8

As a result of continuous improvement and further development of our designs, the information and illustrations in this brochure are not binding.

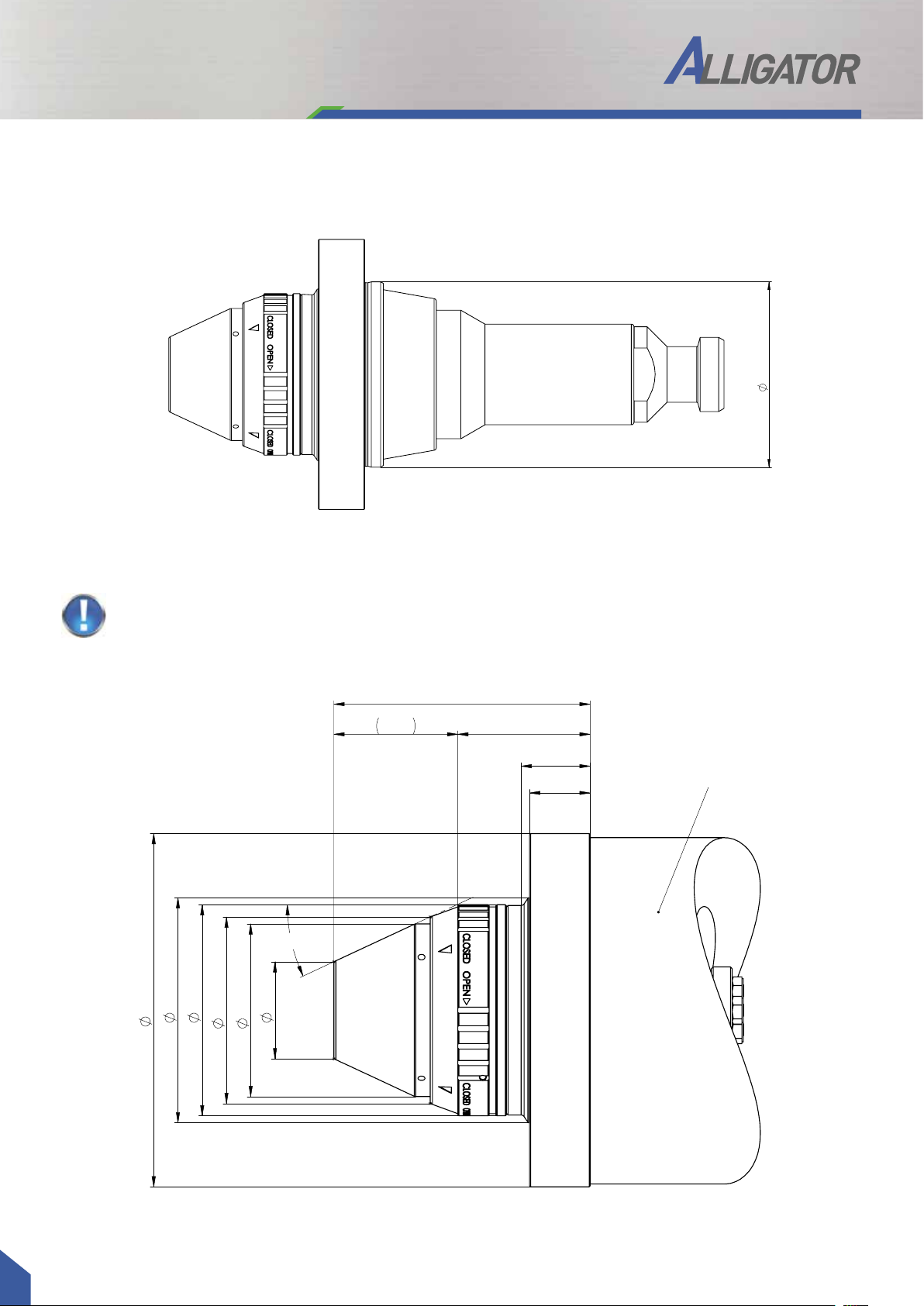

The specifications and installation lengths of the machine manufacturer must be observed. All specifications are in mm. Errors and omissions excepted.

GDS ALLIGATOR

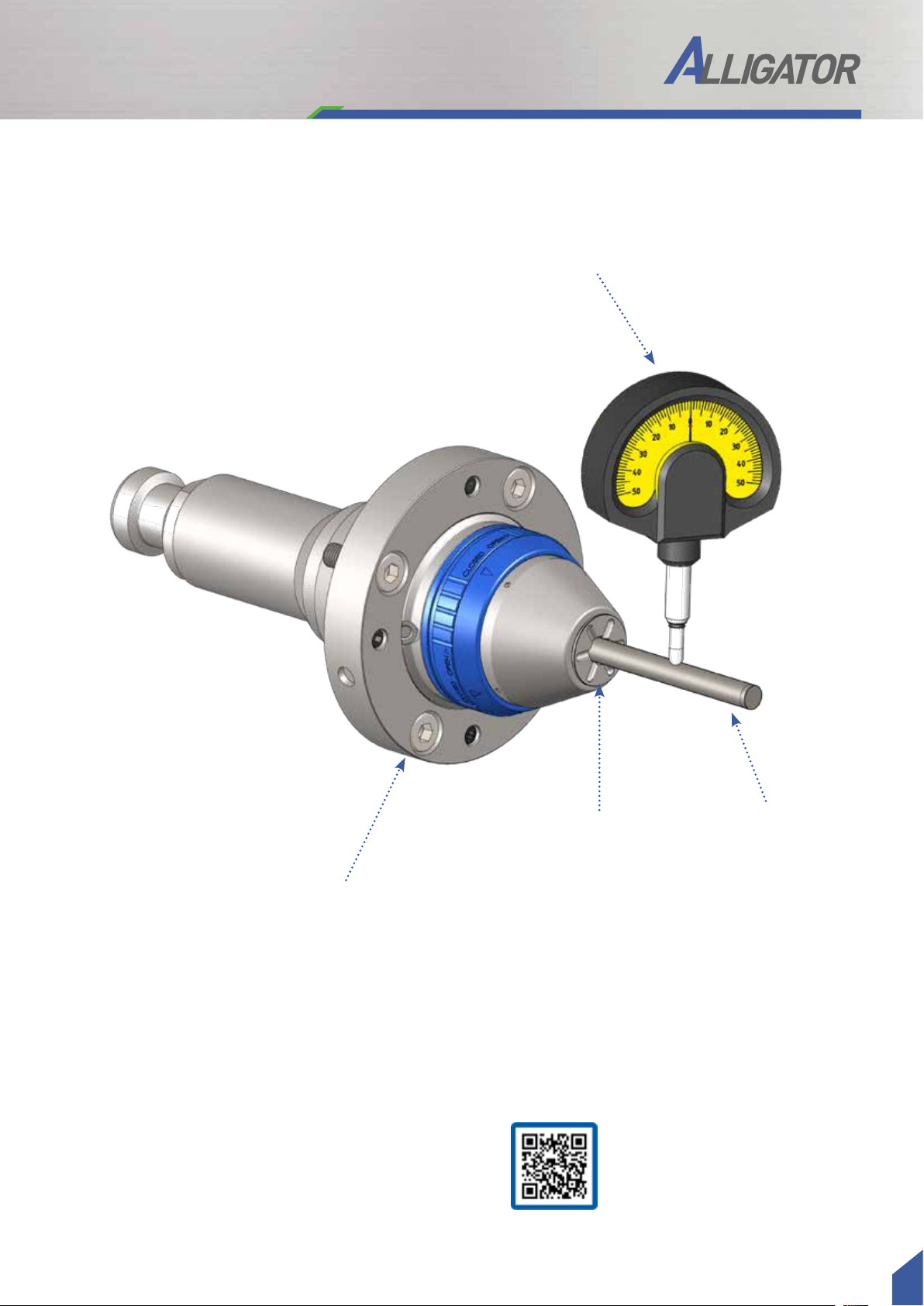

The new ALLIGATOR hydraulic expansion precision clamping system can be used

in the following tool grinding machines:

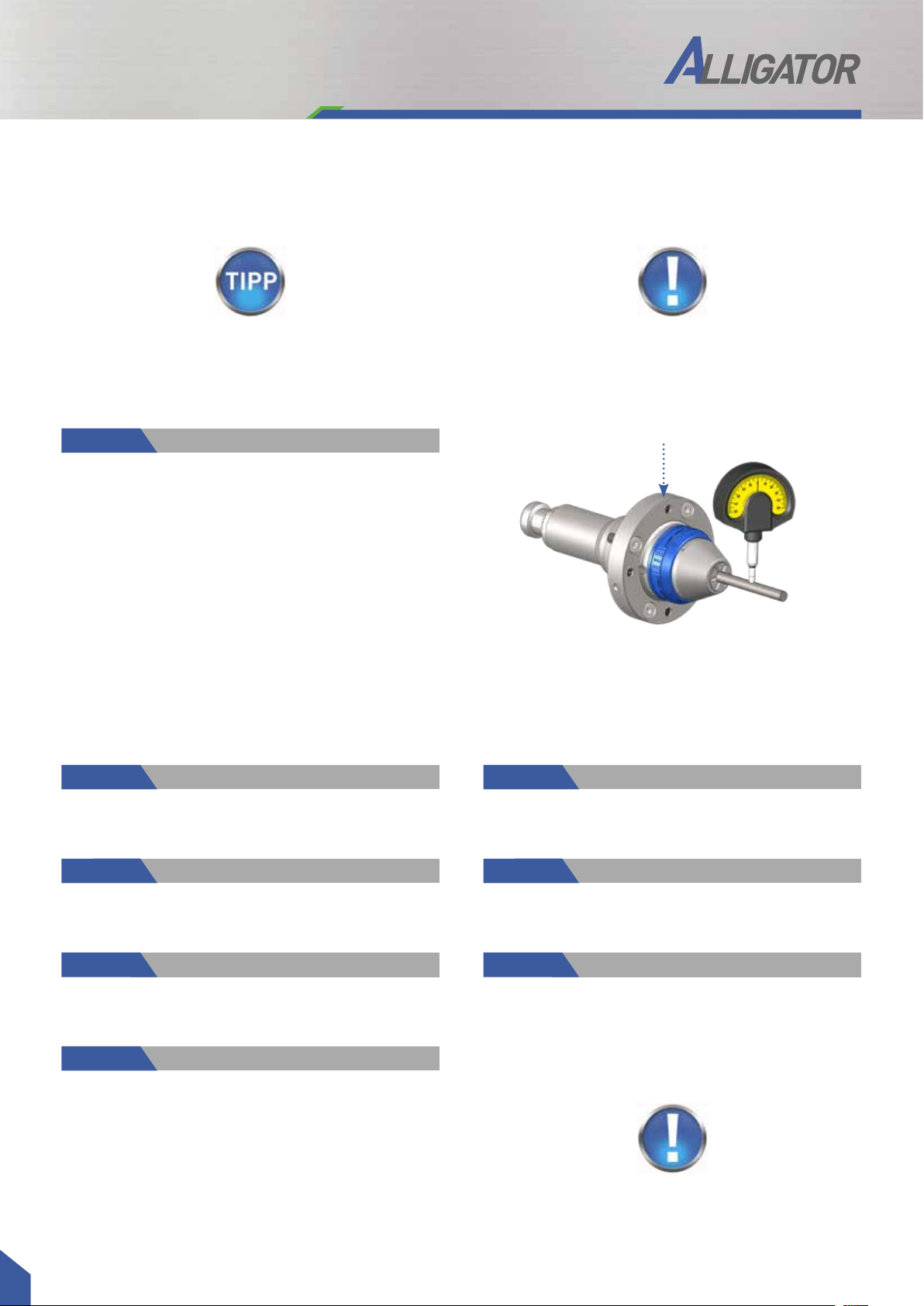

Accessories for ALLIGATOR:

Intermediate bushings with bayonet locking

for automatic bushing exchange

Item No. Name d

350112403 Intermediate sleeve BJ ø20 x 64 3

350112404 Intermediate sleeve BJ ø20 x 64 4

350112405 Intermediate sleeve BJ ø20 x 64 5

350112406 Intermediate sleeve BJ ø20 x 64 6

350112407 Intermediate sleeve BJ ø20 x 64 7

350112408 Intermediate sleeve BJ ø20 x 64 8

350112409 Intermediate sleeve BJ ø20 x 64 9

350112410 Intermediate sleeve BJ ø20 x 64 10

350112411 Intermediate sleeve BJ ø20 x 64 11

350112412 Intermediate sleeve BJ ø20 x 64 12

350112413 Intermediate sleeve BJ ø20 x 64 13

350112414 Intermediate sleeve BJ ø20 x 64 14

350112415 Intermediate sleeve BJ ø20 x 64 15

350112416 Intermediate sleeve BJ ø20 x 64 16

350112417 Intermediate sleeve BJ ø20 x 64 17

250001590 Mounting wrench D20

250001638 Bayonet insert

Reinecker

Item No.

400002006

ANCA

Item No.

400002002

ISOG

Item No.

400002005

Walter

Item No.

400002001

Saacke

Item No. 400002003

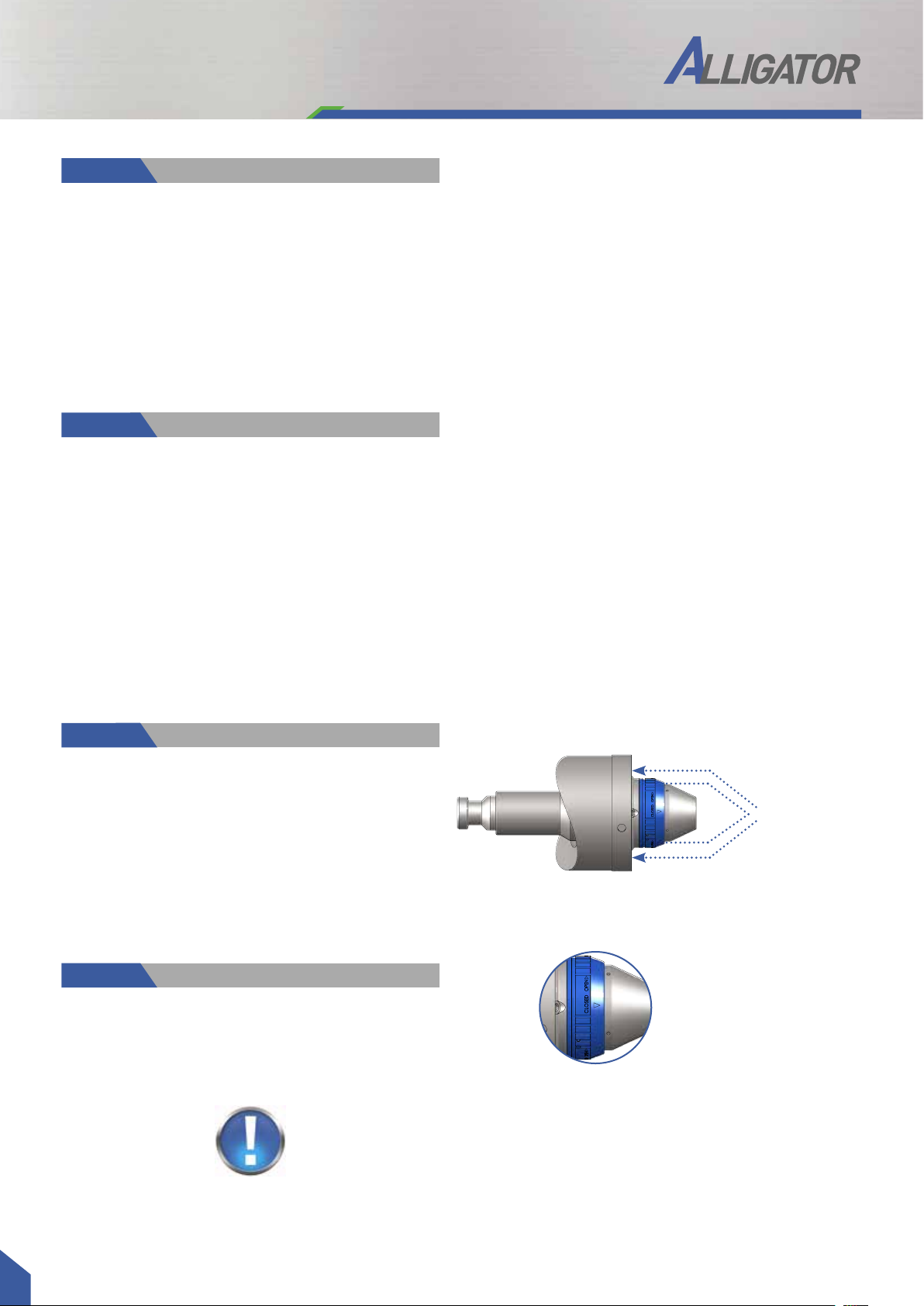

Spindle with union nut

Item No. 400002004

Spindle with flat contact face

Item No. Name d

350111903 Intermediate sleeve RS ø20 3

350111904 Intermediate sleeve RS ø20 4

350111905 Intermediate sleeve RS ø20 5

350111906 Intermediate sleeve RS ø20 6

350111907 Intermediate sleeve RS ø20 7

350111908 Intermediate sleeve RS ø20 8

350111909 Intermediate sleeve RS ø20 9

350111910 Intermediate sleeve RS ø20 10

350111911 Intermediate sleeve RS ø20 11

350111912 Intermediate sleeve RS ø20 12

350111913 Intermediate sleeve RS ø20 13

350111914 Intermediate sleeve RS ø20 14

350111915 Intermediate sleeve RS ø20 15

350111916 Intermediate sleeve RS ø20 16

Intermediate sleeves with radial locking