TABLE OF CONTENTS

MM200 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE toc–1

Table of Contents

Overview ..........................................................................................................................1

Mechanical installation..................................................................................................................................2

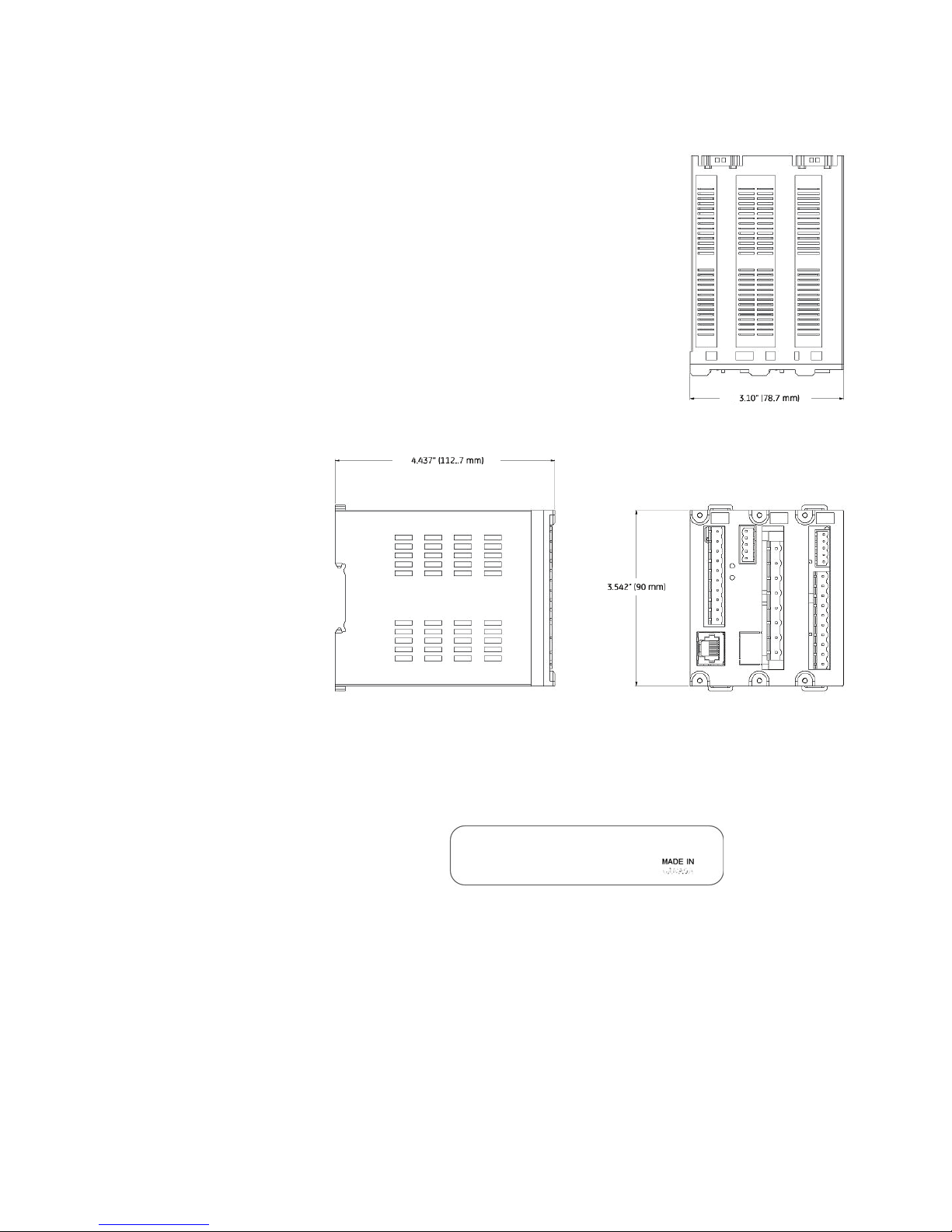

Dimensions ......................................................................................................................................................... 2

Product identification..................................................................................................................................... 3

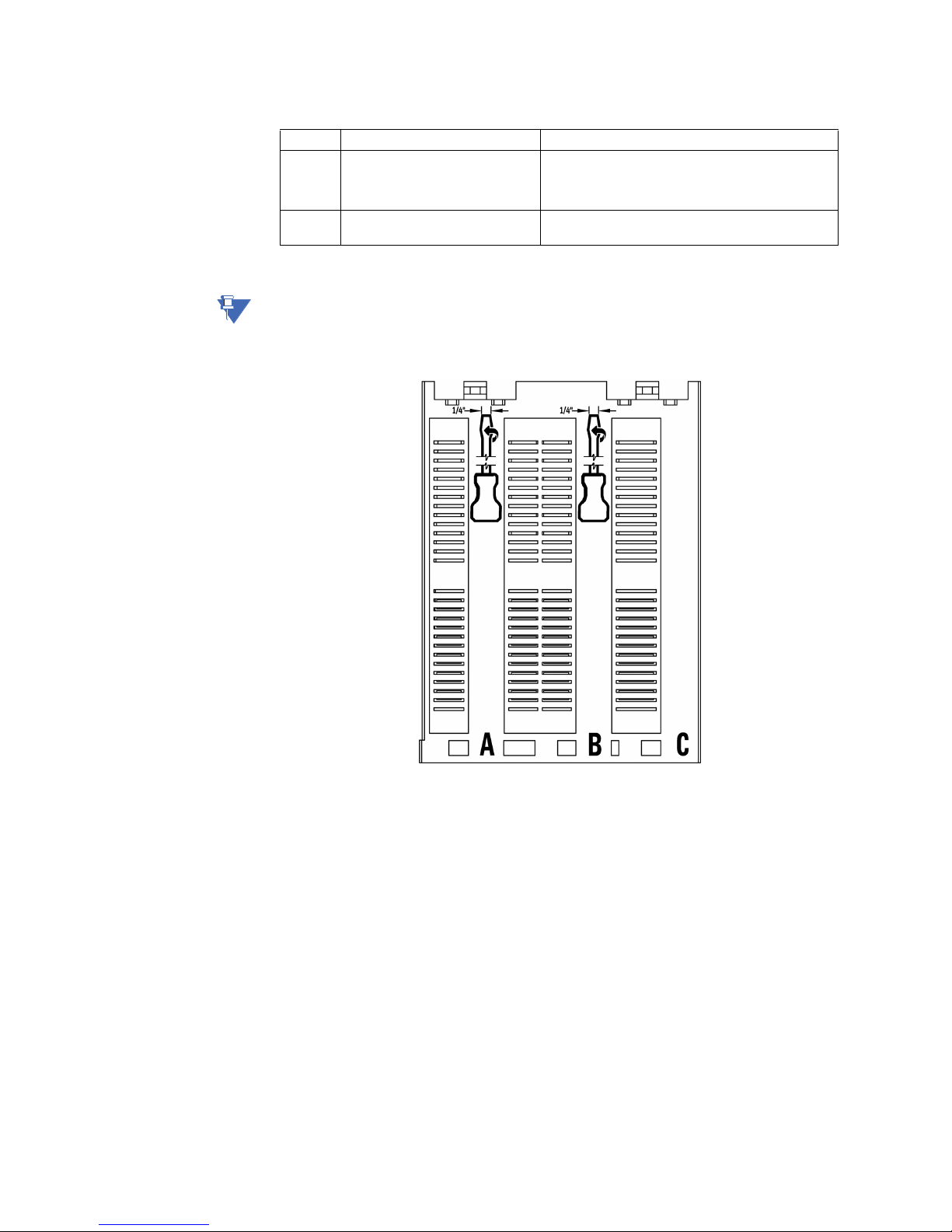

Mounting.............................................................................................................................................................. 4

Electrical installation.......................................................................................................................................5

Full-voltage non-reversing starter........................................................................................................... 9

RS485 connections .......................................................................................................................................10

Control panel...................................................................................................................................................11

Basic control panel .......................................................................................................................................11

Setpoints ........................................................................................................................13

Understanding setpoints ........................................................................................................................... 13

Configuration setpoints..............................................................................................................................13

Motor setpoints...............................................................................................................................................13

Common motor setpoints..........................................................................................................................13

Current transformers ...................................................................................................................................15

Protection elements.....................................................................................................16

Thermal protection....................................................................................................................................... 16

Overload curve................................................................................................................................................16

Communications interfaces .......................................................................................19

Specifications................................................................................................................20

Protection specifications ...........................................................................................................................20

Inputs specifications .................................................................................................................................... 21

Outputs specifications ................................................................................................................................22

Power supply specifications.....................................................................................................................22

Communications specifications.............................................................................................................22

Testing and certification ............................................................................................................................23

Physical specifications................................................................................................................................23

Environmental specifications .................................................................................................................. 24

MM200 order codes......................................................................................................25

Example of an MM200 order code........................................................................................................25

INDEX

SUMMARY OF CERTIFICATION