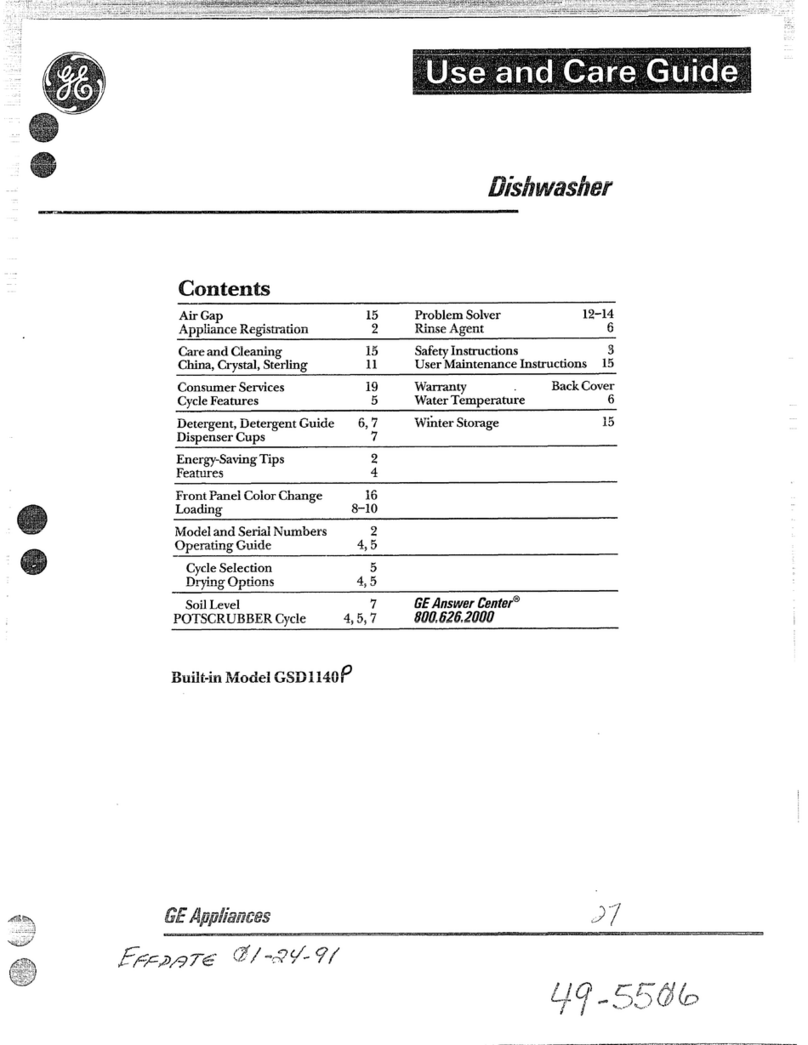

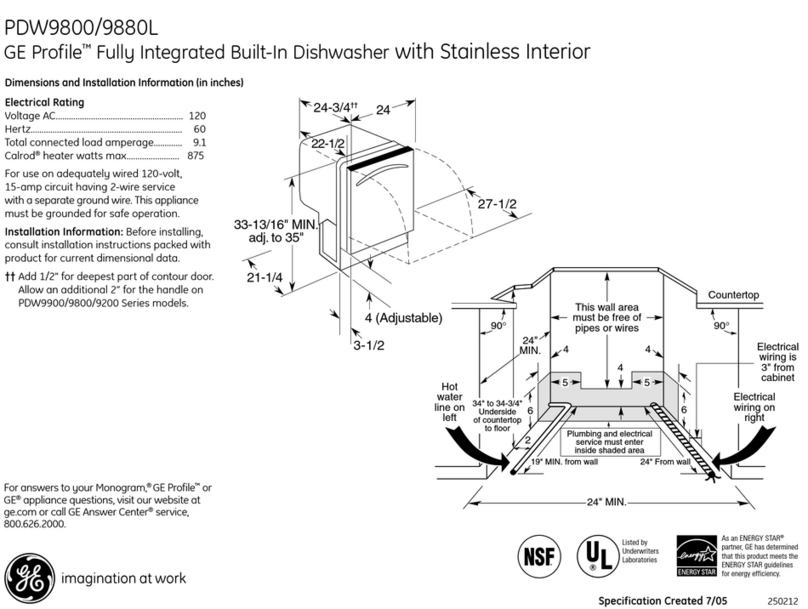

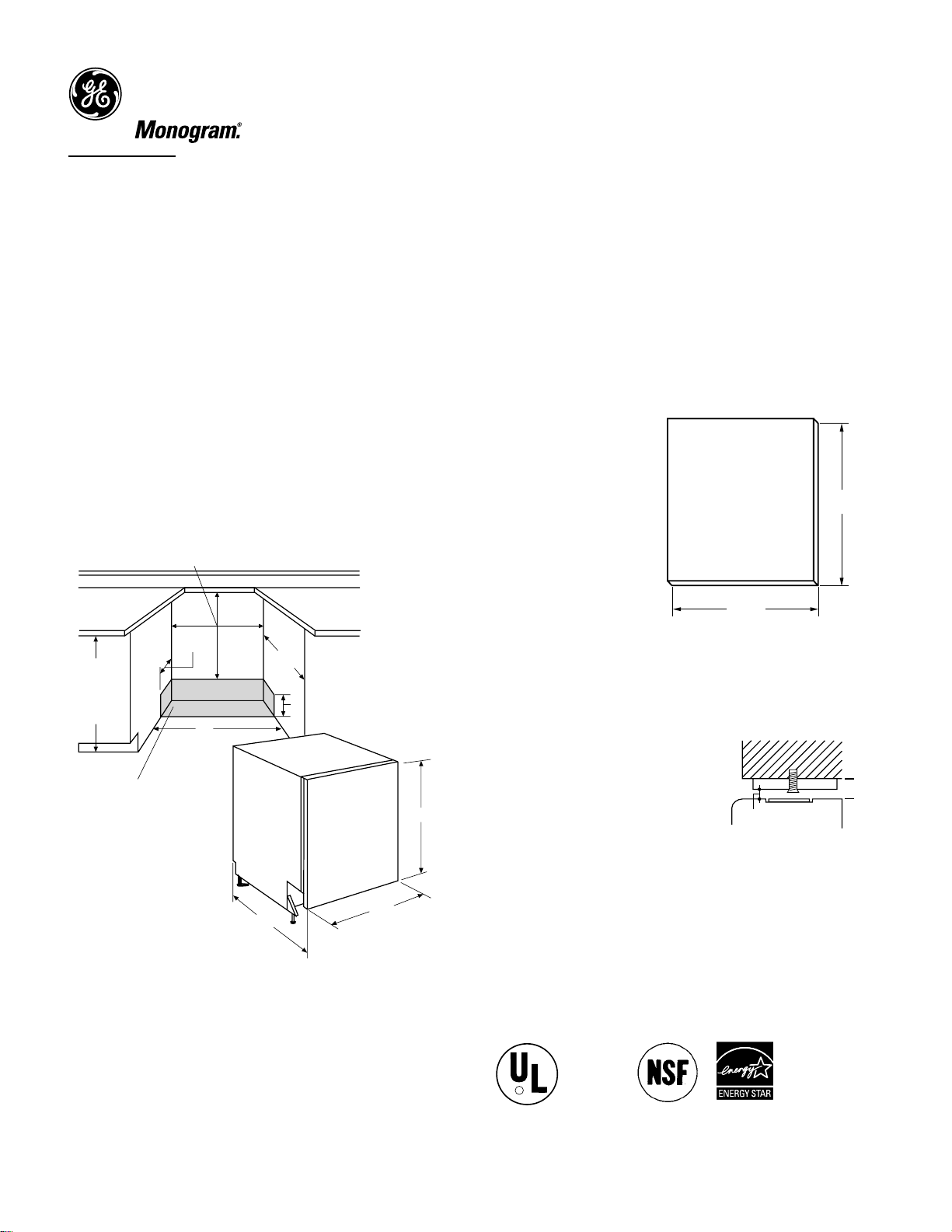

Top of Panel Top of Panel

Trim Around Dotted Line Trim Around Dotted Line

2-9/32" 2-9/32"

Trim Around Dotted Line

Trim Around Dotted Line

Drill 3/32"

Pilot Hole

3/32" Deep

Drill 3/32"

Pilot Hole

3/32" Deep

Drill 3/32"

Pilot Hole

3/32" Deep

Drill 3/32"

Pilot Hole

3/32" Deep

3/4" Thick Custom Panel

Template Instructions for

Top Control Integrated Profile and

Monogram Dishwasher Models

The custom panel should be sized to your installation situation. See Step 1. For easier

installation the custom panel and custom handle should be attached before installing the

dishwasher. Use this template to locate mounting screws and spacers on the custom panel.

IMPORTANT

• A custom handle must be installed onto the custom

panel. Install the custom handle 4-1/2" max. from

the top of the panel.

STEP 2 DRAW CENTERLINE

• Place the custom panel on a flat surface with appearance side

down.

• Locate the vertical center of the panel at the top.

• Use a carpenters square to draw a centerline from top to bottom.

STEP 4 INSTALL MOUNTING SCREWS AND SPACERS

Mark Center

Screw Holes

STEP 5 INSTALL CUSTOM HANDLE

A custom handle must be installed onto the panel

before the panel is secured to the dishwasher door.

• The handle should be installed so that it aligns with

adjacent drawer handles, or 4-1/2" max. from the

top of the panel. Secure the handle in the same

manner as cabinet handles. Screws must be

countersunk into the panel.

STEP 6 INSTALL ASSEMBLED PANEL

• Secure the panel to the door by inserting the top

and bottom mounting screws with spacers into

the matching keyhole slots.

• Make sure all 4 spacers engage the keyhole slots.

• Press the panel against the door and push

downward until the spacers are fully engaged

into the key hole slots. The panel should align

evenly with the top and sides.

• Stand the dishwasher upright.

• Open dishwasher door and drive the supplied

#8 x 1-3/4" truss head screws. Drive one screw at

the top and one on each side as shown, through

the inner door and into the custom panel.

WARNING: Do not overtighten screws. Excessive

tightening of the screws could damage door edges.

STEP 3 ALIGN TEMPLATE TO PANEL

• Trim template on the dotted line along all sides.

• Place the template on the panel aligned with the top edge and

the centerline. Use tape to hold in place.

IMPORTANT: If the template is not aligned with the top edge of the

panel, the 1/2" minimum gap will not be maintained. This 1/2" minimum

gap must be maintained to prevent condensation and damage to the

control panel from screw heads.

• Use an awl to mark the screw hole locations indicated on the

template. Remove the template.

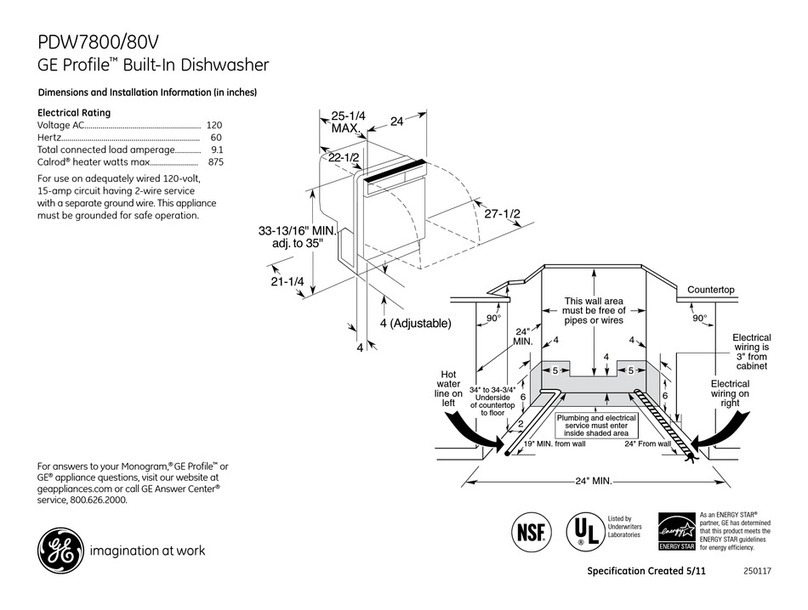

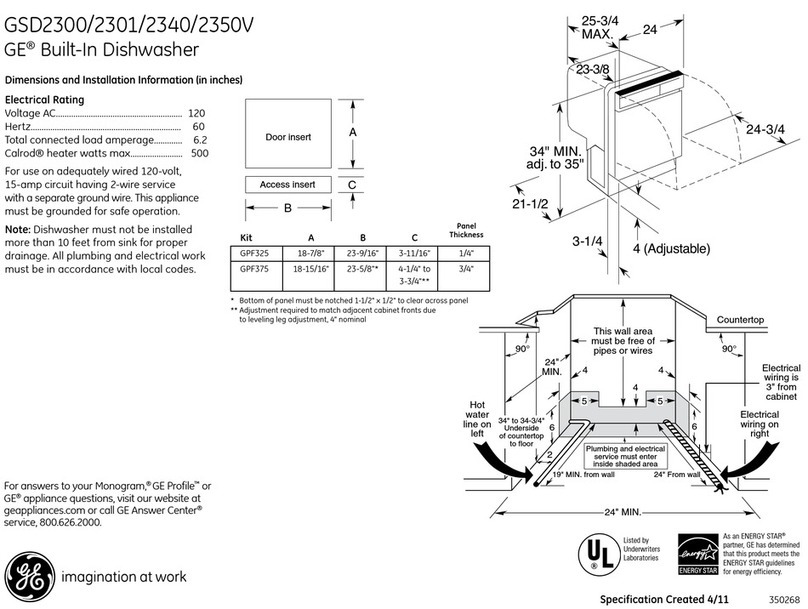

HEIGHT

Panel height must be between 30-1/16" and 30-1/4".

• If the panel height is more than 30-1/4" it will

prevent the door from swinging open.

• If the panel height is less than 30-1/16" it will not

cover the dishwasher door frame.

Minimum 1/2" Gap

for Clearance

Countertop

1/2" min.

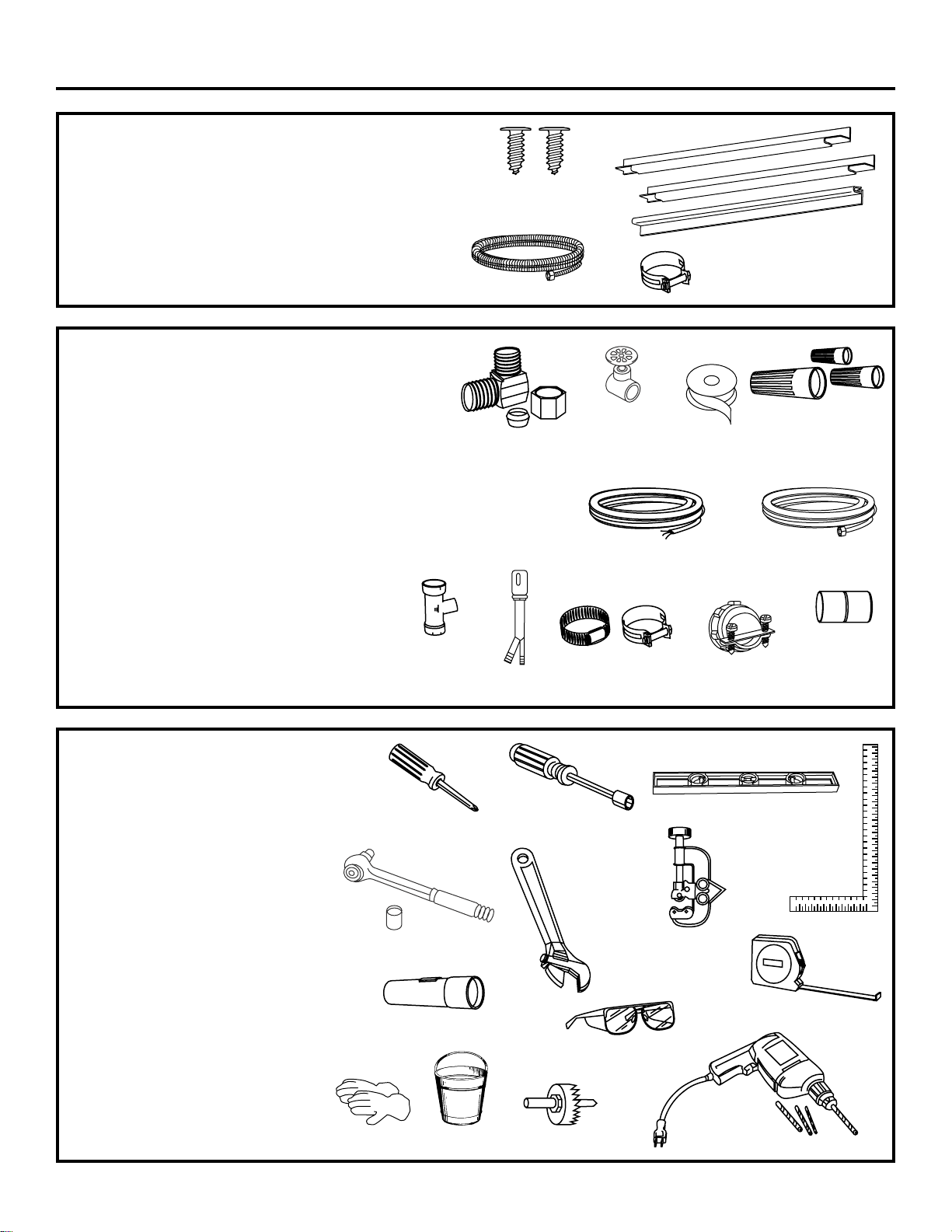

PARTS INCLUDED:

(4) Spacers

(4) #8 x 5/8" Phillips truss head stainless steel screws

(3) #8 x 1-3/4" Phillips truss head stainless steel

wood screws

(2) Heavy duty springs

STEP 1 CUSTOM PANEL SIZE REQUIREMENTS

If the panel is less than 3/4" thick, shorter screws must

be used. Use #8 x 1/2" screws for 1/2" thick panels (not supplied).

• Use a 3/32" drill bit to drill pilot holes 3/32" deep in the marked

locations.

Note: The custom panel is secured to the dishwasher door with

the spacers and screws provided. The spacer will slip into the

keyhole slots on the dishwasher door.

• Drive the supplied #8 x 5/8" Phillips truss head steel screws

through the spacer and into the panel.

• Install remaining spacers and screws as indicated in the marked

locations.

4-1/2" Max.

From Top

of Panel

Handle

Custom

Door Panel

Screws Must

Be Countersunk

Into Panel

Custom

Panel

Shoulder Washers

Engage Keyhole

Slots

Dishwasher

Door

Custom

Panel

Screw

Spacer

IMPORTANT: To ensure optimum door balance

performance, the custom panel must not weigh more

than 14 lbs.

STEP 7 INSTALL DOOR SPRINGS

The dishwasher is shipped from the factory with a

temporary set of balance springs. Use the heavy duty

springs provided and the adjustment holes in the

cable to balance the door after the custom panel

is installed onto the dishwasher.

• With the dishwasher on the wood skid, close and

latch the door.

• Remove and discard both door springs.

• Attach the new heavy duty door springs. Engage

the end with the short hook into the support leg

and the long hook into the cable.

• Open and close the door.

• If the door drops open when released, increase

spring tension. If the door closes when released,

decrease tension.

TIP: If the door does not open easily or falls too

quickly, check spring cable routing. The cable is held

in place by “shoulders” on the pulley. Check to be

sure the cable has not slipped over the pulley

shoulders.

IMPORTANT: Adjust both balance springs to the

same amount of tension to prevent excessive door

twisting during use.

Correct Spring

Cable Routing

Increase

Tension

Decrease

Tension

Pulley

Shoulder

Use This

Mounting

Hole

23-3/4"

30-1/16" Min.

30-1/4" Max.

• The top of the custom panel must be flush

with the top of the door. The 1/2" minimum gap

between the top of the door and the bottom of the

countertop must be maintained.

WIDTH

Panel width must be 23-3/4".

• If the panel width is less than 23-3/4" it will not

cover the dishwasher frame.