ISSUED: 04-21-03 SHEET #: 055-9158-1

4 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

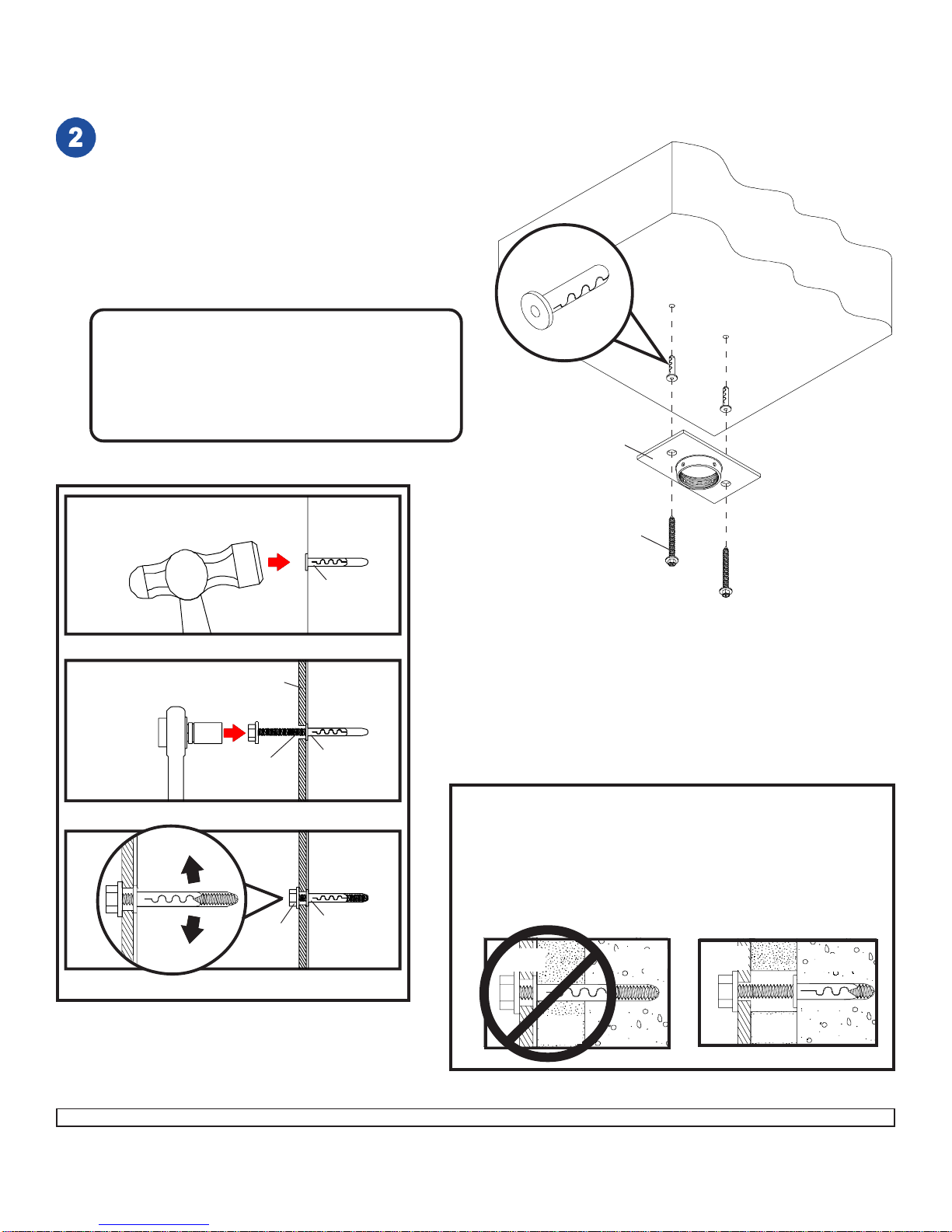

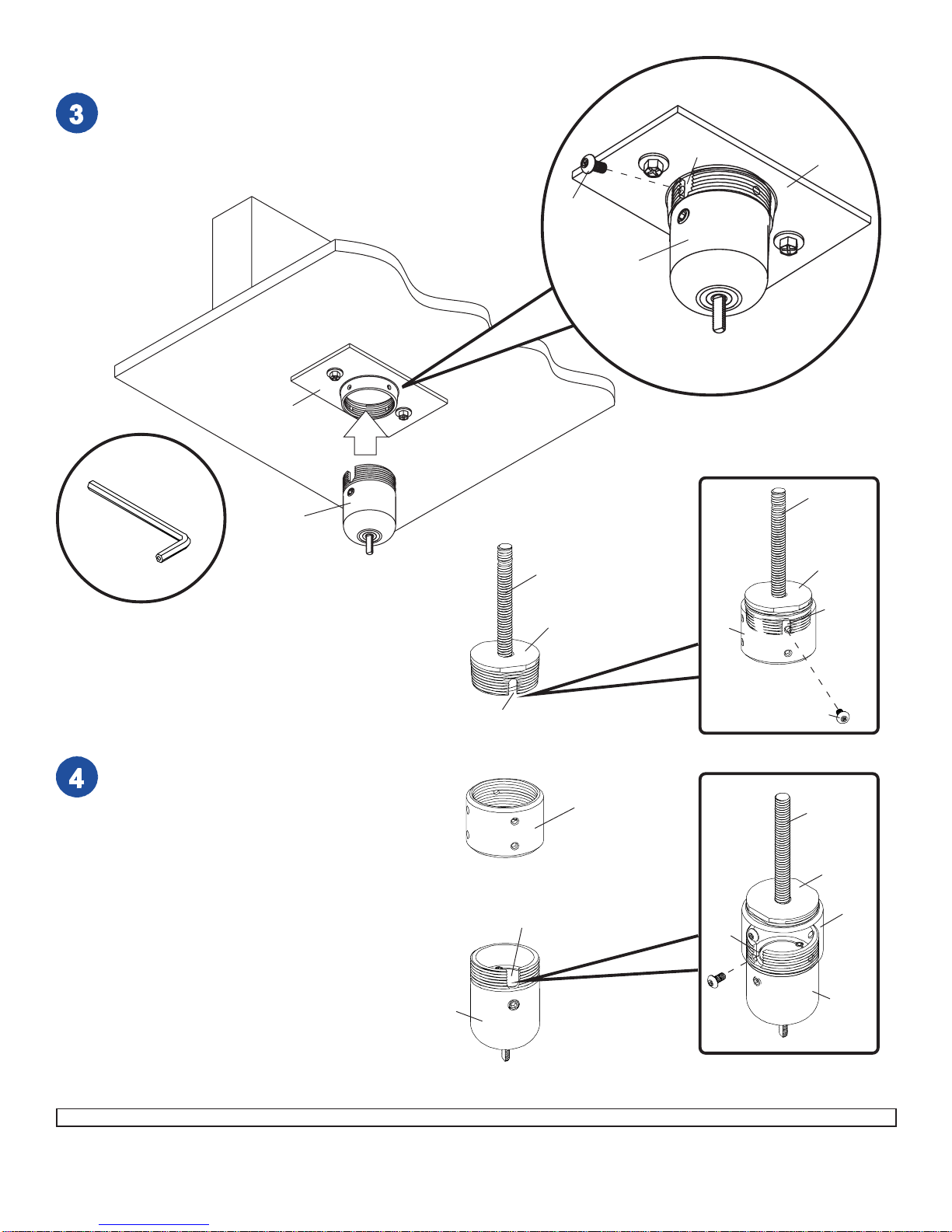

CAUTION: Tighten wood screws so ceiling plate

(G) is firmly attached. But DO NOT TIGHTEN

WITH EXCESSIVE FORCE! Overtightening can

cause stress damage to wood screws, greatly

reducing their holding power! Tighten to 80 in •

lb(9 N.M.) maximum torque.

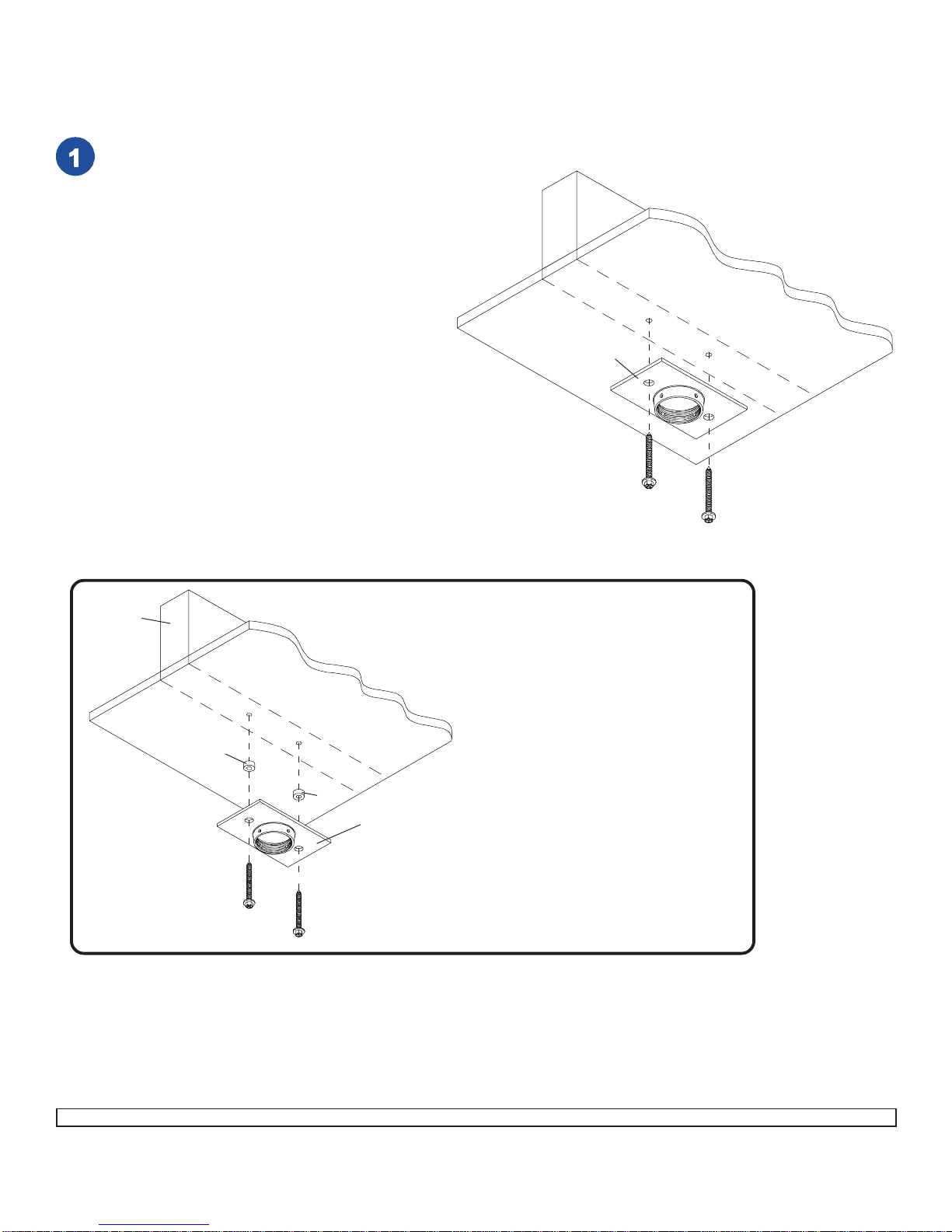

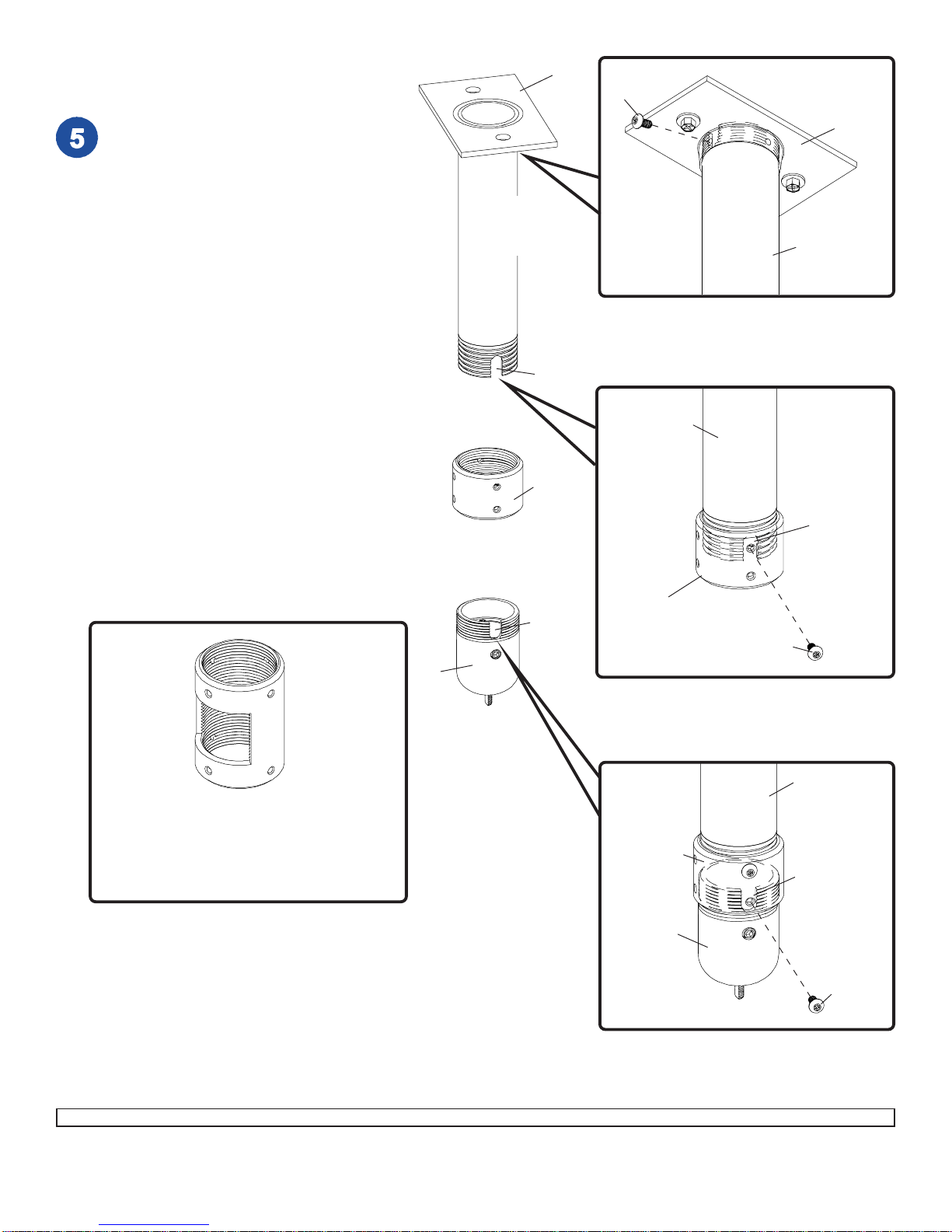

Drill two 1/4" (6 mm) dia. holes to a minimum

depth of 2.5" (64 mm). Attach ceiling plate (G)

using two concrete anchors and #14 x 2.5" wood

screws (F) as shown in Illustration A and 1, 2,

and3(below).Tightenallfasteners.

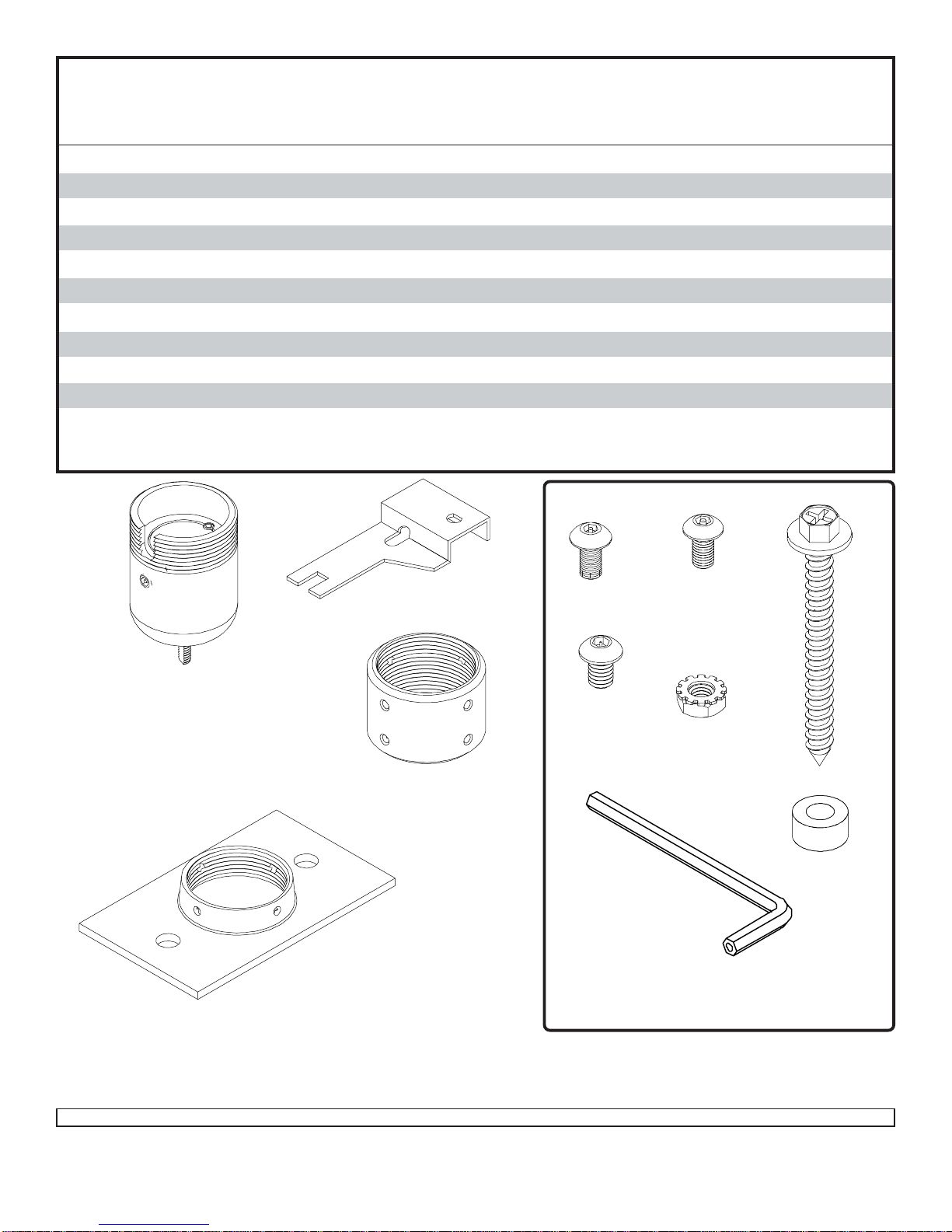

IMPORTANT: It is the responsibility of the

installer to verify that the ceiling will safely

support the combined load of all attached

hardware and components.

1

3

Drill hole and insert anchor

Place ceiling plate over anchor and secure with screw

After repeating step one tighten all fasteners

CUTAWAYVIEW

INCORRECT

concrete

metal

bracket

plaster/

drywall

CORRECT

concrete

metal

bracket

plaster/

drywall

FORDIRECTATTACHMENT TO LOAD BEARING CONCRETE

ONLY! Concrete expansionanchors are not intendedfor

attachment to concrete ceilings covered with a layer of plaster,

drywall,or other finishing material.If mounting toconcrete

ceilingcovered with plaster /drywall is unavoidable,plaster/

drywallmust be counterboredas shown below.

concrete

ceiling

concrete

anchor

concrete

anchor

concrete

anchor

F

F

F

Illustration A

Installation to Concrete Ceilings

ACC 03 (Alligator® concrete anchors) are recommended.

concrete

anchor

G

2G

CONCRETECEILING