FOLLOW THE INSTRUCTIONS CAREFULLY TO GRANT THE MACHINE A CORRECT

FUNCTION AND LONG SERVICE LIFE.

TABLE OF CONTENT

INTRODUCTION --------------------------------------------------------------------------- --- 3

Intended use-- ------------------------------------------------------------------------------------ 3

Technical data--------------------------------------------------------------------------------------- -4.

TRANSPORTATION---------------------------------------------------------------------------------4

UNPACKING ------------------------------------------------------------------------------------------5

INSTALLATION ------------------------------------------------------------------------------ - 5

TRIAL OPERATION---------------------------------------------------------------------------------6

OPERATION --------------------------------------------------------------------------------------- 7

Breaking the bead ------------------------------------------------------------------------------- 7

Tire Demounting -------- ----------------------------------------------------------------------- 8

Tire mounting------------------------------------------------------------------------------------------10

INFLATING -------------------------------------------------------------------------------------- 11

MAINTENANCE--------------------------------------------------------------------------------------12

TROUBLE SHOOTING----------------------------------------------------------------------------13

ELECTR. AND PNEUM. DIAGRAMS -------------------------------------------------------14

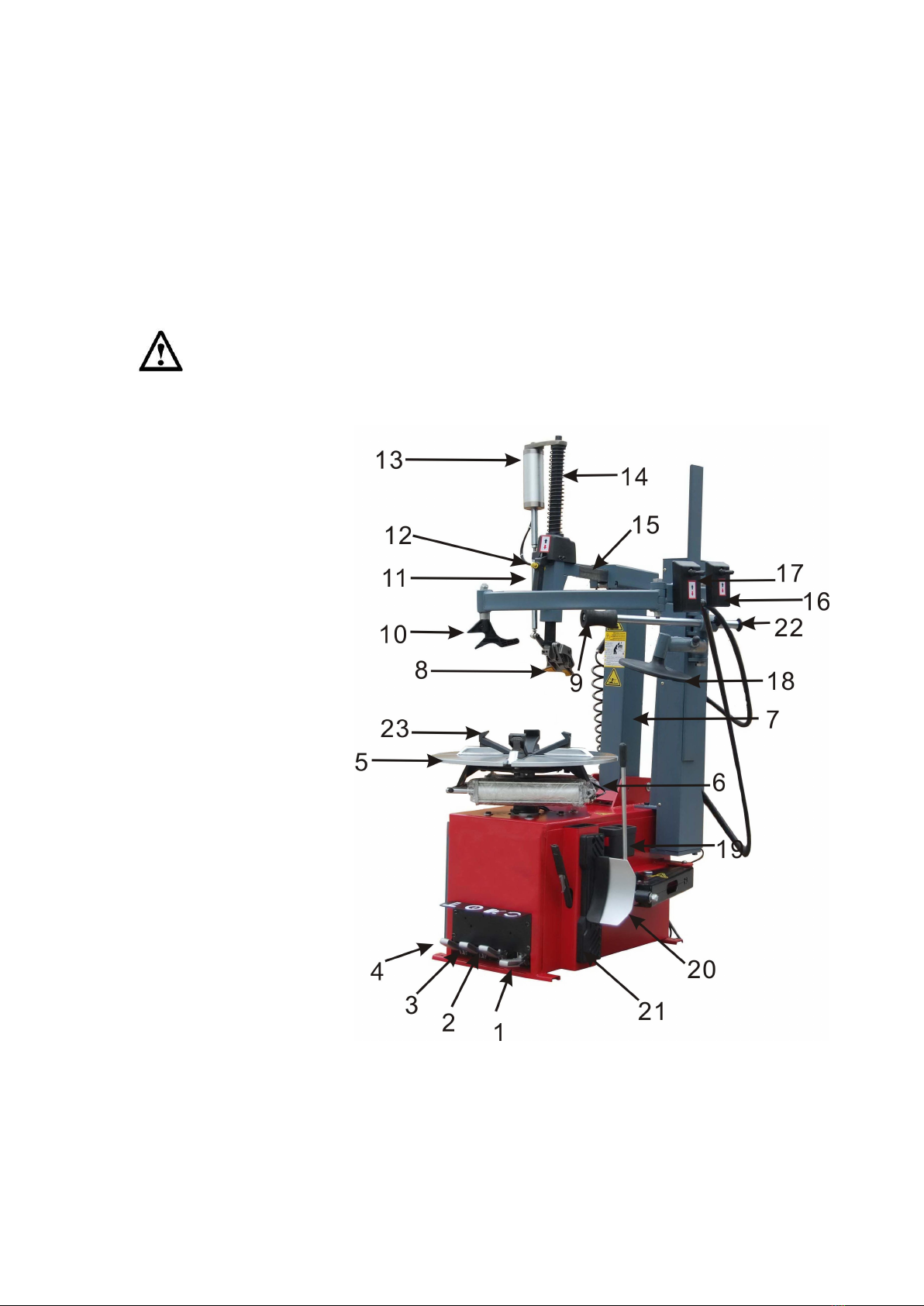

INTRODUCTION