4

TABLE OF CONTENTS

INTRODUCTION.....................................................2

SAFETY

GENERAL HAZARD INFORMATION ....................6

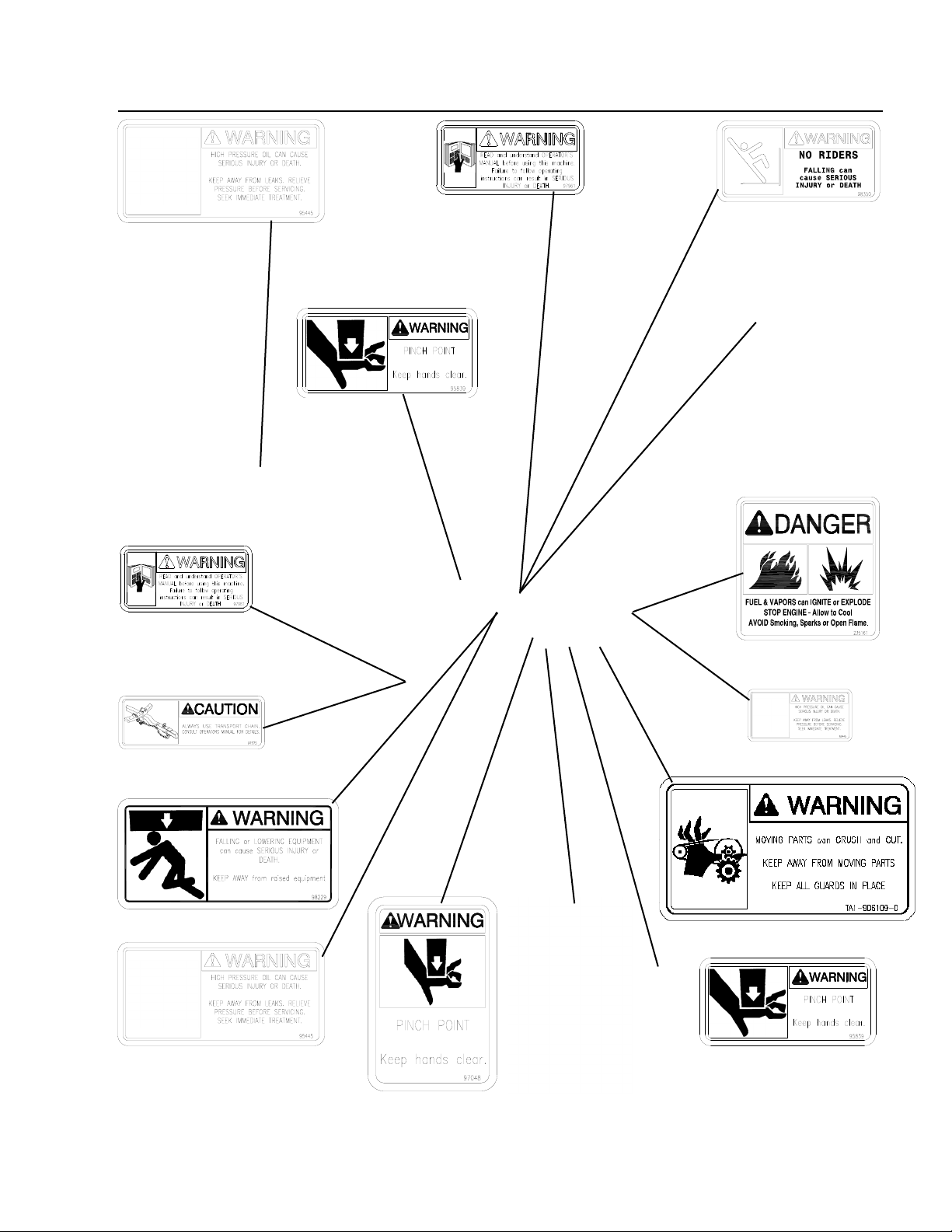

SAFETY DECALS ..................................................7

SAFETY

FOLLOW SAFETY INSTRUCTIONS ..............8

BEFORE OPERATING OR SERVICING........ 8

DURING OPERATION..................................... 9

BEFORE TRANSPORTING.............................9

DURING TRANSPORT..................................10

PRESSURIZED OIL ......................................10

PREPARING FOR EMERGENCIES ............. 11

WEARING PROTECTIVE EQUIPMENT ....... 11

SECTION I - OPERATIONS

PREPARING TOWING VEHICLE .......................1-1

PREPARING IMPLEMENT..................................1-1

HYDRAULICS ...............................................1-1

LUBRICATION ..............................................1-1

TIRES/WHEELS............................................1-1

CONNECTING SEED RUNNER TO

TOWING VEHICLE ......................................1-2

TRANSPORT CHAINS ........................................1-2

TRANSPORTING.................................................1-2

HYDRAULIC POWER UNIT OPERATION.........1-4

HYDRAULIC PRESSURE RELIEF VALVE ........1-5

PIVOTING CONVEYOR SIDE-TO-SIDE ............1-6

RAISING AND LOWERING CONVEYOR ..........1-6

FILLING PLANTER OR DRILL ..........................1-7

FILLING SEED TENDER FROM ANOTHER

WAGON OR BULK CONTAINER

(SELF-FILLING) ............................................1-8

LADDER ..............................................................1-9

TARP..................................................................1-10

UM 2410 & UM 2510 ELECTRONIC SCALE 1-11

BASIC OPERATION................................... 1-11

DETAILED PROCEDURE........................... 1-11

DOWNLOADER MODULE (OPT.) .............1-14

OPTIONAL AUTO-SHUTDOWN FEATURE

FOR UM 2510 SCALE ONLY...................1-15

OPTIONAL LIGHT KIT .....................................1-15

SECTION II - SERVICE

LUBRICATION .....................................................2-1

CONVEYOR BEARINGS..............................2-1

PIVOT POINTS ............................................2-1

WHEEL BEARINGS .....................................2-1

HYDRAULIC POWER UNIT ........................2-1

HYDRAULIC SYSTEM ........................................2-2

PURGE HYDRAULIC SYSTEM...................2-2

RELIEVING HYDRAULIC PRESSURE........2-2

CONVEYOR BELT ..............................................2-3

BELT TENSION............................................2-3

BELT TRACKING .........................................2-3

BRAKE CLEANING AND INSPECTION ............2-5

BRAKE LUBRICATION .......................................2-5

MAGNETS ...........................................................2-5

SHOE & LININGS ..............................................2-5

HOW TO MEASURE VOLTAGE ........................2-6

HOW TO MEASURE AMPERAGE.....................2-6

BRAKE DRUM INSPECTION.............................2-7

BEARING INSPECTION .....................................2-7

BEARING LUBRICATION....................................2-7

TROUBLESHOOTING BRAKES .........................2-7

POWER PAK.......................................................2-8

WHEEL TORQUE CHART &

TIRE SPECIFICATIONS.............................2-10

TORQUE CHART.............................................. 2-11

STORAGE.......................................................... 2-11

TROUBLE SHOOTING .....................................2-12

MASTER DISCONNECT SWITCH

ELECTRICAL SCHEMATIC ........................2-14

FRONT TRAILER

ELECTRICAL SCHEMATIC ........................2-15

TRAILER LIGHTING & BRAKE

ELECTRICAL SCHEMATIC ........................2-16

SEED TANK LIGHTING

ELECTRICAL SCHEMATIC ........................2-17

(March 2013)