, Inc.

Lansford, ND 58750

5 124756 / 6-2014

GENERAL INFORMATION

Gates Coulter Disk Features

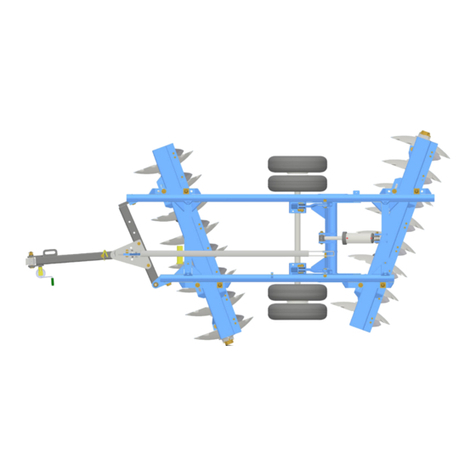

The Gates Coulter Disk is a primary tillage tool designed to cut and chop heavy residue at higher rates of speed. It

accomplishes this task by using two full ranks of coulter blades set at offset angles adjusted by the operator, which allow

for varying field conditions.

The coulter gangs of the Gates Coulter Disk are adjustable to handle varying field conditions and farming practices. Gangs

are easily adjustable from 0 to 15 degrees to allow for minimal soil disturbance or aggressive soil and residue mixing. This

feature accommodates no till operation to conventional till, and any degree in between. When optional Gates Mounted

Harrows and Rolling Baskets are added to the machine, it becomes an excellent, high speed seedbed preparation tool.

Other features were designed into the Gates Coulter Disk to enhance its performance. Highway service tires are used on

bogie wheel arrangements for maximum flotation in wet conditions. Master-slave hydraulics with rephasing cylinders are

used for single point depth control.

The Gates Coulter Disk is available in varying widths of 24’, 32’, 36’, 40’, 48’, 52’ and 56’ with over-center folding wings

for safe transport.

124756 / 6-2014 6

7 124756 / 6-2014

SAFETY

Safety Information

General Safety Practices

1. READ and UNDERSTAND the Operator’s Manual

before using any equipment. Review at least annually

thereafter.

2. VERIFY all safety devices and shields are in place

before using any equipment.

3. KEEP hands, feet, hair and clothing away from

moving parts.

4. STOP engine, place all controls in neutral, set parking

brake, remove ignition key and wait for all moving

parts to stop before servicing, adjusting or

maintaining.

5. BE CAREFUL when working around high pressure

hydraulic system.

6. DO NOT ALLOW RIDERS.

7. NEVER allow anyone unfamiliar, untrained or

complacent operate the implement.

8. ESCAPING FLUID HAZARD: Escaping hydraulic

fluid under pressure can penetrate the skin causing

serious injury. Relieve pressure before disconnecting

the hydraulic lines.

• Check/tighten all connections BEFORE applying

pressure

• Use a piece of cardboard or paper to search for

leaks.

• NEVER use your hand.

• IF ANY fluid is injected into the skin, seek

immediate attention.

Safety During Transportation

1. ONLY TOW at a safe speed do not exceed speeds

higher than 25 mph (40 km/h). Use caution when

making corners and meeting traffic.

2. ALWAYS use a safety chain between tractor drawbar

and implement hitch when transporting on public

roads.

3. ALWAYS use transport locks when transporting on

public roads.

4. BE SURE implement hitch is securely fastened to

hitch equipped with hammer strap on large tractor

before operating hydraulics.

5. COMPLY with local lighting, marking and oversize

regulations when transporting on highways.

6. FREQUENTLY check for traffic from rear, especially

during turns.

7. BE CERTIAN tractor weight is equal to or greater than

coulter disk weight.

8. ALWAYS be certain that no one is behind or around

implement before moving.

9. BE SURE no upward pressure is exerted on tractor by

coulter disk tongue before disconnecting from tractor.

10. NEVER subject the implement to steep sides / grades

while in transport position.

This safety alert symbol is used to denote possible danger and care should be taken to prevent bodily

injury. When you see this symbol is means: ATTENTION!, BECOME ALERT! and/or YOUR SAFETY IS

INVOLVED!

WARNING: Safe practices must be followed when assembling this equipment. All personnel

involved must:

• Read and understand the instructions and manuals for this machine.

• Be instructed in the safe use of tools and all lifting devices involved in the assembly of this equipment.

• Clear the area of all personnel not involved in the assembly of this machine.

124756 / 6-2014 8

SAFETY

Safety During Servicing

1. SHUT DOWN TRACTOR ENGINE remove key from

tractor ignition and be certain all moving parts have

stopped before servicing harrow drawbar.

2. DO NOT OVERINFLATE tires. NEVER lean over tire

while inflating it.

3. ALWAYS USE proper mounting procedures when

mounting a tire to wheel or rim. A tire not seated

properly may explode when being inflated causing

injury or death.

4. ONLY service coulter disk when in full field position.

Safety Decals

1. Keep safety signs clean and legible at all times.

2. Replace safety signs that are missing or have

become illegible.

3. Replaced parts that displayed a safety sign should

also display the current sign.

4. Safety signs are available from your dealer parts

department or the factory.

How to install safety signs:

1. Be sure that the installation area is clean and dry.

2. Be sure the temperature is above 50°F (10°C).

3. Decide on the exact position before removing the

backing paper.

4. Remove the smallest portion of the split backing

paper.

5. Align the sign over the specified area and carefully

press the small portion with the exposed sticky

backing in place.

6. Slowly peel back the remaining paper and carefully

smooth the remaining portion of the sign in place.

7. Small air pockets can be pierced with a pin and

smoothed out using the piece of sign backing paper.

Indicates an immediate hazardous situation that will result in death or serious injury. The color

associated with Danger is RED.

Indicates a potentially hazardous situation that could result in death or serious injury. The color

associated with Warning is ORANGE.

Indicates a potentially hazardous situation that may result in minor or moderate injury. It may

also be used to alert against unsafe practices. The color associated with Caution is YELLOW.

The Notice decals and statements in this manual are to inform the operator of the correct fluids,

or operational practices for this machine. Failure to follow these notices will result in damage to

the machine. The color associated with Notice is BLUE.

9 124756 / 6-2014

SAFETY

This Page Left Blank Intentionally

124756 / 6-2014 10

SAFETY

Safety Decal Location

GM00073

3

3

4

1

43

2

3

5

5

3

2

3

3

4

1

1

4

3

2

2

4

4

1

4

4

4

4

4

4

4

3

4

11 124756 / 6-2014

SAFETY

Safety Decal Location

The types of safety signs and locations on the equipment are shown in the illustration. Familiarize yourself with the various

safety signs, the type of WARNING and the area or particular function related to that area, that requires your SAFETY

AWARNESS.

IMPORTANT: If Safety Signs have been damaged, removed, become illegible or parts replaced

without safety signs, new signs must be applied. New safety signs are available from

your authorized dealer.

Safety Decals

GM00071

1

GM00036

2

GM00072

34

GM00037

5

Wheel Lift Lock

Wing Lift

Wing Lock

Clearance Decal Red (item 3) and Yellow (item 4)

124756 / 6-2014 12

SAFETY

Safety Decal Location (cont’d)

GM00073

6

6

13 124756 / 6-2014

SAFETY

Safety Decal Location (cont’d)

GM00040

6

SMV (Slow Moving Vehicle) Sign

124756 / 6-2014 14

SAFETY

Safety Light Operation

Figure 1

The Safety Light Kit is equipped with a 7-pin connector.

To protect the 7-pin connector, store in dust cap when not

attached to towing vehicle.

GM00033

15 124756 / 6-2014

OPERATION & MAINTENANCE

Tractor Connection

NOTE: Only tow at safe speed. Use caution when

making corners or meeting traffic.

Turn on flashing warning lights when

traveling on public roads except where such

use is prohibited by law.

To prevent accidental disconnection, use a

safety chain between tractor and implement

when transporting on public roads.

Ensure that a Slow Moving Vehicle (SMV) sign

is at the rear of the implement in clear view of

overtaking traffic.

Figure 2

Lock tractor drawbar in center position, be sure hammer

strap is properly secured on the tractor drawbar.

Using the jack supplied, adjust the height of the

implement tongue to the approximate clevis opening

height of the tractor drawbar.

Figure 3

Back tractor until holes of both hitches align.

Attach implement hitch to tractor hitch with a draw pin

(item 1) locked in place with a hair or D-ring pin (item 2).

GM00030

CAUTION: Use caution when backing

tractor up to implement hitch. Always have

all persons in clear view before proceeding

to back up. Always take tractor out of gear

and set park brake before anyone goes

behind tractor to insert drawbar pin.

CAUTION: Do not lower implement with the

jack in the down position while attached to

the tractor hitch or structural damage will

result.

GM00009

2

1

124756 / 6-2014 16

OPERATION & MAINTENANCE

Tractor Connection (Cont’d)

Figure 4

Install the safety chain on the tractor hitch.

Figure 5

Be sure the safety lock is in the position shown.

Figure 6

Lower the drawbar to release pressure from the jack.

Figure 7

Remove the retainer pin (item 1).

GM00008

GM00007

GM00012

GM00011

1

17 124756 / 6-2014

OPERATION & MAINTENANCE

Tractor Connection (Cont’d)

Figure 8

Rotate the jack to the storage position and install the

retainer pin (item 1).

Figure 9

Turn the crank (item 1) to relieve the pressure on the rear

jack. Remove the retaining pin (item 2).

Figure 10

Move the jack to the storage position and install the

retaining pin (item 1).

Figure 11

Connect the implement hydraulic lines to tractor hydraulic

circuit. The hose ends are color coded according to

function as listed on the chart on the hose storage

bracket.

NOTE: Be sure the hydraulic hose ends on the

implement and female hydraulic couplers

on the tractor are clean before connecting

hydraulics.

GM00010

1

GM00059

12

GM00060

1

GM00035

1

1

124756 / 6-2014 18

OPERATION & MAINTENANCE

Tractor Connection (Cont’d) Transport to Field Position

Figure 12

Figure 13

Remove the retaining pins from the wing locks (item 1)

and lift locks (item 2).

CAUTION: Escaping hydraulic fluid under

pressure can penetrate the skin causing

serious injury. Relieve pressure before

disconnecting the hydraulic lines. Check /

Tighten all connections BEFORE applying

pressure. Use a piece of cardboard or paper

to search for leaks. NEVER use your hand.

IF ANY fluid is injected into the skin seek

immediate medical attention.

GM00019

1

GM00038

2

Table of contents

Popular Farm Equipment manuals by other brands

Smithco

Smithco AER 8 Aerifier Parts & Service operators

Amazone

Amazone EasyCheck Original operating manual

GREAT PLAINS

GREAT PLAINS PL5700 Predelivery Manual

Kongskilde

Kongskilde 800 Series Assembly Instructions & Operating Guide

PRONAR

PRONAR T679/5 Operator's manual

Opico

Opico Air 8 Electronic operating instructions