gCreate gMax 2 PRO User manual

v210819 (Marlin 2 Firmware)

gMax 2 PRO

Getting Started

Even if you are familiar with 3d prinƟng, please review this guide

to set up and learn about your gMax Printer.

This guide should be used aŌer you have received the printer and followed the

unboxing instrucƟons. This manual is for Single and Dual extruder printers

Check out youtube.com/gCreate3d

to watch a gMax 2 Geƫng Started Video

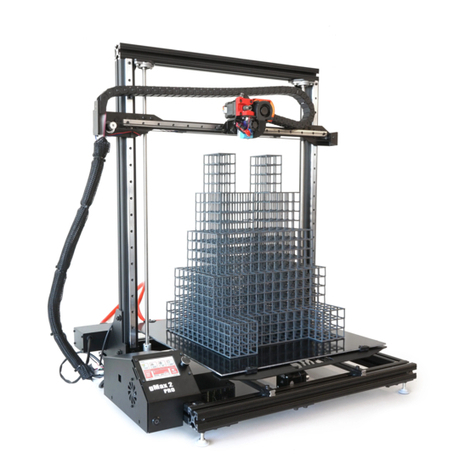

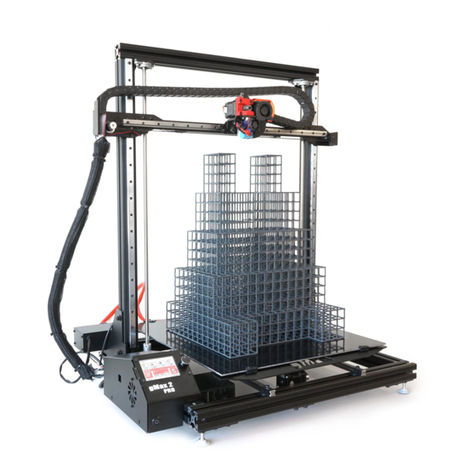

X-Axis

Y-Axis

Z-Axis

Extruder Drive Gear

Hotend

Hotend Fan

(Active cooling)

Blower Fan

Bed Clips

Corner Foot Leveling

gMax 2 PRO

Diagram

Pg 1

Extruder Drag Chain

Extruder Swing Arm

Hotend

Nozzle

BLTouch

Bed Sensor

Extruder Carriage

Extruder

Filament Bracket

Lead Screw

LCD Screen

Power Button

USB Connection

RGB LED

Light Bar

Lead Screw

Pillow Block

Lead Screw

Coupler

Power Supply

SD Card Slot

Lead Screw Nut Block

Print Bed

(Acrylic or G10 FR4)

X-Axis Arm

Electronics Box

Pg 2

Machine Specifications (For Reference)

•

Set your max temperature 5 degrees below the maximum firmware

limit to prevent a “MAXTEMP” error.

•

This machine includes sensitive wiring and hardware. It should be kept

in a well ventilated and dry environment. Humidity can have adverse

or negative affects on the printer and should be avoided.

•

This printer includes parts which can exceed 350C and caution should

be taken. Do not let pets or children near the product without supervi-

sion. Let the hotend cool down 10 minutes before touching it.

•

Always keep a working fire extinguisher and have a working smoke

alarm near the printer. Never place flammable objects near the printer

including liquid chemicals that can release flammable vapors.

•

Never open the electronics case when the printer is powered on.

•

Any modifications or attempted repairs, not explicitly directed by

gCreate, that cause damage are not covered under the Warranty

Max Hotend Temperature

(Do not set above)

350C ( All-Metal) 450C Compaable

Filament Diameter 1.75mm

Layer Height Range

(Suggested)

0.080mm - 0.740mm

(Nozzle Dependent)

Electronics

Power

SKR v2, STM32 32-bit (Arm Cortex M4)

Heated Bed 120C MAX TEMP

Firmware Marlin 2.0 (gCreate Modified)

120V - 240 V (Selectable)

Warning

Pg 3

Printer Accessories

Print Scraper SD Card

Filament Spool Bracket

Spare Hardware Hex Key Set Power Cord

Addional Nozzles

Brass Nozzle

Cleaning Brush

Filament Cuers

Open the accessory box and remove all the parts. Each printer comes with a scraper for removing parts

from the build plate, a power cord, hex keys, nozzle cleaning brush and an extra bag of hardware for

future upgrades.

Pg 4

Insert Filament In Extruder

Plug In and Turn On

3. Pinch the extruder arm above the spring and insert

filament in the white PTFE tube.

4. Slide filament in unl you see it enter the top of the

tube just under the metal drive gear. The filament

should slide in about 4 inches more.

1. Plug in the printer to

a surge protected

power strip.

2. Make sure power

switch is on.

SD Card Slot

Power Buon

1

USB Slot (use

90 degree adapter)

1. We recommend cung offthe first 12” of a new spool of filament.

2. Every me you insert filament, cut end of filament at a 45 degree

angle and straighten 4” of the end of the filament by bending it.

Pg 5

gMax Initial Run (Required)

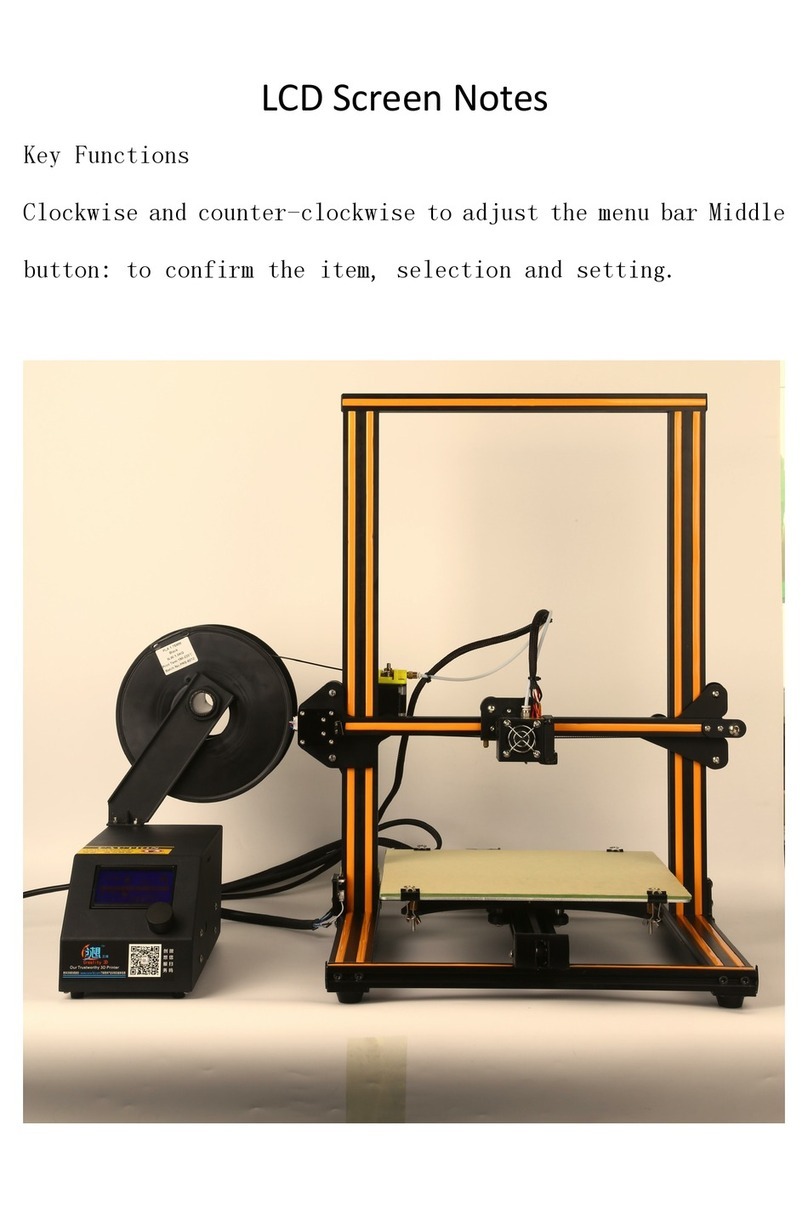

LCD Screen Breakdown

1. You must run the supplied gcode file to test your gMax printer

aer transport. Slide the SD card (upside-down) into the leside

of the LCD screen.

2. On the LCD screen, the noficaon area will say “Card Inserted”.

If not, try removing the SD card and reinserng it and make sure

the “lock” is in the offposion on the side of the card.

3. Select “Print > TFT SD > gMax IniƟal Setup”.

The test file will perform several funcons:

• X, Y, Z Axis Motor test (slow and fast)

• Mulple Homing Test

• Extrusion test (with heat)

• Fan test then cooldown

Heated

Bed Temp

Hotend #1

Temp

Noficaons

Sengs

Menu

Fan

Speed

Printer

Speed

Coordinates of

Extruder (X, Y, Z)

Current Temp /

Target Temp

Print

Menu

Noficaons

“

P

i

The gMax “Initial Run Test File”

should take about 15 minutes

to complete. If the printer fails

during any of these tests or the

bed probe doesn’t drop/raise

contact support.

Note

”.

Pg 6

1. To run the bed leveling roune go to “Menu > Movement > Bed Level > BBL > Start”.

2. Wait for the bed leveling roune to finish then click “Ok” to save the mesh to memory. The bed

leveling mesh will automacally load when you start a print.

Manually Level X-Axis Arm

Bed Leveling

1. Turn the couplers that connect the z-axis motors to the lead screws.

2. Clockwise will raise the x-axis arm and counter clockwise will lower it.

3. Line up the top of the arm to the nearest bolt hole on the linear rails for

both leand right lead screws.

1.

1

To

T

T

T

r

The gMax 2 PRO x-axis arm should be manually leveled prior to bed leveling especially after it has been shipped.

The easiest method is to turn the lead screws with the printer turned off. If the arm is not level the z-axis may bind

while it tries to lift.

The gMax 2 Pro uses Bilinear Bed Leveling (BBL) in marlin to probe the bed and create a 3d mesh for the first

layer. The mesh is saved to memory and helps ensure the extruder lays down a proper fist layer. It is important

the x-axis stays level relative to the bed. If it changes you must re-run the bed leveling. We recommend running

the bed leveling command before any large prints

Note

Make sure to turn Bed

Leveling on after the leveling

has completed if it is off.

Your First Print (Required)

Printing Status Screen

1. Aer conducng the Inial Run and leveling the arm, this first print will confirm that your gMax is

running the same as when it lethe manufacturing facility. This is a necessary and useful print.

Make sure to run it with the supplied filament and on the cold acrylic bed.

2. Go to “Print > TFT SD >Your First Print”. As the prinng

begins, you will need to adjust the first layer height using the

Babystepping feature since it is set intenonally high from the

manufacturing facility so as not to damage the bed. Refer to

the next page for more informaon.

Pg 7

Current Temp /

Target Temp

Print

Progress

Fan

Speed

Print Flow

/ Feed Rate

Cancel Print

Filename

Pause Print

Babystep Menu

(Displays model

thumbnail if acvated)

Bed Temp

More Menu

(Adjust printer sengs)

Note

The printer bed probe is

intentionally set high when

leaving our facility. You will

have to babystep the printer

on your first print.

Pg 8

Babystepping Cheat Sheet

Lower

Extruder Raise

Extruder

Change IncrementSave to

Memory

Too low and nozzle

is digging in the bed

causing damage.

Too high and

not adhering to

the bed

Correct height.

Sticks to bed just

enough.

Extruder Extruder Extruder

Extruder is too low Extruder is perfect Extruder is too high

As your print starts, click

“Babystep”.

You may have to raise or

lower up to 0.50 mm depend-

ing on settings and if your

nozzle has been changed. It

might take a few seconds to

see any change in height

Note

Pg 9

Removing the Print. Strength vs Finesse

1. If the bed is acrylic, aer the print finishes you can immediately remove it.

If you are using a heated bed, turn it offand let it cool several minutes before removing or you risk

damaging the print surface or warping you rpart.

2. If the first layer printed correctly you should see no curling at the edges.

3. USING CAUTION, take the scraper and gently tap at the edges of the print. Look for corners of the

model and tap them. Aer several taps the print should pop offthe bed. If the model has a large

surface area on the print bed, it may be harder to remove and you may have to slide the scraper

below the model.

Tap Edges or

Corners

The scraper is very sharp.

NEVER place your hand

behind the area you are

scraping and take caution

not to dig into any build

surfaces.

Warning

Pg 10

Slicing

1. For slcing, we recommend PrusaSlicer, Cura or Simplify3d. View our forum at forum.gcreate.com, our

YouTube channel youtube.com/gcreate3d or the respecve slicing program websites for more informa-

on.

2. Simplify3D may have older gMax configuraƟons built-in. Use the configuraon files on the SD card or

download them directly from our forum for the latest versions.

Cura (Free)

PrusaSlicer (Free)

Exterior Perimeter

Interior Perimeter

Infill

Boom Surface

Skirt (Brim if it’s

touching the model)

Slicing Tips

• Depending on your 3d model and filament type you should

oen change several main sengs. The majority of print quality

issues can be fixed by changing slicing seƫngs.

• Print speeds, layer height, exterior wall thickness (or perime-

ter count), infill density, support material sengs, hotend

temperature and fan cooling are the typical sengs to modify. Refer to the Cura and Simplify3d

websites and forum.gcreate.com for many useful tutorials.

• Always use high-quality filament to reduce issues and improve your results.

Basic Anatomy of Slicing

I

S

t

t

E

B

I

Simplify3D

Pr

us

aS

li

ce

r

(F

re

e)

Note

Slicing is one of the most important parts of the 3d printing process. The proper settings can result in a great print

however many settings are usually model-specific. Taking the time to learn the best settings will result in a better

printing experience.

Always download the latest

configuration files from us to

ensure you have the correct

settings.

Pg 11

Useful Tips While You Print

1. You can adjust the speed of your print in real me by turning the LCD screen knob. Slowing

the speed can be used to improve the print at a difficult area or if the print isn’t cooling

enough.

2. You can adjust fan speed, hotend temperature and filament flow during a print. Note these

seƫngs are not permanent and they will change when the printer reaches a new gcode

command or is turned off.

3. The cooling fan will not operate below 30% since the power is too low.

4. You can change filament during a print by just pausing a print. It can also be sent by your

host soware or you can put it in your gcode file manually by pung M600 where you want

the change to happen.

When acvated the print will pause, the extruder will raise/move out of the way and it will

retract the filament. Insert your new filament and press resume.

5. Always plug your printer and heated bed into a UPC power backup or surge protector.

6. When the nozzle is hot, carefully use needle nose pliers or the metal bristle brush to

remove any excess plasc which may have built up.

7. Do not use any lubricant on the lead screws, instead clean them offperiodically with

acetone or rubbing alcohol. Lubricant will cause dust to accumulate and get scky.

8. Check your print oen. If any part of the print fails, it may destroy the rest of the print and

possibly damage the printer.

9. Do not use solvents to clean acrylic or BuildTak PEI print bed.

10. If you press the screen for more than 2 seconds, you can revert to the Classic Marlin mode.

Somemes if the screen senses a touch too quickly you will also go to the “Select Mode”

screen. Note: do not switch modes while prinng to avoid possible cancellaon of the print.

Dual Extruder Printers - 2in1 Dual

1. Make sure when using the 2in1 dual

extruder to insert the le(extruder

#1) filament first unl it comes out the

hotend.

2. Then insert the right (extruder #2)

filament unl you feel when it hits the

first filament and pull back about

5mm.

3. Babystep and bed level the printer just

like a single extruder.

The 2in1 dual extruder uses similar settings as the single

extruder and does not require independent adjustments of

the hotend height. Make sure to update your slicing

settings.

Pg 12

s

the

Thermistor Set Screw

Heater Cartridge Set Screw

Sengs:

Skirt/Brim offset: 0

Skirt/Brim Layers: 2

Ooze Shield: On

Ooze Shield Extruder: Both

Dual-Extrusion Printing TIps (Dual Chimera)

Prime Tower

Ooze Shield

LeExtruder (Perimeter)

Right Extruder (Infill)

Brim

1. Use a “Brim” and an “Ooze Shield”. The Ooze Shield will help clean the inacve nozzle

during a print to avoid wiping the plasc on the part.

2. Use a “Prime Tower”. The Prime tower

will help material to begin flowing

when switching between nozzles.

3. Cool the inacve nozzle to avoid that nozzle leaking

during a print. In Cura, search for “Standby Temperature”.

In Simplify 3D you can add code to the

“Scripts > Tool Change Scripts” tab

to cool the inacve nozzle.

G1 X-15 Y210 F3500 ; move to X-15 and wait for temps

; Dual PLA - PLA on the Chimera+

;

;Switch to T0 or LEFT hotend

;

{IF NEWTOOL=0}M104 S170 T1 ; set T1 RIGHT ( inacve) extruder to 170 C

{IF NEWTOOL=0}M109 S190 T0 ; set T0 LEFT (acve) extruder to 190 and wait

{IF NEWTOOL=0}M104 S[extruder0_temperature] T0 ; set T0 LEFT extruder to T0 temp from Temperature tab

;

;Switch to T1 or RIGHT hotend

;

{IF NEWTOOL=1}M104 S170 T0; set T0 LEFT ( inacve) extruder to 170 C

{IF NEWTOOL=1}M109 S190 T1; set T1 RIGHT (acve) extruder to 190 and wait

{IF NEWTOOL=1}M104 S[extruder1_temperature] T1 ; set T1 RIGHT extruder to T0 temp from Temperature tab

P

e

p

art

.

O

R

L

L

B

Tool Change gCode

Pg 13

Water Soluable (PVA) Support Material

1. Follow the previous example sengs for Dual Extrusion

prinng.

2. Make sure to increase the interferance layer density of

the PVA support material to 100% and the distance from

the part to zero. Below are addional sengs to keep an

eye out for.

You can use the gMax 2 PRO dual extruder to print

your part out of one material and the support

material out of water soluable PLA material. This

support can then be dissolved away in water for a

cleaner surface finish.

PLA 3D Print

PVA Support

Simplify 3D Support Sengs

Cura Support Sengs

P

1

. F

o

p

r

2

. M

a

th

P

Solid PVA Top Layer

S

Simplify3D

Pg 14

Other manuals for gMax 2 PRO

2

This manual suits for next models

1

Table of contents

Other gCreate 3D Printer manuals