installation Preparation

PREPARE ELECTRICAL WIRING

AWARNING:

FORPERSONAL SAFETY: Remove house fuse or open circuit breaker

beforebeginninginstallationDonotuseonextensioncordor

adapterplugwith thisappIiance

-A ADVERTENCIA:

PARASEGUR1DAD PERSONAL: Quite e_fusible o abra e! interruptor

decircuitosantesdecomenzarlainsta_aci6nNoutiliceuncable

deextensi6noun enchufeadaptadorconesteartefacto

Electrical Requirements

• Thisappliance must be supplied with 120V,60 Hz and

connected to an individual properlg grounded branch circuit.

protected bg a 15- or 20-ampere circuit breaker or-time-

detag fuse

• Wiring must be 2 wire with ground and rated for 75°C(176°F)

• If the electrical supplg does not meet the above requirements.

call a licensed electrician before proceeding

Grounding Instructions-Permanent Connection

This appliance must be connected to a grounded metal.

permanent wiring sgstem, or an equipment-grounding

conductor must be run with the circuit conductors and be

connected to the equipment-grounding terminal or-lead on

the appliance

Grounding Instructions-Power Cord Models

Thisappliance must be grounded in the event of a malfunction

or breakdown, grounding will reduce the riskof electric shock

bg providing a path of least resistance for electric current,

Thisappliance isequipped with a cord having an equipment-

grounding conductor and a grounding plug Theplug must

be plugged into an appropriate outlet that is installed and

grounded in accordance with all local codes and ordinances.

kWARNING:

The improper connection of the equipment grounding conductor

can resuR in a risk of electric shock Check with a qualified

electrician or service representative if gou ore in doubt that

the appliance is propertg grounded

ADVERTENCIA:

Laconexi6n inadecuada delconductor de conexi6n atierra del

equipamiento puede provocar un riesgode descarga eI6ctrica

Consultea un electddsta calificado orepresentante deservicio

t6cnico sitiene dudassabre la correcto conexi6n a tier_adelaparato 1

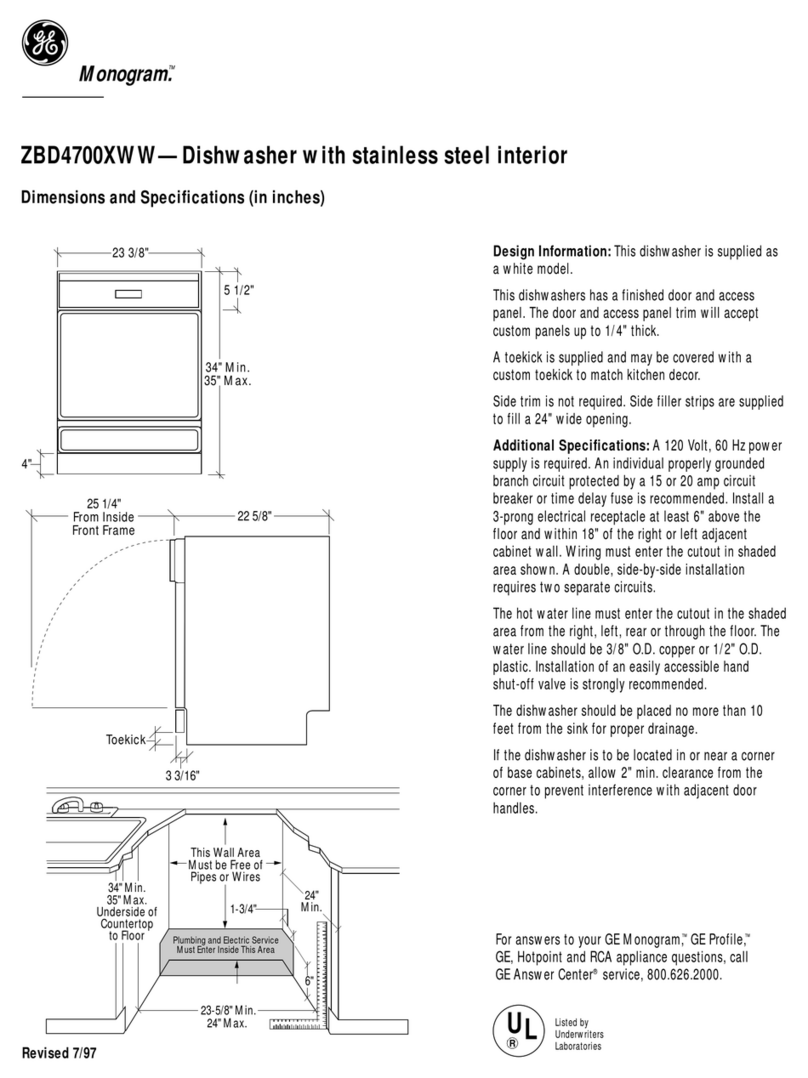

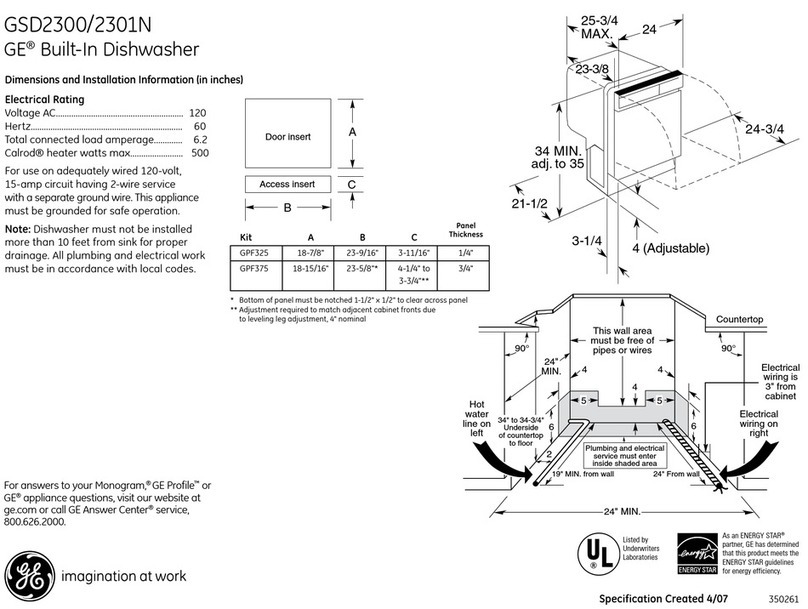

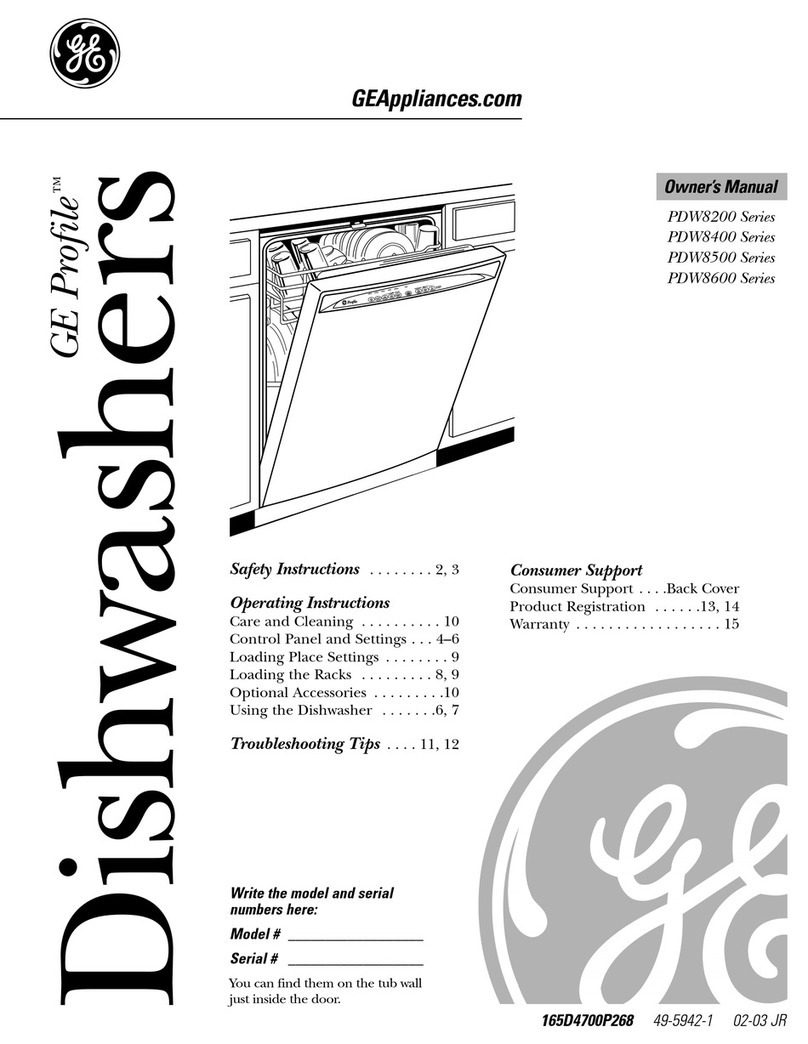

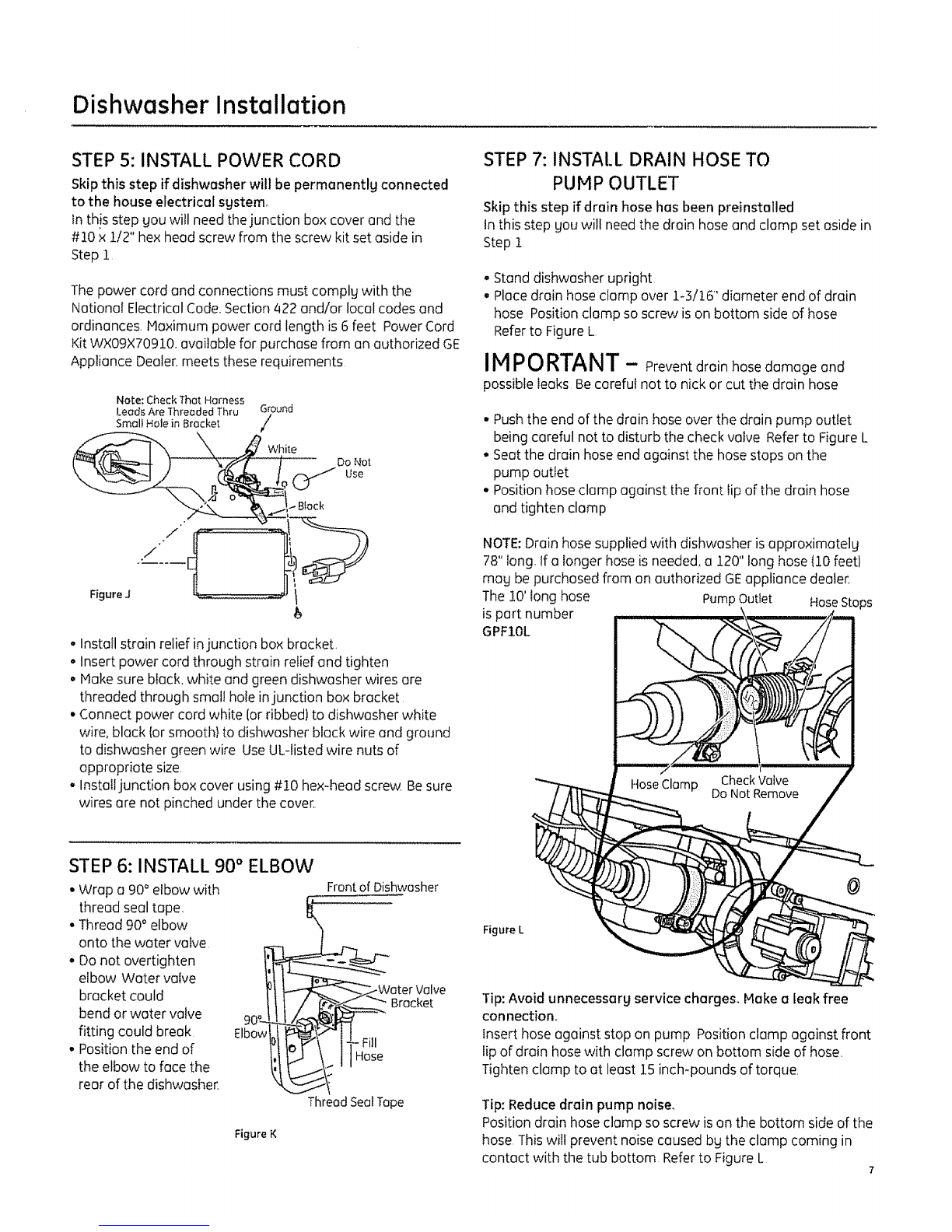

I Receptacle _

" II Location\ ! ',

--41 ' Receptac!#_-l-1/2'DiaHolelMax _\\

, Am04a ' .... all

-\_-N _, Cabinet

24" i

fro

Figure E white

For models equipped with power cord: Do not modifg the plug

provided with the appliance; if it will not fit the outlet have a

proper outlet installedbg a qualified technician

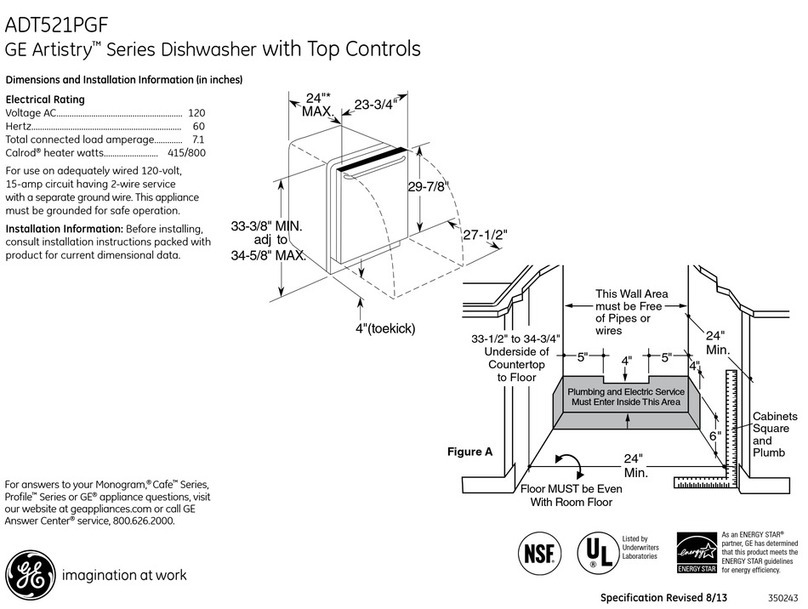

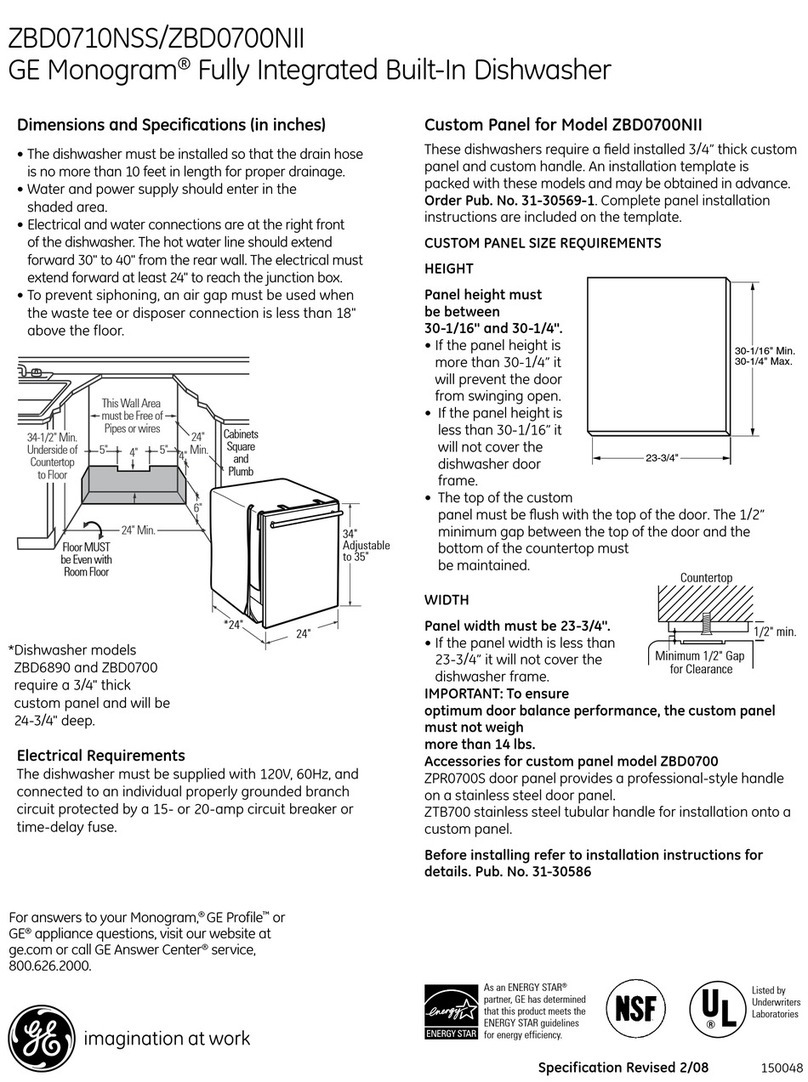

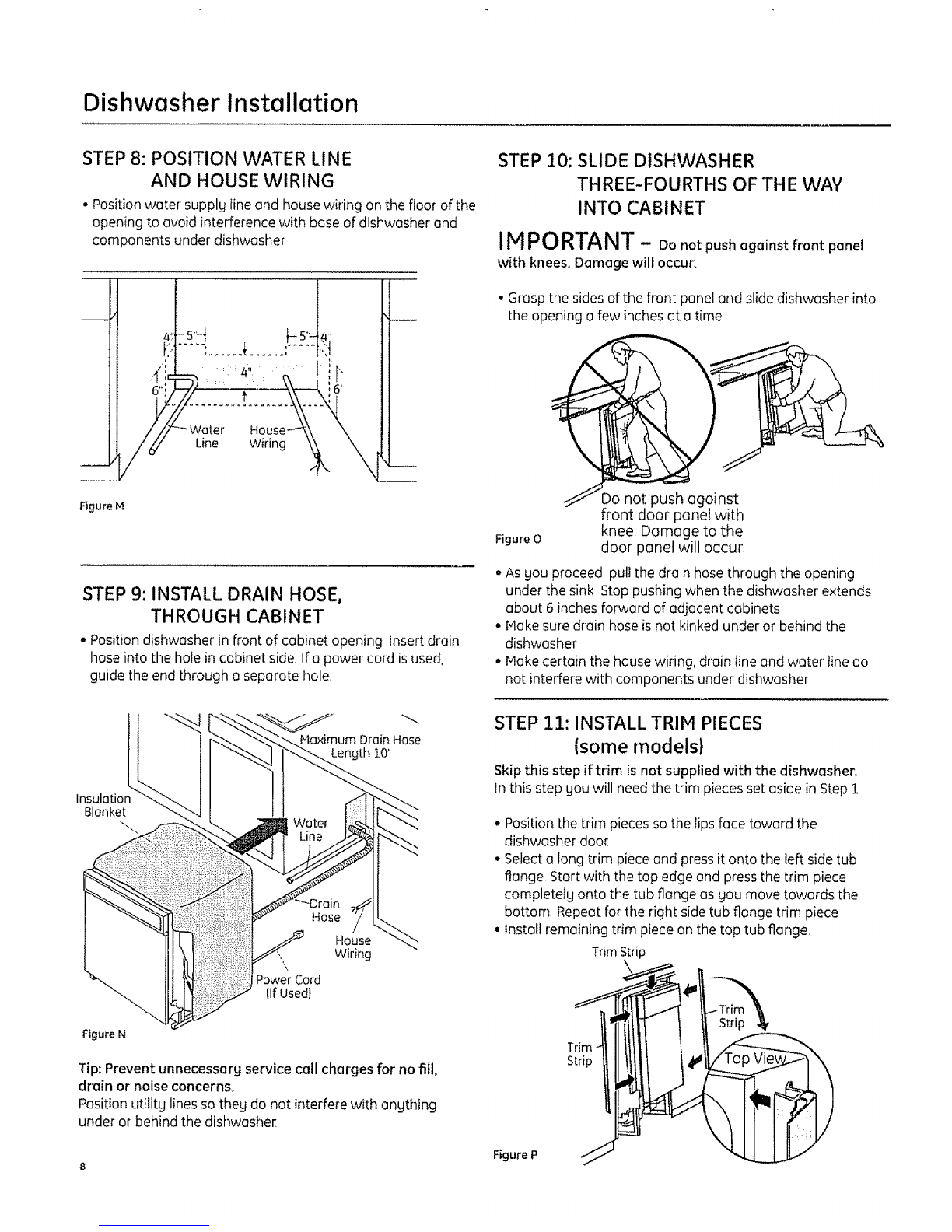

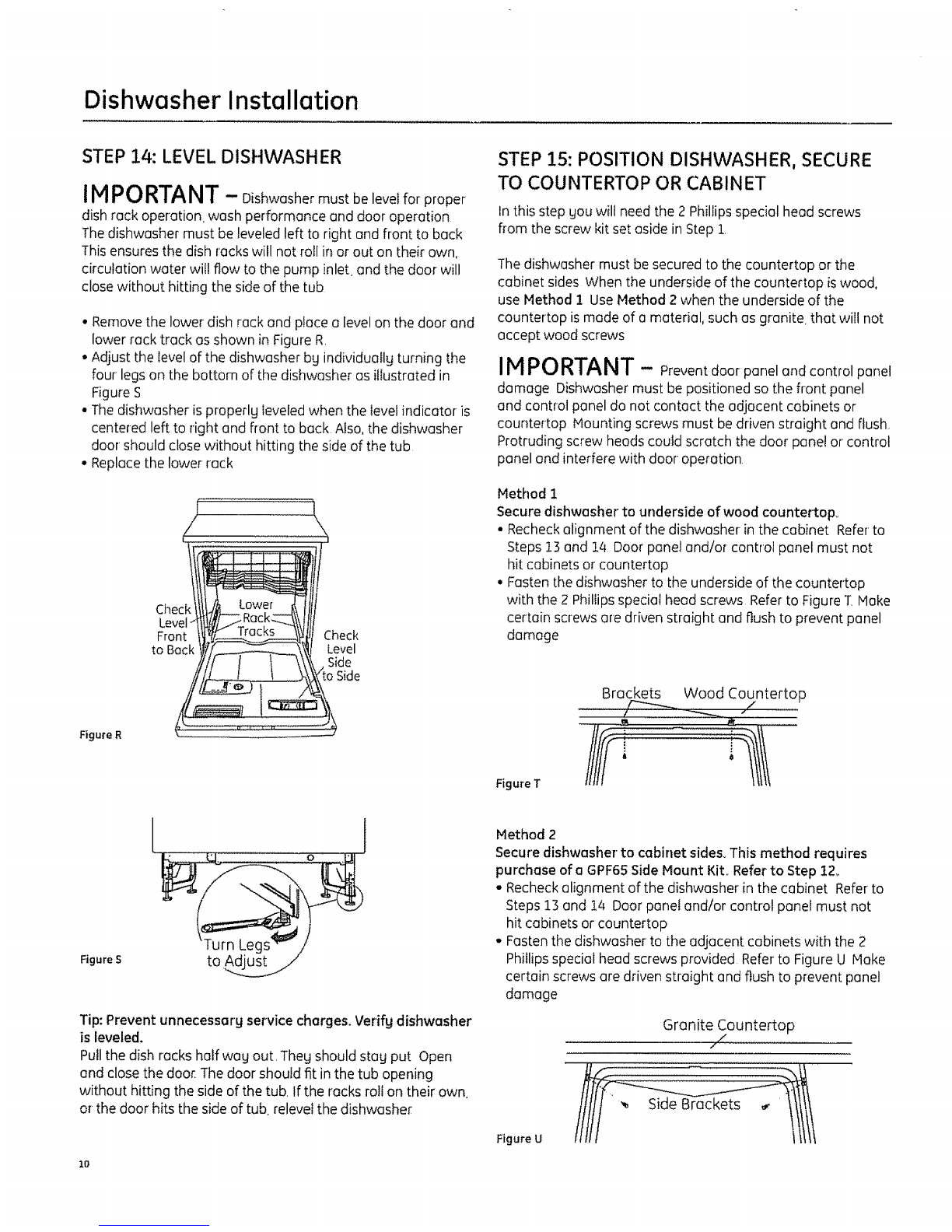

Cabinet Preparation & Wire Routing

• Thewiring mag enter the opening from either side. rear or the

floor within the shaded area illustrated above in Figure Eand

defined in FigureA

° Cut a 1-1/2' maximum diameter hole to admit the electrical

cable Permanent wiring connections mag pass through the

same hole as the drain hoseand hot water line.if convenient

If cabinet wall is metal, thehole edge must be covered with a

bushing

NOTE:Powercords with plug must pass through a separate

hole

Electrical Connection to Dishwasher

Electrical connection ison the right front of dishwashe[

•Forpermanent connections the cable must be routed as

shown in FigureE Cablemust extend a minimum of 24" from

the rear wall

• Forpower cord connections, install a ]-prong grounding

tape receptacle in the sink cabinet rear wall, 6" rain or 18"

maximum from the opening. 6" to 18"above the floor