– 3 –

Table of Contents

Active Vent...........................................................................................................................................................................26

Bottom Door Seal..............................................................................................................................................................27

Center Wash Arm.............................................................................................................................................................28

Coarse Filter........................................................................................................................................................................30

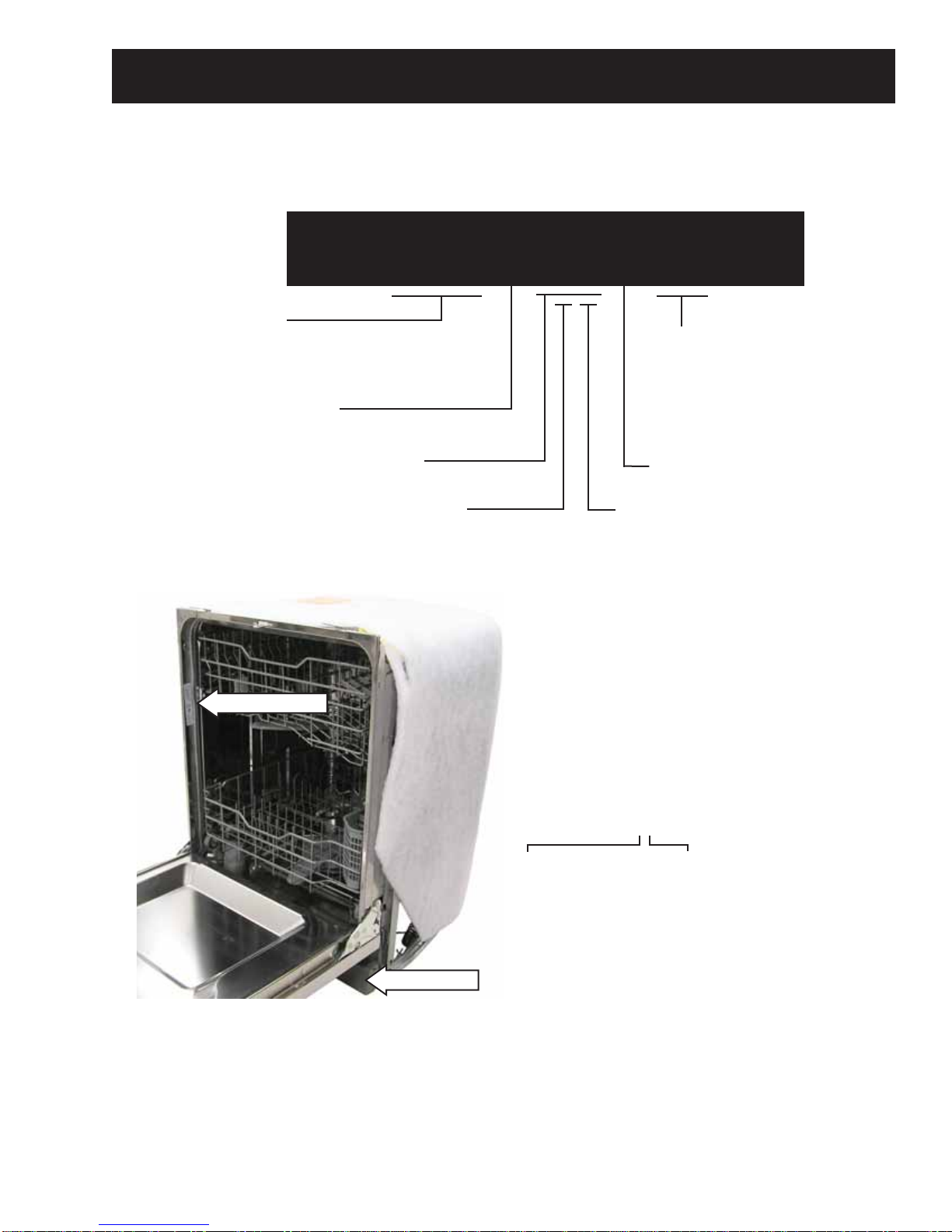

Component Locator Views...........................................................................................................................................13

Control Board......................................................................................................................................................................22

Control Board Connector Locator View.................................................................................................................16

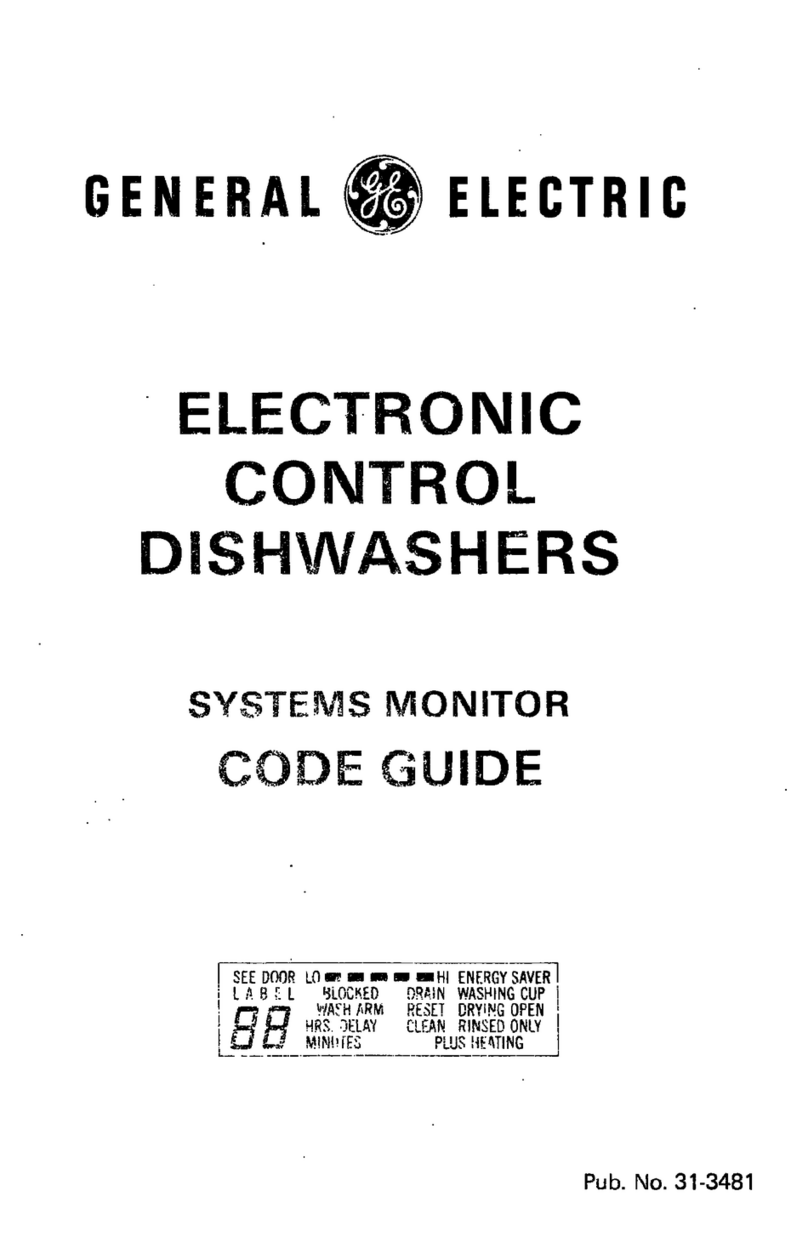

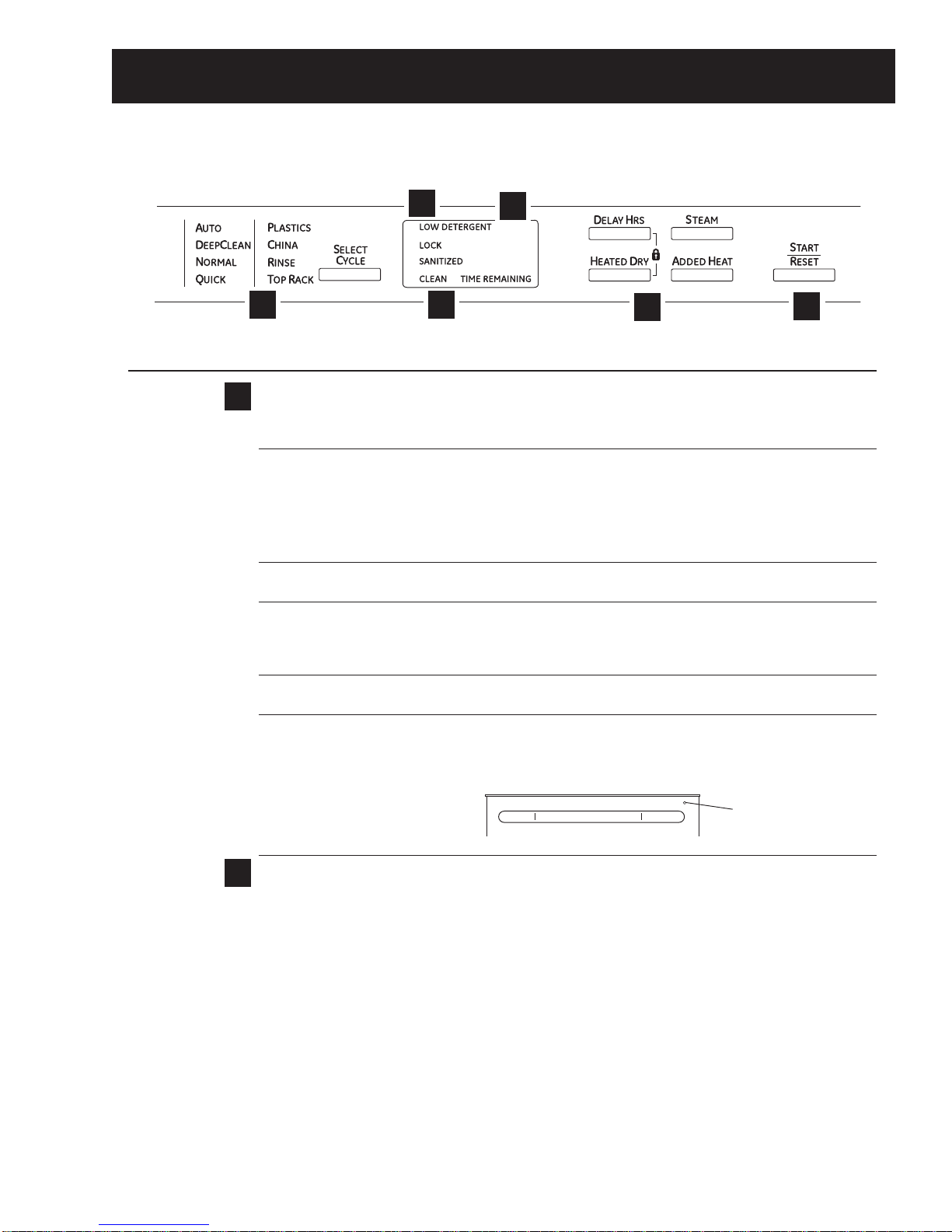

Control Features................................................................................................................................................................ 7

Control Thermal Cutout (TCO)......................................................................................................................................22

Consumer Purge of the Bulk Dispenser Tank......................................................................................................21

Cycle Chart..........................................................................................................................................................................12

Cycles.....................................................................................................................................................................................11

Detergent/Rinse Module................................................................................................................................................24

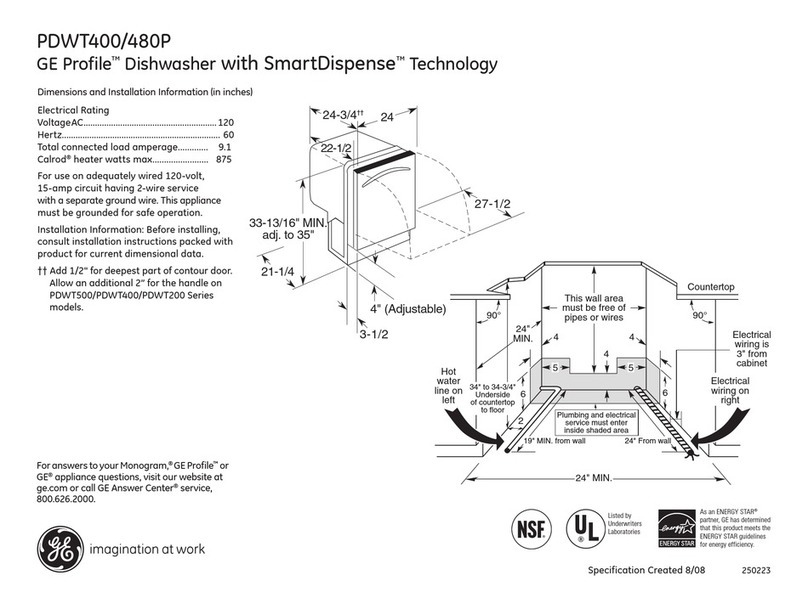

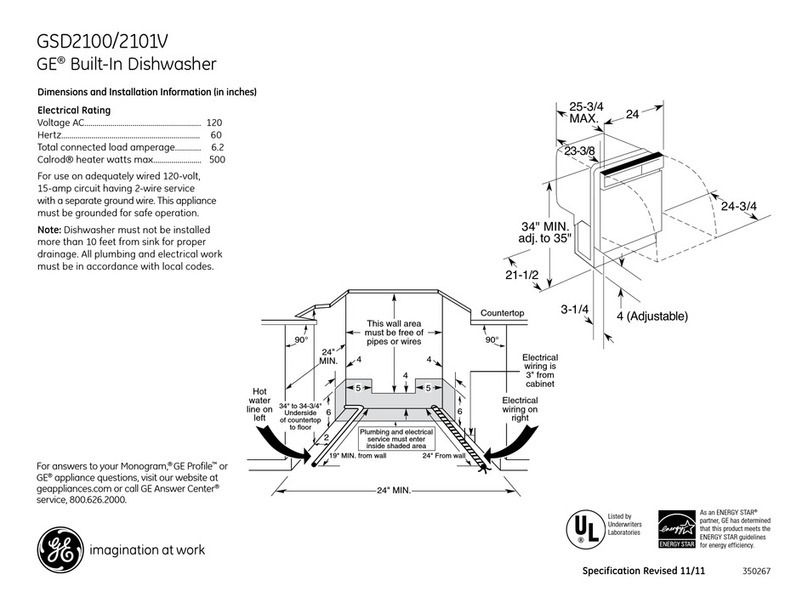

Dishwasher Components..............................................................................................................................................17

Door Handle........................................................................................................................................................................24

Door Switch Assembly...................................................................................................................................................24

Drain Pump Assembly....................................................................................................................................................35

Factory Test Mode............................................................................................................................................................39

Fill Funnel..............................................................................................................................................................................33

Fine Filter..............................................................................................................................................................................29

Float Switch.........................................................................................................................................................................31

Heating Element................................................................................................................................................................32

Inner Door Panel...............................................................................................................................................................26

Introduction......................................................................................................................................................................... 6

Lens.........................................................................................................................................................................................23

Lower Wash Arm..............................................................................................................................................................28

Motor Pump Assembly...................................................................................................................................................35

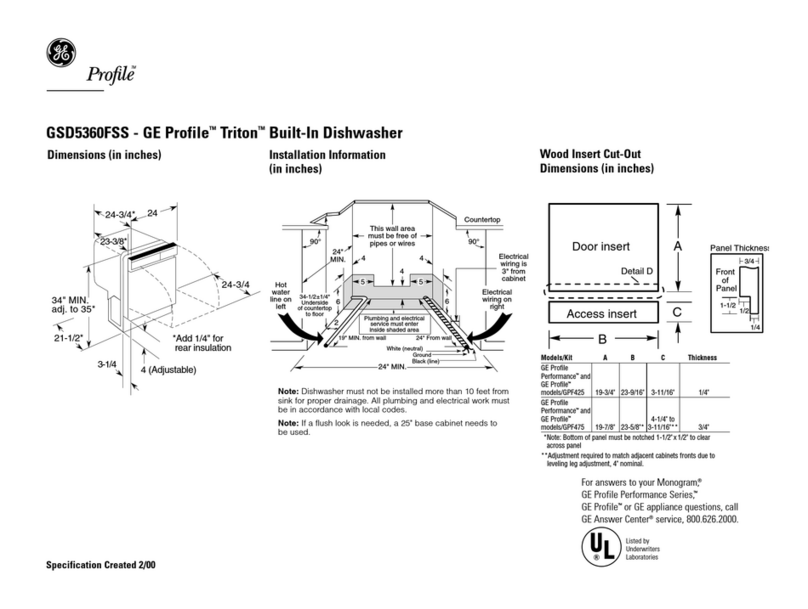

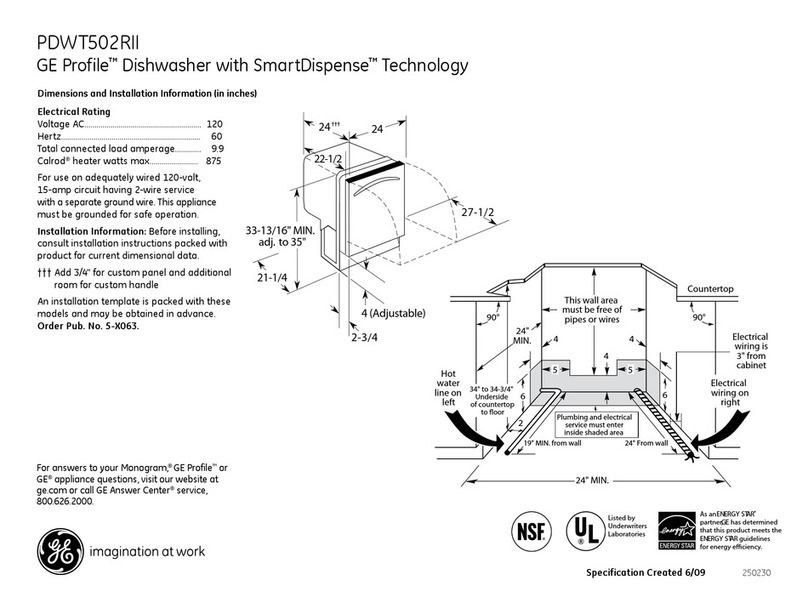

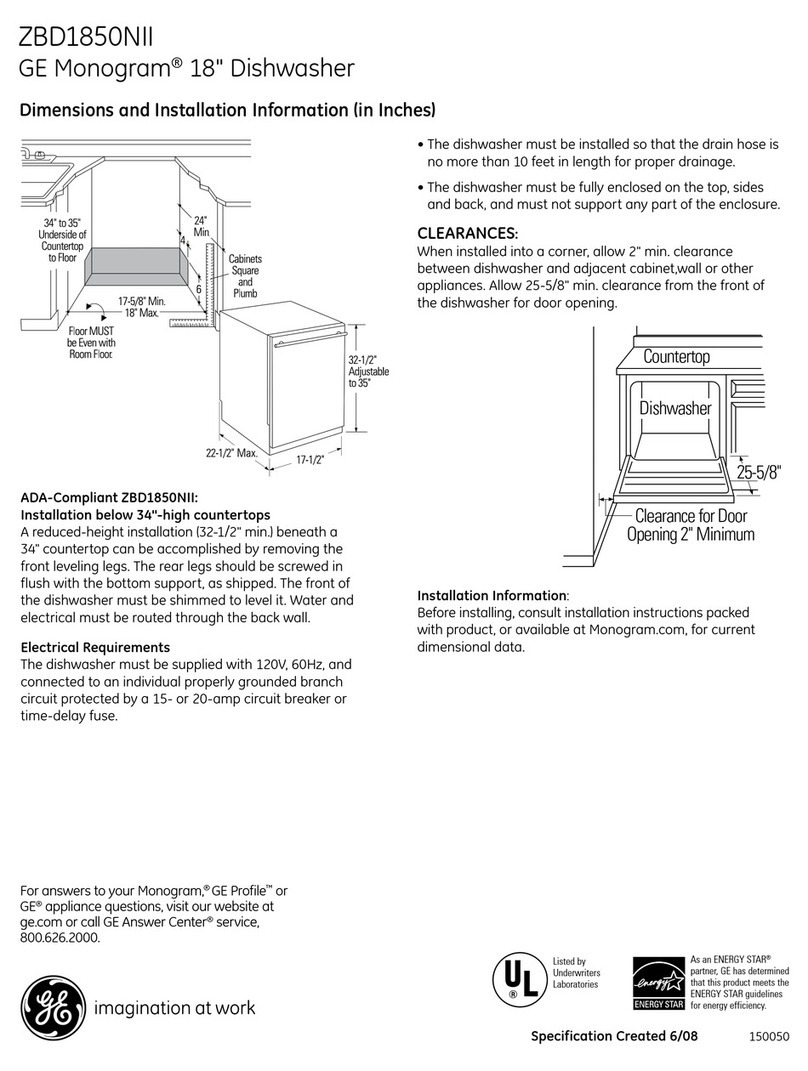

Nomenclature.................................................................................................................................................................... 5

Outer Door Panel..............................................................................................................................................................17

Schematics and Wiring Diagrams............................................................................................................................40

Service Mode......................................................................................................................................................................37

(Continued next page)