Sharp SmartPunch Plus Installation Manual 2

1. Recommendations and Pre-requisites

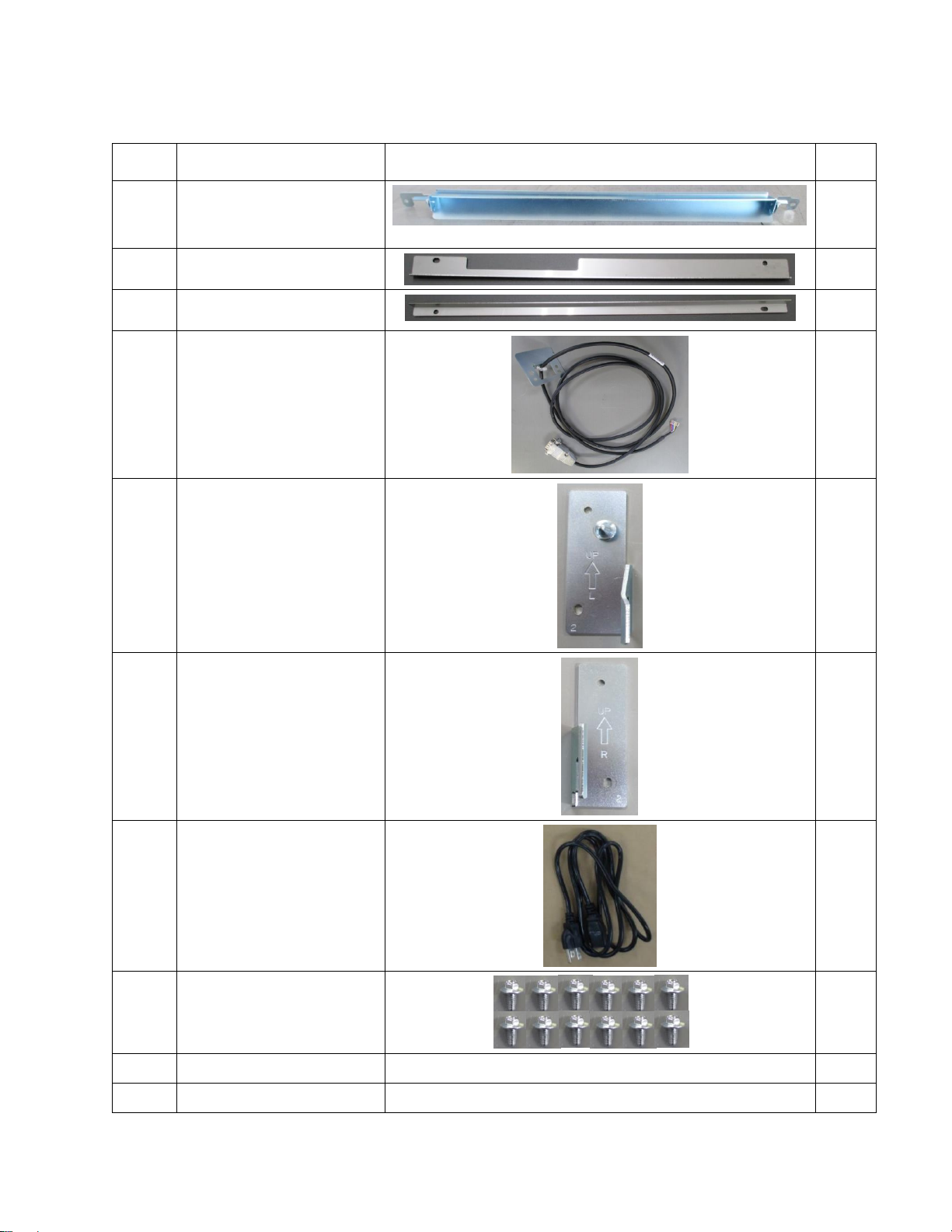

You will need the installation kit provided with the SmartPunch Plus unit, which can be found in the

main carton.

2. Unpacking

Inspect the outside of the package for shipping damage. If there is evidence of shipping damage,

contact the shipping carrier immediately.

Remove the punch from its shipping carton. Three people are recommended, one lifting at the casters

while two lift at the top cover. DO NOT lift using the front door panel.

Retain the smaller accessory box; it contains parts required for correct installation of the SmartPunch

Plus.

Inspect for any concealed damage to the unit. If there is evidence of concealed shipping damage,

contact the shipping carrier immediately.

Remove all shipping tape from doors and levers.