RS-600 High-Temperature Oven Door Manual2

Section 1: Introduction...........................................................................................................................................

Section 1.1: Safety................................................................................................................................................................................

Section 1.1.1: Definitions of Signal Words and Symbols.......................................................................................................................

Section 1.1.2: Statements.......................................................................................................................................................................

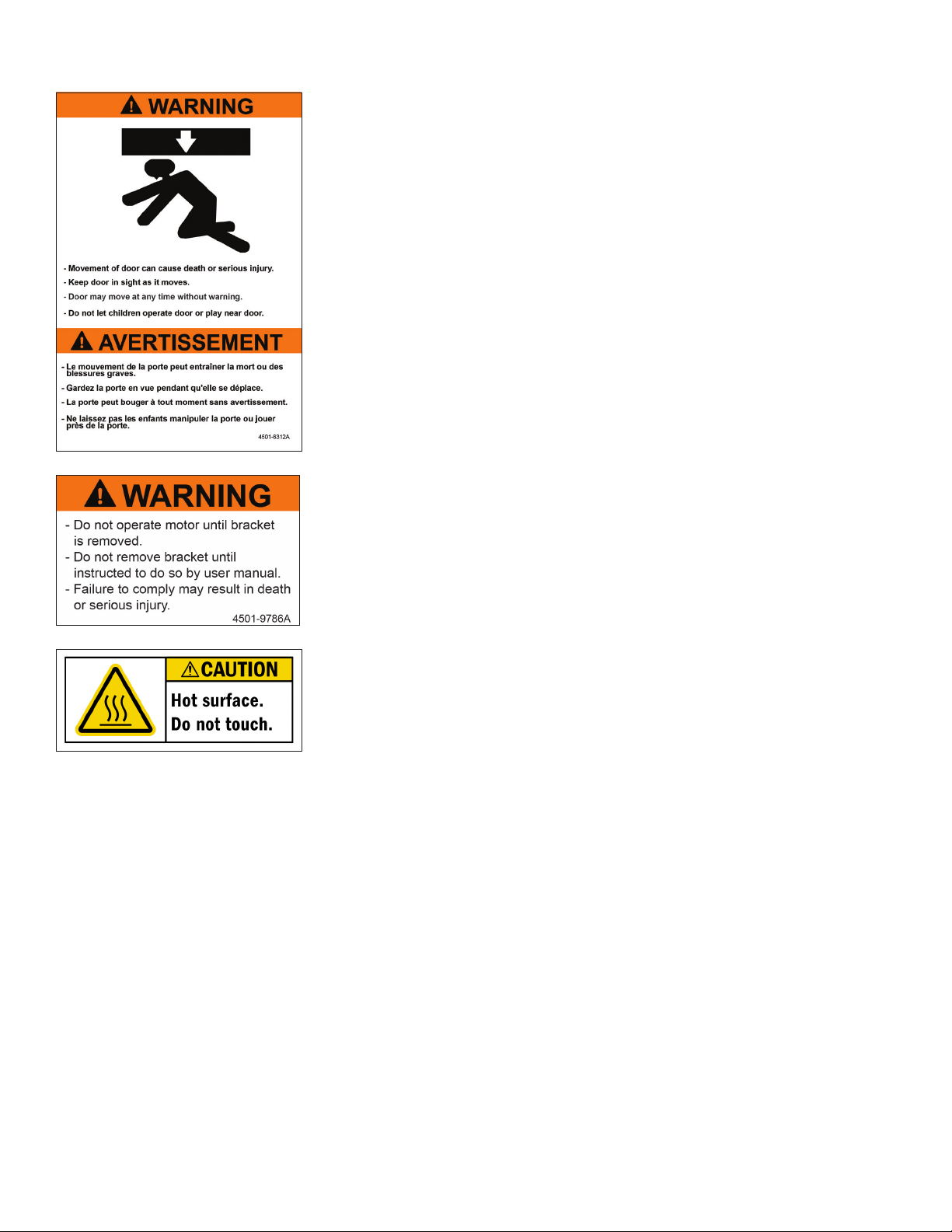

Section 1.1.3: Product Labels..................................................................................................................................................................

Section 1.2: Scope of Manual..............................................................................................................................................................

Section 1.3: Limited Warranty.............................................................................................................................................................

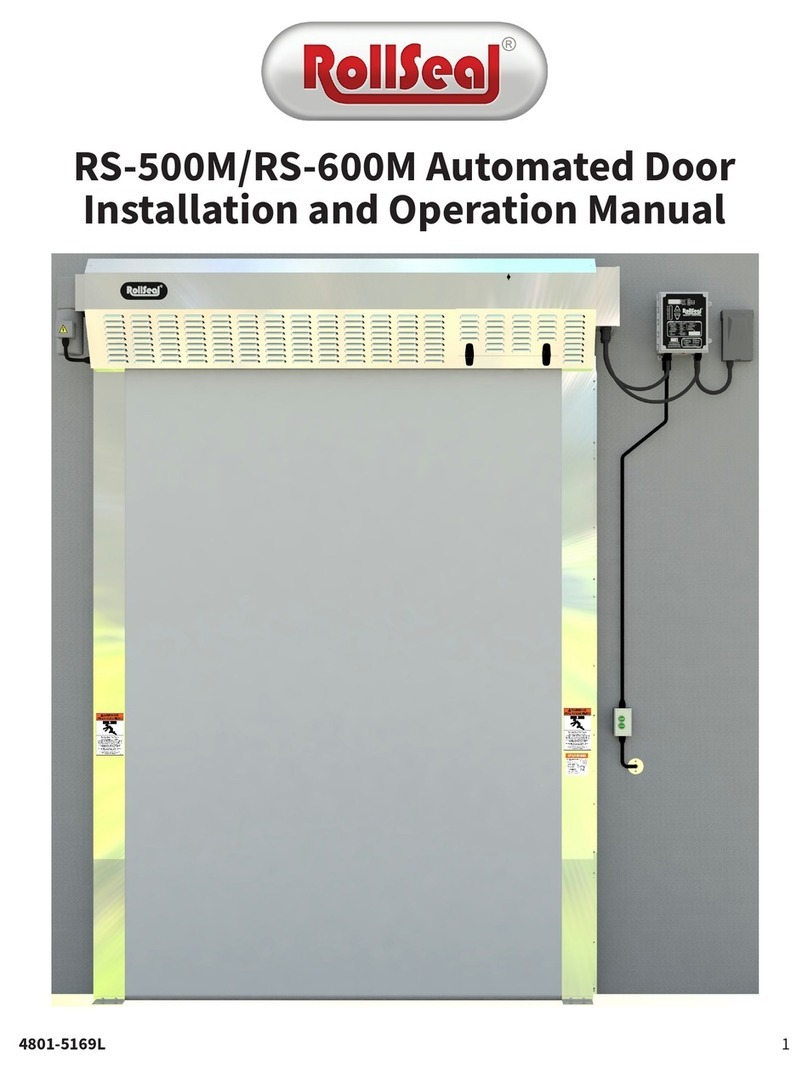

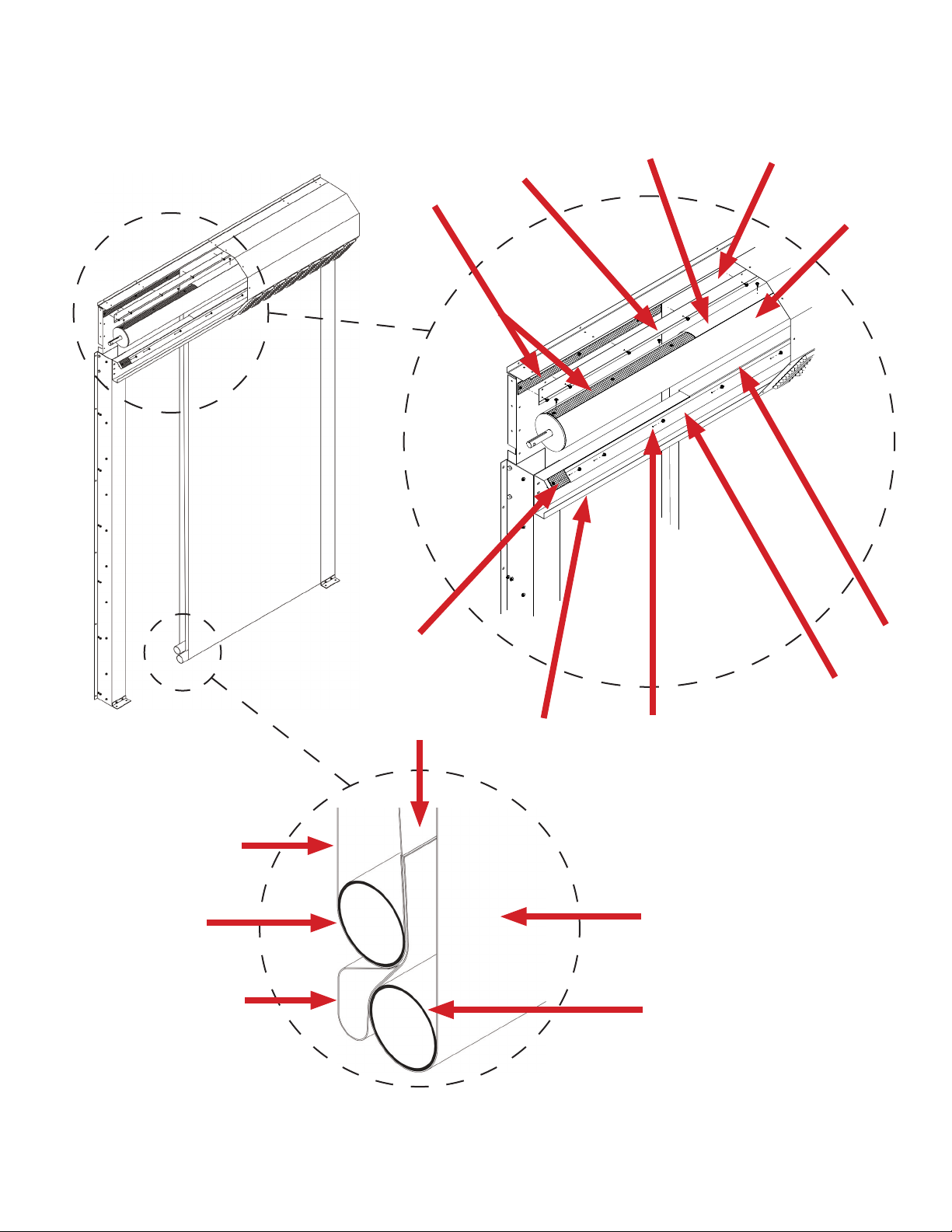

Section 1.4: Door Overview.................................................................................................................................................................

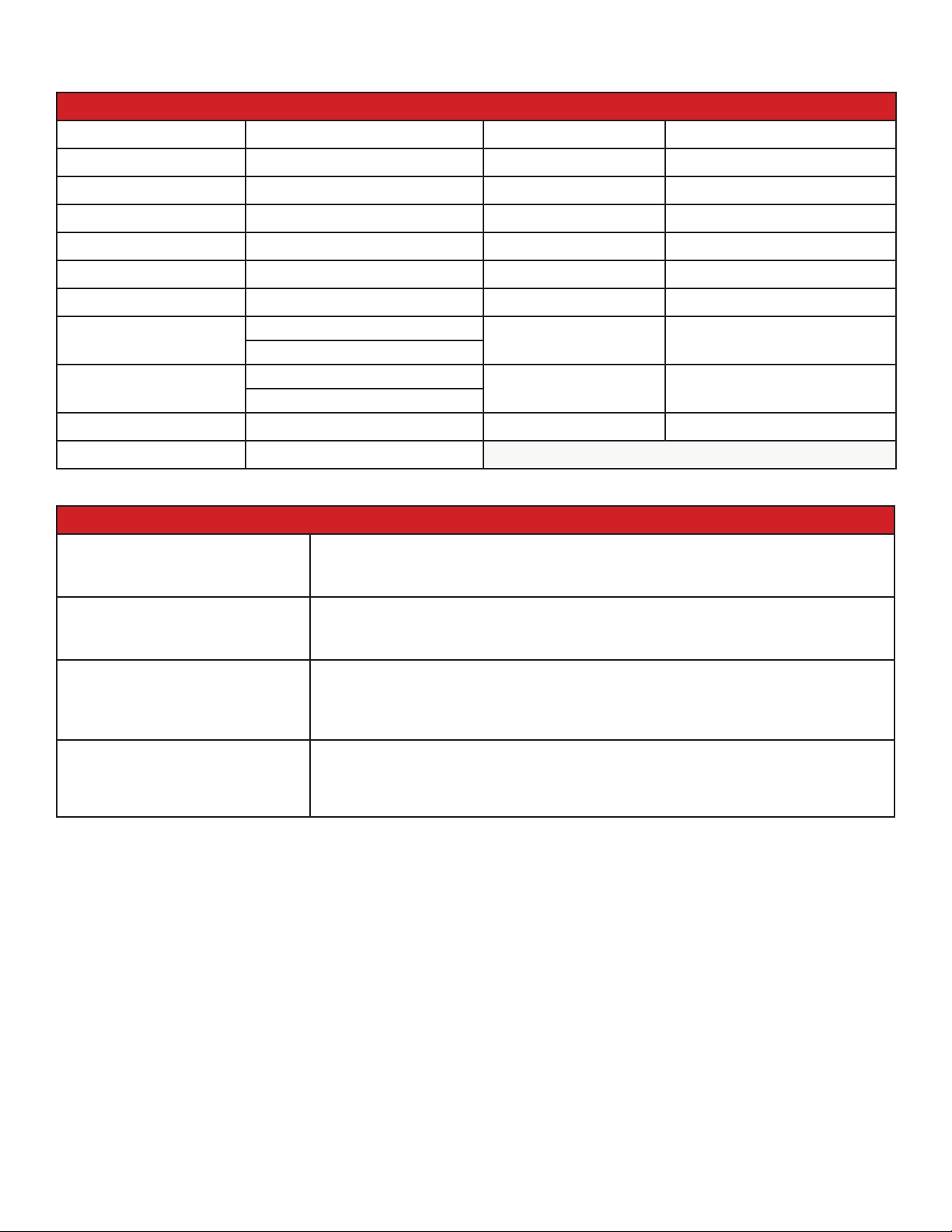

Section 1.5: Components.....................................................................................................................................................................

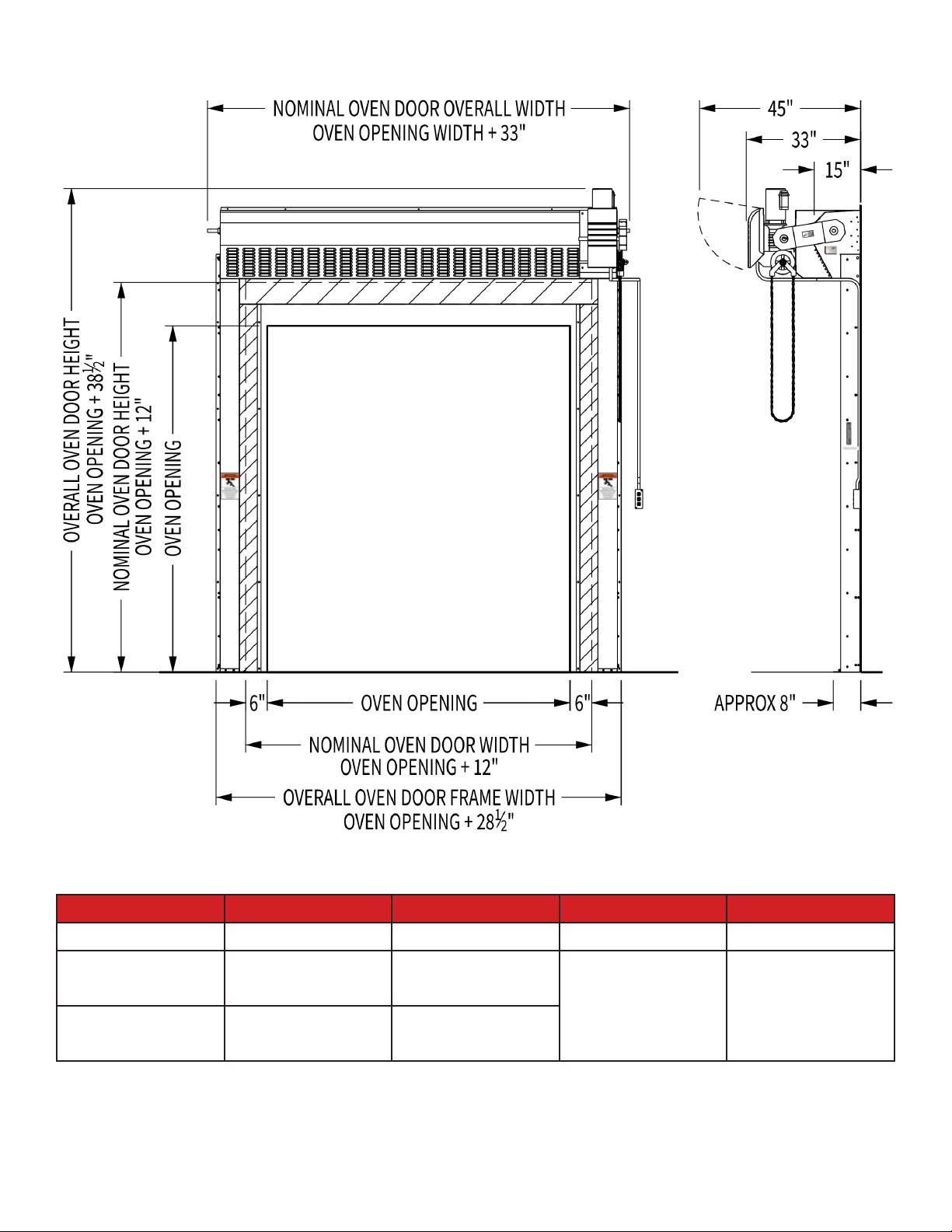

Section 1.6: Dimensions......................................................................................................................................................................

Section 1.7: Installation Requirements...............................................................................................................................................

Section 2: Installation.............................................................................................................................................

Section 2.1: Adjust Framing and/or Clear Opening............................................................................................................................

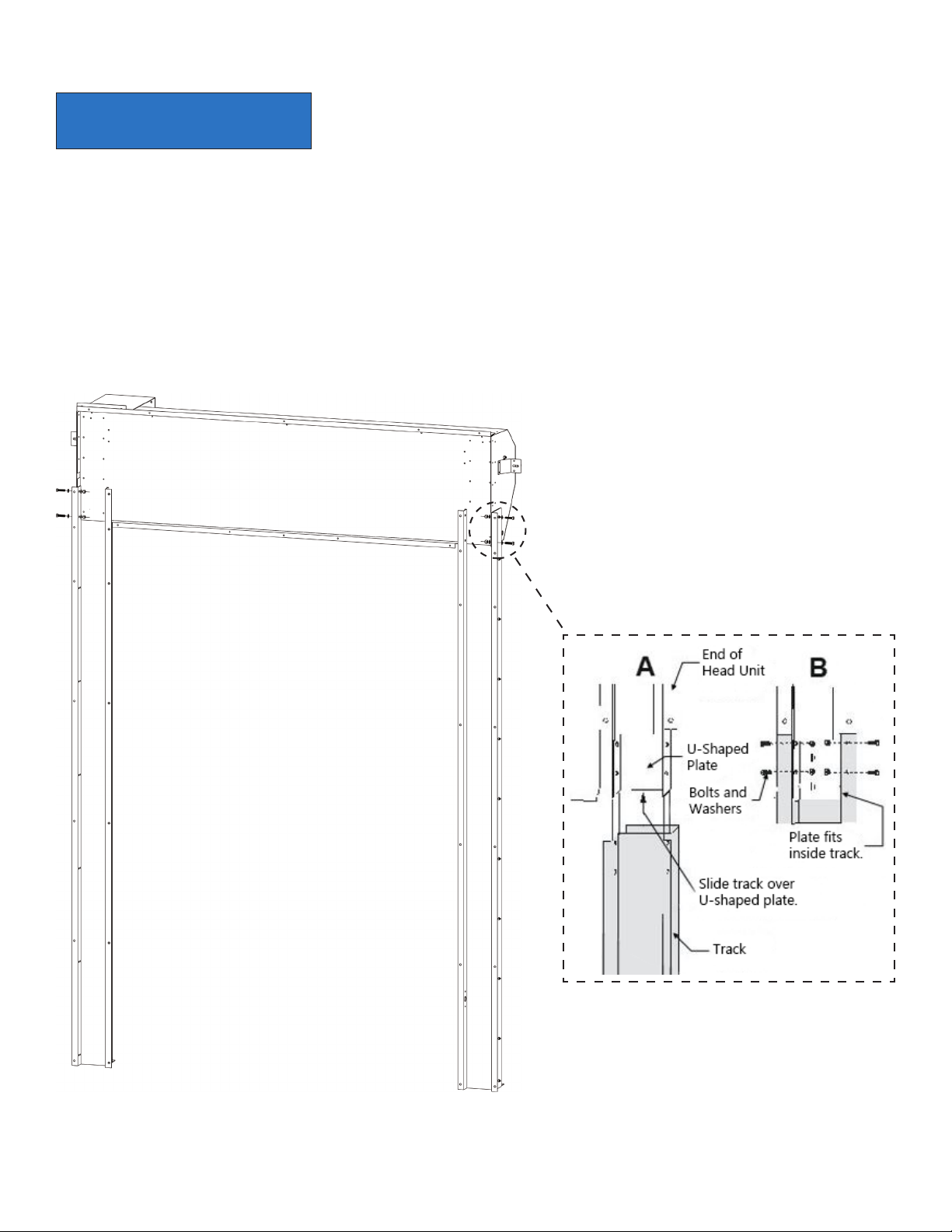

Section 2.2: Connect Tracks to Head Unit...........................................................................................................................................

Section 2.3: Raise Door to Clear Opening...........................................................................................................................................

Section 2.3.1: Up to 6' W x 9' H................................................................................................................................................................

Section 2.3.2: Between 6' W and 12' W...................................................................................................................................................

Section 2.3.3: Between 12' W and 16' W.................................................................................................................................................

Section 2.4: Mount Door to Clear Opening.........................................................................................................................................

Section 2.5: Install Inside Seal.............................................................................................................................................................

Section 2.6: Remove Safety Bracket From Motor Side.......................................................................................................................

Section 2.7: Install Motor.....................................................................................................................................................................

Section 2.8: Install Chain Drive Assembly...........................................................................................................................................

Section 2.9: Remove Safety Bracket From Other Side.......................................................................................................................

Section 2.10: Adjust Limit Switches....................................................................................................................................................

Section 2.11: Wire Motor......................................................................................................................................................................

Section 2.12: Install Infrared Safety Beam System.............................................................................................................................

Section 2.13: Wire Safety Beam Emitter and Receiver........................................................................................................................

Section 2.14: Install Switch..................................................................................................................................................................

Section 2.15: Enable Maintained Activation.......................................................................................................................................

Section 2.16: Prepare for Operation....................................................................................................................................................

Section 3: Operation...............................................................................................................................................

Section 3.1: Switch...............................................................................................................................................................................

Section 3.2: Remote Transmitter.........................................................................................................................................................

Section 4: Maintenance...........................................................................................................................................

Section 4.1: Inspecting and Tightening Chain....................................................................................................................................

Section 4.2: Replacing Panels..............................................................................................................................................................

Section 4.3: Replacing Floating Seal...................................................................................................................................................

Table of Contents

3

3

3

3

4

5

5

6

7

8

8

9

9

10

11

11

12

14

16

17

18

19

20

22

23

24

25

26

27

28

29

30

30

31

32

32

32

33