P:\INSTALLATION INST\Delayed Egress\INST-1511ST\INST-1511ST.vsd Rev G7 02-19 Page 1

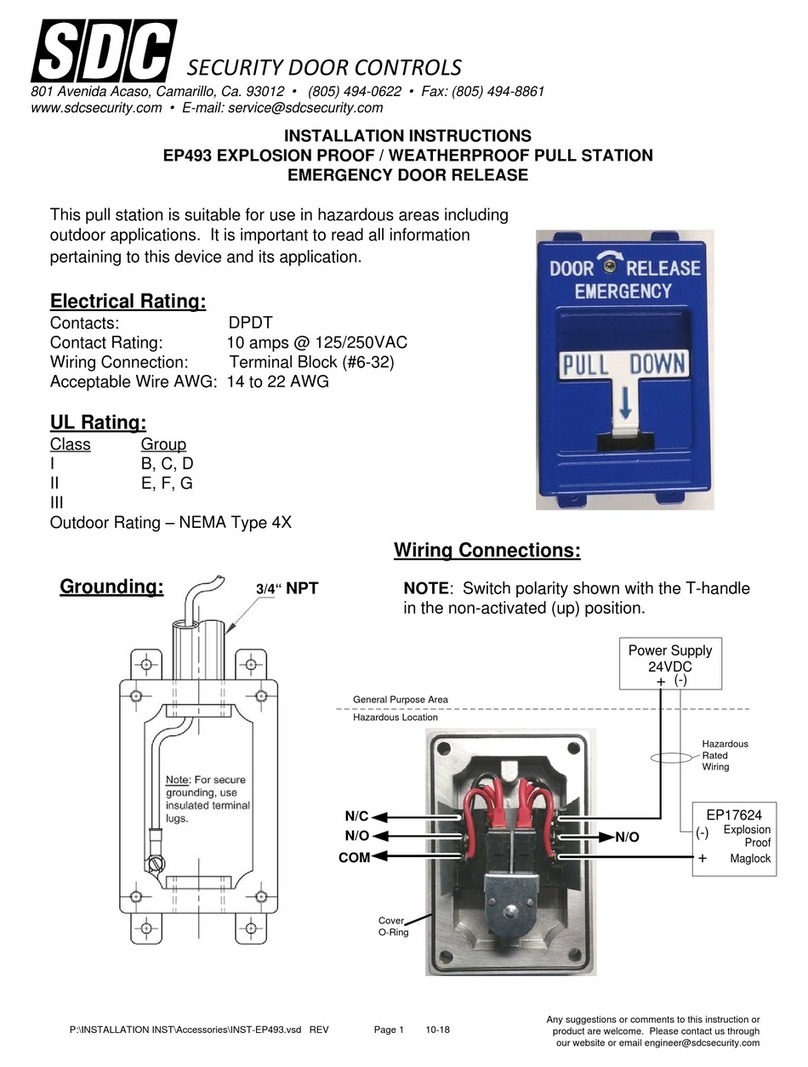

INSTALLATION INSTRUCTIONS

EXIT CHECK®DELAYED EGRESS EMLOCK®

1511S / 1511T

PUSH UNTIL ALARM

SOUNDS. DOOR CAN BE

OPENED IN 15 SECONDS.

Application

When unauthorized egress is initiated, the Exit Check®delays egress through the door for a period of 15 or 30 seconds.

An integral digital countdown display and voice commands inform the person intending to exit of the seconds remaining

to unlock. Meanwhile, the person exiting must wait allowing personnel or security respond. The door unlocks after the

15 or 30 second delay period has elapsed, permitting egress. A signal from the fire/life safety system will release the

lock immediately for uninhibited egress in an emergency.

Exit Check®applications include:

Restricting the egress of patients for their own safety.

Restricting the egress of commercial center patrons for security application needs.

Controlling pedestrian traffic in transportation facilities, including airport jetways and tarmacs

California Building

Code Compliant

KEEP PUSHING. THIS DOOR

WILL OPEN IN 15 SECONDS.

ALARM WILL SOUND.

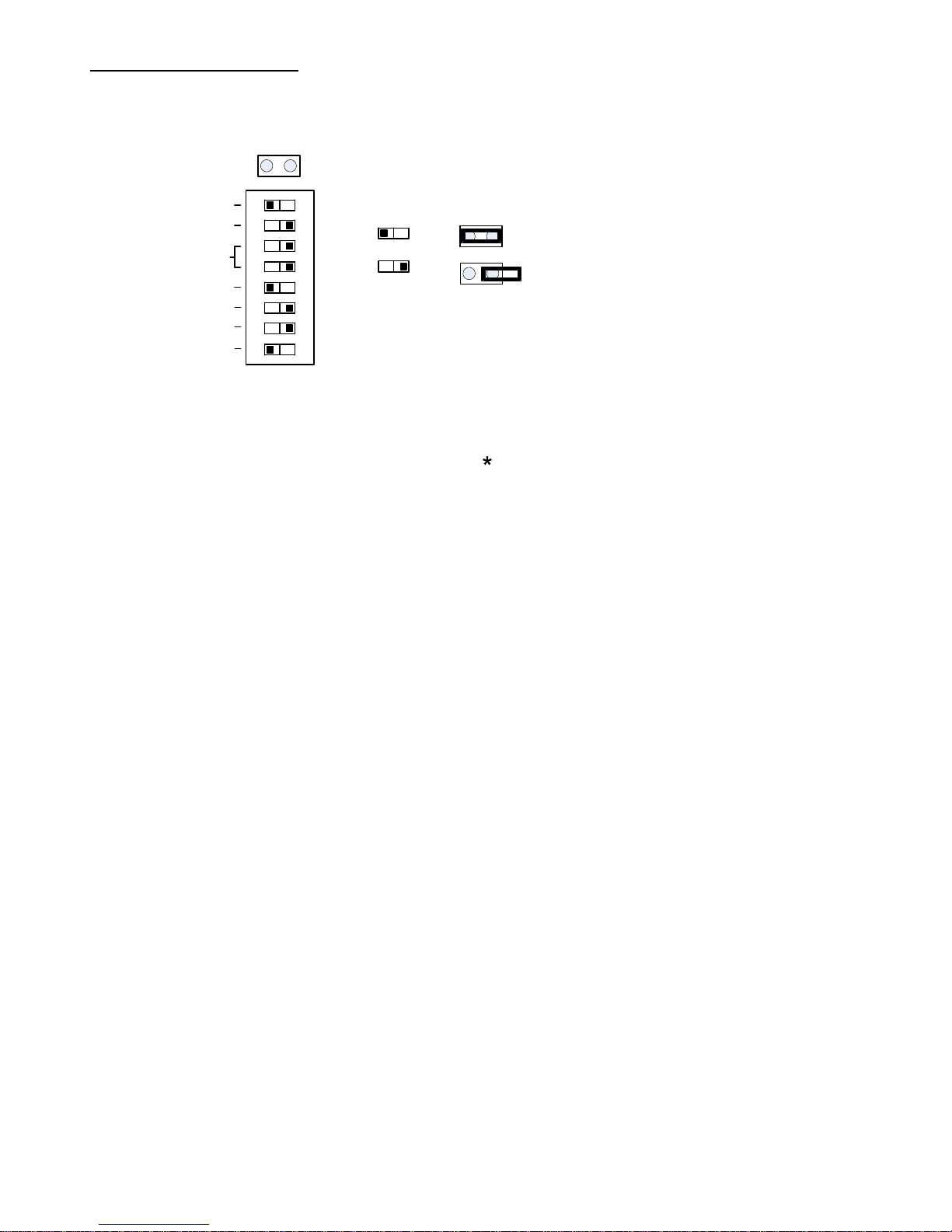

Standard Features

1650 lbs. Holding Force

15 or 30 Second Exit Delay when activated.

1 or 2 Second Nuisance Delay

75dB Alarm Tone with Digital Display & Selectable Voice

Instruction

Choice of Activation Trigger:

- Door Movement

- Exit Device w/ REX Switch

- Touch Sense Bar w/REX Switch

Auto Power-Up – Occurs when power is restored and/or

the fire panel is restored. (When Allowed by Code)

Manual Power-Up – This is a UBC & California Building

Code Compliant Feature – Only after power restoration

and fire panel reset may the lock be reset manually at the

opening. Lock can be reset with the built-in reset key

switch or, a key switch or keypad adjacent to the door.

Vandal resistant Proximity Sensor Trigger

Auto Sensing 12/24VDC input power

Connection for Tandem Option (Pairs of Doors)

Optional Features

D = DPS Door Position Switch

B = BAS Bond Alert Sensor

A = ATS Anti Tamper Switch

E= Energy Saver Option (1200 lb. Holding Force)

Building & Fire Life Safety Code Compliant

IBC International Building Code

IFC International Fire Code

NFPA 101 Life Safety Code

NFPA 1, UFC, Uniform Fire Code

UBC Uniform Building Code

CBC California Building Code

SBC Standard Building Code

BOCA National Building Code compliant

Chicago Building Code compliant

GWXT, GWXT7 - Auxiliary Locks - UL,cUL Listed

FWAX - Special Locking Arrangements - UL Listed

California State

Fire Marshal Listed

CSFM #3774-0324:103

Only the 1511S and the 1511T

have been UL listed as Special

Locking Arrangements to UL

Standard 294, and NFPA 101.

801 Avenida Acaso, Camarillo, Ca. 93012 • (805) 494-0622 •

www.sdcsecurity.com • E-mail: service@sdcsecurity.com