GATEXPERT GK-E Series User manual

INDUSTRIAL DOOR OPERATOR

WITH ELECTRONIC LIMIT SWITCH

USER MANUAL

(GK-E SERIES)

Website: www.gatexpertstore.com

E-mail: sales@gatexpertstore.com

Instructions for GK-E SERIES

www.gatexpertstore.com

WARRANTY

1. To repair against this warranty card and invoice during the warranty period.

2. Warranty period: 1 year after the date of invoice.

3. Without unauthorized dismantling, any product broken or damage due to quality

problem, we’ll offer the repair service for free or replace for free.

4. The malfunction and damages caused by incorrect use or man fault is not covered by

this warranty.

CONTACT US

E-mail: sales@gatexpertstore.com

Please fill in the order information in the form below.

All personal information you provided will be only used for warranty service and kept

strictly confidential.

Refer to this list when contacting GATEXPERT for technical service or assistance with

your automatic gate opener.

Order Number

Product Model

Purchase Date

Country / Region

Email Address

Issue Details

Instructions for GK-E SERIES

www.gatexpertstore.com

Safety Instruction

1. The industrial door operator should be installed and put into operation by qualified

personnel. Otherwise, serious personal injury or property damage may occur.

2. Installation and wiring must be in accordance with the construction standards and

electrical standards, diameter ≧1.5mm2; power must have a reliable grounding, ground

wire must be reliably connected to the place labeled ground tab, ground lead on the

power line is prohibited to be removed; front end of incoming power line should be

installed with electrical leakage protector which is in line with national standards.

3. This industrial door operator is only allowed to be installed on well-balanced door

which has balance spring, otherwise machine may be damaged due to overload.

4. Door should be flexible and run without stagnation; The end of door lead rail must be

installed with mechanical stop block and buffering booster to prevent the door from rolling

out.

5. Control unit should be installed on the wall or a post of 1.4 meters away from the

ground where the operation of door can be observed to prevent children from

inadvertently touching. Keep the remote control well, do not allow children to touch or

play in case of any danger. Do not use the remote control when you didn’t see the

operation of door.

6. Before repairing and moving the industrial door operator and its control unit, please cut

off the power supply, and make sure that the door has been locked and there is no any

risk of falling due to self-weight is null.

7. Pedestrian and vehicle are prohibited to go through or stay when the door is running.

8. Hand-pulled chain is prohibited to be pulled during the operation of the industrial door

operator to prevent the motor from damaged.

9. To ensure the safety of pedestrian and vehicle, it’s recommended to install the infrared

protection and airbag protection devices.

10. Please check the safety protection devices and the door running condition from time

to time to ensure the safety and stability of door operation.

Thank you for choosing this product!

Appreciate for your trust and support!

Please read this manual carefully before installation!

Please keep this manual properly even after installation!

Instructions for GK-E SERIES

www.gatexpertstore.com

CONTENTS

1.TECHNICAL PARAMETER TABLE……….…………………………………….………...…3

2.DIMENSION AND COMPONENT OF INDUSTRIAL DOOROPERATOR…............……4

3.INSTALLATION GUIDE OF INDUSTRIAL DOOR OPERATOR…………………….....…6

4.INDUSTRIAL DOOR OPERATOR WIRING…………………………………………..…...10

5.OPERATION INTERFACE ILLUSTRATION…………………………………….….....…..13

6.OPEN AND CLOSED LIMIT SWITCH SETTING…..……………………….……...….....14

7.WORKING MODE SETTING……………………………............…….…….…..…….......17

8.DIP SWITCH SETTING…………………………….............…….…….…..……..............17

9.PARAMETERS SETTING.........................…………..……………….....….…......….…..18

10.EXTERNAL ACCESSORIES WIRING……………..………………………...…………..20

11.REMOTE CONTROL PASSWARD SETTING…………..………………………......…..22

12.USE OF HAND-PULLED CHAIN ...............................................................................23

13.COMMON FAULTS AND COUNTERMEASURES .....................................................24

14.PACKING LIST…………………………………………………...……………...........……25

Instructions for GK-E SERIES

www.gatexpertstore.com

3

Technical Parameter Table of Door Operator

Model (Single Phase AC220V±10%)

GK30E

GK40E

GK100E

Rated Power

230W

300W

550W

Torque

30N.m

40N.m

100N.m

No-load Continuous Running Time

15 min.

8 min.

Max. gate area

15m2

20m2

35m2

Model (Three Phase AC380V±10%)

GK60SE

GK100SE

Rated Power

400W

550W

Torque

60N.m

100N.m

Max. gate area

30m2

40m2

No-load Continuous Running Time

15 min.

Other Parameters:

Thermal Protection Temperature

120℃

Reduction Ratio

1:58

No-load Rotation Speed

24r/min

Lubricating System

Oil-immersed

Noise

≤55dB

Hand Release Device

Manual release switch

Maximum Travel Limit

Output shaft rotates 20 rounds

Output Shaft Diameter

Φ25.4mm

Environment Temperature

-20℃~+50℃

Working Duty

S2-15min

Protection Class

IP54

Operator Dimension(mm)

357x135x218

Operator Weight(kg)

12.5

Instructions for GK-E SERIES

www.gatexpertstore.com

4

Technical Parameter Table of Control Unit

Model

GKB220E

GKB380E

Power Supply

AC220V/50Hz

AC380V/50Hz

Remote Control

Available

Available

Applicable Model

GK30E/40E/100E

GK60SE/100SE

External Three Button Switch Terminal

Available (Optional)

Available (Optional)

External Single Button Switch Terminal

Available (Optional)

Available (Optional)

Partial Opening Button Switch Terminal

Available (Optional)

Available (Optional)

Interlock Terminal

Available (Optional)

Available (Optional)

Infrared Photocell Terminal

Available (Optional)

Available (Optional)

Airbag Terminal

Available (Optional)

Available (Optional)

Loop Detector Terminal

Available (Optional)

Available (Optional)

Small-door Terminal

Available (Optional)

Available (Optional)

Multi-function Output Terminal

Available (Optional)

Available (Optional)

DC24V Power Terminal

Available (Optional)

Available (Optional)

Protection Class

IP54

IP54

Dimension and Component of Industrial Door Operator

Dimension

Instructions for GK-E SERIES

www.gatexpertstore.com

5

1Electronic limit switch part

②Gearbox

③Wiring terminals

④Plastic cover

⑤Door operator

⑥Hand-pulled chain

⑦Release handle

Component

Control Unit Dimension

Instructions for GK-E SERIES

www.gatexpertstore.com

6

1

2

3

4

5

6

7

1

2

3

4

5

6

7

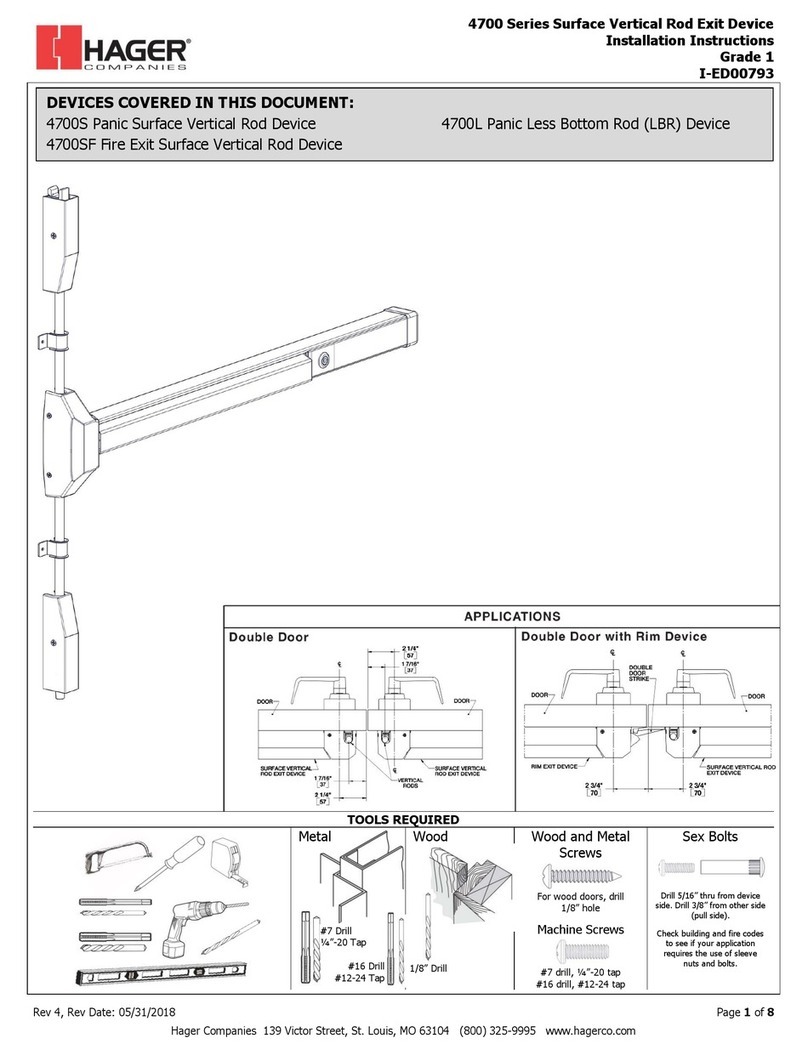

Installation Guide of Industrial Door Operator

This product is commonly used for the industrial sectional door which was equipped

with balance spring and lifting industrial door. There are two installation ways for this

product: shaft drive installation and chain drive installation. The factory standard

configuration is for shaft drive installation. If users require chain drive type, they can

choose the appropriate sprocket chain accessories for installation needs.

Shaft Drive Installation Chain Drive Installation

Shaft Drive Installation

Chain Drive Installation

①Expansion Screw

①Driven Wheel

②Mounting Bracket

②Door Shaft

③Mounting Screw

③Chain

④Door Operator

④Mounting Bracket

⑤Special Flat Key

⑤Driving Sprocket

⑥Door Shaft

⑥Driving Sprocket Shaft

⑦Fixing Sleeve

⑦Door Operator

Instructions for GK-E SERIES

www.gatexpertstore.com

7

Step 1. Check the door

After the door is installed, adjust the torsion spring, ensure manually opening or

closing the door is flexible without stagnation, observe the rotation direction of the

rope sheave which should be consistent with the opening and closing direction of the

industrial door operator.

Step 2. Determine the installation position

Consider the boundary dimension and installation direction of the door operator,

determine the position of the mounting bracket, mark the insert cavity position, drill the

screw hole and fix the mounting bracket. (The mounting bracket can be fixed inside or

outside the door operator, recommended to be installed inside for the convenience of

disassembly of the door operator).

Instructions for GK-E SERIES

www.gatexpertstore.com

8

Step 3. Trial installing the door operator

Install a fixing sleeve on door shaft first, and insert the industrial door operator into the

door shaft.

Step 4. Pre-fix the industrial door operator

Fix the industrial door operator on mounting bracket with 4pcs hexagon head flange

bolts M10×20, do not tighten at this step.

Instructions for GK-E SERIES

www.gatexpertstore.com

9

Step 5. Find the direction of key slot

First pull the red handle A to the bottom to make the hand-pulled chain mechanism e

ngage with the main engine (Manual control mode).

Rotate the output shaft of industrial door operator by pulling the hand-pulled chain up

and down until the key slot of the output shaft is fully aligned with the key slot of the

door shaft.

Step 6. Mount the flat key and fixing sleeve

Mount the flat key, keep two fixing sleeves close to the two ends of the output shaft,

fasten the two M6 head screws in the key slot of door shaft in order to prevent the flat

key from loosening and falling off.

Step 7. Tighten the screws, prepare wiring and debugging Tighten all screws.

Finally pull green handle B to the bottom to make the hand-pulled chain mechanism

detach from the main machine (Electric control mode).

Instructions for GK-E SERIES

www.gatexpertstore.com

10

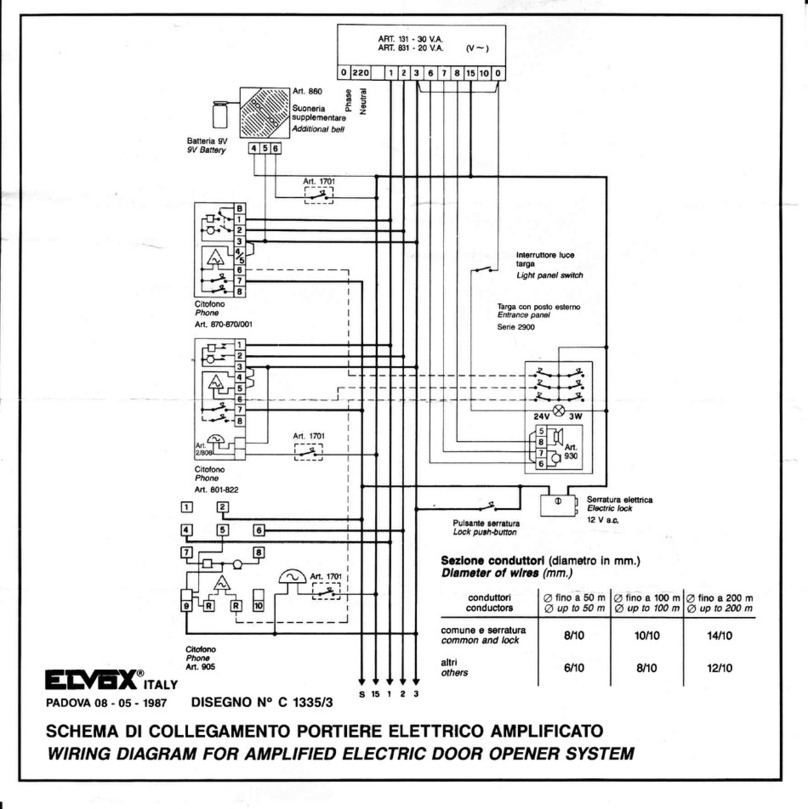

Industrial Door Operator Wiring

Wiring Between Door Operator and Control Unit

1. Motor Wire 2. Encoder Wire 3. Power Supply Wire

Instructions for GK-E SERIES

www.gatexpertstore.com

11

green

red

yellow

white

Wiring of Single Phase Operator

1——Motor Wire: U(blue) V(brown) W(black)

2——Encoder Wire: GND(white) A(yellow) B(red) VCC(green)

3——AC220V(single phase) Power Supply Wire

Note: Please make sure the wirings are tight and in good connection. After wiring,

remember to tighten up the IP plug to ensure all wirings completely fixed.

Warning: Please ensure the power supply wire is not plugged before you finish

all wirings.

Instructions for GK-E SERIES

www.gatexpertstore.com

12

green

red

yellow

white

Wiring of Three Phases Operator

1——Motor Wire: U(blue) V(brown) W(black)

2——Encoder Wire: GND(white) A(yellow) B(red) VCC(green)

3——AC380V(three phases) Power Supply Wire

Note:

1. Please make sure the wirings are tight and in good connection. After wiring,

remember to tighten up the IP plug to ensure all wirings completely fixed.

2. Please notice the phase sequence change when reconnecting wires. If the

phase sequence changed, the motor will run in opposite. The digital screen

won’t display abnormal if the phase sequence is correct.

Warning: Please ensure the power supply wire is not plugged before you finish

all wirings.

Instructions for GK-E SERIES

www.gatexpertstore.com

13

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

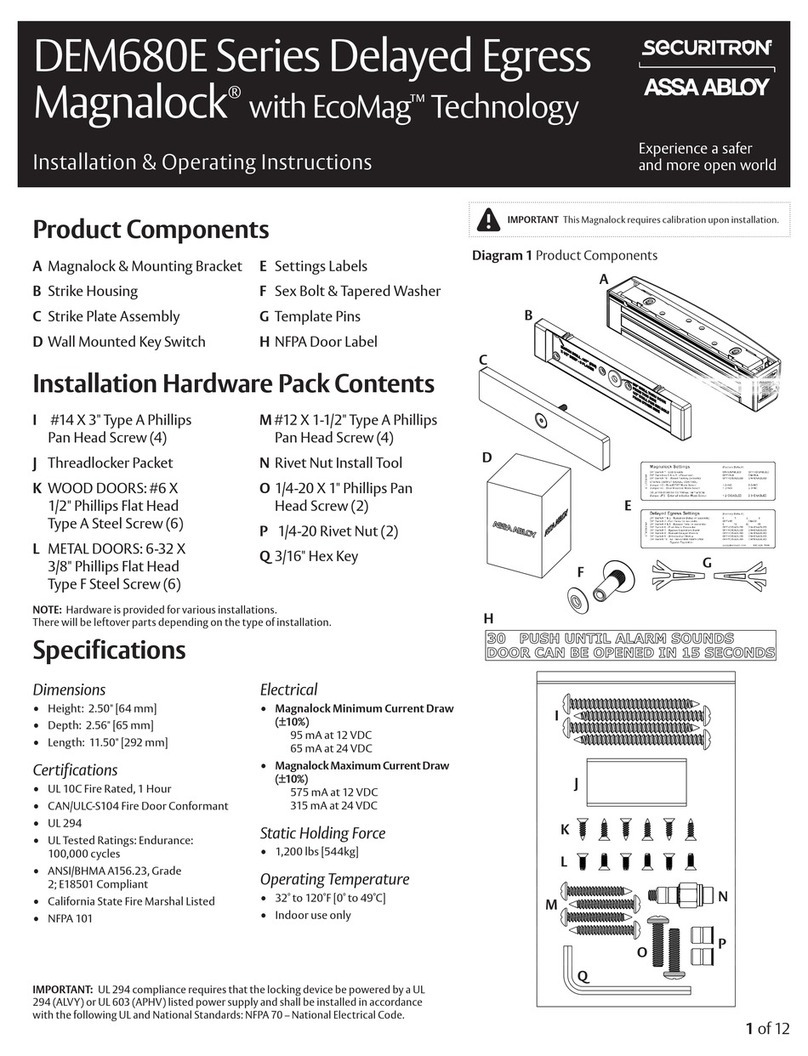

Operation Interface Illustration

STOP

DOWN

DIGITAL

SCREEN

UP

INDICATOR

LIGHT

REDUCE

INCREASE

CONFIRM

NEXT

Opening status

display

Working mode

display

Input status

display

Instructions for GK-E SERIES

www.gatexpertstore.com

14

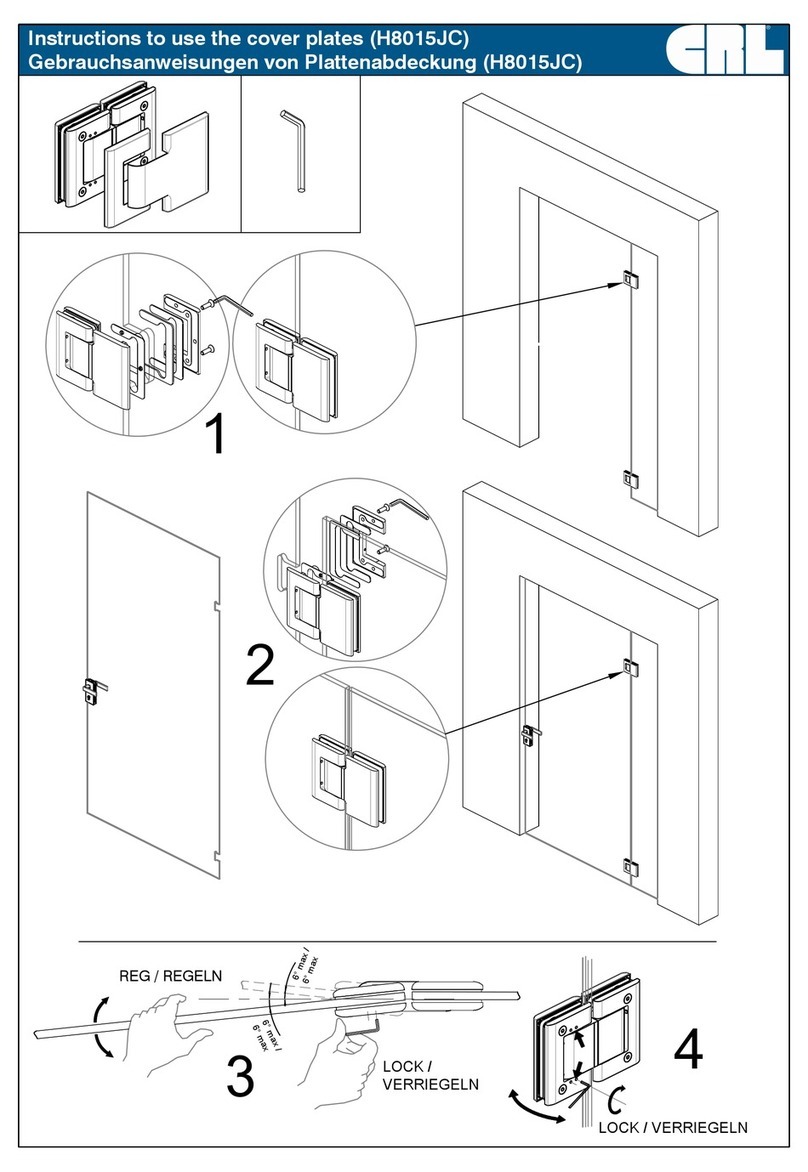

Open and Closed Limit Switch Setting

OPEN

CLOSE

STOP

After powering on, the

digital will display

E-03 (hasn’t set the

limit switch)

OPEN

CLOSE

STOP

Press and hold

“NEXT” for 3

seconds, the digital

will display 00000

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

Enter password 21000:

press “+” twice; press

“NEXT” once; press “+”

once; press “CONFIRM”

once; The digital will

display P1

Instructions for GK-E SERIES

www.gatexpertstore.com

15

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

Press “confirm” once; The

digital will display P1-F1;

press “confirm” once again;

The digital will display — —

Shortly press “OPEN” to check

opening direction, if it’s correct,

then press and hold “OPEN” to set

the open limit switch position,

digital will flash — —

If the opening direction

is wrong, press and hold

“STOP” until the digital

displays“F”or “r”to

change the running

direction. After direction

changed, press and hold

“OPEN” to set the open

limit switch position.

Instructions for GK-E SERIES

www.gatexpertstore.com

16

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN

Release the “OPEN” when

motor arrives at the open

limit switch position, press

“CONFIRM”, the digital will

display the encoder value

for 1 second and then show

— —, then you can set the

closed limit switch position.

Press and hold “CLOSE” to

set the closed limit switch

position until the gate runs to

proper closed limit position,

then release the button, press

“CONFIRM”, the digital will

display the encoder value for

1 second, then show P1-F2,

limit switch was set.

Press “NEXT” twice to

return to primary menu,

you can operate the

operator now.

Instructions for GK-E SERIES

www.gatexpertstore.com

17

CLOSE

STOP

OPEN

O N

1 2 3 4 5

Working Mode Setting

After these 2 steps, please check if the door running condition is to your

standard, if it’s good, you don’t have to do any other settings, the door will work

properly. If it’s not good, you should adjust the relative parameters.

Note:

1) Please adjust the door operator with the buttons on the control unit.

2) After adjustment, please make some trial running first, make sure

everything is correct, fit the control unit on a post that can be observed by you

and should be 1.4 high from the ground to keep it away from Children.

DIP Switch Setting:

ON(Up Position); OFF(Down Position)

No.1: ON-Mechanical Limit Switch; OFF-Electronic Limit switch

No.2: No function

No.3: No function

No.4: ON-Remote Control in Single Button Mode;

OFF-Remote Control in Three Buttons Mode;

No.5: ON-Enable Phase Sequence Detection;

OFF-Disable Phase Sequence Detection

Press and hold “-” for 4 seconds, you can

select manual control or automatic control

mode.

1. Automatic(A): Press “OPEN”, the door

will run to the open limit switch position,

after waiting for the programmed

auto-close time, it’ll automatically close to

the closed limit switch position.

2. Manual(H): Press “OPEN”, the door will

run to the open limit switch position, press

“CLOSE” the door will run to the closed

limit switch position.

Instructions for GK-E SERIES

www.gatexpertstore.com

18

Input Status:

Parameters Setting

Input Status

No.

Instruction

1

Stop

2

Open

3

Close

4

Photo Sensor

5

Air Bag

6

Loop Detector

7

Partial Opening

8

Single Cycle

9

Interlock

No.

Parameters

Value Range

Default

P1

P1-F1

Electronic limit switch setting

P1-F2

Pre-stop before arriving at the open

limit switch position

0-200

50

P1-F3

Pre-stop before arriving at the

closed limit switch position

0-200

60

P1-F4

Delay time for Auto-close

0-120 sec.

10

P1-F5

Height of partial opening

0-100%

50

P1-F6

Inch move for opening

0=Continuously

move;1=Inch move

0

P1-F7

Inch move for closing

0=Continuously

move;1=Inch move

0

P1-F8

Restore to factory setting of P1

0=No;1=Yes

0

P2

P2-F1

Stop of external three buttons

switch

0=NO;1=NC

0

P2-F2

Partial opening

0=NO;1=NC

0

P2-F3

Single cycle

0=NO;1=NC

0

P2-F4

Photo sensor

0=NO;1=NC

0

P2-F5

Loop detector

0=NO;1=NC

0

P2-F6

Airbag

0=NO;1=NC;2=pulse

0

P2-F7

Mechanical limit switch

0=NO;1=NC

1

This manual suits for next models

3

Table of contents

Popular Door Opening System manuals by other brands

DoorHan

DoorHan ARM 320 Installation and operating manual

REYNAERS

REYNAERS 062.8251 Technical manual

Kason

Kason 8600EZ installation instructions

Kenwa

Kenwa NHN 1600U-M Series Installation instruction

Autoslide

Autoslide AutoSwing ASW8-1 installation manual

Dormakaba

Dormakaba ORACODE 480 Series installation instructions

RollSeal

RollSeal RS-600 Series manual

eku

eku COMBINO 60 H Vorfront Mounting instructions

SDC

SDC 1511S installation instructions

B&D

B&D Controll-A-Door Smart SDO-7 installation instructions

Norton

Norton CloserPlus CLP7570 Series installation instructions

Dormakaba

Dormakaba 7400 FH installation instructions