2–2 745 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

MODBUS PROTOCOL CHAPTER 2: MODBUS PROTOCOL

120 Ωfor standard 24 AWG twisted pair wire. The value of the capacitors should be 1 nF.

Shielded wire should always be used to minimize noise. Polarity is important in RS485

communications. The '+' terminal of every device must be connected together for the

system to operate.

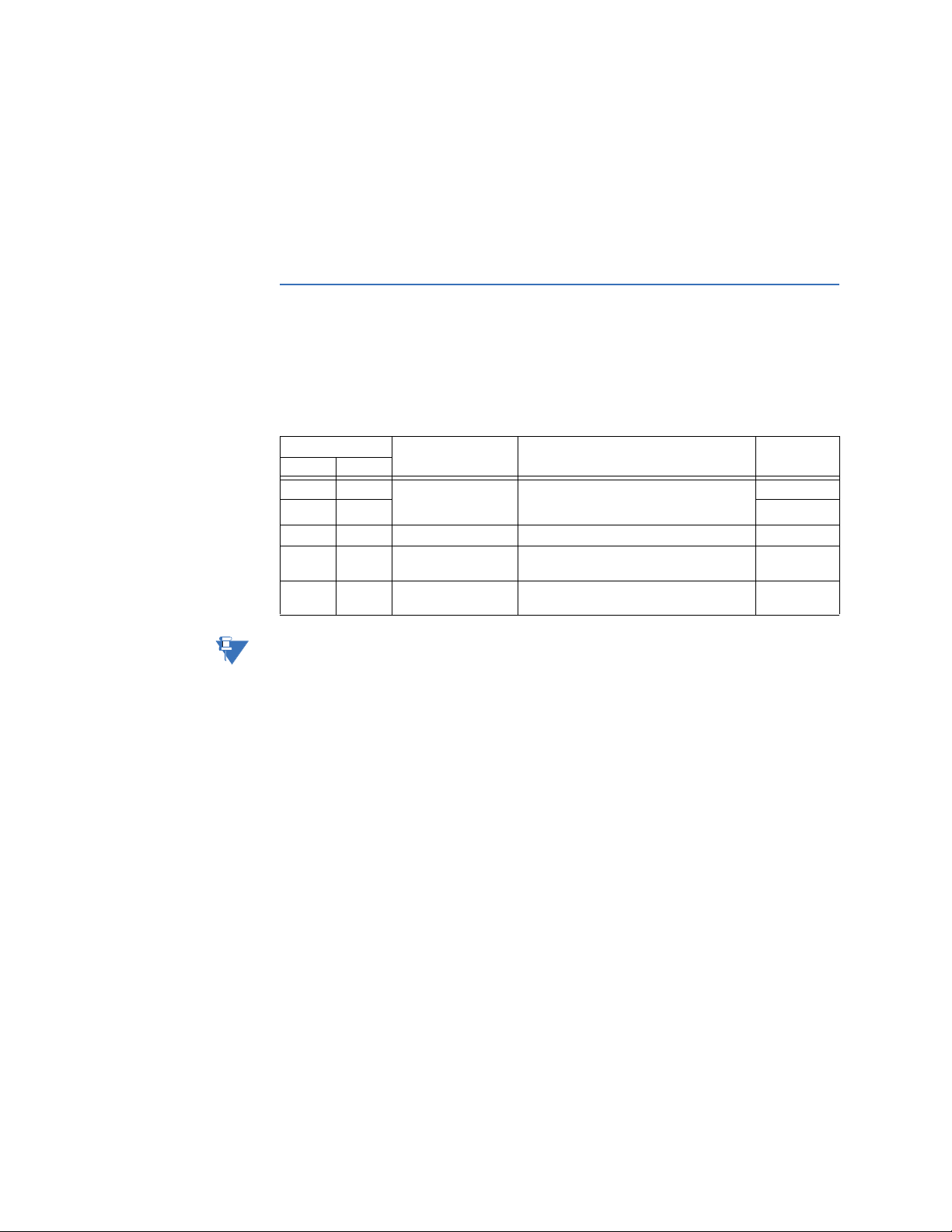

Data frame format

and data rate

One data frame of an asynchronous transmission to or from a GE Multilin 745 consists of 1

start bit, 8 data bits, and 1 stop bit. This produces a 10 bit data frame. The 745 can be

configured to include an additional even or odd parity bit if required, producing an 11 bit

data frame.

All ports of the GE Multilin 745 Transformer Protection System support operation at 300,

1200, 2400, 9600, and 19200 baud.

Data packet format A complete request/response sequence consists of the following bytes transmitted as

separate data frames:

A message is terminated when no data is received for a period of 3½ character

transmission times. Consequently, the transmitting device must not allow gaps between

bytes larger than this interval (about 3 ms at 9600 baud).

•Slave address: This is the first byte of every message. This byte represents the user-

assigned address of the slave device that is to receive the message sent by the

master. Each slave device must be assigned a unique address, and only the addressed

slave will respond to a message that starts with its address. In a master query

message the slave address represents the address of the slave to which the request is

being sent. In a slave response message the slave address is a confirmation

representing the address of the slave that is sending the response. A master query

message with a slave address of 0 indicates a broadcast command. All slaves on the

communication link will take action based on the message, but none will respond to

the master. Broadcast mode is only recognized when associated with function codes

05h, 06h, and 10h. For any other function code, a message with broadcast mode slave

address 0 will be ignored.

•Function code: This is the second byte of every message. Modbus defines function

codes of 1 to 127. The 745 implements some of these functions. In a master query

message, the function code tells the slave what action to perform. In a slave response

message, if the function code sent from the slave is the same as the function code

sent from the master then the slave performed the function as requested. If the high

order bit of the function code sent from the slave is a 1 (i.e. if the function code is >

7Fh) then the slave did not perform the function as requested and is sending an error

or exception response.

•Data: This will be a variable number of bytes depending on the Function Code. This

may include actual values, setpoints, or addresses sent by the master to the slave or

by the slave to the master.

Master query message:

Slave address (1 byte)

Function code (1 byte)

Data (variable number of bytes depending on the function code)

CRC (2 bytes)

Slave response message:

Slave address (1 byte)

Function code (1 byte)

Data (variable number of bytes depending on the function code)

CRC (2 bytes)