– 4 –

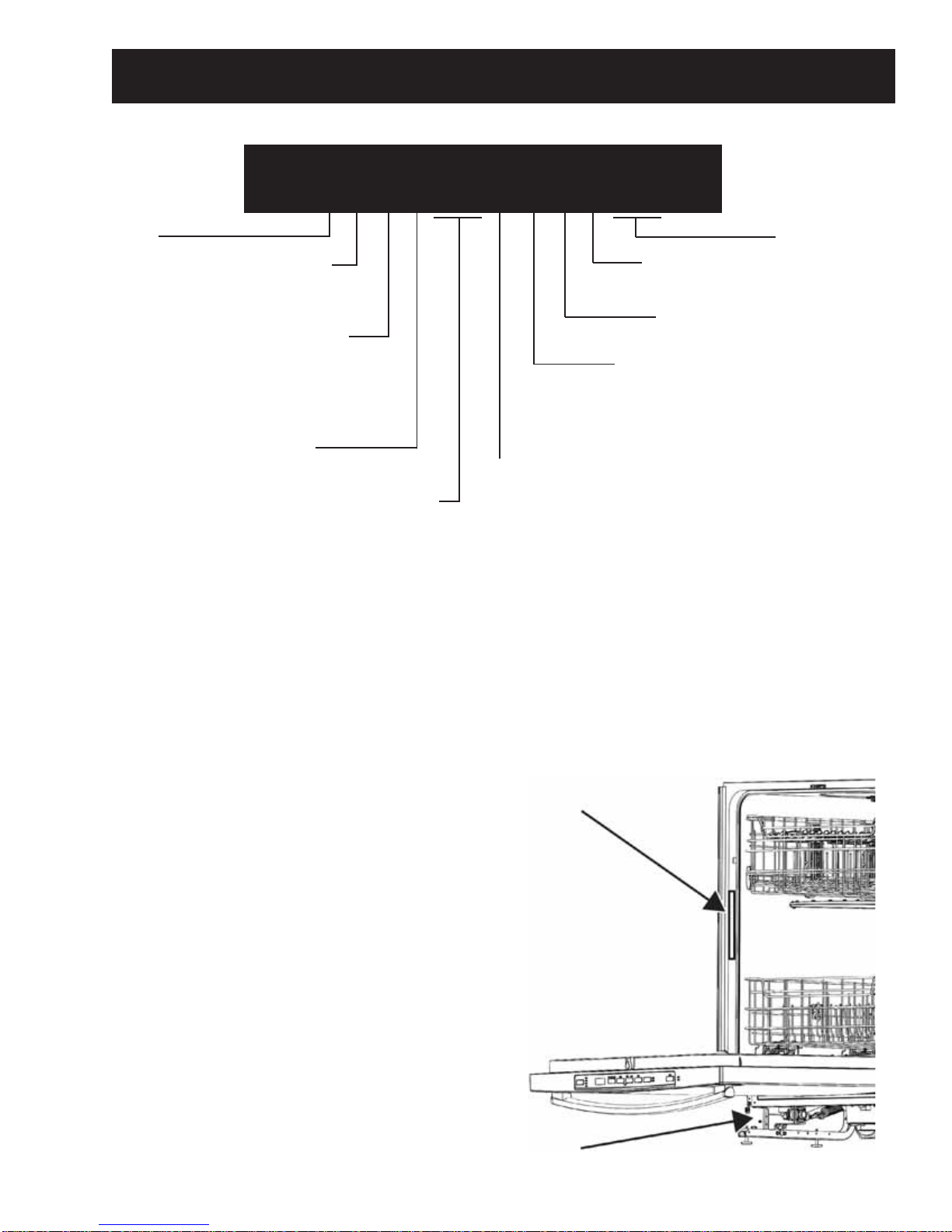

Top Control Panel, UI, Light Pipe and Buttons.........................................................................................................31

Top Control Console Cover...............................................................................................................................................32

Outer Door Panel...................................................................................................................................................................32

Inner Door Panel .................................................................................................................................................................33

Door Gasket.............................................................................................................................................................................33

Vent Parts.................................................................................................................................................................................33

Detergent Dispenser...........................................................................................................................................................34

Door Strike................................................................................................................................................................................35

Sump Module..........................................................................................................................................................................36

Sump Gasket ..........................................................................................................................................................................38

Installing Sump Module.....................................................................................................................................................38

Consumer Error Mode.........................................................................................................................................................39

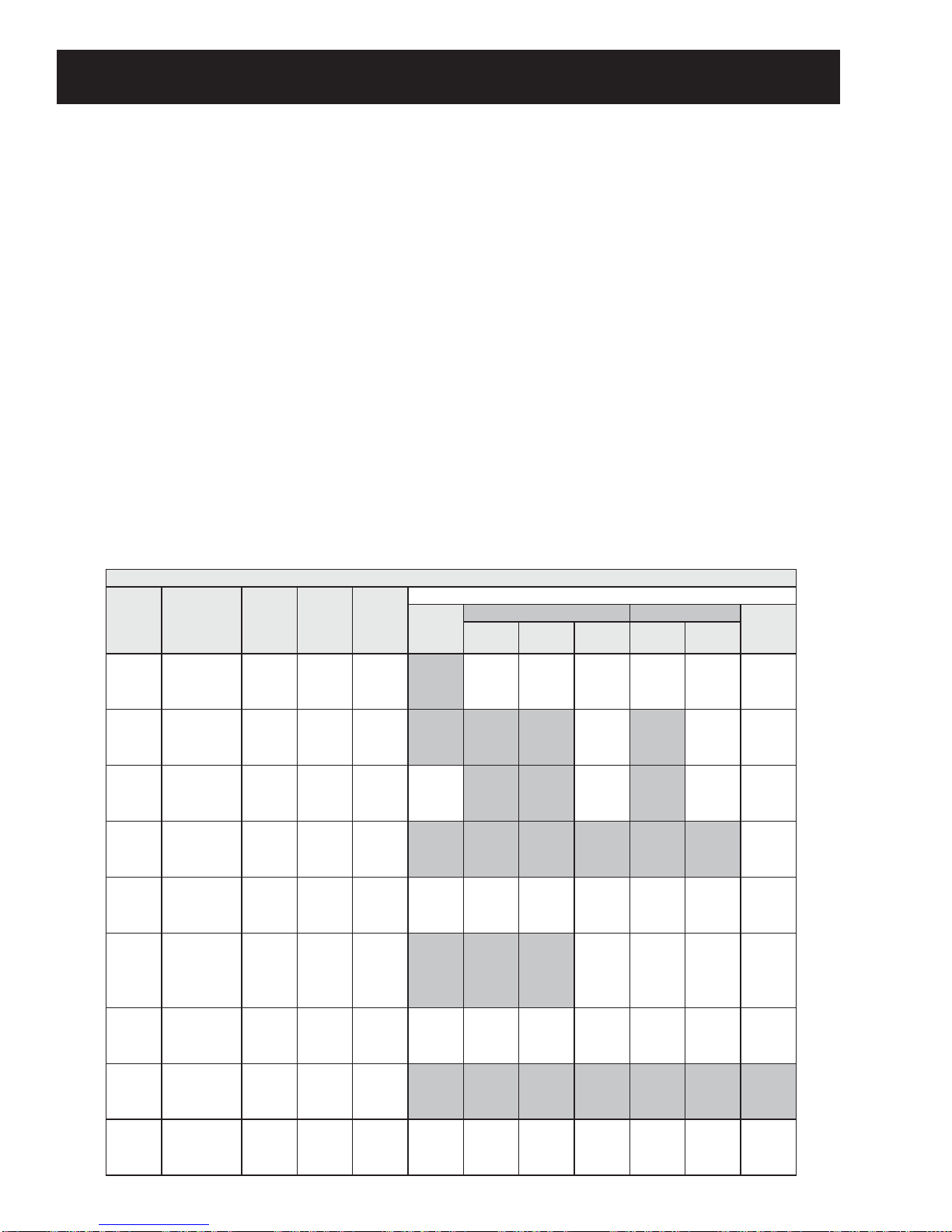

Electronic Controls..........................................................................................................................................................................39

Service Mode...........................................................................................................................................................................40

Diagnosing Electronic Control Boards........................................................................................................................40

Main Control Diagnostics..................................................................................................................................................41

On the Main Control Board CSM....................................................................................................................................42

UI Diagnostics.........................................................................................................................................................................44

Water Level..............................................................................................................................................................................45

Fill System...........................................................................................................................................................................................45

Diagnostics..............................................................................................................................................................................46

Flood Switch and Thermistor..........................................................................................................................................47

Thermistor................................................................................................................................................................................48

Fill Funnel and Hose ...........................................................................................................................................................48

Fill Valve.....................................................................................................................................................................................49

Circulation System..........................................................................................................................................................................50

Diagnostics..............................................................................................................................................................................51

No Circulation.........................................................................................................................................................................52

Filtration....................................................................................................................................................................................53

Circulation Motor and Pump Assembly......................................................................................................................54

Diverter......................................................................................................................................................................................54

Turbidity Sensor.....................................................................................................................................................................57

Conduits and Spray Arms.................................................................................................................................................58