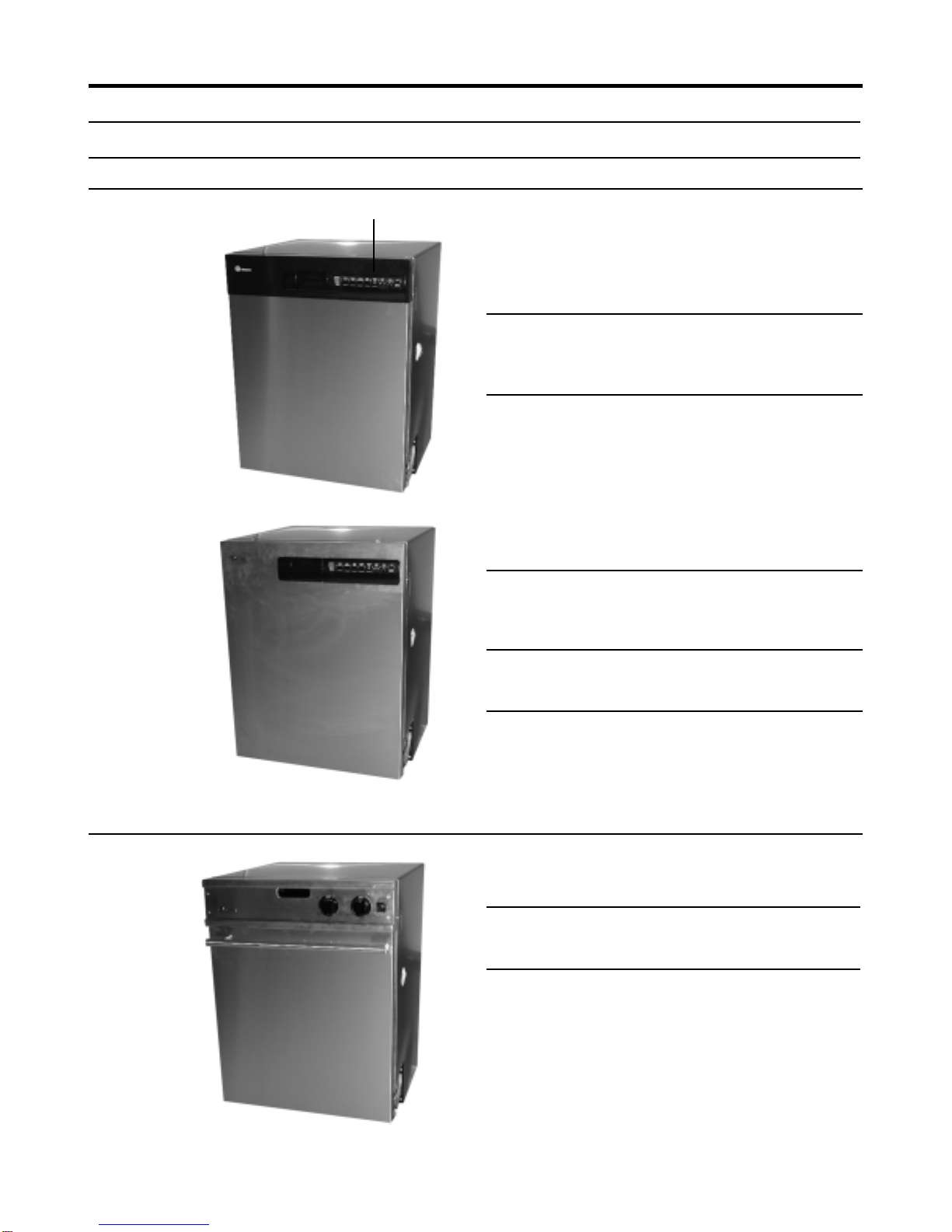

6000 & 7000 Series DISHWASHERS

PAGE 1

1.0 PRODUCT INFORMATION Page 2

1.1 Description 2

1.2 Model Designation 4

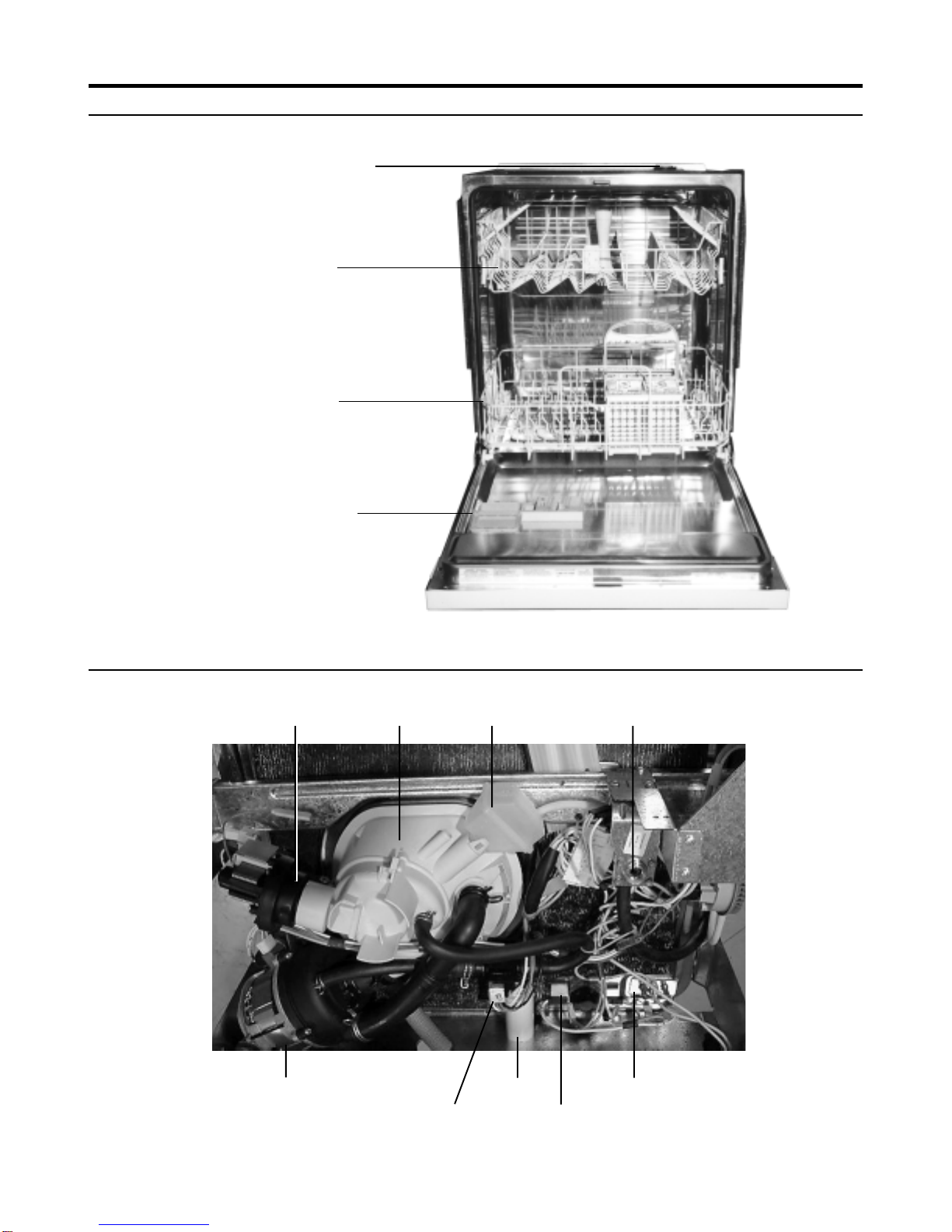

1.3 Major Component Location 6

1.4 Micro Filtration 7

2.0 SAFETY Page 9

2.1 Warning 9

2.2 Safety Practices 9

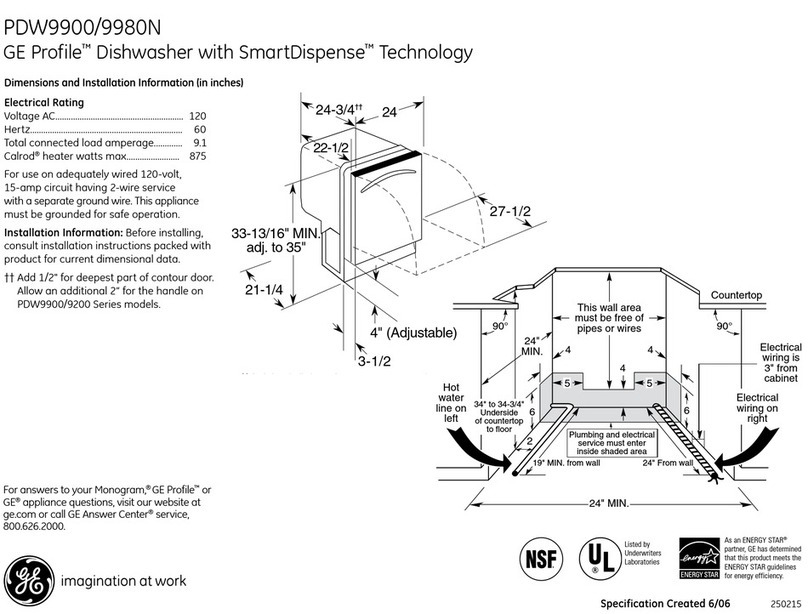

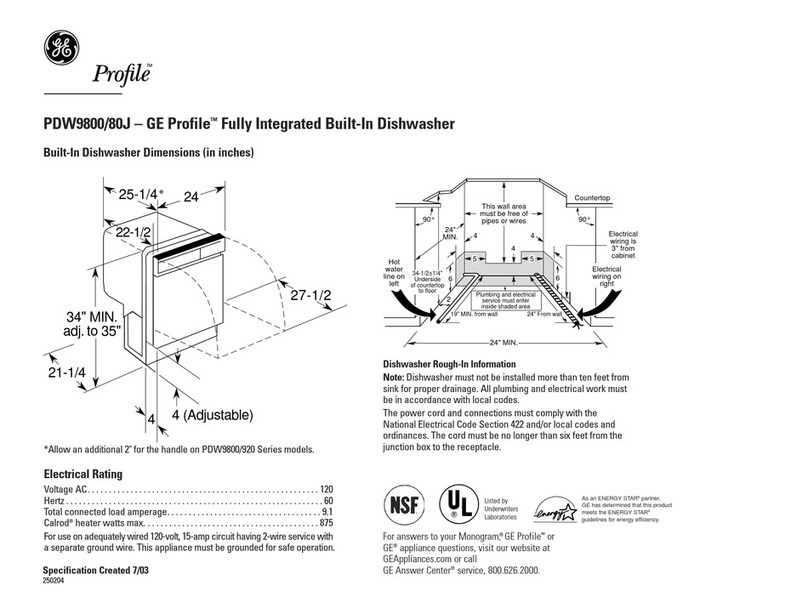

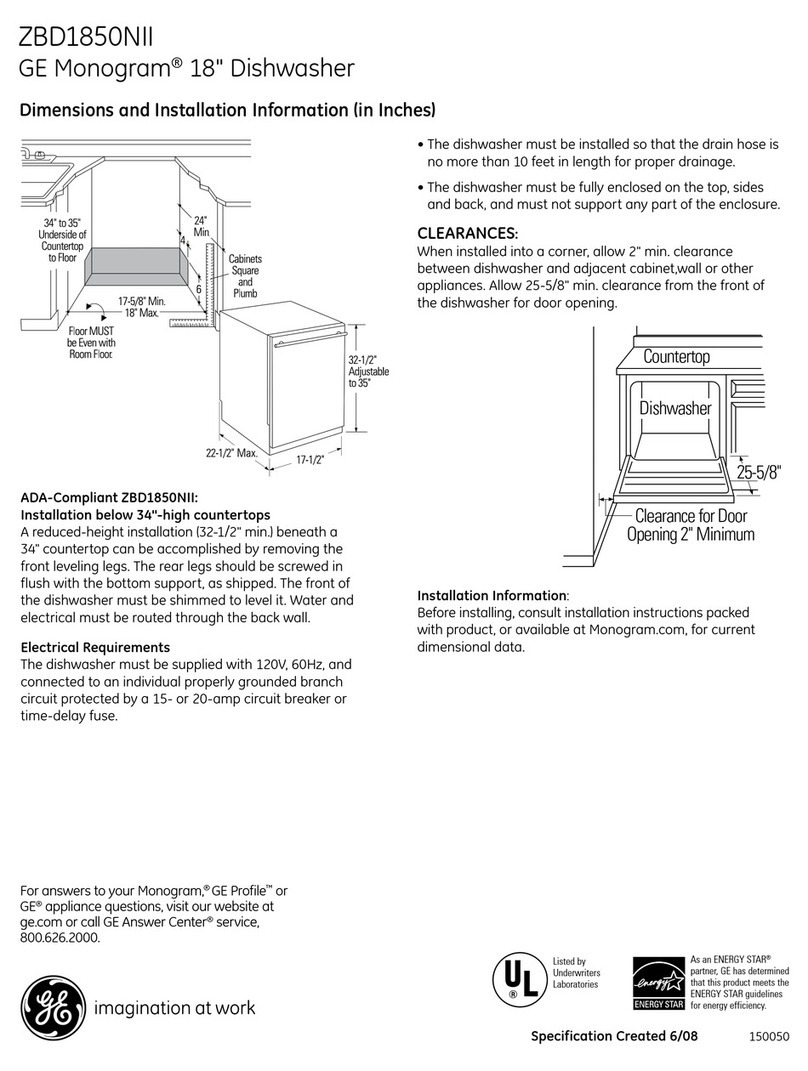

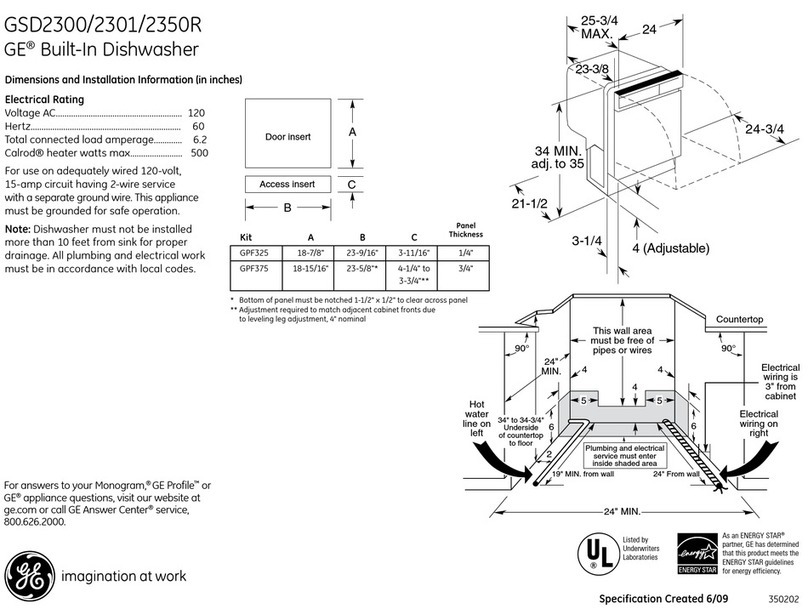

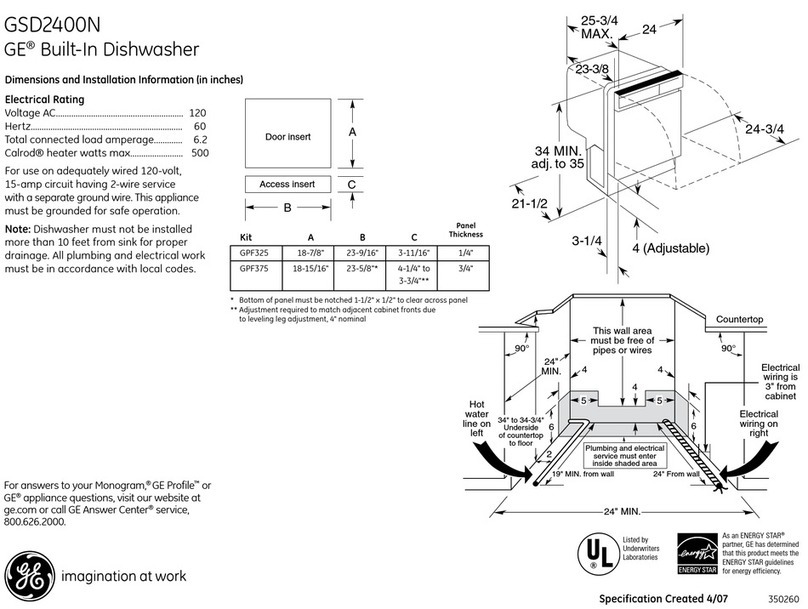

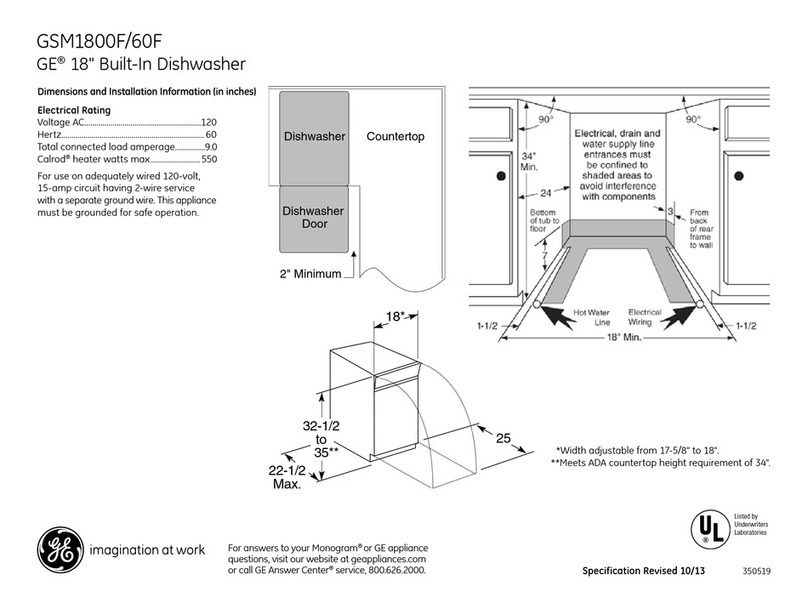

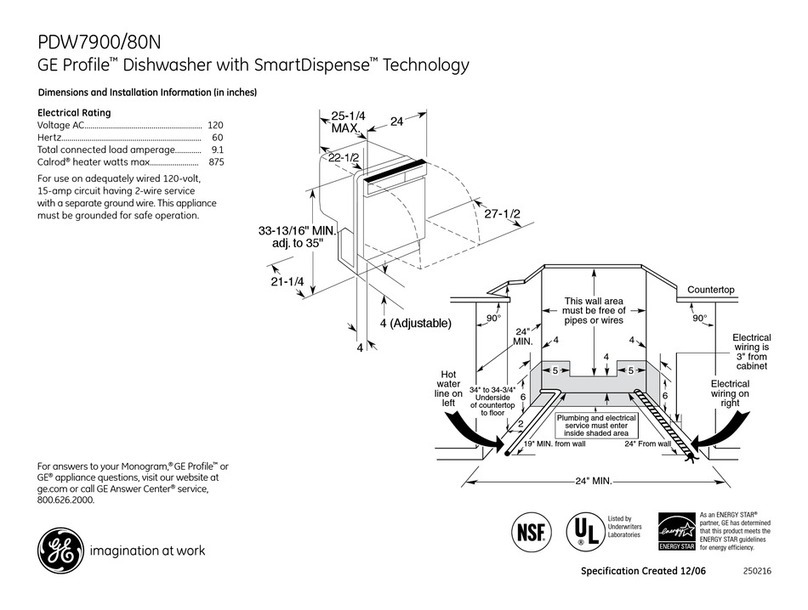

3.0 SPECIFICATIONS Page 10

3.1 General Specifications 10

4.0 FAULT DIAGNOSIS Page 14

4.1 Fault Indication Models 6400/6500, 6905, 7000 14

4.2 Fault Indication Models 6600, 6605 15

4.3 Not Heating 17

4.4 Over Temperature 17

4.5 Not Filling 17

4.6 Not draining 17

4.7 Overfill 17

4.8 Turbidity Sensor Failure 17

4.9 Door Thermistor Failure 17

4.10 Test Facilities 18

4.11 General Diagnostics 27

5.0 SERVICE PROCEDURES Page 32

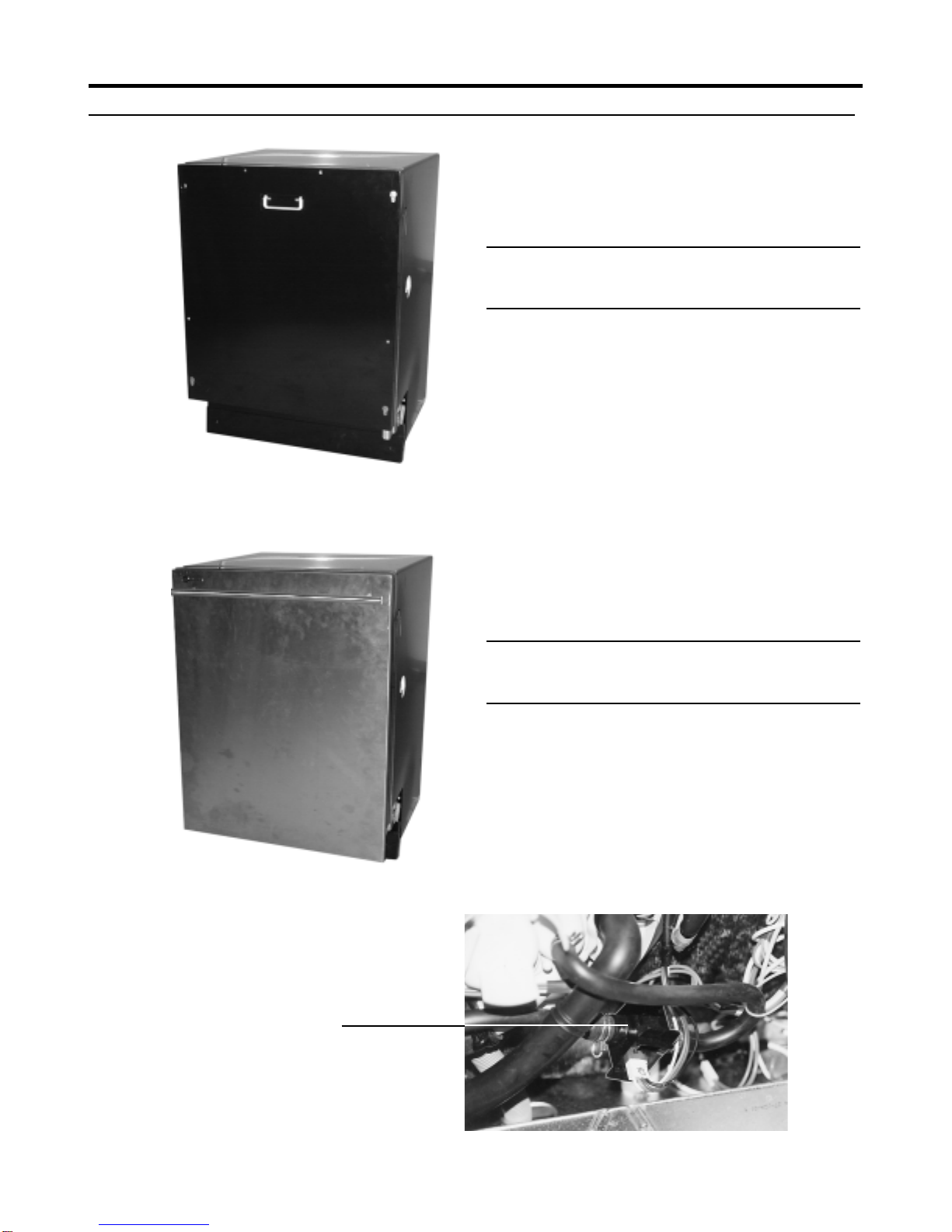

5.1 General Access 32

5.2 Procedures 33

5.2.1 Door Latch 33

5.2.2 Door Panel 6400,6500,6600,6605 33

5.2.3 Door Panel 6700,6900,6905 33

5.2.4 Door Panel 7000,7005,7100,7105 34

5.2.5 Control Panel 6400, 6500, 6600, 6605 35

5.2.6 Power Control Panel 35

5.2.7 Control Panel 6400, 6500 37

5.2.8 Cabinet trims & Wrap Removal 38

5.2.9 Door Hinge, Spring & Support Rods 39

5.2.10 Stainless Steel Door Liner 39

5.2.11 Remove Door Hinges 40

5.2.12 Door Seal 40

5.2.13 Upper Venturi Assembly 41

5.2.14 Upper Venturi Assembly - Dismantle 42

5.2.15 Upper Venturi Assembly - Reassemble 42

5.2.16 Upper Venturi Assembly - Reinstall 42

5.2.17 Upper Basket Rail & Wheel Guides 42

5.2.18 Upper Basket Feed Pipe 43

5.2.19 Siphon Break 43

5.2.20 Drain Cup Filter 45

5.2.21 Perforated Stainless Steel LH side Wash Filter 45

5.2.22 Micro-mesh Barrel Wash Filter 45

5.2.23 Recuperative By-pass Filter 45

5.2.24 Lower Spray Arm Support 46

5.2.25 Perforated Stainless Steel RH side Wash Filter 46

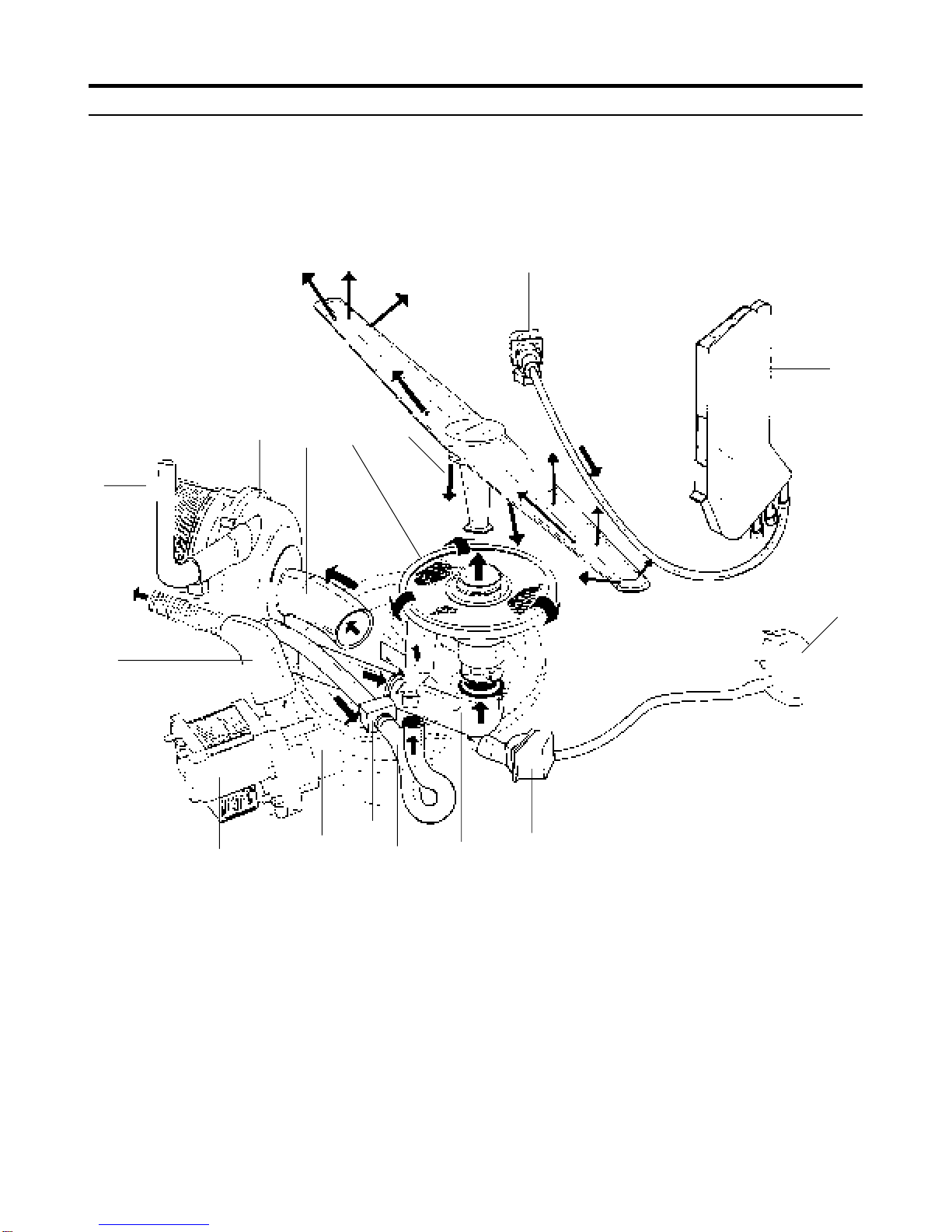

5.2.26 General View beneath the Cabinet 47

5.2.27 Pressure Switch 48

INDEX

5.2.28 Capacitor - Wash Motor 48

5.2.29 Thermostat - Overtemperature 49

5.2.30 Heating Element 50

5.2.31 Turbidity Sensor 51

5.2.32 Air dome 51

5.2.33 Water Inlet Solenoid Valve 52

5.2.34 Drain Pump - Removal 52

5.2.35 Wash Motor Pump Assembly removal 53

5.2.36 Sump 56

5.2.37 Sump Base plate/Non-return Flap Valve 56

5.2.38 Interior Light 57

5.2.39 Detergent and Rinse Aid Dispenser 58

5.2.40 Drying Assist Fan 58

5.2.41 Door Handle 6400, 6500, 6700, 6900, 6905 59

5.2.42 Door Handle Cover Plate 6400, 6500, 6700,

6900, 6905 60

5.2.43 Door Lock Microswitch 6400, 6500, 6700,

6900, 6905, 6600, 6605 60

5.2.44 Door Lock Microswitch 7000, 7005,

7100, 7105 61

5.2.45 Door Lock Microswitch Lever 6400, 6500, 6700,

6900, 6905, 6600, 6605 61

6.0 PROGRAM & CIRCUIT INFORMATION

6.1.1 Programs - 6400 & 6500 Models 62

6.1.2 Programs - 6600 Rotary Model 63

6.1.3 Programs - 6605 Pots Rotary Model 64

6.1.4 Programs - 6700, 6900 & 7000 Models 66

6.1.5 Programs - 6905 Model 66

6.2 Circuit Diagram - Electronic Controller 67